Symptoms of a bad ignition coil on an outboard motor

Learn the key symptoms of a bad coil on an outboard motor, including misfires, rough idling, and reduced power, with expert tips for diagnosis and repair.

Outboard motors are the heart of many boats, providing reliable power for fishing, cruising, or watersports. However, like any mechanical system, they can develop issues over time, and one critical component that often causes problems is the ignition coil. A faulty ignition coil can lead to a range of performance issues, from difficulty starting the engine to complete failure under load. Understanding the symptoms of a bad coil on an outboard motor is essential for boat owners to diagnose issues early, prevent further damage, and maintain optimal performance on the water.

In this comprehensive guide, we’ll explore the role of the ignition coil in an outboard motor, detail the symptoms of a failing coil, explain how to diagnose the problem, and provide actionable steps for testing and addressing issues. We’ll also discuss related spark plug problems, other ignition system issues, and maintenance tips to keep your outboard running smoothly. Whether you’re dealing with a 70hp Johnson or a 175hp Mercury, this guide will help you identify and resolve coil-related issues effectively.

What Does an Ignition Coil Do in an Outboard Motor?

The ignition coil in an outboard motor is a vital component of the ignition system, responsible for transforming low-voltage electricity from the boat’s battery into the high-voltage spark needed to ignite the fuel-air mixture in the engine’s combustion chamber. This spark, delivered through the spark plugs, powers the engine and keeps your boat moving.

The coil operates in two circuits:

- Primary Circuit: Connects to the battery and the engine’s control system, receiving low voltage (typically 12 volts).

- Secondary Circuit: Amplifies the voltage (up to 30,000 volts or more) and sends it to the spark plugs to create a spark.

A failing coil disrupts this process, leading to weak or no spark, which directly impacts engine performance. Understanding the symptoms of a bad coil is the first step to diagnosing and fixing the problem.

Key Symptoms of a Bad Coil on an Outboard Motor

A faulty ignition coil can manifest in several ways, ranging from subtle performance issues to complete engine failure. Below are the primary symptoms to watch for, along with detailed explanations of how they affect your outboard motor.

1. Difficulty Starting the Engine

One of the most common signs of a bad ignition coil is difficulty starting the engine. When the coil is weak or damaged, it may not produce a strong enough spark to ignite the fuel-air mixture. This results in the engine cranking without starting or requiring multiple attempts to fire up. For example, a 175hp Mercury owner reported that their engine started easily when cold but failed to start once warmed up, a classic symptom of a coil that fails under heat stress.

Why It Happens: A weakened coil struggles to generate the necessary voltage, especially under demanding conditions like cold starts or high temperatures. This can also be exacerbated by fouled spark plugs, which increase the demand on the coil.

2. Engine Misfires

Misfires occur when the engine sputters, shakes, or runs unevenly, particularly during acceleration or at higher speeds. You may notice a loss of smoothness as the engine struggles to maintain consistent combustion. Misfires are often caused by a coil that intermittently fails to deliver a spark to one or more cylinders.

Example: A 70hp Johnson owner might experience power surges or a noticeable “hiccup” in performance when one cylinder intermittently loses spark due to a faulty coil. This was noted in a forum discussion where a user described power loss that appeared only after the engine warmed up.

3. Rough Idling

A bad coil can cause the engine to idle unevenly, with excessive vibration or shaking. This happens because one or more cylinders may not be firing correctly, disrupting the engine’s balance. Rough idling is often more noticeable at low speeds or when the boat is stationary.

Impact: Rough idling not only affects the boating experience but can also strain other engine components, leading to further wear over time.

4. Reduced Power or Acceleration

If the ignition coil isn’t delivering consistent voltage, the engine may fail to reach its full power potential. This results in sluggish acceleration and a lack of responsiveness, making it difficult to plane the boat or maintain high speeds. For instance, a 70hp Johnson with one bad coil might run on fewer cylinders, significantly reducing its power output.

User Insight: A forum user noted that a bad coil could cause a “dead cylinder,” leading to a complete loss of power from that cylinder, making the engine feel underpowered.

5. Engine Stalling

Stalling, particularly when the engine is hot or under load, is another hallmark of a failing coil. A coil that works intermittently may function well when cold but fail as the engine heats up due to thermal expansion or insulation breakdown.

Real-World Example: A Mercury 175hp owner reported that their engine stalled after warming up and wouldn’t restart, pointing to a coil that failed under heat stress.

6. Decreased Fuel Efficiency

A faulty coil can lead to incomplete combustion, causing the engine to burn more fuel than necessary. This inefficiency manifests as increased fuel consumption, which can be costly for boaters who spend long hours on the water.

Why It Happens: Incomplete combustion occurs when the spark is too weak to fully ignite the fuel-air mixture, leaving unburnt fuel that reduces efficiency.

7. Check Engine Light

In modern outboard motors equipped with an engine control unit (ECU), a bad coil can trigger the check engine light. The ECU detects misfires or irregular combustion and alerts the operator to a potential issue.

Note: Not all outboards have a check engine light, especially older models like a 70hp Johnson. However, if your engine has one, this is a clear sign to investigate the ignition system.

8. Backfiring

Backfiring, characterized by a popping sound from the exhaust, occurs when unburnt fuel ignites in the exhaust system. A bad coil can cause incomplete combustion, leaving fuel in the cylinder that escapes and ignites later.

Impact: Backfiring not only indicates a problem but can also damage the exhaust system over time if not addressed.

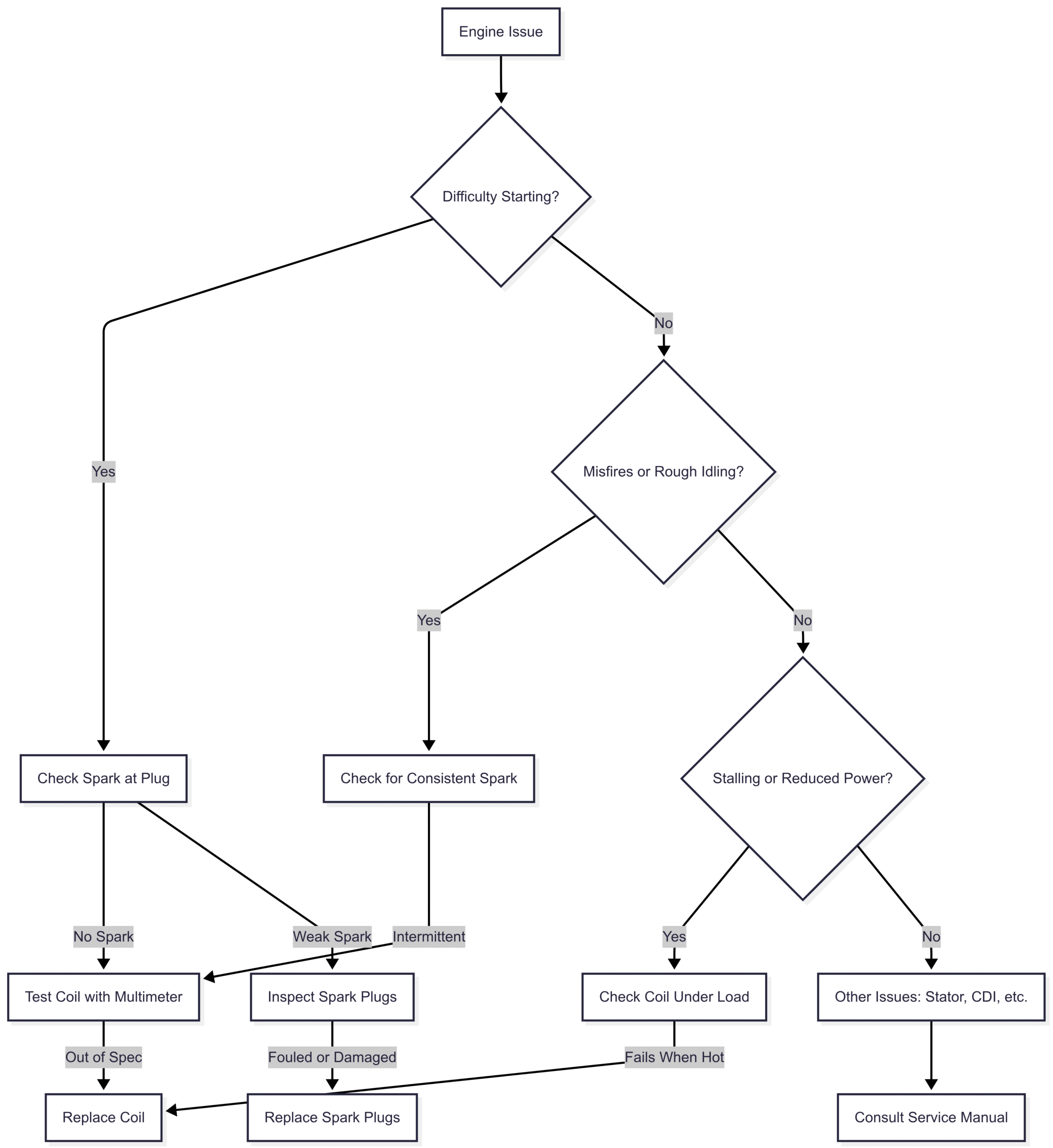

Visualizing Symptoms with a Flowchart

To help boaters identify whether their engine issues are coil-related, the following flowchart outlines the diagnostic process:

This flowchart guides users through the symptoms and directs them to appropriate diagnostic steps, which we’ll explore next.

How to Diagnose a Bad Coil on an Outboard Motor

Diagnosing a bad coil requires systematic testing to confirm the issue and rule out other components, such as spark plugs or the stator. Follow these steps to test your outboard’s ignition coil:

Step 1: Disconnect the Coil

- Primary Circuit: Disconnect the wires from the positive and negative terminals on the coil or unplug the connector to the coil. These wires connect to the battery and engine control system.

- Secondary Circuit: Disconnect the spark plug lead from the spark plug to isolate the coil from the plug.

Safety Note: Always ensure the engine is off and the key is removed before working on electrical components.

Step 2: Set Up Your Multimeter

- Use a digital multimeter set to the OHMS setting to measure resistance, not voltage or current.

- Set the multimeter to the 200-ohm range for the primary circuit and auto-ranging (if available) for the secondary circuit.

Step 3: Test the Primary Circuit

- Place the positive (red) probe on the positive terminal of the coil and the negative (black) probe on the negative terminal.

- Expected Reading: The resistance should be between 0.02 and 0.04 ohms for most outboard coils. Check your engine’s service manual for exact specifications, as values vary by model (e.g., a 70hp Johnson vs. a 175hp Mercury).

- Result: A reading outside this range indicates a faulty coil.

Step 4: Test the Secondary Circuit

- Place the negative probe on the negative terminal and the positive probe on the coil tower (where the spark plug lead connects).

- Expected Reading: The resistance should typically be between 8,000 and 11,000 ohms (8-11 kΩ). Again, consult the service manual for precise values.

- Result: A significantly different reading suggests the coil is defective.

Step 5: Visual Inspection

- Check the coil for physical damage, such as cracks, melting, or burn marks. These indicate overheating or short-circuiting, requiring immediate replacement.

Pro Tip: If the coil tests within spec but symptoms persist, test it under operating conditions (e.g., when hot) using a timing light on the spark plug wires, as suggested by a forum user. A coil may fail only under load or heat.

Common Ignition Coil Specifications and Replacement Costs

To give you an idea of what to expect when replacing a coil, here’s a table summarizing typical specifications and costs for ignition coils on popular outboard motors:

| Outboard Model | Coil Part Number | Primary Resistance (ohms) | Secondary Resistance (kΩ) | Approx. Cost (USD) |

|---|---|---|---|---|

| Johnson 70hp | 582995 / 584477 | 0.02–0.04 | 8–11 | $30–$60 |

| Mercury 175hp | 8M0047310 | 0.02–0.05 | 9–12 | $50–$100 |

| Yamaha 150hp | 6G5-85570-00-00 | 0.03–0.05 | 8–10 | $40–$80 |

| Evinrude 115hp | 0586767 | 0.02–0.04 | 9–11 | $35–$70 |

Note: Prices are approximate and vary by retailer (e.g., Amazon, iBoats, or marine supply stores). Always verify the part number with your engine’s service manual to ensure compatibility.

How a Bad Coil Affects Specific Outboard Motors

To illustrate the impact of a bad coil, let’s consider the 70hp Johnson and 175hp Mercury mentioned in user queries:

- 70hp Johnson: A bad coil on a 70hp Johnson can cause one cylinder to stop firing, leading to a noticeable loss of power. For example, a user described “power surges” when the coil intermittently failed, causing the engine to run on fewer cylinders. This can make the boat sluggish and unresponsive, especially under load. Testing the spark and swapping coils between cylinders can confirm if the issue follows the coil.

- 175hp Mercury: A Mercury owner reported that their engine started fine when cold but failed to restart when hot. This is a common symptom of a coil that breaks down under thermal stress. Replacing the coil and ensuring proper cooling can resolve this issue.

Related Issues: Bad Spark Plugs and Other Ignition Problems

A bad coil isn’t always the culprit. Spark plugs and other ignition components can cause similar symptoms. Here’s how to differentiate and address these issues:

Bad Spark Plugs

Spark plugs are critical for delivering the spark from the coil to the combustion chamber. Signs of bad spark plugs include:

- Fouling: Wet plugs indicate water in the fuel or oil contamination. Black, sooty plugs suggest excessive oil in the fuel mixture.

- Erosion or Heat Damage: A white or eroded insulator tip indicates the plug is running too hot.

- Short Circuit: Use a multimeter to check for continuity between the plug’s tip and threads. A shorted plug (zero resistance) needs replacement.

Testing Tip: Remove and inspect each plug for damage or fouling. Replace plugs that show signs of wear, and ensure they match the manufacturer’s specifications (e.g., NGK or Champion plugs for your engine).

Other Ignition System Problems

If the coil and spark plugs test fine, consider these potential issues:

- No Spark: Check the stop switch, ground wires, and electrical connections. A faulty stator, flywheel magnets, or capacitor discharge ignition (CDI) unit could also be to blame.

- Weak Spark: A weak, orange spark (instead of a strong blue one) may indicate a failing stator or flywheel magnets.

- Intermittent Spark: Insulated copper wiring or CDI components can fail intermittently, especially when hot. This requires thorough testing with a peak reading voltmeter.

- Incorrect Timing: A sheared flywheel key or faulty trigger coils can cause spark timing issues, leading to misfires or backfiring.

- Cross Firing: In multi-cylinder engines, spark plug leads too close together can cause cross firing, leading to backfiring. Ensure proper lead separation.

Maintenance Tips to Prevent Coil Issues

Preventing ignition coil problems starts with regular maintenance. Here are some tips to keep your outboard’s ignition system in top shape:

- Inspect Coils and Plugs Annually: Check for cracks, corrosion, or wear on coils and spark plugs. Replace components as needed.

- Use a Service Manual: A model-specific service manual (available on eBay or from the manufacturer) provides exact testing procedures and specifications for your engine’s coils.

- Check Electrical Connections: Ensure all wiring and terminals are clean, tight, and free of corrosion.

- Monitor Engine Temperature: Overheating can damage coils. Ensure proper cooling system function and avoid running the engine out of water for extended periods.

- Replace Spark Plugs Regularly: Follow the manufacturer’s recommended replacement schedule to reduce strain on the ignition coils.

When to Seek Professional Help

While many boaters can diagnose and replace a bad coil themselves, complex ignition issues may require professional expertise. If you’ve tested the coil and spark plugs but still experience problems, consult a certified marine mechanic. They can use advanced tools, like peak reading voltmeters, to diagnose issues with the stator, CDI, or flywheel.

Forum Advice: As one user suggested, starting a new thread on a platform like iBoats can connect you with experienced boaters who may have faced similar issues with your specific engine model.

Conclusion

A bad ignition coil on an outboard motor can cause a range of frustrating symptoms, from hard starting and misfires to reduced power and stalling. By understanding these signs and following a systematic diagnostic process, you can pinpoint whether the coil is the issue or if other components, like spark plugs or the stator, are to blame. Regular maintenance, including inspecting coils and plugs, using a service manual, and ensuring proper electrical connections, can prevent these issues and keep your outboard running smoothly.

If you’re experiencing symptoms like those described for a 70hp Johnson or 175hp Mercury, act quickly to diagnose and replace faulty components. With the right tools and knowledge, you can restore your engine’s performance and get back to enjoying your time on the water.

For further guidance, check out online resources like iBoats forums or YouTube channels dedicated to marine engine repair. Investing in a service manual for your specific outboard model is also a smart move for tackling complex issues efficiently.

Happy Boating!

Share Symptoms of a bad coil on an outboard motor with your friends and leave a comment below with your thoughts.

Read 5 Most Common Problems with Suzuki 350 Outboard until we meet in the next article.

Clear and helpful post! It made it easy to spot the signs of a bad outboard ignition coil. Simple explanations—great for DIY boat owners like me.