Scavenge Fire of Two Stroke Marine Diesel Engine on Ships

Scavenge fires in two-stroke marine diesel engines represent one of the most critical and hazardous incidents that can occur aboard a ship. These fires, ignited in the scavenge spaces where air is prepared for combustion, can lead to catastrophic engine damage, operational downtime, and even life-threatening situations for the crew. Understanding the causes, recognizing early warning signs, implementing effective response strategies, and adhering to rigorous prevention protocols are essential for marine engineers and ship operators.

This comprehensive guide explores scavenge fires in detail, providing actionable insights, real-world examples, and technical specifications to ensure maritime safety and operational efficiency.

What is a Scavenge Fire?

A scavenge fire occurs in the scavenge space of a two-stroke marine diesel engine, an area located beneath the piston where fresh air is compressed and directed into the combustion chamber while expelling exhaust gases. This process, known as scavenging, is critical for engine efficiency. However, under certain conditions, unburned fuel, carbon deposits, or lubricating oil can accumulate in this space, creating a flammable mixture. When ignited by a heat source, such as hot gases from piston blow-by or mechanical friction, a scavenge fire erupts.

The fire triangle—oxygen, fuel, and heat—is the foundation of any fire, including scavenge fires:

- Oxygen: Abundant in the scavenge space due to the constant flow of compressed air.

- Fuel: Consists of unburned fuel, carbonized lubricating oil, or carbon residues from incomplete combustion.

- Heat: Generated by hot combustion gases leaking past worn piston rings, friction between engine components, or overheated pistons.

When these elements combine within the flammable limit, the scavenge space becomes a hotspot for ignition, leading to a potentially devastating fire.

Why Are Scavenge Fires Dangerous?

Scavenge fires are among the deadliest engine room incidents due to their potential to cause:

- Engine Damage: Intense heat can distort pistons, liners, and other components, leading to costly repairs.

- Operational Downtime: A single fire can halt operations for days or weeks, impacting shipping schedules and revenue.

- Safety Risks: Explosions or uncontrolled fires can endanger the crew, especially if the fire spreads to the crankcase or other engine spaces.

- Environmental Impact: Fires can lead to fuel or oil leaks, posing environmental hazards.

A real-world example is the MV Horizon incident in 2018, where a scavenge fire caused by leaking piston rings and accumulated oil in the scavenge space led to a 10-day operational shutdown and millions in repair costs. This underscores the importance of understanding and mitigating scavenge fires.

Causes of Scavenge Fires

Scavenge fires result from a combination of mechanical, operational, and maintenance-related issues. Below are the primary causes:

1. Piston and Cylinder Wear:

- Worn Piston Rings: Excessive wear or broken rings allow hot combustion gases to bypass into the scavenge space, igniting accumulated oil or fuel.

- Worn Cylinder Liners: A degraded liner surface increases blow-by, contributing to fuel and oil accumulation.

- Insufficient Piston Ring Clearance: Inadequate axial clearance can cause rings to stick, exacerbating blow-by.

2. Fuel System Issues:

- Leaking Fuel Injectors: Faulty injectors can release unburned fuel into the scavenge space.

- Incorrect Injection Timing: Poor timing leads to incomplete combustion, leaving fuel residues.

- Poor Fuel Quality: Off-spec fuel can damage injectors and increase carbon deposits.

3. Lubrication Problems:

- Excessive Cylinder Lubrication: Over-lubrication allows oil to drain into the scavenge space, providing fuel for a fire.

- Faulty Stuffing Box Scraper Rings: Malfunctioning scraper rings fail to prevent oil ingress into the scavenge space.

4. Engine Overload or Operational Issues:

- Overloading: Operating the engine beyond its design limits increases peak pressures, leading to blow-by.

- Exhaust Back Pressure: A choked economizer or turbine can cause exhaust gases to blow back into the scavenge space, carrying hot gases and unburned fuel.

5. Scavenge Space Contamination:

- Sludge and Carbon Buildup: Accumulated oil, fuel, and carbon residues create a flammable mixture.

- Dirty Scavenge Space: Infrequent cleaning allows deposits to accumulate, increasing fire risk.

6. Mechanical Faults:

- Overheated Pistons: Caused by faulty fuel atomization, inadequate cooling, or scale formation in cooling passages.

- Friction: Rubbing between the piston and liner can generate sufficient heat to ignite residues.

Real-World Example: Coral Voyager (2022)

The container ship Coral Voyager delayed scavenge space inspections to meet tight operational deadlines, leading to a fire caused by excessive carbon buildup and worn piston rings. The incident required dry-docking and significant repairs, highlighting the dangers of neglecting maintenance.

Indications of a Scavenge Fire

Early detection is critical to mitigating the damage caused by scavenge fires. The following signs indicate a potential fire:

- Increased Scavenge Space Temperature: A rise in local temperature, often exceeding 200°C, signals overheating.

- Turbocharger Surging: Unstable turbocharger operation due to disrupted airflow.

- High Exhaust Temperatures: Incomplete combustion in the affected cylinder raises exhaust temperatures.

- Loss of Engine Power: Reduced RPM and power output due to back pressure in the scavenge space.

- Smoke from Scavenge Drains: Visible sparks, flames, or smoke indicate combustion.

- Blistering Paint: High temperatures may cause paint on scavenge doors to peel or blister, especially in severe cases.

- Unstable Engine Operation: Irregular running or fluctuations in control room parameters.

- Temperature Sensor Alarms: In unmanned machinery spaces (UMS), sensors trigger automatic slowdowns or alarms.

Detection Technologies

Modern ships employ advanced detection systems to identify scavenge fires early:

- Electrical Temperature Sensors: Installed in the scavenge trunk, these trigger alarms when temperatures exceed safe limits (e.g., 200°C).

- Thermal Imaging Cameras: Used during inspections to detect hotspots.

- Smoke Detectors: Positioned near scavenge drains to alert the crew to combustion byproducts.

A notable example is the Atlantic Star (2020), where the crew used thermal imaging to identify a hotspot in the scavenge space, allowing them to intervene before a fire ignited.

Actions to Take During a Scavenge Fire

The response to a scavenge fire depends on its severity—small fires may be managed with minimal disruption, while large fires require immediate and decisive action.

For Small Fires

- Reduce Engine Speed: Gradually lower RPM to slow or dead slow to reduce airflow and heat generation.

- Increase Cylinder Lubrication: Carefully increase lubrication to the affected unit, ensuring it does not exacerbate the fire.

- Cut Fuel Supply: Lift the fuel pump of the affected cylinder to stop unburned fuel from feeding the fire.

- Close Scavenge Drains: Prevent oxygen from entering and contain the fire.

- Monitor Temperatures: Continuously track scavenge and exhaust temperatures to ensure the fire burns out.

- Gradual RPM Increase: Once the fire is extinguished, slowly increase RPM while monitoring for re-ignition.

- Inspect Post-Fire: After cooling, inspect the scavenge trunk and affected components for damage.

For Large Fires

- Stop the Engine: Immediately shut down the engine to halt combustion and airflow.

- Engage Turning Gear: Rotate the engine to prevent seizure due to heat-induced distortion.

- Activate Fire Suppression: Use fixed systems like CO2, dry powder, or steam to extinguish the fire.

- Maintain Cooling: Ensure normal coolant flow through jackets and pistons to prevent thermal damage.

- Close Scavenge Air Duct: Shut the flap valve to isolate the fire.

- External Cooling (If Needed): On older ships without fixed systems, apply external cooling to prevent distortion.

- Ventilate Before Inspection: If CO2 is used, ventilate the space before opening scavenge doors to avoid explosions.

Safety Precautions

- Avoid Relief Valves: Crew should steer clear of scavenge space relief valves to prevent injury from sudden pressure releases.

- Sound the Alarm: Notify the bridge and summon assistance immediately.

- Post-Fire Ventilation: Never open the scavenge trunk while hot, as this could trigger an explosion.

Real-World Example: Pacific Dawn (2021)

The Pacific Dawn experienced a scavenge fire during a transoceanic voyage. The crew swiftly shut off fuel, activated the CO2 suppression system, and engaged the turning gear, preventing engine seizure. The ship resumed operations within 48 hours after thorough inspections, demonstrating the effectiveness of rapid response.

Post-Fire Inspection and Maintenance

After extinguishing a scavenge fire, a thorough inspection is critical to assess damage and prevent recurrence. Key steps include:

- Check Piston Alignment: Turn the engine manually to detect binding, which indicates misalignment.

- Inspect Piston Rings and Liners: Look for distortion, reddish burn marks, or excessive wear.

- Examine Scavenge Space: Clean the trunk and ports to remove carbon and oil residues.

- Check Relief Valves and Springs: Ensure springs near the fire site are not weakened by heat.

- Inspect Diaphragm and Frame: Look for structural damage near the affected area.

- Verify Tie Bolt Tension: Confirm bolts are secure to maintain engine integrity.

- Clean Scavenge Drains: Remove any oil or sludge to prevent future fires.

- Recharge Fire Extinguishers: Refill CO2 or dry powder systems and test injection spreaders.

The following table summarizes key inspection points:

| Component | Inspection Focus | Potential Issues |

|---|---|---|

| Piston Rings | Wear, distortion, burn marks | Blow-by, reduced sealing |

| Cylinder Liner | Wear, scoring, burn marks | Increased oil/fuel ingress |

| Scavenge Trunk | Carbon/oil buildup, structural damage | Fire fuel accumulation |

| Relief Valves | Spring integrity, functionality | Failure to release pressure |

| Tie Bolts | Tension, alignment | Engine instability |

| Fire Suppression System | Gas levels, spreader condition | Ineffective fire suppression |

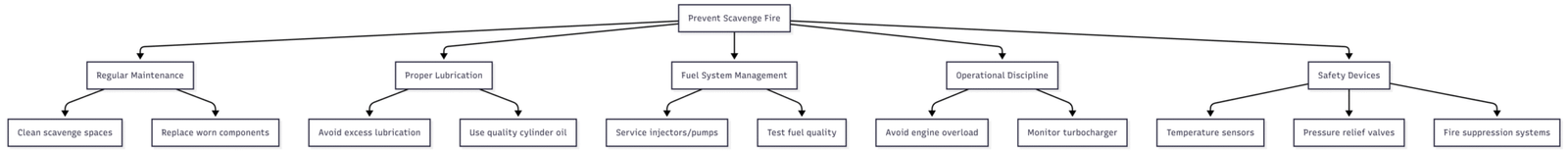

Prevention of Scavenge Fires

Preventing scavenge fires requires a combination of proactive maintenance, vigilant monitoring, and adherence to operational best practices. Key prevention strategies include:

1. Regular Maintenance:

- Clean scavenge spaces and drains at scheduled intervals to remove oil and carbon deposits.

- Inspect and replace worn piston rings and cylinder liners as per the Planned Maintenance System (PMS).

- Maintain stuffing box scraper rings to prevent oil ingress.

2. Proper Lubrication:

- Avoid excessive cylinder lubrication, which can drain into the scavenge space.

- Use high-quality cylinder oil suited to the engine’s specifications.

- Check timed lubrication systems to ensure accurate delivery.

3. Fuel System Management:

- Regularly service fuel injectors and pumps to ensure proper atomization and timing.

- Use high-quality fuel and test for off-spec batches to prevent injector damage.

4. Operational Discipline:

- Avoid overloading the engine, which increases blow-by and heat generation.

- Monitor turbocharger performance to prevent surging or exhaust back pressure.

5. Safety Devices:

- Install and maintain electrical temperature sensors to detect overheating (alarm threshold: ~200°C).

- Periodically test pressure relief valves to ensure they function correctly.

- Maintain fixed fire suppression systems (CO2, dry powder, or steam) and check gas container levels.

The following chart illustrates the prevention workflow:

Safety Devices and Specifications

Modern two-stroke marine diesel engines are equipped with safety devices to detect and mitigate scavenge fires. Below are key systems and their specifications:

| Device | Function | Specifications |

|---|---|---|

| Temperature Sensors | Detect overheating in scavenge space | Alarm threshold: 200°C, electrical |

| Pressure Relief Valves | Release excess pressure to prevent explosion | Self-closing, spring-loaded |

| Fixed Fire Suppression System | Extinguish fires with CO2, dry powder, or steam | CO2: 50-100 bar, Dry Powder: 10-20 kg |

| Smoke Detectors | Alert crew to combustion byproducts | Sensitivity: 0.5-2% obscuration |

Maintenance of Safety Devices

- Temperature Sensors: Test daily to ensure accurate readings.

- Relief Valves: Inspect and test monthly to confirm spring tension and sealing.

- Fire Suppression Systems: Check CO2 or dry powder levels quarterly, rotate dry powder containers to prevent clumping, and clean injection spreaders.

Challenges and Solutions

Challenge: Balancing Operational Demands and Safety

High-pressure shipping schedules often lead to delayed maintenance, increasing fire risks. The Coral Voyager incident (2022) is a stark reminder of this issue.

Solutions:

- Predictive Maintenance: Use IoT sensors to monitor piston ring wear and scavenge space deposits in real-time.

- Automated Systems: Install CO2 suppression systems linked to temperature sensors for rapid response.

- Crew Training: Conduct regular drills to ensure familiarity with fire response protocols.

Challenge: Limited Spares Onboard

Frequent port calls and supply chain issues can delay the replacement of worn components.

Solutions:

- Maintain a robust inventory of critical spares (e.g., piston rings, injector nozzles).

- Partner with reliable suppliers for quick delivery during port calls.

Costs and Economic Impact

Scavenge fires can result in significant financial losses due to repairs, downtime, and potential environmental penalties. Below is an estimated cost breakdown for a typical incident:

| Expense | Estimated Cost (USD) |

|---|---|

| Engine Repair (Parts) | $50,000 – $200,000 |

| Labor (Overhaul) | $20,000 – $50,000 |

| Downtime (Per Day) | $10,000 – $50,000 |

| Fire Suppression Refill | $5,000 – $15,000 |

| Environmental Fines | $10,000 – $100,000 |

Preventive maintenance is far more cost-effective, with routine cleaning and inspections costing $5,000-$20,000 annually, depending on the vessel size.

Conclusion

Scavenge fires in two-stroke marine diesel engines are a serious threat to ship safety, operational efficiency, and financial stability. By understanding the causes—such as piston wear, fuel system issues, and improper lubrication—marine engineers can implement proactive measures to prevent these incidents. Early detection through temperature sensors, smoke detectors, and vigilant monitoring is critical, while swift response strategies, including fuel cutoff and CO2 suppression, can mitigate damage. Regular maintenance, adherence to operational limits, and investment in modern safety technologies are essential to keeping scavenge fires at bay.

For ship operators, the key takeaways are clear:

- Prioritize regular scavenge space cleaning and component inspections.

- Invest in advanced detection and suppression systems.

- Train crews to recognize early signs and respond decisively.

By adopting these practices, the maritime industry can reduce the risk of scavenge fires, ensuring safer voyages and protecting valuable assets.

Happy Boating!

Share Scavenge Fire of Two Stroke Marine Diesel Engine on Ships with your friends and leave a comment below with your thoughts.

Read Sensors and IoT in the Maritime Industry until we meet in the next article.