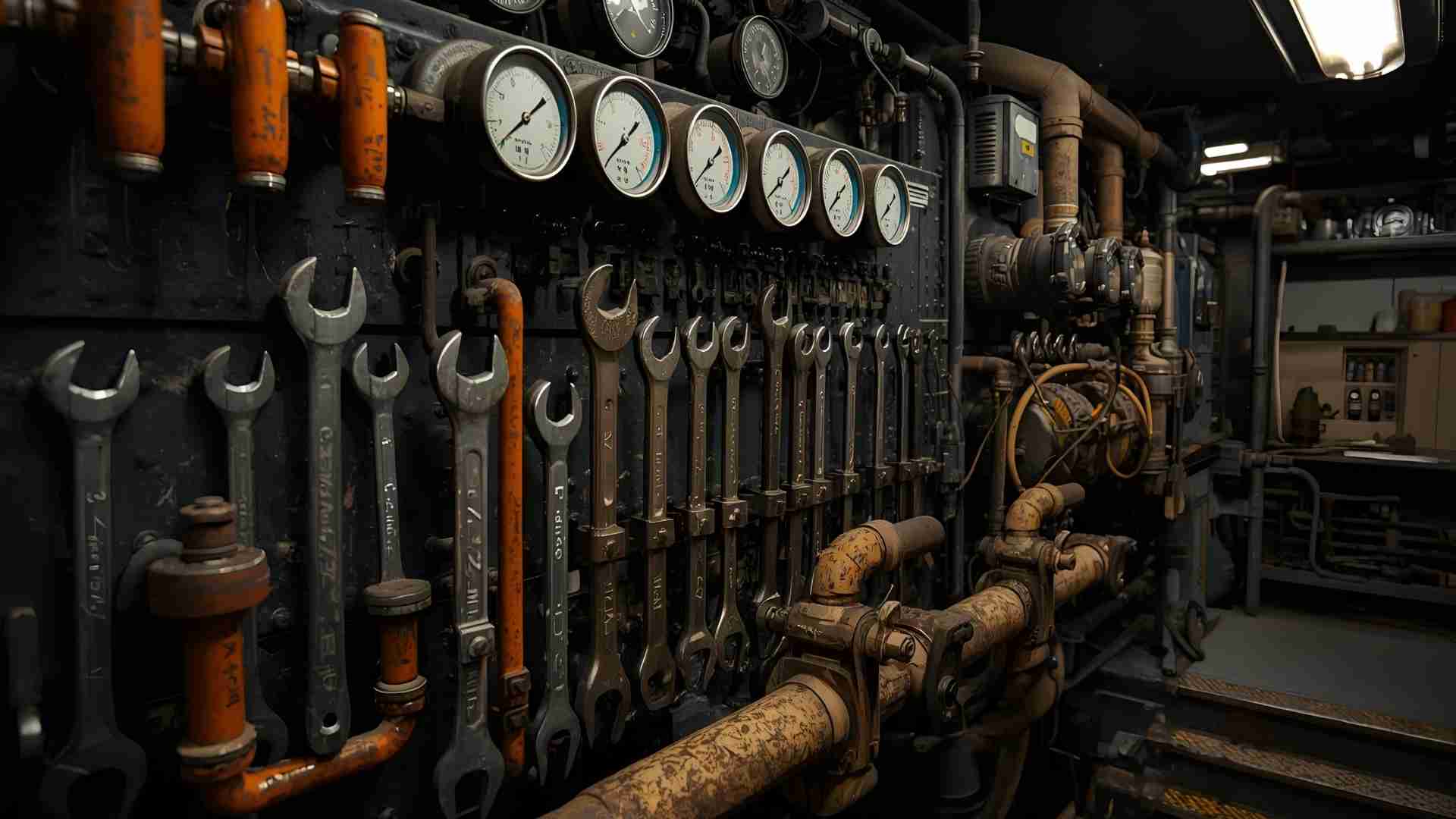

Essential Tools in a Ship’s Engine Room

The engine room is the beating heart of any vessel, housing the machinery that propels ships across vast oceans and powers critical systems like electricity, water, and fuel management. From massive cargo ships to sleek passenger liners, the engine room is a complex environment where propulsion systems, generators, pumps, and auxiliary equipment operate in harmony. Maintaining this intricate ecosystem requires a diverse array of tools, ranging from basic hand implements to advanced diagnostic devices. These tools enable marine engineers and crew to perform routine maintenance, execute repairs, and respond to emergencies, ensuring compliance with international standards like those set by the International Maritime Organization (IMO).

This guide explores the essential tools found in a ship’s engine room, categorized into hand tools, power tools, measurement and diagnostic instruments, lifting and moving equipment, cleaning tools, safety gear, and specialized devices. Each category includes detailed descriptions, specifications, use cases, and approximate prices (in USD, based on standard marine-grade models, though prices vary by supplier and region). The tools are selected for their reliability, durability, and suitability for the harsh marine environment, where corrosion, vibration, and confined spaces pose unique challenges. By understanding and maintaining this toolkit, maritime professionals can ensure safe, efficient, and environmentally compliant operations.

Hand Tools: The Foundation of Engine Room Maintenance

Hand tools are the cornerstone of engine room maintenance, offering precision and control for tasks like tightening, loosening, cutting, or shaping components. Their simplicity and versatility make them indispensable in confined spaces where power tools may be impractical. Marine-grade hand tools are typically made from corrosion-resistant materials like chrome-vanadium steel or stainless steel to withstand the salty, humid environment of a ship.

Wrenches and Spanners

Wrenches are essential for gripping and turning nuts, bolts, and pipes, critical for assembling and disassembling engine components. The engine room relies on several types of wrenches, each designed for specific tasks.

- Adjustable Wrench: Known for its versatility, the adjustable wrench features a movable jaw to accommodate various nut and bolt sizes. Specifications include a jaw opening of 0-2 inches, lengths of 6-18 inches, and construction from chrome-vanadium steel for durability. Use cases include tightening fuel line fittings or adjusting pump housings. These tools are lightweight yet robust, making them ideal for quick adjustments in tight spaces. Approximate price: $20-50.

- Torque Wrench: Precision is critical in engine rooms, where over-tightening can damage components. Torque wrenches apply specific force, measured in Newton-meters (Nm). Specifications include a torque range of 20-200 Nm, 1/2-inch drive, and accuracy of ±3%. They are used for securing cylinder heads, crankshaft bolts, or propeller shaft components to manufacturer specifications. Price: $50-150.

- Pipe Wrench: Designed for cylindrical objects, pipe wrenches feature serrated jaws for a firm grip. Specifications include sizes from 10-48 inches, cast iron or aluminum bodies, and jaw capacities up to 6 inches. They are used for turning large pipes in fuel, cooling, or exhaust systems. Price: $30-100.

- Combination Wrench Set: These have an open end and a box end, offering versatility. Specifications: Sizes 6-32 mm, chrome-plated steel. Use: Tightening or loosening bolts in engine mounts. Price: $40-100 per set.

| Tool Type | Key Specifications | Primary Use | Approx. Price (USD) |

|---|---|---|---|

| Adjustable Wrench | Jaw: 0-2 in, Length: 6-18 in | General nut/bolt adjustments | 20-50 |

| Torque Wrench | Range: 20-200 Nm, Accuracy: ±3% | Precision torquing in engines | 50-150 |

| Pipe Wrench | Jaw: Up to 6 in, Size: 10-48 in | Handling pipes in systems | 30-100 |

| Combination Wrench | Sizes: 6-32 mm, Chrome-plated | Bolt tightening in confined spaces | 40-100 |

Screwdrivers and Pliers

Screwdrivers and pliers are vital for fine adjustments and handling small components.

- Screwdriver Set: Includes flathead, Phillips, and Torx types to cover various screw heads. Specifications: Magnetic tips for easier handling, insulated handles for electrical safety, lengths of 4-12 inches. Use cases include adjusting valve settings, securing electrical panels, or assembling control units. Price: $15-40 per set.

- Pliers: Types include needle-nose (for precision in tight spaces), slip-joint (adjustable for versatility), and cutting pliers (for wires or cables). Specifications: Forged steel, cushioned grips, cutting capacity up to 1/4 inch wire. Use: Bending wires in control systems, gripping small parts, or cutting cables during electrical repairs. Price: $10-30 each.

- Locking Pliers: Also called vise-grips, these lock onto components for a secure hold. Specifications: Jaw capacity up to 2 inches, length 5-10 inches. Use: Holding bolts during removal. Price: $15-35.

Hammers and Chisels

Hammers and chisels are used for shaping, cutting, or driving components.

- Ball-Peen Hammer: Features a flat striking face and a rounded peen for shaping. Specifications: Head weight 6-16 oz, hickory or fiberglass handle. Use: Driving pins or shaping metal sheets during repairs. Price: $15-30.

- Sledgehammer: For heavy-duty tasks. Specifications: Head weight 2-8 lbs, handle length 12-36 inches. Use: Breaking apart rusted components. Price: $20-50.

- Cold Chisel: Hardened steel blade for cutting metal. Specifications: Cutting edge at a 60° angle, length 6-12 inches. Use: Cutting rusted bolts or shaping metal. Price: $5-15.

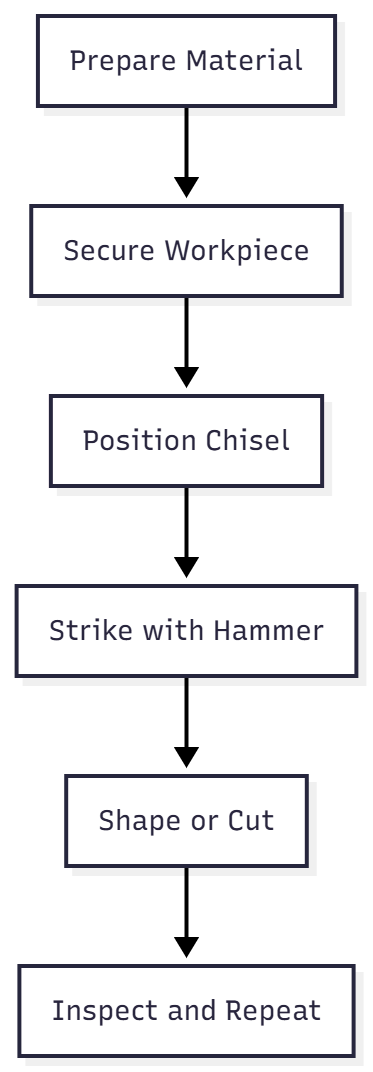

A simple process for using hammers and chisels in metalwork:

This flowchart outlines the steps for shaping metal, such as during emergency repairs to engine components.

Scrapers and Punches

- Bearing Scraper: Features a curved blade for precision. Specifications: High-carbon steel, handle length 8 inches. Use: Removing high spots on bearings for proper fitment. Price: $10-25.

- Center Punch: Marks precise points for drilling. Specifications: 90° tip angle, length 4-6 inches. Use: Marking metal surfaces before drilling. Price: $5-10.

- Gasket Scraper: Flat blade for removing old gaskets. Specifications: Stainless steel, 1-2 inch blade width. Use: Cleaning engine surfaces before reassembly. Price: $10-20.

Hand tools must be stored in organized racks or toolboxes to prevent corrosion and ensure accessibility. Regular maintenance, such as sharpening chisels or cleaning wrenches, extends their lifespan in the marine environment.

Power Tools: Amplifying Efficiency in High-Pressure Tasks

Power tools enhance productivity in the engine room, where time and precision are critical. Powered by electricity, pneumatics, or hydraulics, they handle heavy-duty tasks like drilling, grinding, or cutting, reducing physical strain and speeding up repairs.

Drills and Grinders

- Electric Drill: Corded or battery-powered for flexibility. Specifications: 1/2-inch chuck, variable speed 0-3000 RPM, power 500-1000W. Use: Drilling holes for mounting brackets or tapping threads in metal. Price: $50-150.

- Angle Grinder: Equipped with a rotating disc for cutting or grinding. Specifications: Disc size 4-9 inches, 8000-12000 RPM, power 800-2000W. Use: Removing rust from pipes, cutting metal plates, or smoothing welds. Price: $40-100.

- Bench Grinder: Stationary for sharpening tools. Specifications: Dual wheels (6-8 inches), 3000-3600 RPM. Use: Sharpening chisels or drill bits. Price: $80-200.

| Tool | Specs (Power/Speed) | Use Example | Approx. Price (USD) |

|---|---|---|---|

| Electric Drill | 500-1000W, 0-3000 RPM | Drilling holes in brackets | 50-150 |

| Angle Grinder | 800-2000W, 8000-12000 RPM | Rust removal, metal cutting | 40-100 |

| Bench Grinder | 300-500W, 3000-3600 RPM | Tool sharpening | 80-200 |

Impact Wrenches and Hydraulic Tools

- Impact Wrench: Delivers high torque for stubborn fasteners. Specifications: 1/2-inch or 3/4-inch drive, torque 300-1000 Nm, pneumatic or electric. Use: Loosening or tightening bolts on engine mounts or propeller shafts. Price: $100-300.

- Hydraulic Torque Wrench: For extreme precision. Specifications: Torque 500-3000 Nm, hydraulic pressure up to 10,000 PSI. Use: Securing large flanges in turbines. Price: $500-2000.

- Hydraulic Jack: Lifts heavy loads. Specifications: Capacity 5-50 tons, lift height 6-24 inches. Use: Raising machinery for maintenance access. Price: $50-200.

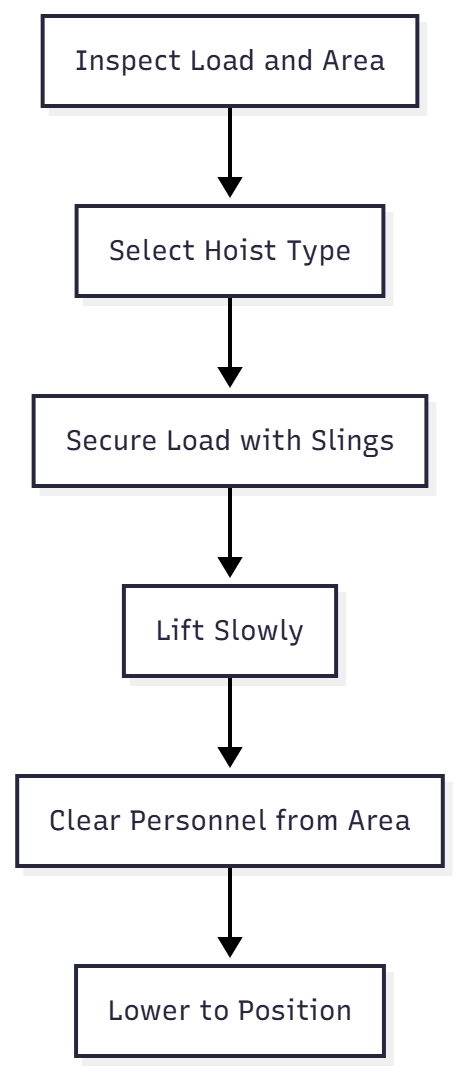

Lifting process flowchart:

This ensures safe handling of heavy components, critical in confined engine rooms.

Power tools require regular maintenance, such as checking cords for wear or replacing grinder discs, to ensure safety. Crew must wear protective gear like gloves, goggles, and ear protection to mitigate risks from sparks, noise, or debris.

Measurement and Diagnostic Tools: Ensuring Precision and Reliability

Precision is paramount in the engine room, where even minor misalignments can lead to catastrophic failures. Measurement and diagnostic tools ensure components meet tight tolerances and detect issues before they escalate.

Calipers, Micrometers, and Gauges

- Vernier Caliper: Measures internal and external dimensions with high accuracy. Specifications: Range 0-6 inches, accuracy 0.001 inch, digital or analog display. Use: Checking piston ring gaps or shaft diameters. Price: $20-50.

- Micrometer: Offers greater precision for small measurements. Specifications: Range 0-1 inch, accuracy 0.0001 inch, ratchet stop for consistent pressure. Use: Measuring bearing thicknesses or valve clearances. Price: $30-80.

- Pressure Gauge: Monitors fluid or gas pressure. Specifications: Range 0-500 PSI, dial size 4 inches, accuracy ±1%. Use: Checking boiler or fuel system pressures. Price: $15-40.

- Dial Indicator: Measures small distances or alignments. Specifications: Range 0-1 inch, resolution 0.0005 inch. Use: Checking shaft alignment. Price: $40-100.

| Tool | Accuracy/Range | Primary Use | Approx. Price (USD) |

|---|---|---|---|

| Vernier Caliper | 0.001 in, 0-6 in | Dimension checks | 20-50 |

| Micrometer | 0.0001 in, 0-1 in | Precise thickness | 30-80 |

| Pressure Gauge | ±1%, 0-500 PSI | System pressure monitoring | 15-40 |

| Dial Indicator | 0.0005 in, 0-1 in | Alignment verification | 40-100 |

Diagnostic Equipment

- Vibration Analyzer: Detects imbalances or wear in rotating machinery. Specifications: Frequency range 0-10kHz, portable with accelerometers, data logging capability. Use: Identifying bearing wear or misalignment in pumps. Price: $500-2000.

- Ultrasonic Thickness Gauge: Measures material thickness non-destructively. Specifications: Range 0.04-12 inches, accuracy ±0.002 inch, digital display. Use: Checking hull or pipe corrosion. Price: $300-800.

- Borescope: Allows visual inspection of inaccessible areas. Specifications: Flexible probe 3-6m, camera resolution 720p, LED lighting. Use: Inspecting internal engine components or fuel injectors. Price: $200-500.

- Thermal Imager: Detects heat leaks or electrical faults. Specifications: Resolution 160×120 pixels, temperature range -20°C to 400°C. Use: Identifying overheating bearings or electrical panels. Price: $400-1000.

Diagnostic tools enable predictive maintenance, reducing downtime by catching issues early. Regular calibration ensures accuracy, especially for calipers and micrometers, which are sensitive to mishandling.

Lifting and Moving Equipment: Managing Heavy Loads

Engine rooms contain heavy components like pistons, generators, and pumps, requiring robust lifting equipment to move them safely.

- Chain Hoist: Manual or motorized for lifting. Specifications: Capacity 1-5 tons, lift height 10-20 feet, steel chain. Use: Lifting pistons or engine blocks. Price: $100-500.

- Hydraulic Jack: As described earlier.

- Overhead Crane: Fixed system for heavy loads. Specifications: Capacity 5-20 tons, span 20-40 feet, electric operation. Use: Moving generators or turbines. Price: $5000-20000 (installed).

- Forklift: For moving pallets or heavy parts. Specifications: Capacity 1-3 tons, lift height 10-15 feet. Use: Transporting spare parts within the engine room. Price: $5000-15000.

Hoisting process flowchart:

This ensures safe and controlled lifting, critical for avoiding injuries or equipment damage.

Cleaning Tools: Maintaining a Pristine Engine Room

A clean engine room prevents contamination and extends equipment life. Cleaning tools are designed to handle oil, grease, and debris in a marine environment.

- Degreasers: Chemical solutions for removing oil and grease. Specifications: Non-flammable, pH neutral, biodegradable for environmental compliance. Use: Cleaning engine parts or bilge areas. Price: $10-30 per gallon.

- Industrial Vacuum: Wet/dry capability for versatility. Specifications: Capacity 5-20 gallons, HEPA filter for fine particles, power 1000-1500W. Use: Removing metal shavings or spilled fluids. Price: $100-300.

- Pressure Washer: High-pressure water for deep cleaning. Specifications: 2000-3000 PSI, flow rate 2-4 GPM. Use: Cleaning engine room floors or machinery exteriors. Price: $200-500.

- Wire Brushes: For manual cleaning. Specifications: Stainless steel bristles, plastic or wooden handles. Use: Removing rust or scale from surfaces. Price: $5-15.

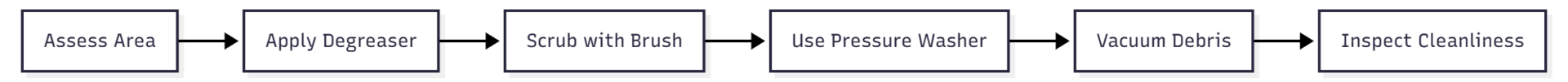

Cleaning process flowchart:

This ensures thorough cleaning, maintaining operational efficiency.

Safety Equipment: Protecting Crew and Vessel

Safety is paramount in the engine room, where hazards like fire, gas leaks, or mechanical failures are ever-present.

- Personal Protective Equipment (PPE): Includes gloves, safety goggles, helmets, and steel-toe boots. Specifications: ANSI-rated, flame-resistant materials. Use: Daily protection during maintenance. Price: $50-100 per kit.

- Gas Detector: Portable device for detecting hazardous gases. Specifications: Detects CO, H2S, O2, accuracy ±5%. Use: Monitoring air quality in confined spaces. Price: $200-500.

- Fire Extinguisher: CO2 or dry powder types for engine room fires. Specifications: 10-20 lb capacity, suitable for Class B and C fires. Use: Extinguishing electrical or fuel fires. Price: $50-100.

- First Aid Kit: Comprehensive for emergencies. Specifications: Includes bandages, antiseptics, burn dressings. Use: Treating cuts, burns, or minor injuries. Price: $30-70.

| Fire Extinguisher Type | Class of Fire | Method | Approx. Price (USD) |

|---|---|---|---|

| Dry Powder | A, B, C | Smothering | 40-80 |

| CO2 | B, C | Smothering/Cooling | 50-100 |

| Foam | A, B | Smothering | 50-100 |

Specialized Tools: For Advanced and Specific Repairs

Specialized tools address unique engine room challenges, often tailored to specific systems like boilers or bearings.

- Tube Expander: Expands tubes in boilers or heat exchangers. Specifications: For 1-3 inch tubes, hydraulic or manual operation. Use: Securing tubes for leak-proof joints. Price: $200-500.

- Bearing Puller: Removes bearings without damage. Specifications: Jaw spread 4-12 inches, hydraulic or mechanical. Use: Extracting bearings from shafts. Price: $50-150.

- Valve Seat Cutter: Restores valve seats. Specifications: Cutting angles 30°-45°, compatible with engine valves. Use: Repairing fuel injector valves. Price: $100-300.

- Lapping Tool: For precision surface finishing. Specifications: Handheld, diamond or silicon carbide abrasives. Use: Polishing valve faces. Price: $20-50.

Tube expanding process:

This ensures secure tube installations, critical for boiler efficiency.

Tool Maintenance and Storage: Ensuring Longevity

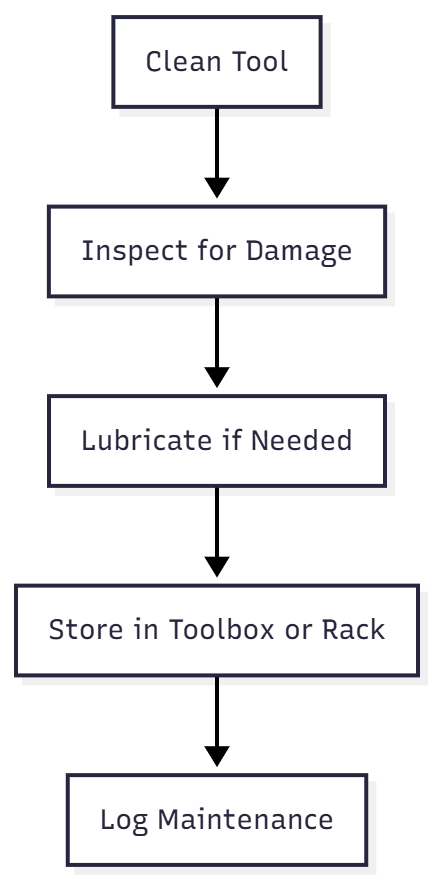

Proper maintenance and storage of tools are critical in the marine environment. Corrosion-resistant coatings, regular cleaning, and lubrication prevent rust and wear. Tools should be stored in waterproof, organized toolboxes or wall-mounted racks to protect against moisture and vibration. A maintenance schedule might include:

- Daily: Wipe tools clean after use, inspect for damage.

- Weekly: Lubricate moving parts, sharpen blades.

- Monthly: Calibrate diagnostic tools, check power tool cords.

A storage flowchart:

Training and Best Practices: Maximizing Tool Effectiveness

Crew training is essential to ensure tools are used correctly and safely. Regular drills on tool operation, safety protocols, and emergency procedures enhance efficiency. Best practices include:

- Tool Familiarity: Train crew on each tool’s function and limitations.

- Safety Protocols: Enforce PPE use and hazard awareness.

- Inventory Management: Maintain a tool log to track usage and condition.

Conclusion: A Toolkit for Maritime Success

The tools in a ship’s engine room are the lifeline of maritime operations, enabling maintenance, repairs, and emergency responses. From hand tools like wrenches and screwdrivers to advanced diagnostic devices like vibration analyzers, each tool plays a critical role in ensuring safety, efficiency, and compliance with IMO standards. By investing in high-quality, marine-grade tools, maintaining them diligently, and training crew effectively, ship operators can minimize downtime, extend equipment life, and navigate the seas with confidence. As maritime technology evolves, so too will the tools, incorporating innovations like IoT-enabled diagnostics or automated lifting systems, ensuring the engine room remains the robust heart of the vessel.

Happy Boating!

Share Essential Tools in a Ship’s Engine Room with your friends and leave a comment below with your thoughts.

Read Emergencies on Ships until we meet in the next article.