Learn how to check marine diesel engine performance with expert tips on PMAX, PMI systems, and key parameters for efficiency and reliability.

Marine diesel engines are the backbone of maritime operations, powering ships for propulsion and electricity generation. Ensuring these engines operate at peak performance is critical for efficiency, cost savings, and environmental compliance. Monitoring performance data allows marine engineers to detect faults early, optimize combustion, and extend engine life. This comprehensive guide explores the tools, techniques, and key parameters for assessing marine diesel engine performance, with a focus on maximum combustion pressure (PMAX), Performance Measurement Indicators (PMI) systems, and other critical metrics.

Why Monitor Marine Diesel Engine Performance?

Marine diesel engines are subjected to harsh operating conditions, including variable loads, saltwater exposure, and prolonged runtime. Regular performance monitoring ensures:

- Fuel Efficiency: Optimized combustion reduces specific fuel oil consumption (SFOC), lowering operating costs.

- Emission Compliance: Efficient engines produce fewer pollutants, aligning with International Maritime Organization (IMO) regulations.

- Reliability: Early detection of issues prevents costly breakdowns and unscheduled maintenance.

- Regulatory Compliance: Standards like the Standards of Training, Certification, and Watchkeeping (STCW) mandate performance monitoring.

Performance degradation, if unchecked, can lead to increased fuel consumption, higher emissions, and catastrophic failures. For example, a bulk carrier saved over USD 50,000 by identifying a clogged injector nozzle through PMAX monitoring, avoiding piston ring failure.

Key Parameters for Performance Monitoring

To assess marine diesel engine health, engineers monitor several critical parameters:

| Parameter | Significance | Potential Issues |

|---|---|---|

| Exhaust Gas Temperature | Indicates combustion quality and turbocharger performance | High temperatures suggest poor combustion or injector issues |

| Lube Oil Pressure | Ensures proper lubrication to reduce friction | Low pressure increases wear and risk of engine damage |

| Cooling Water Temperature | Reflects cooling system efficiency | Elevated temperatures indicate cooling system faults or overloading |

| Scavenge Air Pressure | Affects combustion efficiency and power output | Low pressure reduces engine efficiency |

| Turbocharger Speed | Monitors air intake and turbocharger health | Variations signal air intake or turbocharger problems |

| PMAX (Maximum Combustion Pressure) | Measures cylinder combustion efficiency | Low or high PMAX indicates injector, timing, or compression issues |

These parameters are recorded manually or through automated systems, with data analyzed for trends and deviations.

Tools and Techniques for Performance Monitoring

Marine diesel engine performance is monitored using a combination of manual and automated methods. Below are the primary approaches:

1. Manual Monitoring and Data Logging

Manual checks involve recording key parameters at least twice daily using gauges and logbooks. Common tools include:

- Mechanical Peak Pressure Gauge: Measures PMAX and compression pressure in each cylinder, typically used on four-stroke auxiliary engines.

- Indicator Valves: Mounted on cylinder heads, these allow real-time pressure measurement during engine operation.

- Infrared Temperature Gauge: Measures exhaust and cooling water temperatures non-invasively.

- Pressure Gauges: Monitor lube oil and scavenge air pressures.

Process:

- Record parameters like exhaust gas temperature, lube oil pressure, and turbocharger speed.

- Compare readings with manufacturer specifications and previous logs to identify trends.

- Use logbooks to track long-term performance, comparing monthly data to detect deterioration.

Advantages:

- Simple and cost-effective.

- Serves as a backup during automated system failures.

Limitations:

- Time-consuming and prone to human error.

- Limited data for in-depth analysis.

2. Indicator Card Measurement

Indicator cards are mechanical diagrams plotted using an indicator drum to assess cylinder performance. Two types are used:

- Power Card: Measures peak pressure and engine power.

- Draw Card: Analyzes compression pressure and combustion timing.

Process:

- Attach the indicator drum to the cylinder head.

- Plot pressure data as the engine cycles.

- Analyze diagrams for compression, peak pressure, and power output.

Advantages:

- Provides visual representation of cylinder performance.

- Useful for older engines without digital systems.

Limitations:

- Requires skilled interpretation.

- Less precise than digital methods.

3. Digital Pressure Monitoring (DPI)

Digital Pressure Indicators (DPIs) use electronic sensors to measure cylinder pressure and plot data graphically.

Process:

- Connect the DPI to the cylinder head and RPM sensor.

- Record pressure data and transfer it to a computer for analysis.

- Interpret graphs to assess combustion efficiency and cylinder balance.

Advantages:

- High precision and graphical output.

- Faster than manual methods.

Limitations:

- Requires manual setup for non-online systems.

- Costlier than mechanical gauges.

4. Performance Measurement Indicators (PMI) Systems

PMI systems automate performance monitoring, calculating parameters like effective power, mean indicated pressure, and PMAX.

Features:

- Offline PMI: Engineers manually connect the system to measure and analyze data.

- Graphical Analysis: Displays pressure-time (PT), pressure-volume (PV), and balance diagrams.

- Fuel Pump Index Proposals: Suggests adjustments to optimize fuel consumption.

Process:

- Activate the PMI system during stable engine operation.

- Analyze graphical outputs for combustion characteristics and cylinder balance.

- Adjust fuel pump settings based on PMI recommendations.

Advantages:

- Comprehensive and automated data analysis.

- Optimizes fuel efficiency and engine balance.

Limitations:

- High installation and maintenance costs.

- Requires trained personnel.

5. Intelligent Combustion Monitoring (ICM)

ICM systems provide continuous, real-time monitoring of in-cylinder pressure across all cylinders.

Features:

- Measures pressure, exhaust valve operation, and fuel injection performance.

- Offers data processing tools for diagnosing blow-by, valve issues, and injector faults.

- Provides remote access to performance data in the control room or chief engineer’s cabin.

Process:

- Monitor real-time data via ICM dashboards.

- Analyze trends to predict maintenance needs.

- Adjust engine parameters like fuel injection timing or turbocharger vane angles.

Advantages:

- Real-time insights and predictive maintenance.

- Reduces downtime and spare parts costs.

Limitations:

- Expensive and complex to install.

- Primarily used on modern, high-value vessels.

6. Engine Emission Monitoring

Exhaust smoke color and density indicate combustion quality:

- Black Smoke: Incomplete combustion, often due to injector faults or poor air supply.

- White Smoke: Unburned fuel, indicating ignition delays or low compression.

- Blue Smoke: Oil burning, suggesting worn piston rings or valve seals.

Process:

- Visually inspect exhaust trunks during operation.

- Correlate smoke characteristics with cylinder performance data.

- Investigate underlying issues like injector wear or scavenge air problems.

Advantages:

- Quick and non-invasive.

- Complements other monitoring methods.

Limitations:

- Subjective and less precise.

- Requires correlation with other data.

Measuring PMAX: A Critical Diagnostic Tool

PMAX, the maximum combustion pressure in a cylinder, is a key indicator of engine health. Regular PMAX checks reveal issues like injector wear, combustion delays, or timing errors.

Tools Required

- Pressure Indicator: Mechanical or digital, with a range of 0–150 bar for medium-speed engines.

- Anti-Burnout Compound: Protects indicator threads from heat damage.

- Wrenches and Valve Keys: For securing the indicator to the cylinder cock.

- Safety Gear: Heat-resistant gloves, safety goggles, and protective overalls.

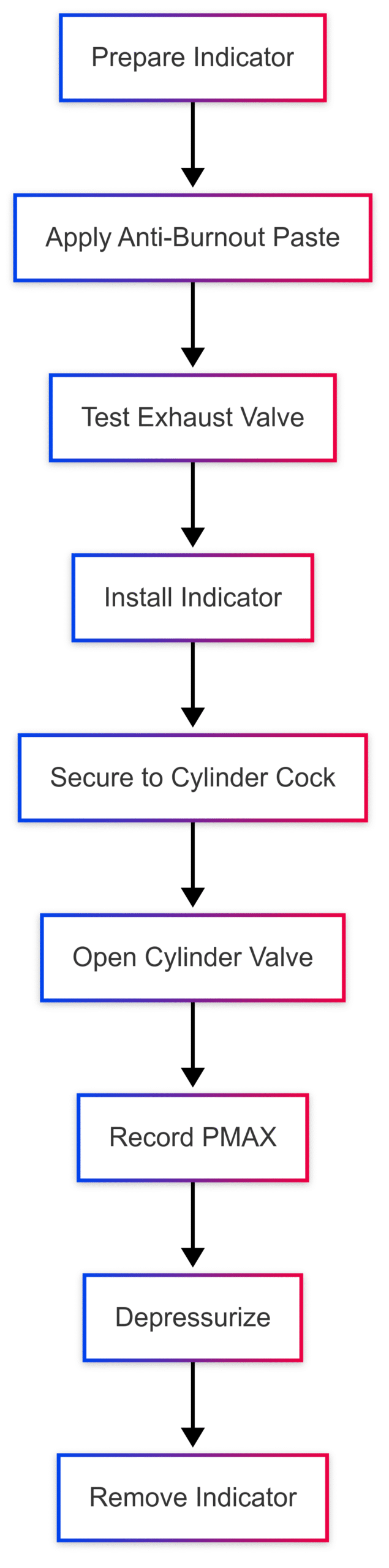

Step-by-Step PMAX Measurement

- Prepare the Indicator:

- Apply anti-burnout paste to the indicator threads.

- Test the exhaust valve by “gunning” it to ensure functionality.

- Install the Indicator:

- Securely attach the indicator to the cylinder indicator cock.

- Tighten to prevent leaks.

- Open Cylinder Valve:

- Gradually open the valve to allow pressure measurement.

- Monitor the gauge as the engine cycles.

- Record PMAX:

- Note the maximum pressure when the gauge stabilizes.

- Typical range: 80–120 bar (consult engine manual for specifics).

- Depressurize and Remove:

- Open the exhaust valve to release pressure.

- Confirm the gauge reads zero before removing the indicator.

Safety Precautions

- Measure PMAX at stable engine load to avoid inaccurate readings.

- Wear protective gear to prevent burns or injuries.

- Calibrate indicators regularly for accuracy.

- Clean indicator ports before and after use to prevent contamination.

Analyzing PMAX Data

- Uniform Readings: Indicate balanced cylinder performance.

- Variation >3–5 bar: Suggests issues like worn injectors, poor compression, or scavenge air problems.

- Trend Analysis: Plot PMAX over time to predict maintenance needs.

Chart: PMAX Measurement Workflow

Troubleshooting and Optimization

Once performance data is collected, engineers analyze it to identify irregularities and optimize engine operation.

Identifying Irregularities

- Compare current data with manufacturer specifications and historical logs.

- Look for deviations in PMAX, exhaust temperatures, or lube oil pressure.

- Use graphical outputs from PMI or ICM systems to pinpoint cylinder-specific issues.

Root Cause Analysis

Investigate potential causes, such as:

- Fuel Injection System: Clogged nozzles or incorrect timing.

- Air Intake System: Low scavenge air pressure or turbocharger faults.

- Cooling System: Blocked coolers or pump failures.

- Mechanical Components: Worn piston rings or valve leaks.

Performance Optimization

- Adjust fuel injection timing or fuel-air mixture based on PMI recommendations.

- Optimize turbocharger vane angles or exhaust valve timing.

- Schedule maintenance for faulty components to restore efficiency.

Real-World Applications

Case Study: Bulk Carrier Injector Failure

A bulk carrier’s Cylinder #3 showed a PMAX of 70 bar, compared to 110 bar for other cylinders. Inspection revealed a clogged injector nozzle, which was replaced, restoring performance and preventing piston ring damage. Estimated savings: USD 50,000.

Case Study: Container Ship Fuel Optimization

A container ship implemented ICM to monitor real-time cylinder pressure. By adjusting fuel pump indexes based on ICM data, the vessel reduced SFOC by 5%, saving USD 100,000 annually in fuel costs.

Best Practices for Performance Monitoring

- Consistency: Measure parameters under similar conditions (e.g., same RPM and load).

- Record-Keeping: Maintain detailed logbooks for trend analysis.

- Calibration: Regularly calibrate mechanical and digital tools.

- Training: Ensure engineers are trained in PMI and ICM systems.

- Backup Systems: Retain manual methods for emergency use.

Specifications and Costs of Monitoring Tools

| Tool/System | Specifications | Approx. Cost (USD) |

|---|---|---|

| Mechanical Peak Pressure Gauge | 0–150 bar, manual operation | 500–1,000 |

| Digital Pressure Indicator (DPI) | 0–200 bar, graphical output | 2,000–5,000 |

| PMI System (Offline) | Automated data collection, PT/PV diagrams | 10,000–20,000 |

| ICM System | Real-time monitoring, remote access | 50,000–100,000+ |

| Infrared Temperature Gauge | -50°C to 550°C | 100–300 |

Note: Costs vary based on brand, engine size, and installation requirements. For precise pricing, contact manufacturers like MAN Energy Solutions or Wärtsilä.

Challenges and Considerations

- Bollard Pull Testing: Not recommended for planing craft, as it can strain engines and docks. Caterpillar advises free-running tests for pleasure craft.

- Marina Restrictions: High-RPM testing at docks may be prohibited due to noise, smoke, or structural concerns.

- Cost vs. Benefit: Advanced systems like ICM are expensive but offer significant long-term savings.

- Skill Requirements: Interpreting PMI and ICM data requires specialized training.

FAQ

- How often should performance data be checked?

Monthly for main and auxiliary engines, or every 500–1,000 hours for PMAX. - Are digital systems better than mechanical ones?

Digital systems offer precision and automation but are costlier. Mechanical systems are reliable backups. - What if PMAX varies significantly?

Inspect injectors, compression, and scavenge air systems for faults. - Is performance monitoring mandatory?

Yes, under STCW and ISM Code requirements. - Can performance checks be done remotely?

ICM systems allow remote monitoring, but manual checks require on-site presence.

Conclusion

Checking performance data in marine diesel engines is essential for maintaining efficiency, reliability, and compliance. By monitoring parameters like PMAX, exhaust temperatures, and lube oil pressure, engineers can detect faults early, optimize combustion, and reduce operating costs. Tools like PMI and ICM systems provide advanced insights, while manual methods remain valuable backups. With consistent monitoring, proper analysis, and timely maintenance, marine diesel engines can deliver peak performance, ensuring safe and cost-effective maritime operations.

Happy Boating!

Share How to Check Performance Data in Marine Diesel Engines with your friends and leave a comment below with your thoughts.

Read EEXI and CII – ship carbon intensity and rating system until we meet in the next article.