Water Pressure Gauge Role in Monitoring Pressure Systems

Discover the vital role of water pressure gauges in monitoring and optimizing water systems for residential, commercial, and industrial use. Learn types, applications, and more.

Water pressure gauges are indispensable tools for ensuring the safe and efficient operation of water systems across residential, commercial, and industrial settings. By providing real-time pressure readings, these devices help maintain optimal performance, prevent system failures, and enhance safety. This article explores the functionality, types, applications, and selection criteria for water pressure gauges, emphasizing their importance in modern water management systems. Additionally, we’ll highlight advanced solutions from trusted providers like Mid-West Instrument and John Brooks Company, and include practical insights into specifications, pricing, and troubleshooting.

What Is a Water Pressure Gauge?

A water pressure gauge is a precision instrument designed to measure the force exerted by water within a system, typically expressed in units such as pounds per square inch (PSI) or bar. These gauges are installed at key points in water distribution networks, such as near pressure regulators, pumps, or filtration units, to monitor static (non-moving water) or dynamic (moving water) pressure. By delivering accurate readings, water pressure gauges enable operators to detect issues like leaks, blockages, or pressure irregularities that could compromise system performance.

Why Water Pressure Monitoring Matters

Monitoring water pressure is critical for several reasons:

- System Safety and Integrity: Excessive pressure can lead to pipe bursts, leaks, or damage to appliances, while insufficient pressure may result in inadequate water supply. Maintaining pressure within safe limits—typically 45-80 PSI for residential systems and 20-50 PSI for marine systems—prevents costly repairs and ensures consistent performance.

- Efficiency and Performance: Proper pressure ensures optimal water flow for applications like irrigation, industrial processes, and household plumbing. Gauges help identify inefficiencies, such as pressure drops across filters, enabling timely maintenance.

- Diagnostic Capabilities: Sudden pressure changes can signal problems like leaks, clogs, or equipment malfunctions. Gauges act as early warning systems, allowing operators to address issues before they escalate.

- Regulatory Compliance: In industries like water treatment or power generation, maintaining specific pressure ranges is often mandated by standards like ASME B40.100, ensuring safety and operational reliability.

How Water Pressure Gauges Work

Most water pressure gauges operate using a pressure-sensitive element that responds to the force exerted by water. The most common mechanism is the Bourdon tube, a curved, hollow tube that straightens as pressure increases. This movement drives a needle across a calibrated dial, displaying the pressure in PSI or bar. Other gauge types, such as diaphragm or digital gauges, use different mechanisms but follow the same principle of converting physical pressure into a readable output.

For example, in a differential pressure gauge, two pressure points are compared, often across a filter or valve, to measure the pressure drop. This is particularly useful in water treatment plants, where a rising pressure differential indicates filter clogging, signaling the need for maintenance.

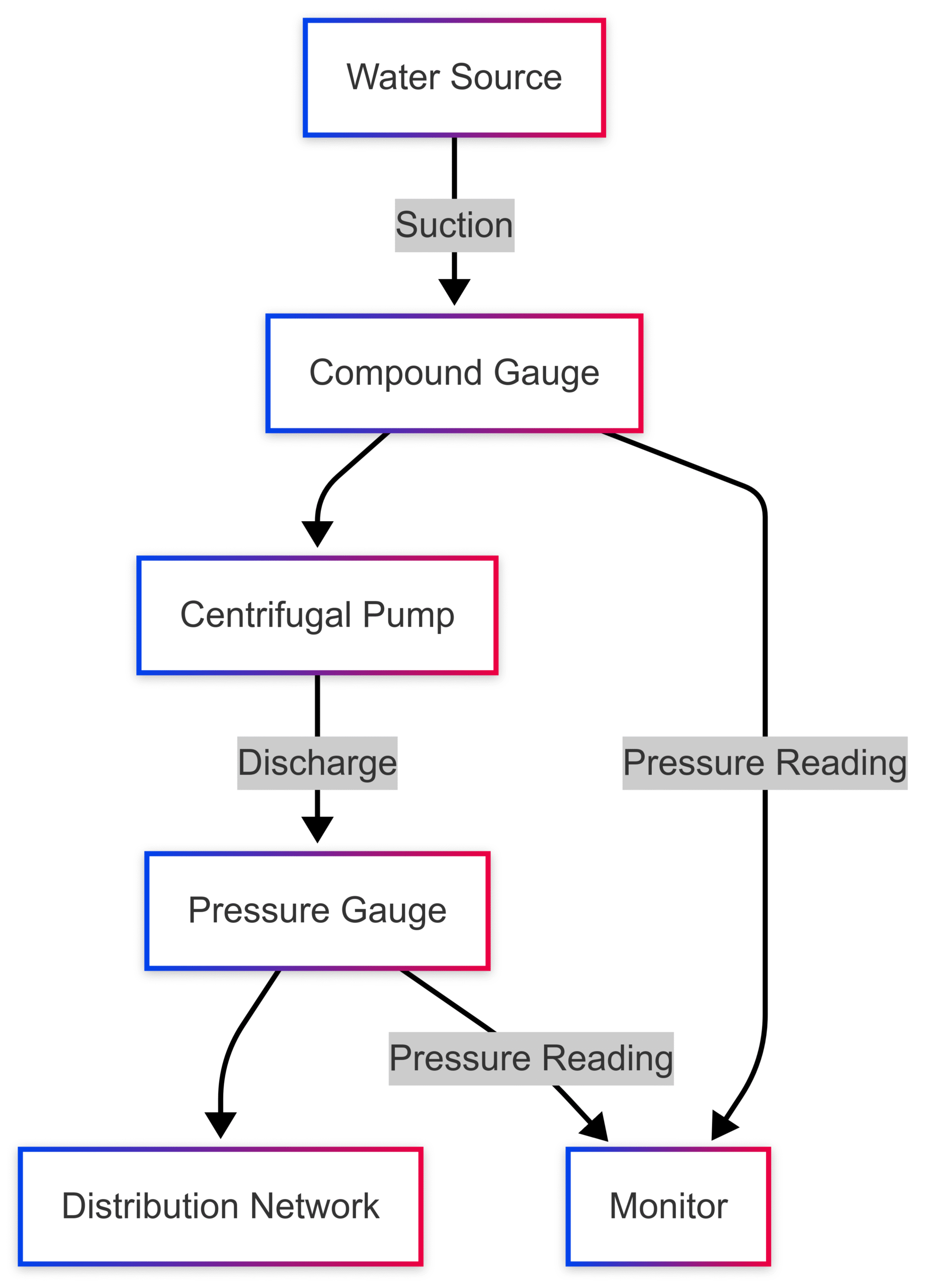

Example: Pressure Measurement in a Pumping System

Consider a centrifugal pump in a water distribution system. A compound gauge on the suction side and a pressure gauge on the discharge side measure the pressure difference. If the discharge pressure is 50 PSI and the suction pressure is 10 PSI, the pump boosts the system by 40 PSI. This data helps operators verify the pump’s performance and detect issues like blockages or wear.

Types of Water Pressure Gauges

Water pressure gauges come in various designs, each suited to specific applications. Below is an overview of the main types, their mechanisms, and their uses.

1. Bourdon Tube Pressure Gauge

- Mechanism: A curved tube straightens under pressure, moving a needle on a dial.

- Pressure Range: 0.6–7000 bar (8–10,000 PSI).

- Applications: General-purpose use in plumbing, HVAC, agriculture, and automotive industries. Ideal for high-pressure and dynamic load environments.

- Advantages: Durable, no external power required, corrosion-resistant (typically stainless steel).

- Price Range: $20–$150, depending on size and accuracy.

2. Diaphragm Pressure Gauge

- Mechanism: A flexible diaphragm deforms under pressure, moving a needle via a pinion system.

- Pressure Range: Low-pressure applications, typically up to 10 bar (145 PSI).

- Applications: Petrochemical, pharmaceutical, and food processing industries, especially for high-temperature or corrosive fluids.

- Advantages: Suitable for low-pressure measurements and harsh environments.

- Price Range: $50–$200.

3. Capsule Pressure Gauge

- Mechanism: Two corrugated diaphragms form a capsule that expands or contracts under pressure.

- Pressure Range: Up to 600 mbar (8.7 PSI), ideal for low-pressure gas measurements.

- Applications: Ventilation systems, vacuum compressors, and filter monitoring.

- Advantages: High precision for low-pressure applications.

- Price Range: $40–$120.

4. Differential Pressure Gauge

- Mechanism: Measures the pressure difference between two points, often using a diaphragm separating a media chamber from a vacuum chamber.

- Applications: Water treatment plants, HVAC systems, and filtration monitoring.

- Advantages: Detects pressure drops across components, ensuring system efficiency.

- Price Range: $100–$500, with advanced models like Mid-West Instrument’s gauges at the higher end.

5. Digital Pressure Gauge

- Mechanism: Uses a piezoresistive sensor to convert pressure into an electronic signal, displayed on a digital screen.

- Applications: Pharmaceutical, food processing, and oil/gas industries requiring precise data logging.

- Advantages: High accuracy (0.5–1% full scale), easy to read, and data transmissible.

- Price Range: $100–$400.

6. Manometer Pressure Gauge

- Mechanism: Balances a fluid column (e.g., mercury) against atmospheric pressure in a U-shaped tube.

- Applications: HVAC, chemical processing, and medical devices like ventilators.

- Advantages: Simple, accurate for low-pressure measurements.

- Price Range: $30–$100.

7. Absolute Pressure Gauge

- Mechanism: Measures pressure relative to a perfect vacuum, unaffected by atmospheric changes.

- Applications: Aeronautics, HVAC, and scientific laboratories.

- Advantages: Ideal for high-altitude or vacuum environments.

- Price Range: $80–$250.

Comparison Table: Water Pressure Gauge Types

| Gauge Type | Pressure Range | Applications | Accuracy | Price Range |

|---|---|---|---|---|

| Bourdon Tube | 0.6–7000 bar | Plumbing, HVAC, agriculture | 1–3% full scale | $20–$150 |

| Diaphragm | Up to 10 bar | Petrochemical, food processing | 1–2% full scale | $50–$200 |

| Capsule | Up to 600 mbar | Ventilation, vacuum systems | 1–2% full scale | $40–$120 |

| Differential | Varies by model | Water treatment, filtration | 0.5–2% full scale | $100–$500 |

| Digital | Varies by model | Pharmaceutical, oil/gas | 0.5–1% full scale | $100–$400 |

| Manometer | Low-pressure | HVAC, medical devices | 1–2% full scale | $30–$100 |

| Absolute | Varies by model | Aeronautics, laboratories | 1–2% full scale | $80–$250 |

Applications of Water Pressure Gauges

Water pressure gauges are used across diverse industries and settings to ensure system reliability and safety.

Residential Applications

In homes, gauges are typically installed near the main water supply or pressure-reducing valve (PRV) to monitor incoming water pressure. Maintaining pressure between 45-80 PSI prevents damage to fixtures like faucets and appliances. For well systems, gauges ensure pumps operate correctly, turning on and off at designated pressures.

Commercial Applications

In commercial buildings, gauges monitor water pressure in HVAC systems, fire suppression systems, and irrigation networks. Regular monitoring prevents issues like low flow in sprinklers or overheating in cooling systems.

Industrial Applications

- Water Treatment Plants: Differential pressure gauges monitor pressure drops across filters, indicating when cleaning or replacement is needed.

- Power Plants: Gauges at boiler inlets and outlets ensure safe pressure levels for steam and feedwater.

- Manufacturing: Gauges regulate pressure in cooling towers, pumps, and process water systems to maintain efficiency.

- Marine Systems: On boats, gauges monitor water pressure in engines (typically 8-12 PSI, or up to 30 PSI for high-power engines) to prevent overheating.

Specialized Applications

- Oil and Gas: Digital gauges monitor hazardous materials in pipelines.

- Pharmaceuticals: Diaphragm gauges measure pressure in sterile fluid systems.

- HVAC: Manometers balance duct pressure for optimal air quality.

Selecting the Right Water Pressure Gauge

Choosing a water pressure gauge requires careful consideration of several factors:

- Pressure Range: Select a gauge rated for at least twice the system’s maximum operating pressure. For example, a residential system with a working pressure of 60 PSI should use a gauge rated for 120 PSI or higher.

- Accuracy: Most applications require 1–3% full-scale accuracy. High-precision applications, like pharmaceuticals, may need 0.5% accuracy.

- Material Compatibility: Gauge components (e.g., Bourdon tube, diaphragm) should resist corrosion from the fluid. Stainless steel is ideal for water systems, withstanding up to 212°F (100°C). For hotter media, use Inconel (up to 600°F).

- Mounting Options: Choose in-line, panel-mounted, or remote gauges based on installation needs. Marine gauges, for example, are often dash-mounted for visibility.

- Environmental Factors: Ensure the gauge can withstand temperature, humidity, and vibration. Hermetically sealed gauges are best for wet or humid conditions.

- Certifications: For regulated industries, select gauges compliant with standards like ASME B40.100.

- Visibility and Size: Larger dials (e.g., 4 inches) improve readability in industrial settings, while compact gauges suit residential use.

Recommended Brands and Models

- Mid-West Instrument Differential Pressure Gauges: Known for precision in water treatment and filtration systems. Prices range from $150–$500.

- Faria Beede Marine Gauges: Durable, accurate gauges for boats, priced at $50–$150.

- Monument 2510F Mains Water Pressure Gauge: Ideal for residential use, priced at $30–$60.

Installation and Maintenance

Proper installation and maintenance are critical for accurate readings and gauge longevity.

Installation Tips

- Residential: Install near the main water supply or PRV discharge side.

- Industrial: Place gauges at key points like pump discharges or filter inlets/outlets.

- Marine: Mount on the engine’s intake manifold or dash, using hard or soft lines based on the fitting type.

Maintenance and Troubleshooting

Regular maintenance prevents gauge failure. Common issues and solutions include:

- Pressure Spikes: Caused by sudden pressure surges. Check the regulator screw and system for faults. Use a gauge with a higher pressure rating if spikes persist.

- Clogging: Debris in the water line can block the gauge. Inspect and clear blockages regularly.

- Corrosion: Inspect the inlet tube for rust, especially in marine environments. Use stainless steel or corrosion-resistant gauges.

- Vibration Damage: Securely mount gauges to minimize vibration, common in industrial or marine settings.

- Zero Reading: A persistent 0 PSI reading indicates a broken gauge or disconnected line. Replace or reconnect as needed.

Calibration

Calibrate gauges annually or per manufacturer guidelines to ensure accuracy. Professional calibration services cost $20–$100, depending on the gauge type.

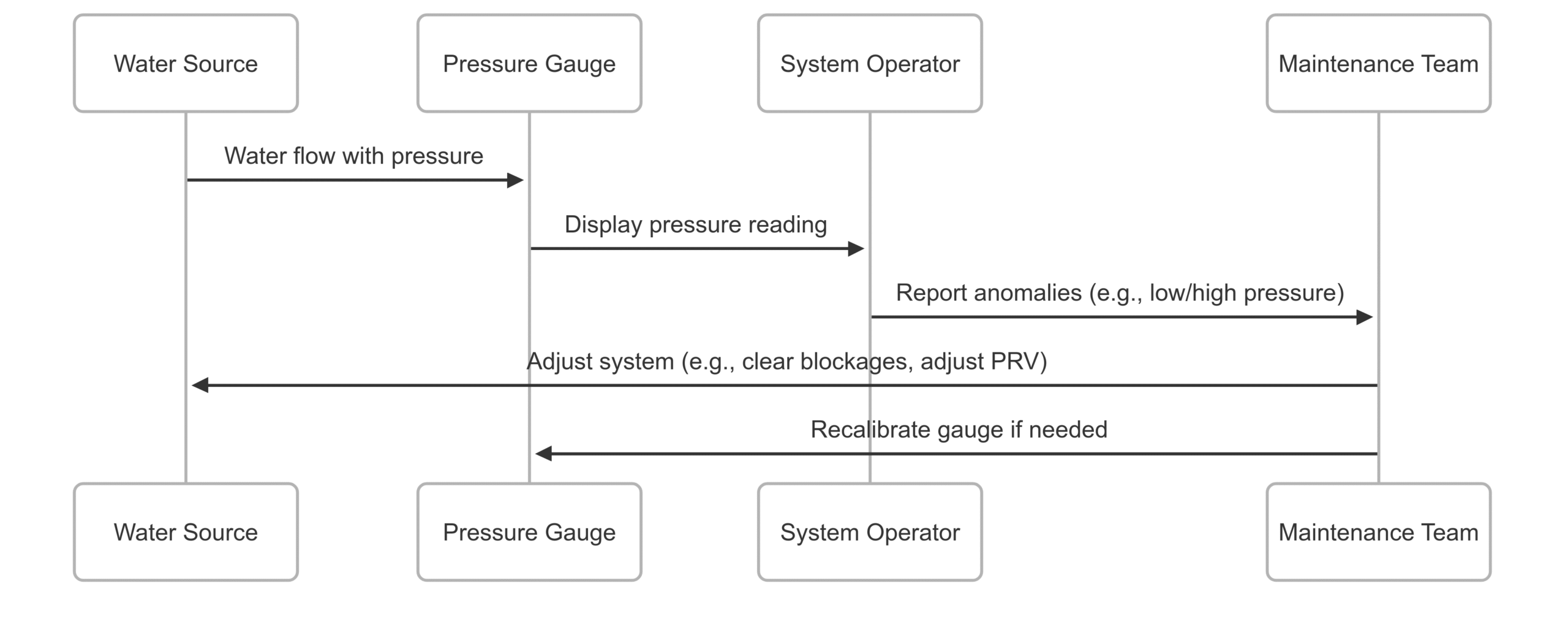

Chart: Water System Monitoring Workflow

Advanced Solutions from Mid-West Instrument and John Brooks Company

Mid-West Instrument specializes in differential pressure gauges, offering robust solutions for water treatment and industrial applications. Their gauges feature high accuracy (0.5–2% full scale) and durable stainless steel construction, ideal for harsh environments. Prices range from $150–$500, reflecting their advanced features like digital outputs and customizable ranges.

John Brooks Company, an authorized distributor, provides a wide selection of pressure gauges, including Bourdon tube and digital models. Their expertise ensures customers select gauges tailored to specific applications, from residential plumbing to industrial processes. Consultation services are available, with gauge prices starting at $20 for basic models and up to $400 for digital or differential gauges.

FAQs

How accurate are water pressure gauges?

What should a boat water pressure gauge read?

How often should gauges be replaced?

Conclusion

Water pressure gauges are vital for maintaining the safety, efficiency, and reliability of water systems across residential, commercial, and industrial applications. From Bourdon tube gauges for general use to differential gauges for precise filtration monitoring, these devices provide critical insights into system performance. By selecting the right gauge—considering factors like pressure range, accuracy, and material compatibility—and maintaining it properly, operators can prevent costly failures and ensure optimal water delivery. Trusted providers like Mid-West Instrument and John Brooks Company offer high-quality solutions, making it easier to equip systems with reliable gauges. Whether you’re managing a home plumbing system, a boat engine, or a water treatment plant, a well-chosen water pressure gauge is key to long-term success.

Happy Boating!

Share Water Pressure Gauge Role in Monitoring Pressure Systems with your friends and leave a comment below with your thoughts.

Read Daily Water Intake Calculator until we meet in the next article.