What are the symptoms of VST filters clogging?

Learn the key symptoms of a clogged VST filter in Yamaha outboards, from rough idling to power loss, and how to fix them for optimal engine performance.

The Vapor Separator Tank (VST) is a critical component in fuel-injected Yamaha outboard engines, often referred to as the Fuel Supply Module (FSM) in other brands like Mercury. Its primary function is to separate fuel vapors, maintain consistent fuel pressure, and deliver clean fuel to the engine’s fuel injectors. The VST houses several key components, including the high-pressure fuel pump, pressure regulator, float and needle valve assembly, and multiple filters. When any of these components, particularly the VST filter, become clogged, the engine’s performance can suffer significantly, leading to costly repairs if not addressed promptly.

A clogged VST filter restricts fuel flow, disrupting the delicate balance required for efficient combustion in a marine engine. This issue is particularly problematic for boaters who rely on their outboards for reliable performance during fishing trips, leisure cruises, or commercial operations. Understanding the symptoms of a clogged VST filter, its causes, and the steps to address it can save time, money, and frustration. This comprehensive guide explores the telltale signs of a clogged VST filter, delves into the components of the VST system, and provides actionable solutions to keep your Yamaha outboard running smoothly.

What Is a VST and Why Does It Matter?

The VST is an integral part of the fuel delivery system in Yamaha outboard engines. It serves two primary purposes:

- Vapor Separation: The VST removes fuel vapors from liquid fuel, ensuring that only liquid fuel is delivered to the engine’s injectors. This prevents vapor lock, a condition where fuel vapor disrupts the fuel flow, causing performance issues.

- Fuel Pressure Regulation: The VST maintains the precise fuel pressure required for the engine’s fuel injectors to operate effectively. This is achieved through components like the high-pressure fuel pump and pressure regulator.

The VST contains several components that are prone to clogging or failure, particularly when exposed to dirty or ethanol-blended fuel. These components include:

- High-Pressure Fuel Pump: Pressurizes fuel for delivery to the fuel rail.

- Pressure Regulator: Maintains consistent fuel pressure.

- Float and Needle Valve Assembly: Controls fuel flow into the VST to prevent overfilling.

- VST Filters and Strainers: Remove contaminants from the fuel before it reaches the injectors.

Dirty fuel, especially ethanol-blended fuel, is the primary culprit behind VST filter clogging. Ethanol can loosen debris in fuel tanks and lines, which then accumulates in the VST filter, restricting fuel flow and causing a cascade of performance issues.

Symptoms of a Clogged VST Filter

A clogged VST filter can manifest in various ways, impacting engine performance, fuel efficiency, and reliability. Below is a detailed breakdown of the most common symptoms, supported by real-world insights from Yamaha outboard owners.

1. Reduced Engine Performance

A clogged VST filter restricts fuel flow, starving the engine of the fuel it needs for optimal combustion. This leads to several performance-related symptoms:

- Hesitation or Sputtering: The engine may hesitate or sputter, especially during acceleration. Boaters often report a noticeable lag when throttling up, as the engine struggles to receive adequate fuel.

- Loss of Power: A significant reduction in power, particularly at higher speeds, is a common complaint. For example, a Yamaha OX66 150 HP owner reported frequent power loss after only 148 hours of use, attributing it to a clogged VST filter.

- Rough Idling: The engine may shake or vibrate excessively when idling, indicating an inconsistent fuel supply. This can feel like the engine is “hunting” for the right fuel-air mixture.

2. Starting Issues

Starting problems are another hallmark of a clogged VST filter:

- Difficulty Starting: The engine may crank but fail to start, especially when cold. This occurs because the restricted fuel flow prevents the injectors from delivering enough fuel to initiate combustion.

- Stalling: The engine may stall unexpectedly, particularly at idle or under load. One boater described their Yamaha 225 OX66 stalling repeatedly, later traced to a clogged VST filter.

3. Fuel Economy Issues

A clogged VST filter forces the engine to work harder, leading to increased fuel consumption. Boaters often notice they’re refueling more frequently without a clear explanation. This inefficiency stems from the engine compensating for restricted fuel flow by burning more fuel to maintain performance.

4. Misfires

Misfires occur when one or more cylinders fail to combust properly, resulting in a rough-running engine. A clogged VST filter can disrupt the fuel-air mixture, causing erratic combustion. This symptom is often accompanied by vibrations or a noticeable loss of smoothness in engine operation.

5. Unusual Noises

Restricted fuel flow can sometimes cause unusual noises, such as whining or whistling, due to pressure imbalances in the fuel system. While less common, these noises are a red flag that the VST filter may be clogged.

6. Check Engine Light

In modern Yamaha outboards, a clogged VST filter may trigger the check engine light. This warning indicates a problem in the fuel system or engine performance, prompting further investigation.

7. Fuel Overflow from VST Vent

A clogged float and needle valve assembly, often caused by debris, can lead to overfilling of the VST. Excess fuel may escape through the VST’s vent system, appearing as a stream of fuel from the engine’s cowling or belly pan. This is a critical symptom that requires immediate attention to prevent fuel system damage.

Table 1: Common Symptoms of a Clogged VST Filter

| Symptom | Description | Impact on Performance |

|---|---|---|

| Hesitation/Sputtering | Engine lags or stumbles during acceleration | Reduced responsiveness |

| Loss of Power | Decreased power output, especially at high speeds | Limits top speed and performance |

| Rough Idling | Engine shakes or vibrates at idle | Unstable operation |

| Difficulty Starting | Engine cranks but struggles to start, especially when cold | Delays or prevents engine startup |

| Stalling | Engine shuts down unexpectedly, often at idle or under load | Disrupts boating activities |

| Increased Fuel Consumption | Higher fuel usage due to inefficient combustion | Increased operating costs |

| Misfires | Erratic combustion in one or more cylinders | Rough operation, potential engine damage |

| Unusual Noises | Whining or whistling from fuel system | Indicates pressure issues |

| Check Engine Light | Warning light triggered by fuel system issues | Signals need for diagnostic check |

| Fuel Overflow | Fuel escapes through VST vent due to float/needle valve issues | Potential fuel system damage |

Common VST Problems and Their Causes

Beyond a clogged filter, other VST components can contribute to the symptoms described above. Understanding these issues is crucial for accurate diagnosis and repair.

1. Clogged High-Pressure Fuel Pump Filter

The high-pressure fuel pump inside the VST has a strainer at its base that can become clogged with debris. This restricts fuel intake, preventing the pump from pressurizing fuel adequately. Common causes include:

- Dirty Fuel: Contaminants in the fuel, such as dirt or sediment, accumulate on the strainer.

- Ethanol-Blended Fuel: Ethanol can loosen debris in the fuel tank or lines, which then collects in the VST. Boaters frequently report a fine gray or white powder clogging their filters, often linked to ethanol fuel interactions.

2. Failed High-Pressure Fuel Pump

A worn-out or failed fuel pump can mimic the symptoms of a clogged filter. Over time, dirt and debris passing through the pump can cause it to burn out or lose efficiency. Replacement costs for a high-pressure fuel pump range from $100 to $750, depending on the engine model.

3. Faulty Pressure Regulator

The pressure regulator ensures the fuel system maintains a specific pressure (typically 30–50 PSI for Yamaha outboards). Debris in the regulator can disrupt this balance, leading to over- or under-pressurization. Cleaning the regulator is often sufficient, but replacement may be necessary if the internals are damaged.

4. Float and Needle Valve Issues

The float and needle valve assembly controls fuel flow into the VST. If debris prevents the needle from sealing properly, the VST may overfill, leading to fuel overflow through the vent system. This issue is often mistaken for a clogged filter but requires specific attention to the float assembly.

5. Wiring Issues

Less common but still significant, wiring problems can affect the high-pressure fuel pump’s operation. A blown fuse, broken power wire, or faulty ground can prevent the pump from functioning, mimicking the symptoms of a clogged filter. Always check the electrical connections before replacing components.

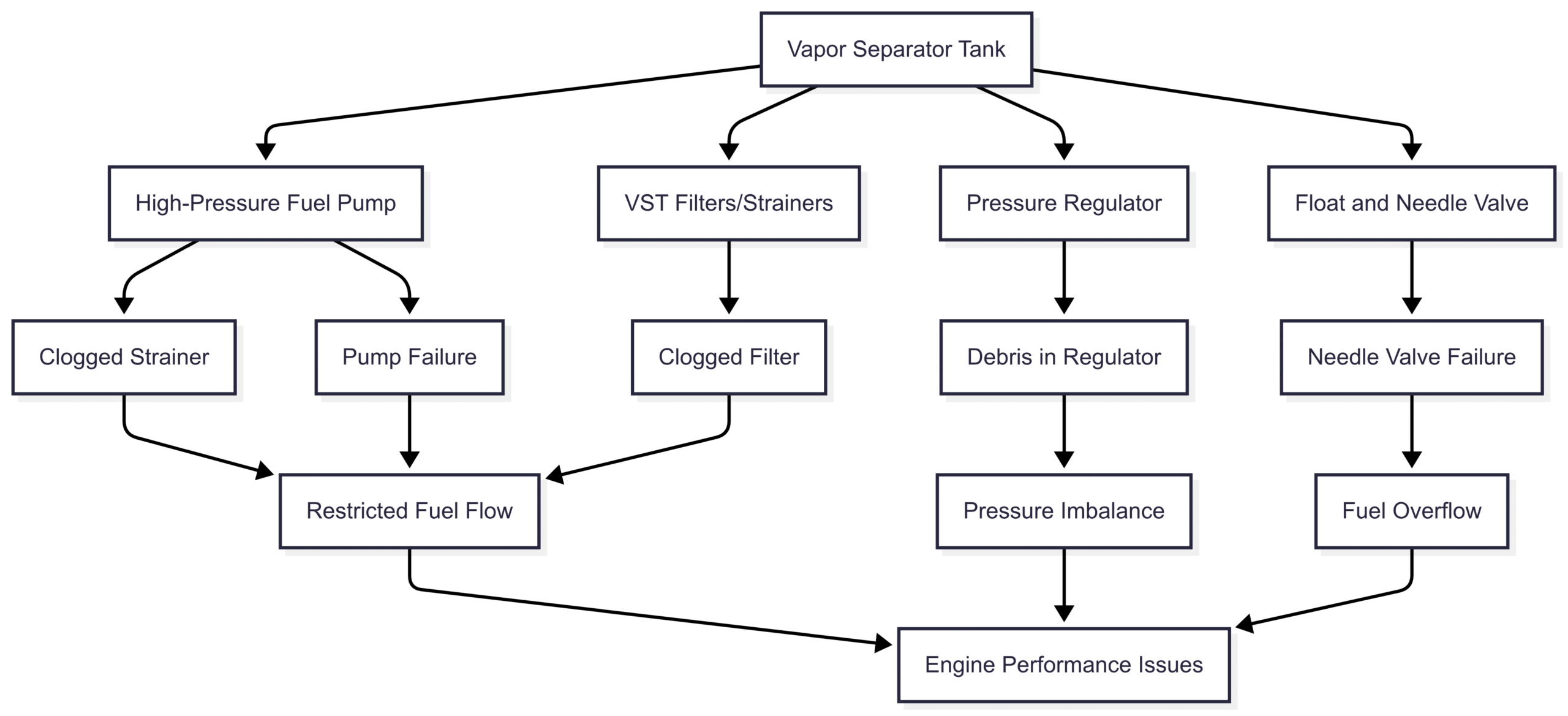

Chart: VST Component and Failure Points

Diagnosing a Clogged VST Filter

Diagnosing a clogged VST filter requires a systematic approach to rule out other fuel system issues. Follow these steps:

- Visual Inspection: Remove the VST filter and inspect it for debris. A clogged filter may appear discolored or coated with a fine gray/white powder, black specks, or brown crud.

- Check Fuel Quality: Test the fuel for contamination. Ethanol-blended fuel is notorious for loosening tank deposits, which can clog the VST filter.

- Inspect Other Components: Check the high-pressure fuel pump strainer, pressure regulator, and float assembly for debris or damage.

- Test Fuel Pressure: Use a fuel pressure gauge to verify that the system maintains the correct pressure (consult your engine’s service manual for specifications).

- Check Electrical Connections: Ensure the fuel pump is receiving proper power and ground.

Important Note: Symptoms like rough idling or stalling can also stem from issues like clogged fuel injectors, faulty spark plugs, or low-pressure fuel pump failure. A qualified marine mechanic should be consulted for a definitive diagnosis.

Solutions for Clogged VST Filters

Once a clogged VST filter is identified, you have two primary options: clean the filter or replace it. Here’s a detailed look at both approaches, along with preventive measures.

1. Cleaning the VST Filter

Some VST filters, particularly strainers, can be cleaned with contact cleaner or carb cleaner. Boaters like TomS recommend using a can of spray carb cleaner with a hose attachment to blast debris from the filter. However, cleaning is a temporary solution and may not be effective for heavily clogged or damaged filters.

Steps to Clean a VST Filter:

- Remove the VST filter from the tank (consult your engine’s service manual for location and removal instructions).

- Spray the filter with contact cleaner, focusing on the “pie” sections of the filter.

- Inspect for remaining debris and repeat if necessary.

- Reinstall the filter and test engine performance.

2. Replacing the VST Filter

Most VST filters are designed to be replaced rather than cleaned, especially the “U” shaped or canister-type filters found in Yamaha outboards. Replacement costs vary depending on the engine model:

- Standard VST Filter: $16.49–$25.88 (e.g., Yamaha 65L-13915-00-00 for 200–250 HP models).

- HPDI Canister Filter: $60–$75 (e.g., Yamaha 60V-24251-00-00 for 150–300 HP HPDI models).

- Fuel/Water Separator Filter: $18.99–$28.99 (e.g., Sierra International 18-7866 or Kofil R12T).

Table 2: Replacement VST Filter Costs

| Filter Type | Part Number | Price Range | Compatible Models |

|---|---|---|---|

| VST Fuel Filter | 65L-13915-00-00 | $16.49–$25.88 | Yamaha 200–250 HP |

| HPDI Canister Filter | 60V-24251-00-00 | $60–$75 | Yamaha 150–300 HP HPDI |

| Fuel/Water Separator (10 Micron) | Sierra 18-7866, Kofil R12T | $18.99–$28.99 | Yamaha, Mercury, Honda |

| Fuel Injection Strainer | 63P-13915-00-00 | $9.85–$15 | Yamaha 115–350 HP |

| VST Filter & Gasket Kit | 68V-13915-00-0 | $66.17–$74.99 | Yamaha F115, LF200, F225 (4-Stroke) |

Note: Always verify the part number with your engine’s model and year to avoid ordering incorrect parts, as variations exist (e.g., 65L vs. 66K filters for Yamaha S250TXRX).

3. Addressing Other VST Components

- High-Pressure Fuel Pump: If the pump is clogged, clean the strainer. If it’s failed, replace it ($100–$750).

- Pressure Regulator: Clean or replace if debris is present ($50–$150).

- Float and Needle Valve: Inspect and clean the assembly. Replace the needle valve if it’s deformed ($20–$50).

4. Preventive Maintenance

To minimize VST filter clogging, adopt these best practices:

- Use High-Quality Fuel: Source fuel from reputable marinas with newer tanks to reduce contamination.

- Install a 10-Micron Fuel/Water Separator: Replace it every 50–100 hours to catch debris before it reaches the VST.

- Avoid Ethanol-Blended Fuel: If possible, use non-ethanol fuel to prevent tank deposits from loosening.

- Regularly Clean the Fuel Tank: Have a professional clean the tank to remove sediment and debris.

- Replace Low-Pressure Fuel Pumps: Update these pumps every 2–3 years to prevent diaphragm failure, which can flood the engine with fuel.

- Check Injector Filters: Clean or replace injector filters to ensure the entire fuel system is free of debris.

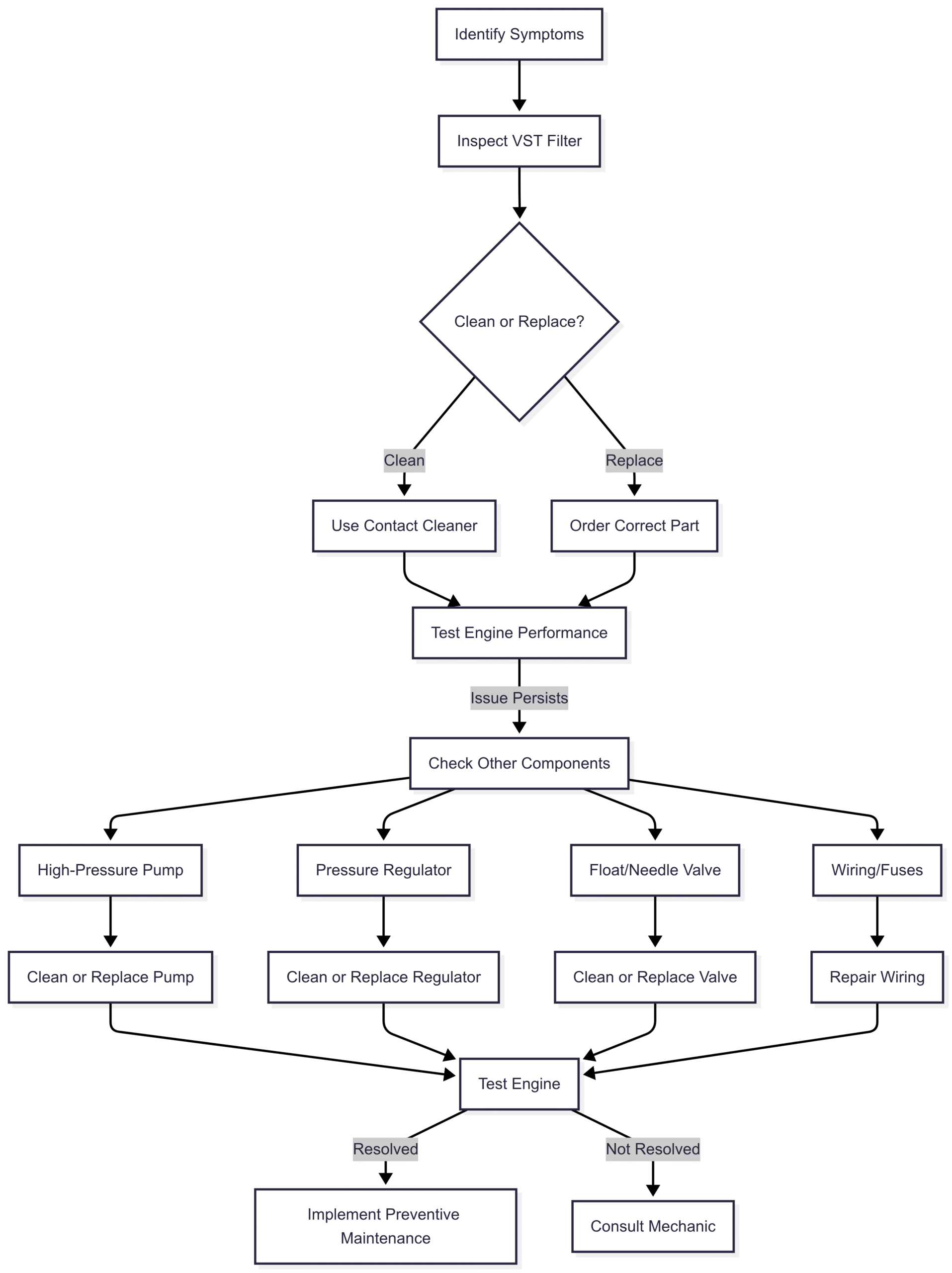

Chart: VST Maintenance Workflow

Real-World Insights from Boaters

Boaters on forums like The Hull Truth have shared their experiences with clogged VST filters, highlighting the prevalence of this issue:

- TimC2520 (2002 Yamaha OX66 150 HP): Reported replacing the VST filter twice in one year, despite using Yamaha water separators and ethanol treatments. Suggested that fuel quality or tank cleanliness might be the issue.

- dream catcher (2002 Yamaha 225 OX66): Experienced frequent VST clogs, with a fine gray/white powder as the culprit. Considered repowering due to recurring issues, even after switching to a 2-micron fuel/water separator.

- Striperswiper (1999 Yamaha 225 OX66): Found metal tabs from fuel additives clogging the fuel tank’s pickup tube, which exacerbated VST filter issues. Resolved the problem by removing the debris and cleaning the VST and injector filters.

- Capt Bill Welder (Yamaha OX66 200 HP): Avoided ethanol fuel and replaced the Racor filter every 50 hours, reporting no significant VST issues. Recommended professional tank cleaning and sourcing fuel from reputable vendors.

These accounts underscore the importance of addressing fuel quality and maintaining the entire fuel system, not just the VST filter.

The Role of Ethanol in VST Clogging

Ethanol-blended fuel is a leading cause of VST filter clogging. Ethanol acts as a solvent, loosening deposits in older fuel tanks and lines, which then flow into the VST filter. Boaters frequently report a fine gray or white powder clogging their filters, likely a byproduct of ethanol interacting with aluminum tanks or fuel additives. To mitigate this:

- Use ethanol-free fuel whenever possible.

- Install a 10-micron Racor or Yamaha fuel/water separator to catch debris early.

- Regularly inspect and clean the fuel tank to remove sediment.

When to Seek Professional Help

While cleaning or replacing a VST filter is a manageable DIY task for some, complex issues like pump failure, pressure regulator problems, or injector clogs require professional expertise. If symptoms persist after replacing the VST filter, consult a certified marine mechanic. They can perform diagnostic tests, such as fuel pressure checks or injector cleaning, to identify underlying issues.

Conclusion

A clogged VST filter in a Yamaha outboard can lead to a cascade of performance issues, from rough idling and power loss to stalling and increased fuel consumption. By recognizing the symptoms early—hesitation, difficulty starting, or fuel overflow—you can take proactive steps to clean or replace the filter and maintain other VST components. Regular maintenance, including using high-quality fuel, installing a 10-micron fuel/water separator, and cleaning the fuel tank, can prevent clogs and extend the life of your outboard engine. For persistent issues, don’t hesitate to seek professional help to ensure your boat remains reliable on the water.

FAQs

- How often should I replace my VST filter?

Replace the VST filter every 100–400 hours, depending on usage and fuel quality. If using ethanol-blended fuel, check it more frequently (every 50–100 hours). - Can I clean a VST filter instead of replacing it?

Some strainers can be cleaned with contact cleaner, but most VST filters are designed for replacement. Cleaning is a temporary fix and may not restore full performance. - Why does ethanol fuel cause VST clogs?

Ethanol loosens deposits in fuel tanks and lines, which then collect in the VST filter, causing clogs and restricting fuel flow. - What’s the worst-case scenario if I ignore a clogged VST filter?

Ignoring a clogged filter can lead to engine stalling, injector damage, or complete engine failure, resulting in costly repairs or the need for a new engine. - How do I know if my VST filter is the problem?

Symptoms like rough idling, power loss, or stalling, combined with a visual inspection of the filter for debris, can indicate a clog. A fuel pressure test can confirm the issue.

Share Yacht Broker vs. Self-Selling Your Yacht: Pros and Cons with your friends and Leave a comment below with your thoughts.