What are the duties of watchkeeping in the engine room?

Engine room watchkeeping is a critical function in maritime operations, ensuring the continuous monitoring, operation, and maintenance of propulsion and auxiliary systems aboard ships. This 24/7 vigilance safeguards vessel integrity, crew safety, and environmental protection.

Watchkeepers, typically engineers and assistants, rotate shifts to maintain coverage while preventing fatigue. Their duties encompass inspections, parameter logging, machinery management, alarm responses, and regulatory compliance. This article outlines these responsibilities in detail, highlighting procedures, best practices, and regulatory frameworks to provide a comprehensive guide for marine professionals.

Core Responsibilities of Engine Room Watchkeeping

Watchkeeping duties form the backbone of safe and efficient ship operations. Engineers must conduct regular rounds, focusing on detecting leaks, unusual vibrations, sounds, or temperatures in machinery like main engines, generators, boilers, and pumps. This proactive monitoring prevents minor issues from escalating into failures that could cause fires, explosions, or environmental spills.

Parameter recording is essential. Watchkeepers log pressures, temperatures, and levels in fuel, lube oil, and cooling water tanks. These records track performance trends and enable early intervention. For instance, deviations in exhaust gas temperatures or lube oil pressures signal potential problems requiring immediate action.

Machinery operations follow Standard Operating Procedures (SOPs). This includes starting, stopping, and adjusting main engines, auxiliary generators, boilers, and fuel purifiers. Watchkeepers also manage electrical systems, ensuring stable power distribution and monitoring air compressor pressures.

Emergency response is a priority. Alarms from fire detection, machinery monitoring, or power systems demand instant investigation. Watchkeepers differentiate genuine alerts from faulty ones—statistics show 80% of serious engine incidents involve main diesel engines, often due to turbocharger or bearing failures. Prompt action, guided by SOPs, mitigates risks like breakdowns or power outages.

Environmental compliance aligns with MARPOL regulations. Duties include overseeing bilge management, oily water separators, and emissions monitoring to prevent pollution. Watchkeepers ensure systems like sewage treatment plants and sludge tanks operate within limits, avoiding fines or operational halts.

Safety compliance extends to verifying firefighting equipment, watertight doors, and safety devices. Adherence to ISM Code, SOLAS, and ISPS standards is mandatory, with watchkeepers confirming all systems are operational during rounds.

Communication with the bridge is vital for maneuvers, speed changes, or power demands. Watchkeepers brief on engine status, potential issues, and maintenance activities to support navigational decisions.

Finally, watch handover ensures continuity. The relieving engineer receives a full briefing on operational changes, maintenance, tank levels, and abnormalities before assuming duty.

Here’s a table summarizing core responsibilities:

| Responsibility | Key Tasks |

|---|---|

| Continuous Monitoring & Inspections | Rounds to check leaks, vibrations, sounds, temperatures; inspect all levels of machinery. |

| Log Book Record Keeping | Record pressures, temperatures, tank levels (fuel, lube oil, cooling water). |

| Machinery Operations & Maintenance | Operate engines, generators, boilers per SOPs; manage fuel purifiers and pumps. |

| Emergency Response | Investigate alarms; handle breakdowns, fires, or power failures. |

| Environmental Protection | Monitor bilges, separators, emissions for MARPOL compliance. |

| System Controls | Oversee electrical distribution, air compressors. |

| Safety Compliance | Verify firefighting gear, watertight doors, ISM/SOLAS/ISPS adherence. |

| Watch Handover | Brief relieving engineer on status, issues, and orders. |

Key Procedures in Engine Room Watchkeeping

Effective watchkeeping relies on structured procedures to maintain consistency and safety. Communication protocols ensure seamless interaction between engine room and bridge, especially during port operations or emergencies. The Engine Room Procedures Guide emphasizes information sharing to enhance teamwork.

Safety procedures mandate adherence to the company’s Safety Management System (SMS). This includes managing rest periods to combat fatigue, a leading cause of errors. Watchkeepers must take at least 77 hours of rest weekly, with no more than 14 hours continuous duty, per STCW regulations.

Tool usage involves leveraging senses and technology. Engineers use sight for gauge readings, sound for abnormal noises, smell for leaks or burns, touch for vibrations, and even taste for fluid contamination (e.g., distinguishing seawater from freshwater in cooling systems). Digital systems complement this with real-time monitoring.

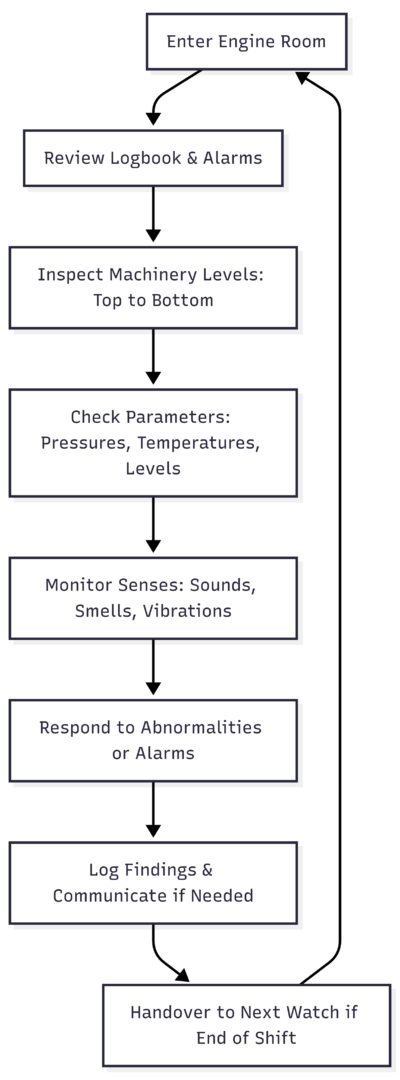

To illustrate the watchkeeping workflow, here’s a flowchart depicting a typical round:

This cycle ensures thorough coverage, with each step building on the previous for comprehensive oversight.

The Handover Process: Ensuring Seamless Transitions

Taking over a watch requires a detailed exchange to maintain operational continuity. The process begins with special orders from the chief engineer or bridge, including control system adjustments or maintenance restrictions.

Tank levels are reviewed: bilges, ballast, sewage, reserve, slop, and fuel. Critical levels, like those in stern tube oil tanks, are highlighted for monitoring.

Fire safety briefing covers equipment readiness and any isolated systems or disabled alarms. Emergency procedures address special modes for damage control, icy waters, or shallow navigation.

Ongoing maintenance details include machinery under repair, work locations, involved crew, and hazards. Equipment failures are disclosed, with notes on corrective actions.

Pre-departure and arrival checks are confirmed, ensuring all propulsion, steering, and boiler systems are verified. Machinery status covers main engines, boilers, and auxiliaries like purifiers, freshwater generators, and pumps.

Manual monitoring requirements, such as frequency for specific gauges, are specified. Adverse conditions impacting operations, like rough seas, are discussed.

Unattended issues from the prior watch are prioritized. Boiler controls and steam equipment conditions are detailed.

All information is documented in the logbook, recording parameters like engine load, pressures (e.g., sea water, lube oil), temperatures (e.g., exhaust gas, engine room), turbocharger readings, and tank levels.

A sample watch schedule table:

| Watch Period | Responsible Engineer |

|---|---|

| 0800-1200 | 2nd Engineer |

| 1200-1600 | 3rd Engineer |

| 1600-2000 | 4th Engineer |

| 2000-0000 | 2nd Engineer |

| 0000-0400 | 3rd Engineer |

| 0400-0800 | 4th Engineer |

This rotation supports 24/7 coverage with rest intervals.

The Importance of Documentation in Watchkeeping

Documentation standardizes procedures, ensuring efficiency and safety. Logbooks provide historical records for troubleshooting, revealing patterns in machinery performance.

Compliance with regulations requires accurate records for audits and incidents. In insurance or charter claims, log entries serve as evidence of maintenance and operations.

For handovers and training, documents offer overviews of current status and issues, aiding new crew integration.

Key logbook entries include:

| Logbook Entry | Importance |

|---|---|

| Timing of Watches | Tracks shift coverage and rest compliance. |

| Fuel Lever Settings | Monitors consumption and efficiency. |

| Engine Load | Identifies power deviations. |

| Pressures (e.g., Lube Oil, Sea Water) | Detects system issues. |

| Temperatures (e.g., Exhaust Gas) | Signals overheating or inefficiencies. |

| Running Hours of Machinery | Schedules maintenance. |

| Tank Levels | Ensures resource management. |

| Incidents and Breakdowns | Supports claims and analysis. |

Thorough logging reduces risks and enhances decision-making.

Regulatory Oversight and Compliance

The International Maritime Organization (IMO) sets global standards for safety, security, and pollution prevention. The ISM Code mandates a Safety Management System (SMS) covering all operations, including watchkeeping.

Compliance is enforced via flag state (registration country) and port state controls, inspecting for adherence to design, equipment, and operational standards.

Training under the STCW Convention requires certification in technical skills, emergency response, and communication. Engine personnel complete modules on machinery operation, environmental awareness, and fatigue management.

The Maritime Labour Convention (MLC) addresses work hours, rest, and welfare, ensuring no excessive fatigue.

A comparison of key conventions:

| Convention | Focus Areas |

|---|---|

| ISM Code | Safety management, pollution prevention, SMS implementation. |

| STCW Convention | Training, certification, watchkeeping standards. |

| MLC | Seafarers’ rights, work/rest hours, living conditions. |

| SOLAS | Safety of life at sea, equipment standards. |

| MARPOL | Pollution prevention, emissions control. |

These frameworks ensure watchkeeping aligns with international norms.

Best Practices for Effective Watchkeeping

Mastering watchkeeping involves building knowledge across mechanical, electrical, and regulatory domains. Stay updated on technologies like automated monitoring systems.

Utilize all senses for detection: touch for heat/vibrations, hearing for noises, smell for leaks, sight for visuals, taste for fluids, and intuition for anomalies.

Adhere to manuals, instructions, and safety guidelines. Documentation types include:

| Document Type | Purpose |

|---|---|

| Manuals | Operation, maintenance, troubleshooting. |

| Operating Instructions | Start/stop procedures. |

| Safety Guidelines | Emergency responses. |

| Pollution Prevention Procedures | Environmental incident management. |

Analyze logbooks to spot trends, comparing past and current parameters.

Maintain clear communication: Report operations, issues, and updates to bridge and seniors. ERM principles from STCW emphasize this for teamwork.

Conduct thorough inspections: Check logs, alarms, tanks, sumps, bilges, and generators. Note findings meticulously.

Respond to alarms promptly: Investigate causes, consult records, and act per procedures. Human errors cause 60% of incidents, often from poor handling.

Report faults immediately; seek assistance for complex issues. Follow orders but apply judgment.

Adhere to alcohol policies; impairment risks safety.

Manage fatigue: Prioritize rest, communicate needs. Factors like sleep deprivation and irregular schedules impair performance.

| Fatigue Risk Factor | Impact |

|---|---|

| Sleep Deprivation | Reduced reaction time, accidents. |

| Irregular Schedules | Circadian disruptions. |

| Environmental Stressors | Noise/vibration affects sleep. |

| Workload Pressures | Prolonged wakefulness. |

The Future of Watchkeeping

Advancing technology integrates AI-driven monitoring and predictive maintenance, enhancing efficiency. However, core principles—vigilance, knowledge, and communication—remain essential. Watchkeepers must adapt to these tools while upholding regulatory standards.

Conclusion

Engine room watchkeeping duties ensure vessel safety, efficiency, and compliance. By monitoring machinery, responding to emergencies, maintaining records, and adhering to regulations, engineers prevent breakdowns and protect the environment. Proficiency in these areas demands ongoing training and best practices, contributing to reliable maritime operations worldwide.

FAQ

What are the primary duties of an engine room watchkeeping team?

Inspect propulsion and auxiliary machinery, detect irregularities (temperature, sounds, smells), report and correct malfunctions.

How can an engineer enhance their watchkeeping duties?

Build knowledge, use all senses, follow documentation, analyze logs, communicate clearly, inspect thoroughly, respond to alarms, report issues, seek help, adhere to policies, manage fatigue.

Why is efficient watchkeeping crucial?

It prevents accidents, breakdowns, fires, explosions, and environmental damage; reduces maintenance needs.

What is the importance of using all senses during rounds?

Senses detect issues early: touch for vibrations, hearing for noises, smell for leaks, etc.

How should an engineer interpret the logbook?

Track past parameters to analyze trends, identify problems, and ensure accurate recording.

What is the significance of communication between engine room and bridge?

Ensures safe operations; allows bridge to plan and prepare.

How should an engineer respond to alarms?

Differentiate faulty from genuine, investigate promptly, follow procedures.

What to do if detecting a fault or mistake?

Report immediately, attempt repair, seek help if needed.

How to manage fatigue?

Prioritize rest, take breaks, communicate needs to maintain alertness.

What role does regulatory oversight play?

IMO, ISM Code, STCW ensure standards for safety, training, and compliance through flag/port controls.

Happy Boating!

Share What are the duties of watchkeeping in the engine room? with your friends and leave a comment below with your thoughts.

Read The international convention for the safety of life at sea until we meet in the next article.