What Happens If Timing Is Off in an Outboard Motor

Discover the impact of incorrect timing in outboard motors, symptoms like knocking and power loss, and how to diagnose and fix timing issues effectively.

Outboard motors are the heart of many boats, providing the power needed to navigate waters smoothly. However, when the ignition timing is off, these engines can exhibit a range of performance issues that affect efficiency, reliability, and safety. Incorrect timing disrupts the precise coordination required for fuel combustion, leading to symptoms like engine knocking, power loss, and poor fuel economy. This comprehensive guide explores the consequences of bad timing in outboard motors, how to identify symptoms, potential causes, and actionable steps to diagnose and resolve timing issues. Whether you’re a seasoned boater or a novice, understanding these problems can save you time, money, and frustration on the water.

Understanding Ignition Timing in Outboard Motors

Ignition timing refers to the precise moment when the spark plug fires to ignite the air-fuel mixture in the engine’s combustion chamber. This process occurs during the compression stroke, just before the piston reaches top dead center (TDC). Proper timing ensures maximum pressure is generated to push the piston downward, optimizing power output and efficiency. In outboard motors, timing is measured in degrees before top dead center (BTDC) and can be advanced (firing earlier) or retarded (firing later) to suit engine demands.

Outboard motors, particularly two-stroke and four-stroke models, rely on mechanical or electronic systems to control timing. Older models use mechanical linkages and distributors, while modern engines employ electronic control modules (ECMs) or electronic spark timing (EST) systems. When timing is off, the combustion process becomes inefficient, leading to a cascade of performance issues. Let’s dive into the symptoms that indicate timing problems and their underlying causes.

Symptoms of Incorrect Timing in Outboard Motors

Incorrect timing manifests in several ways, each affecting the engine’s performance and the overall boating experience. Below are the primary symptoms, explained in detail:

1. Engine Knocking or Pinging

Knocking or pinging occurs when the air-fuel mixture ignites prematurely, often due to overly advanced timing. This premature combustion creates a shockwave that collides with the rising piston, producing a metallic sound. Over time, knocking can damage pistons, bearings, and cylinder walls, leading to costly repairs. For example, a boater on a forum described hearing a “gatling gun” sound when throttling up, a classic sign of timing-related misfiring.

2. Loss of Power and Acceleration

When timing is off, the engine struggles to produce optimal power, resulting in sluggish acceleration and reduced top speed. Advanced timing may cause detonation, while retarded timing delays combustion, reducing the force on the piston. Boaters often notice the engine feels unresponsive, especially under load, such as when pulling a skier or navigating rough waters.

3. Decreased Fuel Economy

Inefficient combustion due to incorrect timing forces the engine to burn more fuel to maintain performance. This leads to a noticeable drop in fuel mileage, increasing operating costs. For instance, a misaligned timing setup might cause the engine to consume fuel at a rate 10-20% higher than normal, depending on the severity.

4. Rough Idle

A shaky or unstable idle, particularly at low speeds, is a common symptom of timing issues. The engine may vibrate excessively or feel like it’s “hunting” for the right RPM. This is often due to inconsistent combustion across cylinders, which disrupts the engine’s smooth operation.

5. Difficulty Starting or Running Smoothly

Bad timing can make starting the engine challenging, as the spark may not align with the optimal point in the compression cycle. Once started, the engine might run erratically, with frequent stalling or surging. Boaters report engines that start fine at idle but falter when throttle is applied, indicating a timing-related problem.

6. Misfire, Backfire, or Stalling

Misfires occur when a cylinder fails to ignite properly, often due to timing that’s too advanced or retarded. Backfiring, where unburned fuel ignites in the exhaust, is another sign, producing loud pops or bangs. Stalling, especially during acceleration, suggests the engine can’t maintain consistent combustion.

7. Overheating

Premature ignition increases cylinder temperatures, leading to overheating. This can damage engine components like gaskets and seals. Conversely, retarded timing may cause incomplete combustion, increasing exhaust temperatures and straining the cooling system.

8. Reduced RPM Range

Incorrect timing can limit the engine’s ability to reach its maximum RPM, reducing performance. For example, a Mercruiser 3.0L engine was reported to max out at 4000 RPM instead of the expected 4600-4800 RPM, a clear sign of timing issues.

Causes of Timing Issues in Outboard Motors

Timing problems can stem from various sources, ranging from mechanical failures to operator errors. Understanding these causes is crucial for accurate diagnosis:

1. Faulty Sensors

Temperature sensors, knock sensors, or crankshaft position sensors can malfunction, sending incorrect signals to the ECM or EST module. For instance, a damaged temp sensor might falsely trigger “SLOW” mode, limiting RPM to 2000 and causing misfiring.

2. Worn or Damaged Components

Timing belts, chains, or gears can wear out, causing misalignment. In some Mercruiser 3.0L engines, the cam gear keyway slot is prone to “wollowing out” after 200-500 hours, disrupting timing accuracy.

3. Incorrect Module or Parts

Using aftermarket ignition modules with improper timing curves can cause issues. A boater discovered that an automotive EST module (stamped 369) lacked the correct advance curve for marine use, unlike the marine-specific module (stamped 399).

4. Improper Maintenance

Incorrect timing adjustments during maintenance, such as setting base timing without a timing light, can lead to problems. A Mercruiser owner reported a mechanic adjusting timing “by ear,” resulting in poor performance.

5. Electrical Issues

Low voltage or loose connections, such as a faulty ignition switch or fuse block, can disrupt the timing module’s operation. One boater traced timing advance issues to a loose wire at the dash, which reduced voltage to the coil.

6. Fuel System Problems

While not directly related to timing, fuel system issues like clogged filters or a failing fuel pump can mimic timing symptoms, complicating diagnosis. Regular maintenance of fuel filters is essential to rule out these issues.

Diagnosing Timing Issues

Diagnosing timing problems requires a systematic approach, using tools like a timing light and multimeter. Here’s a step-by-step guide:

- Check Symptoms: Note specific symptoms, such as knocking, misfiring, or limited RPM, to narrow down the issue.

- Inspect Sensors: Test temperature and crankshaft sensors for proper resistance using a multimeter. For example, a temp sensor reading 240-250°F on a cold engine likely indicates a fault.

- Verify Timing: Use a timing light to check base timing at idle and advance at higher RPMs. For a Mercruiser 3.0L, base timing should be 1° BTDC, advancing to 12° BTDC at idle and 23° BTDC at 2400-2800 RPM.

- Test Electrical Connections: Measure voltage at the coil and ignition module to ensure 12V+ is present. Check for loose or corroded connections.

- Examine Components: Inspect timing chains, gears, and belts for wear. Replace any damaged parts, such as a wollowed cam gear.

- Rule Out Fuel Issues: Verify fuel pump pressure and replace filters to ensure proper fuel delivery.

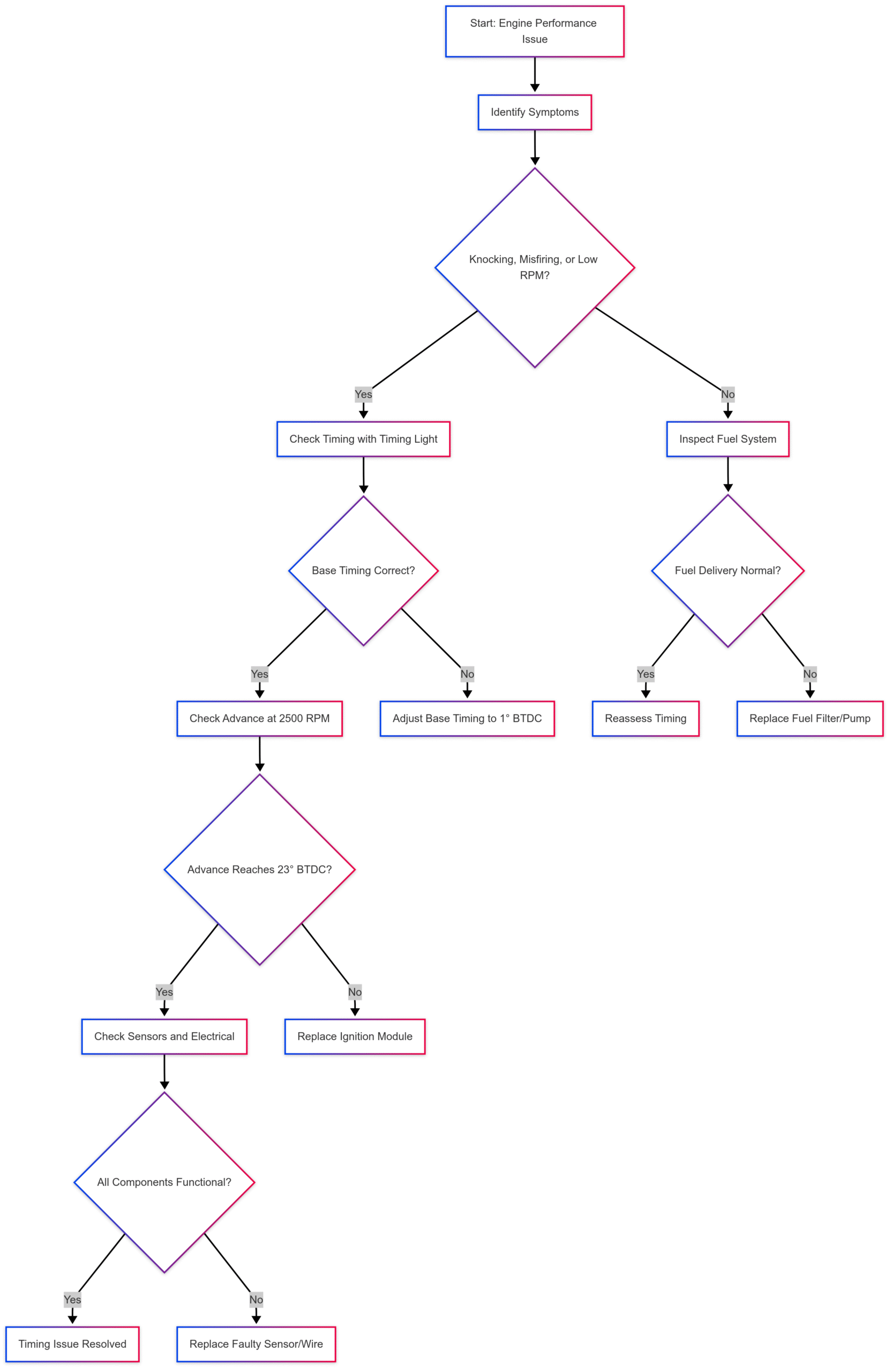

Chart: Timing Diagnosis Workflow

Impact of Minor Timing Deviations

Even small timing deviations can affect performance. A timing error of 1° may cause a slight reduction in power and efficiency, often unnoticed unless under heavy load. A 3° deviation can lead to noticeable issues like rough idle, reduced top speed, and increased fuel consumption. Beyond 5°, the engine may misfire, overheat, or stall, risking serious damage. For example, excessive advance at wide-open throttle (WOT) can burn pistons, while retarded timing reduces RPM and loads the engine, potentially causing overheating.

Table: Effects of Timing Deviations

| Deviation (°) | Symptoms | Potential Damage | Action Required |

|---|---|---|---|

| 1° | Minor power loss, slight efficiency drop | Minimal | Monitor, adjust if persistent |

| 3° | Rough idle, reduced top speed | Wear on components | Adjust timing, check module |

| 5°+ | Misfiring, overheating, stalling | Piston damage, bearing wear | Immediate adjustment, inspect components |

Fixing Timing Issues

Resolving timing problems involves precise adjustments and, in some cases, part replacements. Here’s how to address common issues:

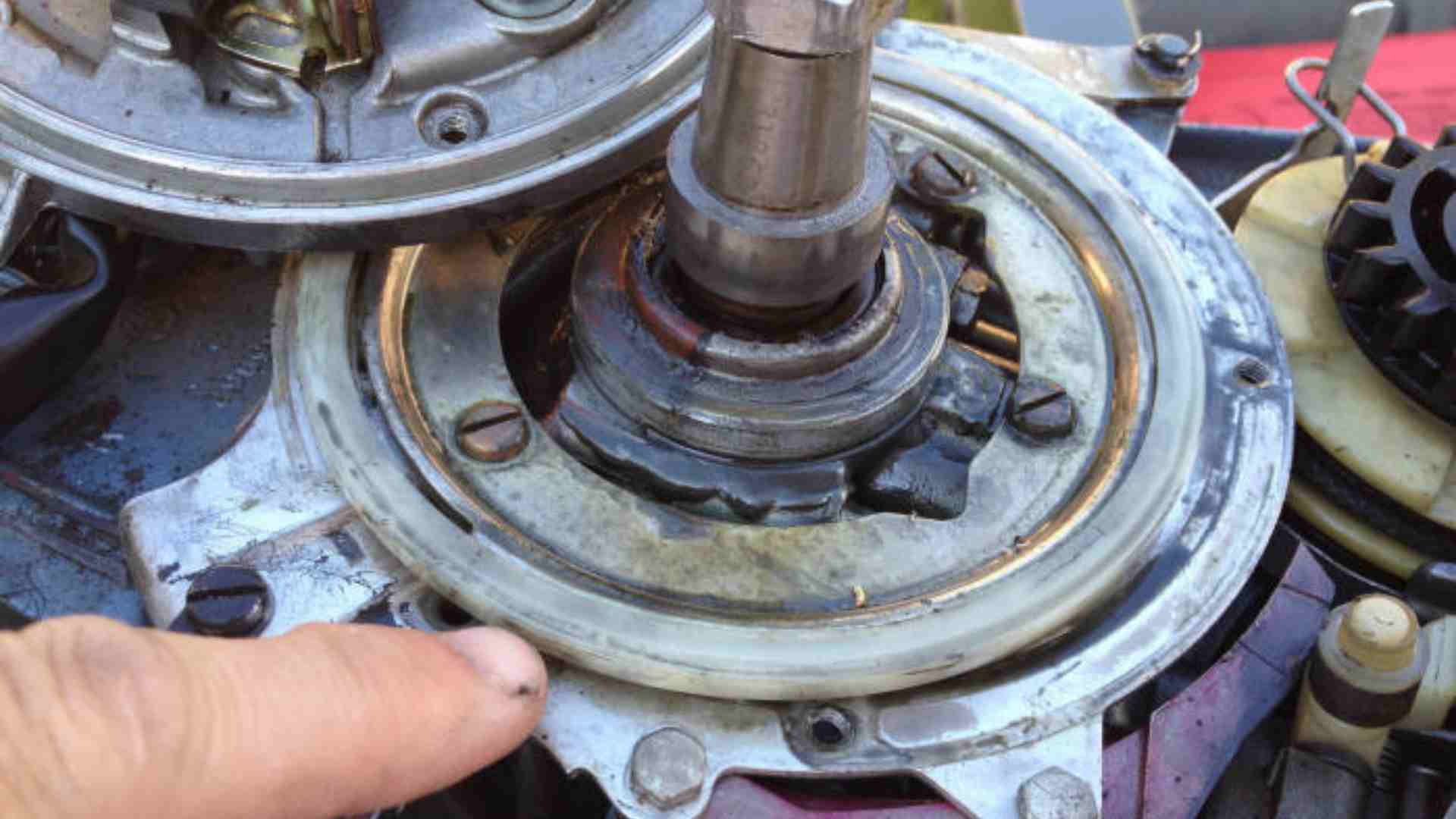

- Adjust Timing: Use a timing light to set base timing according to manufacturer specs. For a Johnson 150HP, ensure the linkage under the flywheel aligns correctly. Always follow the factory manual, as aftermarket manuals may lack specificity.

- Replace Faulty Sensors: Swap out defective temp or crankshaft sensors. A new temp sensor for a Mercruiser costs around $20-$50.

- Upgrade Ignition Module: Use OEM marine-specific modules (e.g., ACDelco D1965A for Mercruiser 3.0L, ~$80) to ensure proper timing curves.

- Inspect and Replace Worn Parts: Replace timing chains or gears showing wear. A cam gear replacement for a Mercruiser 3.0L costs ~$100-$200, plus labor.

- Check Electrical System: Tighten loose connections and replace faulty fuse blocks or ignition switches (~$10-$50).

- Regular Maintenance: Change fuel filters annually (~$10-$20) and inspect spark plugs for proper gap and heat range.

Table: Common Parts and Prices

| Component | Approx. Price (USD) | Replacement Frequency |

|---|---|---|

| Temperature Sensor | $20-$50 | As needed |

| Ignition Module (OEM) | $80-$150 | As needed |

| Timing Chain/Gear | $100-$200 | 400-500 hours |

| Fuel Filter | $10-$20 | Annually |

| Spark Plugs | $5-$15 each | Annually or as needed |

| Timing Light (Basic) | $30-$100 | One-time purchase |

Preventive Measures

To avoid timing issues, follow these best practices:

- Use OEM Parts: Stick to manufacturer-recommended components to ensure compatibility and performance.

- Regular Inspections: Check timing and sensor function during seasonal maintenance.

- Proper Tools: Invest in a quality timing light for accurate adjustments.

- Avoid Overloading: Don’t run the engine under excessive load, which can stress timing components.

- Consult Experts: For complex issues, seek a certified marine mechanic, especially for older engines like the Johnson 150HP or Mercruiser 3.0L.

Real-World Examples

Boaters frequently encounter timing issues, as seen in online forums. One owner of a Johnson 150HP reported perfect idle but misfiring at throttle, traced to a faulty temp sensor triggering SLOW mode. Another with a Mercruiser 3.0L struggled with low RPM due to an automotive EST module, resolved by switching to a marine-specific module. These cases highlight the importance of proper diagnosis and using the right parts.

Conclusion

Incorrect timing in outboard motors can lead to a host of problems, from knocking and power loss to overheating and stalling. By understanding the symptoms, causes, and diagnostic steps, boaters can address issues promptly and prevent costly damage. Regular maintenance, OEM parts, and proper tools like a timing light are essential for keeping your engine running smoothly. Whether you’re troubleshooting a rough idle or a misfiring engine, this guide provides the insights needed to get back on the water with confidence.

Happy boating!

Share What happens if timing is off? with your friends and leave a comment below with your thoughts.

Read 3 Most Common Problems with Yamaha VMAX SHO until we meet in the next article.