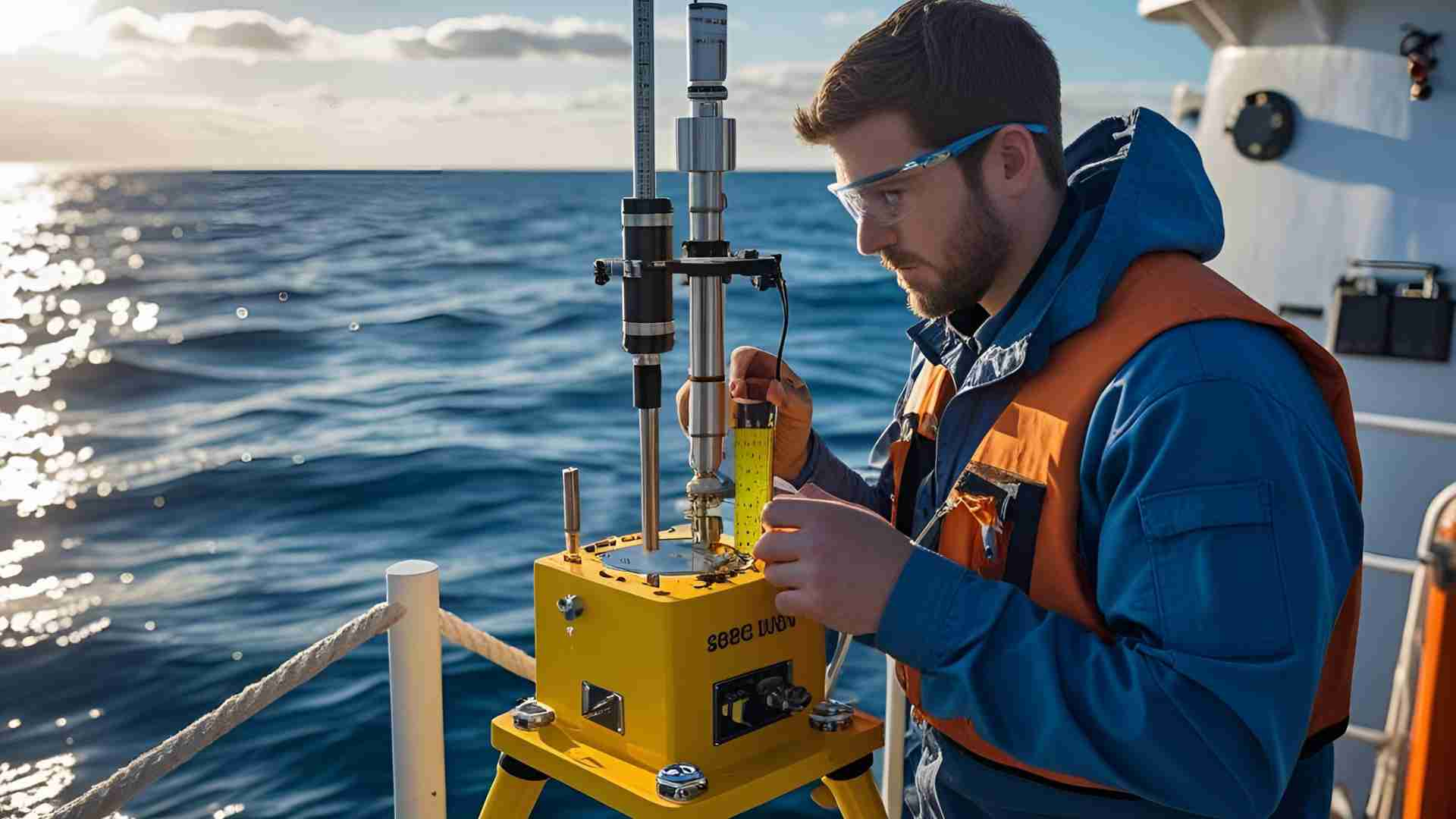

Right equipment for measurement in marine applications

Discover the best marine measurement equipment for accurate pressure, level, and weather monitoring in maritime applications, ensuring safety and efficiency.

Marine operations, from commercial shipping to scientific research, rely on precise measurements to ensure safety, efficiency, and compliance with stringent regulations. The harsh marine environment—marked by corrosive saltwater, extreme temperatures, and constant motion—demands robust, reliable, and accurate instrumentation. This article explores essential marine measurement equipment, focusing on pressure gauges, level transmitters, and weather instruments, and provides insights into their applications, specifications, and best practices for optimal performance.

Importance of Accurate Marine Measurements

Accurate measurements are the backbone of safe and efficient maritime operations. Whether navigating treacherous waters, monitoring engine performance, or conducting oceanographic research, precise data drives informed decision-making. Inaccurate readings can lead to catastrophic consequences, such as vessel instability, equipment failure, or environmental hazards. Marine instruments must withstand unique challenges like corrosion, vibration, and extreme weather while delivering consistent, reliable data.

Key Applications of Marine Instruments

Marine instruments serve a wide range of functions across various maritime sectors:

- Navigation: GPS, compasses, and depth sounders provide critical data for safe route planning and hazard avoidance.

- Engine and System Monitoring: Pressure gauges and level transmitters ensure optimal performance of engines, fuel systems, and ballast tanks.

- Oceanographic Research: Instruments like conductivity-temperature-depth (CTD) profilers and acoustic Doppler current profilers (ADCPs) support studies of ocean currents, salinity, and marine ecosystems.

- Weather Monitoring: Wind, temperature, and humidity sensors enhance safety and efficiency in shipping, fishing, and recreational boating.

- Safety and Compliance: Accurate measurements ensure adherence to regulations set by bodies like DNV and IMO, minimizing risks to crew and cargo.

Essential Marine Measurement Equipment

Below, we detail key instruments designed for marine applications, focusing on their specifications, applications, and approximate price ranges (where applicable).

Pressure Measurement Instruments

Pressure measurement is critical for monitoring fluids, gases, and oils in marine systems, such as fuel tanks, hydraulic systems, and ballast tanks. The following devices are widely used in marine environments:

Additel ADT680 Digital Pressure Gauge

The Additel ADT680 is a high-precision digital pressure gauge designed for demanding marine applications. Its advanced features make it suitable for both routine and specialized tasks.

| Specification | Details |

|---|---|

| Pressure Range | -1 to 4200 bar(g) |

| Accuracy | Up to ±0.05% FS (full scale) |

| Display | Large, backlit LCD for readability in low-light conditions |

| Features | Data logging and wireless communication (ADT680W model) |

| Certifications | IP67-rated for dust and water resistance |

| Applications | Calibration of pressure systems, monitoring fuel and hydraulic systems |

| Price | Approximately $1,000–$2,500 (depending on model and configuration) |

Advantages:

- Robust design for harsh marine environments

- Wireless data transfer simplifies remote monitoring

- Wide pressure range suits diverse applications

Additel ADT681 Digital Pressure Gauge

The ADT681 series is tailored for environments requiring high accuracy and intrinsic safety, such as fuel tank monitoring on vessels.

| Specification | Details |

|---|---|

| Pressure Range | ±2.5 mbar to 4200 bar |

| Accuracy | Up to ±0.025% FS |

| Features | Intrinsically safe (ADT681IS model), IP67-rated |

| Applications | Calibration in hazardous areas, monitoring in dusty or wet conditions |

| Price | Approximately $1,200–$3,000 |

Advantages:

- Intrinsically safe option for explosive environments

- High accuracy for precise measurements

- Durable construction for long-term reliability

XMP i Pressure Transmitter

The XMP i from BD Sensors is an analog pressure transmitter designed for the process industry, including marine applications.

| Specification | Details |

|---|---|

| Pressure Range | Vacuum to 600 bar |

| Accuracy | ±0.1% Full Scale (FS) |

| Material | Stainless steel sensor |

| Applications | Monitoring vacuum, gauge, and absolute pressure in marine systems |

| Price | Approximately $500–$1,500 |

Advantages:

- Corrosion-resistant stainless steel construction

- Suitable for high-pressure environments

- Reliable performance in process monitoring

XMP ci Pressure Transmitter

The XMP ci features a capacitive ceramic sensor, offering high overpressure capability and media stability.

| Specification | Details |

|---|---|

| Pressure Range | Up to 600 bar |

| Accuracy | ±0.1% FS |

| Features | Capacitive ceramic sensor for enhanced durability |

| Applications | Measuring aggressive media in marine processes |

| Price | Approximately $600–$1,800 |

Advantages:

- Exceptional media stability

- High overpressure tolerance

- Ideal for challenging marine environments

x|act i and x|act ci Pressure Transmitters

These BD Sensors transmitters are designed for precision in maritime, food, and biotechnology industries.

| Specification | x|act i | x|act ci |

|---|---|---|

| Pressure Range | Configurable based on application | Configurable |

| Accuracy | ±0.1% FS | ±0.1% FS |

| Features | — | Pure ceramic sensor for high overpressure capability |

| Applications | Maritime, food, and pharmaceutical pressure monitoring | Aggressive media and high-precision tasks |

| Price | Approximately $700–$2,000 | Approximately $800–$2,200 |

Advantages:

- Tailored for maritime and sanitary applications

- High durability and precision

DMP 331Pi Precision Pressure Transmitter

The DMP 331Pi is an advanced version of the DMP 331P, featuring a piezoresistive stainless steel sensor and digital electronics.

| Specification | Details |

|---|---|

| Pressure Range | Configurable up to 600 bar |

| Accuracy | ±0.05% Full Scale (FS) |

| Applications | Precision pressure monitoring in marine systems |

| Price | Approximately $600–$1,800 |

Advantages:

- High-precision digital signal processing

- Robust design for marine conditions

Badotherm DFS Diaphragm Attachment

This accessory enhances pressure transmitters by isolating them from aggressive or sanitary media.

| Specification | Details |

|---|---|

| Compatibility | Works with pressure and differential pressure transmitters |

| Material | Corrosion-resistant alloys |

| Applications | Protecting transmitters in aggressive or sanitary environments |

| Price | Approximately $200–$800 |

Advantages:

- Extends transmitter lifespan in harsh conditions

- Ensures accurate measurements with aggressive media

Level Measurement Instruments

Level transmitters are essential for monitoring fluid levels in fuel, oil, ballast, and water tanks, ensuring vessel stability and operational efficiency.

Masoneilan 12400 Series Level Transmitter

The Masoneilan 12400 integrates level measurement and switch functions, offering reliability and ease of use.

| Specification | Details |

|---|---|

| Measurement Type | Continuous level measurement |

| Features | Combines transmitter and switch functions |

| Applications | Ballast, fuel, and water tank monitoring |

| Price | Approximately $1,500–$3,500 |

Advantages:

- Easy installation and operation

- Cost-effective with integrated functionality

- Reliable for critical marine applications

Weather Measurement Instruments

Accurate weather data is vital for safe navigation and operational planning in marine environments. Key variables include wind speed, direction, temperature, pressure, and humidity.

Depth Sensors

Depth sensors use ultrasonic pulses to measure water depth, preventing groundings and aiding navigation.

| Specification | Details |

|---|---|

| Range | Up to 100 meters |

| Accuracy | ±0.5% of measured depth |

| Applications | Navigation, grounding prevention |

| Price | Approximately $300–$1,000 |

Advantages:

- High accuracy in varying conditions

- Essential for safe navigation

Wind Sensors

Wind sensors measure true and apparent wind speed and direction, critical for route optimization and safety.

Here is the information presented in a table format:

| Specification | Details |

|---|---|

| Range | 0–60 m/s (wind speed) |

| Accuracy | ±2% for speed, ±3° for direction |

| Applications | Navigation, route planning |

| Price | Approximately $500–$2,000 |

Advantages:

- Enhances route efficiency

- Improves safety in adverse conditions

Temperature and Humidity Sensors

These sensors monitor environmental conditions to protect equipment and ensure crew safety.

| Specification | Details |

|---|---|

| Temperature Range | -40°C to +80°C |

| Humidity Range | 0–100% RH |

| Accuracy | ±0.5°C (temperature), ±2% RH (humidity) |

| Applications | Equipment protection, crew safety |

| Price | Approximately $200–$800 |

Advantages:

- Prevents corrosion and equipment damage

- Ensures optimal operating conditions

Mechanical Gauges and Tools

Mechanical gauges are critical for measuring physical parameters like clearance, diameter, and wear in marine machinery.

| Tool | Purpose | Accuracy | Price Range |

|---|---|---|---|

| Vernier Caliper | Measures internal/external dimensions | ±0.01 mm | $50–$300 |

| Micrometer | High-precision diameter measurement | ±0.001 mm | $100–$500 |

| Feeler Gauge | Measures clearance between surfaces | ±0.01 mm | $20–$100 |

| Telescopic Feeler Gauge | Measures clearance in hard-to-reach areas | ±0.01 mm | $30–$150 |

| Poker Gauge | Measures propeller stern shaft clearance | ±0.1 mm | $100–$400 |

| Bridge Gauge | Measures main engine bearing wear | ±0.01 mm | $150–$500 |

| Liner Measurement Tool | Measures engine liner wear | ±0.01 mm | $200–$600 |

| Bore Gauge | Measures hole diameters | ±0.00025 cm | $100–$400 |

| Depth Gauge | Measures slot/hole depth | ±0.001 cm | $50–$200 |

Best Practices for Marine Instrumentation

To ensure accuracy and longevity, marine instruments require proper calibration, maintenance, and installation. Here are five key practices:

- Regular Calibration: Calibrate instruments against certified standards (e.g., thermometers, barometers) to maintain accuracy. Follow manufacturer guidelines and industry standards like DNV.

- Corrosion Protection: Use corrosion-resistant housings and clean instruments regularly to prevent salt buildup. Apply lubricants to moving parts.

- Strategic Placement: Position sensors away from heat sources, turbulence, or direct sunlight to ensure accurate readings.

- Software Updates: Keep digital instruments’ firmware and software updated to correct errors and improve performance.

- Preventive Maintenance: Inspect instruments for wear or damage and schedule professional check-ups to ensure optimal functionality.

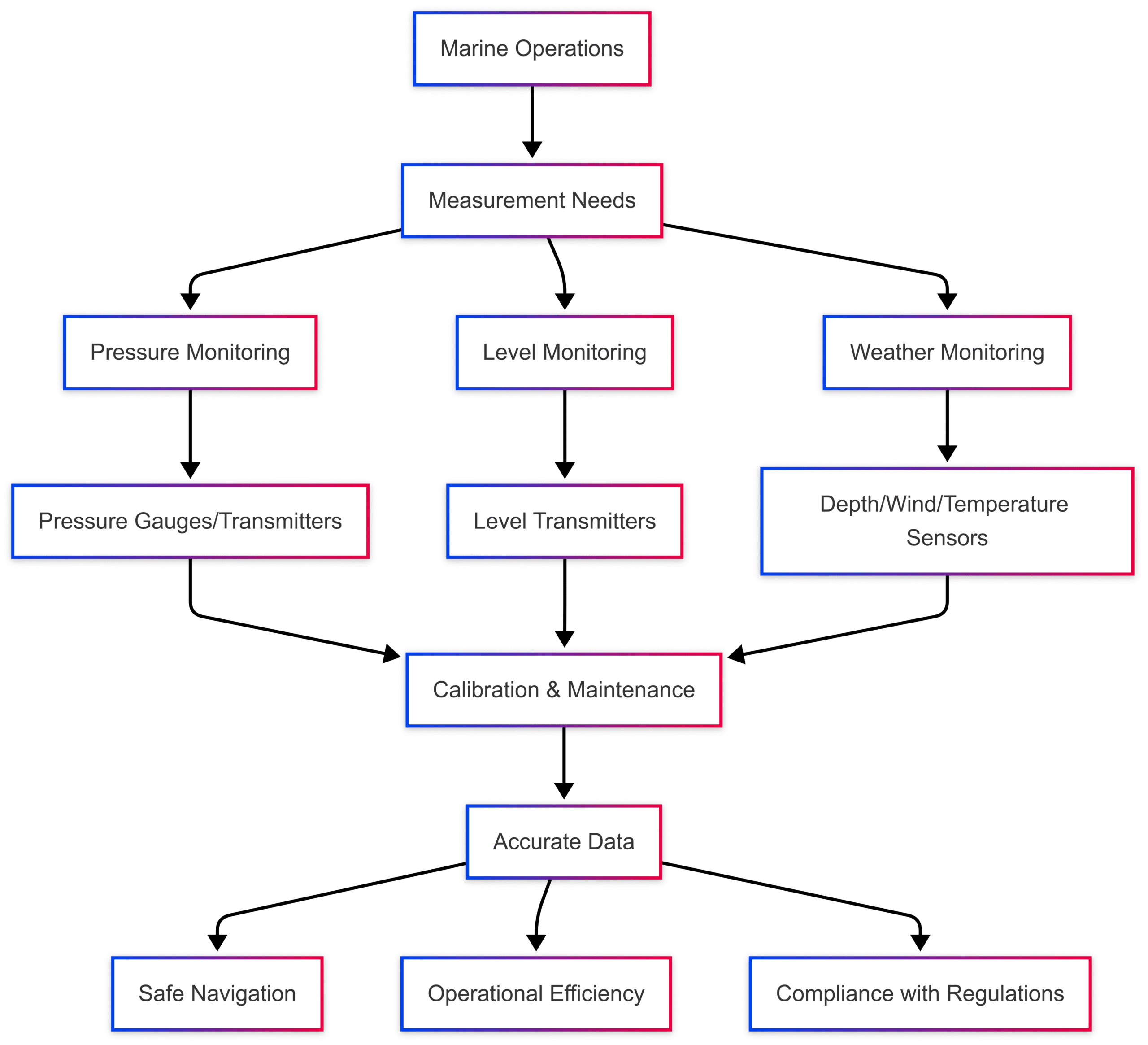

Chart: Marine Instrumentation Workflow

This chart illustrates the workflow from identifying measurement needs to achieving safe and efficient marine operations through proper instrumentation and maintenance.

Case Studies: Real-World Applications

Case Study 1: Transoceanic Voyage

A commercial shipping company used advanced GPS, radar, and the Additel ADT680 pressure gauge to monitor fuel systems during a transoceanic voyage. The ADT680’s wireless data logging allowed real-time monitoring, enabling the crew to optimize fuel consumption and avoid pressure-related hazards. The result was a 10% reduction in fuel costs and a safe, on-schedule arrival.

Case Study 2: Marine Research Breakthrough

Oceanographers studying thermohaline circulation deployed CTD profilers and XMP ci pressure transmitters to collect precise data on salinity and pressure at various depths. The XMP ci’s ceramic sensor ensured stability in corrosive seawater, leading to accurate data that improved climate models and marine ecosystem understanding.

Future Trends in Marine Instrumentation

The marine instrumentation field is evolving rapidly, driven by technological advancements:

- Advanced Sensors: Next-generation sensors with improved accuracy and connectivity are enhancing real-time data collection.

- AI and Machine Learning: AI algorithms analyze vast datasets from instruments, enabling predictive maintenance and data-driven navigation.

- Autonomous Systems: Autonomous underwater vehicles (AUVs) equipped with advanced sensors are expanding the scope of oceanographic research.

Conclusion

Selecting the right equipment for marine measurement is critical for ensuring safety, efficiency, and compliance in maritime operations. From pressure gauges like the Additel ADT680 and XMP ci to level transmitters like the Masoneilan 12400 and weather sensors for depth and wind, these instruments provide the precision needed to navigate challenging marine environments. By adhering to best practices for calibration, maintenance, and installation, marine professionals can maximize instrument performance and safeguard their operations. As technology advances, the integration of AI, advanced sensors, and autonomous systems will further enhance the capabilities of marine instrumentation, paving the way for safer and more sustainable maritime activities.

Happy Boating!

Share Right equipment for measurement in marine applications with your friends and leave a comment below with your thoughts.

Read The Ultimate Guide to Bilge Pump Float Switches until we meet in the next article.