Procedures for Starting and Stopping Generators on a Ship

Learn the step-by-step procedures for safely starting and stopping marine diesel generators on ships, ensuring reliability and preventing blackouts.

Marine diesel generators are the backbone of a ship’s electrical power system, providing the critical energy needed to support navigation, communication, and onboard operations. Operating these generators is a precise task that demands strict adherence to safety protocols and manufacturer-specific procedures to ensure reliability and prevent catastrophic failures like blackouts. This comprehensive guide outlines the detailed steps for starting, operating, and stopping marine diesel generators, alongside their working principles, specifications, and maintenance considerations. Whether you’re a marine engineer or a ship operator, understanding these procedures is essential for efficient and safe vessel operations.

Importance of Marine Diesel Generators

Marine diesel generators are often referred to as the “heart of the ship” due to their role in powering essential systems, from propulsion controls to lighting and refrigeration. Unlike land-based generators, marine generators operate in a dynamic environment, subject to vibrations, saltwater corrosion, and varying load demands. A single misstep in their operation can lead to a blackout—a complete loss of electrical power that can jeopardize the safety of the vessel, especially in restricted waters or during maneuvering. Proper starting and stopping procedures, combined with regular maintenance, are critical to ensuring continuous and reliable power supply.

Working Principle of Marine Diesel Generators

Marine diesel generators convert diesel fuel’s chemical energy into electrical power through a four-stroke internal combustion process. Below is a simplified explanation of their operation:

- Fuel Injection: Diesel fuel is injected into the combustion chamber via a high-pressure fuel injection system, ensuring precise delivery for optimal combustion.

- Compression Stroke: The piston compresses air in the cylinder, raising its temperature and pressure to ignite the fuel spontaneously.

- Ignition: The injected fuel ignites due to the high temperature, causing rapid gas expansion that drives the piston downward.

- Power Stroke: The piston’s movement rotates the crankshaft, converting linear motion into rotational energy.

- Crankshaft Rotation: The crankshaft drives the alternator, inducing an electromagnetic field to generate electricity.

- Electrical Output: The alternator produces stable electrical power, regulated by an automatic voltage regulator (AVR), for use across the ship’s systems.

This cycle repeats continuously, with the generator’s efficiency depending on precise fuel injection timing, compression ratios, and cooling systems. Modern marine generators often incorporate electronic control units (ECUs) to optimize performance and reduce emissions.

Key Components of Marine Diesel Generators

Marine diesel generators are complex systems comprising several critical components, each designed to withstand the harsh marine environment. Below is a table summarizing the main components and their functions:

| Component | Function |

|---|---|

| Diesel Engine | Converts diesel fuel into mechanical energy via combustion. |

| Alternator | Converts mechanical energy into electrical power. |

| Fuel System | Stores and delivers diesel fuel to the engine (includes tank, pump, injectors). |

| Cooling System | Maintains optimal engine temperature using water or air cooling. |

| Exhaust System | Expels combustion gases and reduces noise via silencers. |

| Control System | Monitors and regulates generator performance (includes AVR, ECM, governor). |

| Base Frame | Provides structural support and vibration isolation. |

| Vibration Isolators | Reduces transmission of engine vibrations to the ship’s structure. |

Starting Procedures for Marine Diesel Generators

Starting a marine diesel generator requires meticulous preparation and execution to ensure safe and efficient operation. The process varies slightly between automatic and manual starts, but both follow a structured sequence to prevent damage and ensure synchronization with the ship’s power grid.

Preparation for Starting

Before initiating the start sequence, thorough checks are necessary to ensure the generator and its surroundings are ready:

- Safety Checks:

- Inspect the engine compartment for debris, leaks, or hazards.

- Ensure all personnel are clear of moving parts.

- Verify that fuel, cooling water, and ventilation valves are open.

- Lubrication:

- Confirm the standby lubricating oil pump is operational (automatic or manual).

- Check oil levels and pressure to ensure adequate lubrication.

- Fuel Supply:

- Open the diesel oil supply valve to the engine.

- Verify fuel quality and tank levels to prevent interruptions.

- Cooling Water:

- Ensure header tanks are full and cooling water is circulating properly.

- Check for leaks in the cooling system.

- Air Supply:

- For compressed-air starting systems, confirm air tanks are charged to the required pressure (typically 20–30 bar).

Automatic Start Procedure

Automatic starts are common in modern ships equipped with a Power Management System (PMS). This method is efficient but relies on sufficient starting air and system automation.

- Initiate Start:

- Access the PMS via the engine control room (ECR) computer.

- Navigate to the generator page and click the “Start” button.

- The PMS automatically checks interlocks and valve positions.

- Synchronization:

- The system matches the incoming generator’s voltage, frequency, and phase angle with the main bus.

- Once synchronized, the generator is connected to the load automatically.

- Monitoring:

- Observe parameters like oil pressure, coolant temperature, and voltage via the PMS display.

- Ensure the generator shares the load equally with other running units.

Automatic starts are typically used during normal operations or maneuvering in restricted areas, but manual intervention may be required in blackout or dead-ship conditions.

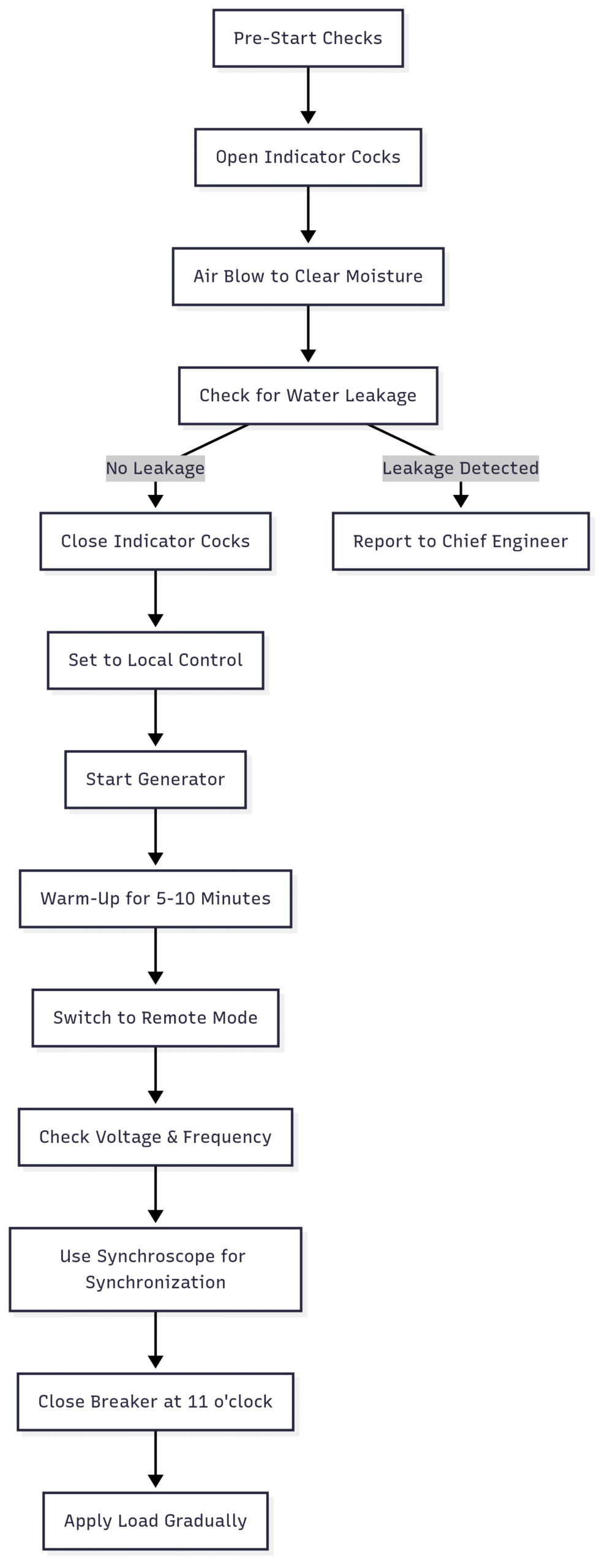

Manual Start Procedure

Manual starts are common in older vessels or during emergency situations. This method requires hands-on operation and careful monitoring.

- Pre-Start Checks:

- Open indicator cocks to check for water accumulation in cylinders.

- Perform an air blow (if applicable) by giving a small air kick to clear moisture, then return the starting lever to zero.

- Report any water leakage to the chief engineer for further inspection.

- Local Control:

- Set the generator control to the “Local” position.

- Close indicator cocks after confirming no leaks.

- Start the generator by turning the key switch or pressing the start button.

- Warm-Up:

- Allow the generator to run at no load for 5–10 minutes to stabilize temperatures and pressures.

- Monitor oil pressure (typically 4–6 bar) and coolant temperature (around 70–85°C).

- Switch to Remote:

- Transfer control to “Remote” mode for integration with the PMS or ECR panel.

- If automation is unavailable, manually check voltage (e.g., 440V) and frequency (e.g., 60Hz) on the generator panel.

- Synchronization:

- Use the synchroscope to match the incoming generator’s frequency with the main bus.

- Adjust the governor to align frequency (clockwise needle movement indicates fast; counterclockwise indicates slow).

- Close the breaker when the synchroscope needle is at the 11 o’clock position, moving slowly clockwise, to avoid reverse power trips.

- Loading:

- Gradually apply load to prevent sudden stress on the engine.

- Ensure load sharing is balanced among running generators.

Chart: Manual Start Process

Safety Considerations During Starting

- Avoid False Alarms: In engine rooms with water mist fire suppression systems, avoid manual air blows with open indicator cocks, as smoke may trigger false fire alarms.

- Supervision: First-time operators should perform synchronization under the guidance of an experienced officer to prevent blackouts.

- Interlocks: Ensure no interlocks (e.g., low oil pressure, high temperature) are active before starting.

Operating Marine Diesel Generators

Once started, the generator must be monitored to maintain stable performance and prevent failures.

- Continuous Monitoring:

- Check oil pressure, coolant temperature, and exhaust gas temperature regularly.

- Monitor voltage (e.g., 440V ±5%) and frequency (e.g., 60Hz ±1%) to ensure stability.

- Use the control panel or PMS for real-time data.

- Maintenance During Operation:

- Ensure adequate fuel supply and monitor tank levels.

- Verify cooling water circulation and ventilation blower operation.

- Check for unusual noises, vibrations, or leaks.

- Load Management:

- Avoid sudden load changes to prevent engine stress.

- Ensure load sharing is balanced in parallel operations.

Stopping Procedures for Marine Diesel Generators

Proper shutdown procedures are critical to prevent thermal stress, component wear, or incomplete shutdowns that could lead to operational issues.

Automatic Stop Procedure

The PMS simplifies the shutdown process but includes safety interlocks to prevent blackouts.

- Initiate Stop:

- Access the PMS and select the generator to stop.

- Press the “Stop” button; the system will only proceed if other generators are running to maintain power supply.

- Load Reduction:

- The PMS gradually reduces the generator’s load to zero.

- The breaker opens automatically once the load is minimal.

- Cool Down:

- The generator runs at no load for 5–10 minutes to dissipate heat.

- The PMS stops the engine after the cool-down period.

- Secure Systems:

- Close fuel, cooling water, and ventilation valves.

- Isolate the generator from the main bus.

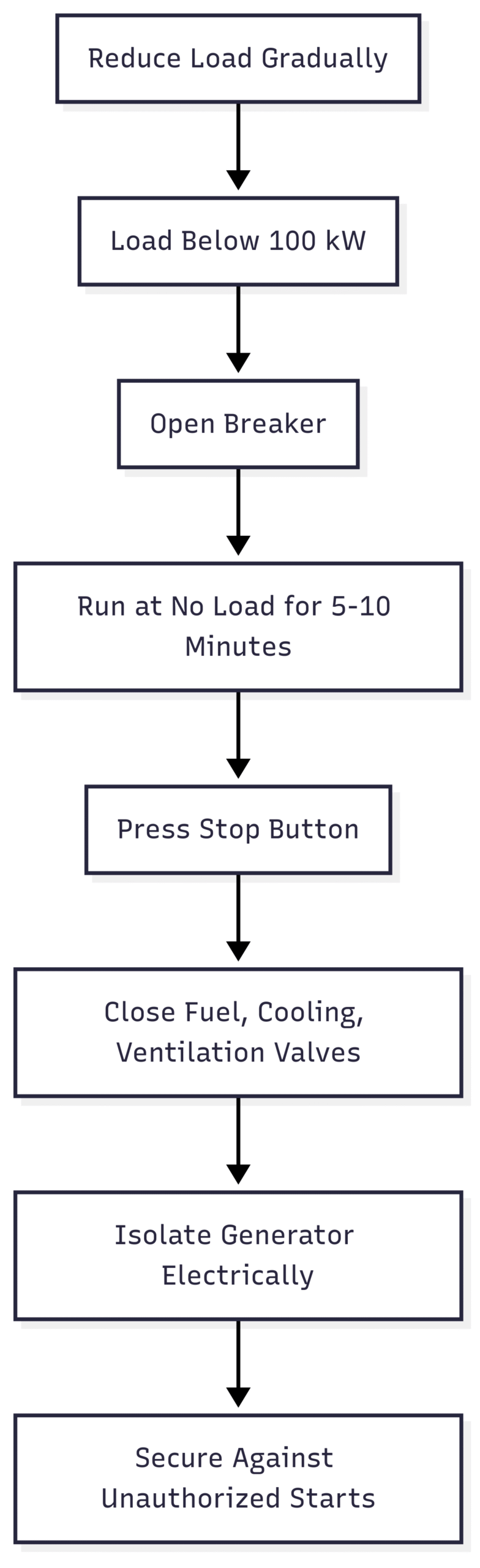

Manual Stop Procedure

Manual shutdowns are performed when automation is unavailable or during maintenance.

- Load Reduction:

- Reduce the load gradually using the governor control on the ECR panel.

- Continue until the load is below 100 kW (or as specified by the manufacturer).

- Open Breaker:

- Press the breaker to take the generator off-load.

- Verify the generator is no longer supplying power.

- Cool Down:

- Run the generator at no load for 5–10 minutes to cool internal components.

- Monitor temperatures to ensure they drop to safe levels (e.g., below 60°C for coolant).

- Stop Engine:

- Press the stop button or turn the key switch to stop the engine.

- Confirm the engine has stopped completely.

- Secure Generator:

- Close all necessary valves (fuel, cooling water, ventilation).

- Isolate the generator electrically and secure it against unauthorized starts.

Chart: Manual Stop Process

Specifications and Pricing of Marine Diesel Generators

Marine diesel generators come in various sizes and configurations, tailored to the ship’s power requirements. Below is a table summarizing common specifications and indicative pricing for popular models from EMS Power Machines, a leading manufacturer:

| Model | Power Output (kVA) | Engine Brand | Cooling System | Fuel Tank Capacity | Price (USD) |

|---|---|---|---|---|---|

| Perkins 75 kVA | 75 | Perkins (UK) | Water-Cooled | 200 L | $15,000–$20,000 |

| Ricardo 100 kVA | 100 | Ricardo (China) | Air-Cooled | 250 L | $12,000–$16,000 |

| Cummins 200 kVA | 200 | Cummins (USA) | Water-Cooled | 400 L | $25,000–$35,000 |

| Volvo 500 kVA | 500 | Volvo (Sweden) | Water-Cooled | 800 L | $50,000–$70,000 |

Note: Prices are approximate and vary based on customization, additional features (e.g., soundproof canopy, parallel operation capability), and market conditions. For precise pricing, contact EMS Power Machines or visit their official website.

Key Features of EMS Power Machines Generators

- Engine Design: 4-stroke, direct-injection diesel engines with electronic or mechanical governors for precise speed control.

- Base Frame: Steel construction with vibration isolators for stability and noise reduction.

- Fuel System: Equipped with filling caps, tank ventilation, and optional automatic filling.

- Exhaust System: Includes silencers and flexible compensators to reduce noise and emissions.

- Control Systems: Manual, automatic, standby, or parallel operation modes, housed in lockable steel panels.

Maintenance Considerations

Regular maintenance is vital for the longevity and reliability of marine diesel generators. Key tasks include:

- Daily Checks: Inspect oil levels, fuel quality, and cooling water circulation.

- Weekly Inspections: Check for leaks, test battery chargers, and verify control system functionality.

- Monthly Maintenance: Replace fuel and air filters, inspect exhaust systems, and lubricate moving parts.

- Annual Overhauls: Conduct thorough inspections of the engine, alternator, and fuel injection system, following the manufacturer’s schedule.

Neglecting maintenance can lead to reduced efficiency, increased fuel consumption, and unexpected failures. Always consult the generator’s operating manual for model-specific maintenance guidelines.

Environmental and Safety Considerations

Operating marine diesel generators involves environmental and safety challenges that must be addressed:

- Emissions Control: Modern generators incorporate diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems to comply with IMO Tier III regulations.

- Noise Reduction: Silencers and vibration isolators minimize noise pollution, critical for crew comfort and regulatory compliance.

- Fire Safety: Avoid manual air blows in engine rooms with water mist systems to prevent false fire alarms.

- Corrosion Resistance: Use corrosion-resistant materials for base frames and fuel tanks to withstand saltwater exposure.

Installation Guidelines

Proper installation ensures optimal generator performance and safety. Key considerations include:

- Site Selection: Choose a clean, dry, well-ventilated location away from harsh environmental conditions.

- Foundation: Construct a level, sturdy foundation to support the generator’s weight and minimize vibrations.

- Electrical Connections: Install an automatic transfer switch (ATS) and ensure proper grounding.

- Fuel and Exhaust Systems: Verify fuel quality and install exhaust piping to vent gases safely.

For detailed installation instructions, refer to the manufacturer’s manual or consult a qualified marine engineer.

Conclusion

Marine diesel generators are indispensable for powering ships, but their operation requires precision, vigilance, and adherence to safety protocols. By following the outlined procedures for starting, operating, and stopping generators, marine engineers can ensure reliable power supply and prevent costly blackouts. Regular maintenance, proper installation, and compliance with environmental regulations further enhance generator performance and longevity. With advanced control systems and robust designs from manufacturers like EMS Power Machines, marine diesel generators continue to serve as the lifeline of modern maritime operations.

For further details on specific models or pricing, visit the EMS Power Machines website or contact their support team. Always prioritize safety and manufacturer guidelines to keep your ship’s heart beating strong.

Happy Boating!

Share Procedures for Starting and Stopping Generators on a Ship with your friends and leave a comment below with your thoughts.

Read Maintenance of the Fuel Oil System in Marine Diesel Engine Generators until we meet in the next article.