Shipboard Oil Pollution Emergency Plan (SOPEP)

Learn about the Shipboard Oil Pollution Emergency Plan (SOPEP), a vital MARPOL-compliant guide for preventing and responding to oil spills on ships.

The maritime industry plays a critical role in global trade, transporting goods across oceans. However, with this responsibility comes the risk of environmental harm, particularly from oil spills. To mitigate these risks, the Shipboard Oil Pollution Emergency Plan (SOPEP) is a mandatory framework for vessels, ensuring preparedness and swift response to oil pollution incidents. Required under the International Convention for the Prevention of Pollution from Ships (MARPOL) Annex I, Regulation 37, SOPEP is a cornerstone of maritime environmental protection. This article explores the purpose, components, regulatory requirements, and practical implementation of SOPEP, providing a detailed guide for maritime professionals and stakeholders.

What is SOPEP?

The Shipboard Oil Pollution Emergency Plan (SOPEP) is a vessel-specific document designed to guide the ship’s crew in preventing, managing, and responding to oil spills. It outlines procedures for reporting, containing, and mitigating oil pollution incidents to minimize environmental damage and ensure compliance with international regulations. SOPEP is mandatory for:

- Oil tankers of 150 gross tonnage (GT) and above.

- Other ships of 400 GT and above carrying oil in bulk.

- Ships carrying noxious liquid substances in bulk, often integrated into a combined Shipboard Marine Pollution Emergency Plan (SMPEP).

SOPEP serves as a proactive tool, enabling crews to act decisively during emergencies, such as operational spills, collisions, groundings, or equipment failures. By providing clear protocols, it ensures environmental protection, crew safety, and regulatory compliance.

Why SOPEP Matters

Oil spills pose severe threats to marine ecosystems, coastal environments, and human health. They can devastate marine life, contaminate shorelines, and incur significant cleanup costs, legal penalties, and reputational damage. SOPEP addresses these challenges by:

- Protecting the Environment: SOPEP outlines measures to contain and clean up oil spills, reducing their ecological impact.

- Ensuring Safety: Clear procedures minimize risks to crew members during spill response.

- Ensuring Compliance: Adherence to MARPOL and other regulations avoids fines and operational disruptions.

- Enhancing Efficiency: A well-executed SOPEP reduces downtime and financial losses by enabling rapid response.

The importance of SOPEP extends beyond compliance—it is a critical tool for safeguarding the marine environment and maintaining operational integrity.

Regulatory Framework

SOPEP is governed by international regulations, primarily under MARPOL Annex I, Regulation 37, which mandates that oil tankers of 150 GT and above and other ships of 400 GT and above carry an approved SOPEP. Additionally, Article 3 of the International Convention on Oil Pollution Preparedness, Response and Co-operation (OPRC), 1990, reinforces this requirement. For ships carrying noxious liquid substances, MARPOL Annex II, Regulation 17, mandates a similar plan, which can be combined with SOPEP into an SMPEP for practicality.

The International Maritime Organization (IMO) provides detailed guidance through the Guidelines for the Development of Shipboard Marine Pollution Emergency Plans (2010 Edition), incorporating resolutions such as MEPC.54(32), MEPC.86(44), and MEPC.137(53). These guidelines ensure that SOPEPs are comprehensive, standardized, and effective.

A key requirement is maintaining an updated List of National Operational Contact Points (MSC-MEPC.6-Circ.23) onboard. This list, updated annually on January 31 and quarterly on April 30, July 31, and October 31, provides contact details for authorities responsible for receiving spill reports. Vessels must carry the most recent version to ensure effective communication during emergencies.

Panama Canal SOPEP (PCSOPEP)

Vessels transiting the Panama Canal must comply with the Panama Canal Ship Oil Pollution Emergency Plan (PCSOPEP), effective since January 2005. The Panama Canal Authority (ACP) acts as the sole Oil Spill Response Organization (OSRO) for vessels in transit, requiring ships to submit a PCSOPEP and pay tariffs for response resources. This ensures rapid response capabilities in the canal’s sensitive ecosystem.

Key Components of SOPEP

A SOPEP is a comprehensive document tailored to the vessel’s operations, crew, and equipment. Its key components include:

1. Reporting Procedures

SOPEP outlines when and how to report oil spills, including contact details for:

- National authorities (e.g., coast guard, port state control).

- Oil spill response teams.

- Shipowners and operators.

The plan specifies communication protocols, ensuring timely and accurate reporting to initiate coordinated response efforts.

2. Operational Procedures

SOPEP provides step-by-step instructions for containing and controlling oil spills, such as:

- Closing valves to prevent further discharge.

- Deploying containment booms and absorbent materials.

- Transferring oil to safe storage areas.

These procedures are designed to comply with MARPOL Annex I, Regulation 37, and minimize environmental impact.

3. Equipment and Resources

SOPEP details the location and use of onboard spill response equipment, typically stored in a SOPEP locker. Common equipment includes:

| Equipment | Description | Purpose |

|---|---|---|

| Oil Boom (e.g., WB510SN) | 3m x 13-14m inflatable barrier | Contains oil on water surface |

| Oil Socks (e.g., WSO410) | 120 cm x 7.5 cm absorbent tubes | Absorbs oil in confined areas |

| Oil Pads (e.g., WP200S) | 50 x 40 cm absorbent sheets | Soaks up oil spills |

| Oil Sweep (e.g., WSWL100F) | 48 cm x 30 cm skimming material | Removes oil from water surface |

| PPE (e.g., PVC gloves) | Protective gear | Ensures crew safety |

| Disposal Bags (e.g., MTL103) | Heavy-duty bags for waste | Safe disposal of contaminated materials |

| Non-Sparking Hand Pump | Manual pump for oil transfer | Safe handling of flammable liquids |

The SOPEP locker’s inventory is vessel-specific, ensuring equipment availability for various spill scenarios.

4. Communication Protocols

Effective communication is critical during an oil spill. SOPEP includes:

- Contact details for shore-based response teams and authorities.

- Protocols for internal communication among crew members.

- Procedures for coordinating with external responders, such as cleanup teams.

5. Training and Familiarization

SOPEP emphasizes crew training to ensure familiarity with spill response procedures. Regular drills and exercises are conducted to:

- Familiarize crew with SOPEP equipment and protocols.

- Simulate spill scenarios (e.g., operational spills, collisions).

- Ensure readiness for real emergencies.

6. Specific Spill Scenarios

SOPEP addresses various spill scenarios, including:

- Operational Spills: Caused by routine operations like bunkering or cargo handling.

- Casualty Spills: Resulting from collisions, groundings, or structural failures.

- Equipment Failure Spills: Due to malfunctioning systems, such as pumps or pipelines.

Each scenario includes tailored response strategies to mitigate risks.

7. Ship-Specific Information

SOPEP includes detailed vessel information, such as:

- General arrangement plans showing oil tank locations and capacities.

- Drawings of fuel and oil lines, including vents and save-all trays.

- Shipowner and operator details for emergency coordination.

8. Record-Keeping

SOPEP mandates maintaining records of spill incidents for liability, compensation, and insurance purposes. This includes:

- Incident logs.

- Actions taken during response.

- Communication records with authorities.

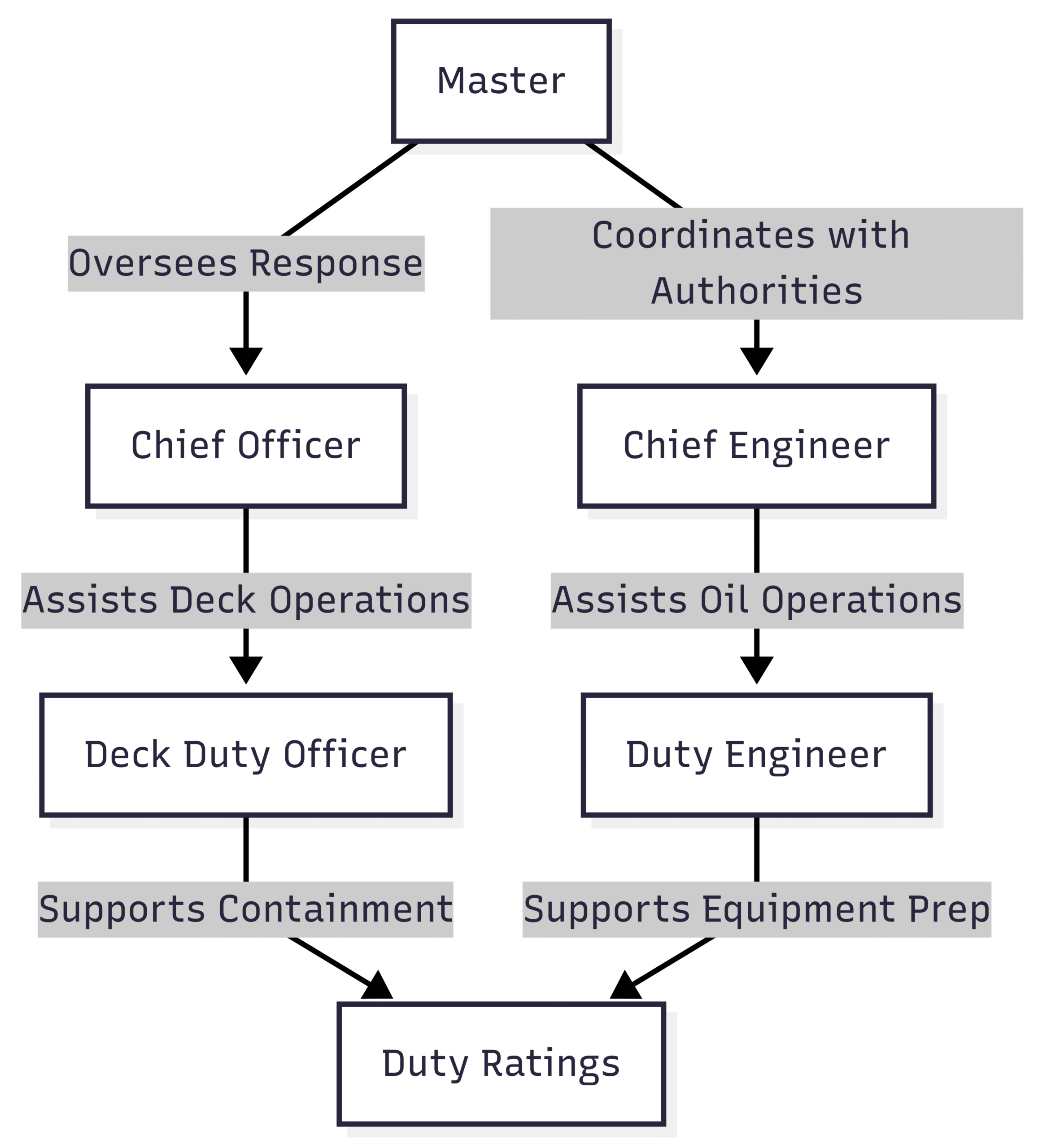

Roles and Responsibilities

SOPEP assigns specific duties to crew members to ensure a coordinated response. Key roles include:

- Master: Oversees the entire response, communicates with authorities, and ensures compliance with SOPEP.

- Chief Officer: Manages deck operations, implements spill containment measures, and updates the master on progress.

- Chief Engineer: Supervises bunkering and oil transfer operations, prepares SOPEP equipment, and mitigates oil outflow.

- Deck Duty Officer: Assists the chief officer, monitors for potential spills, and alerts the crew.

- Duty Engineer: Supports the chief engineer in oil-related operations and prepares firefighting equipment.

- Duty Ratings: Assist in spill detection, containment, and cleanup, deploying additional SOPEP materials as needed.

The following Mermaid chart illustrates the hierarchy of responsibilities under SOPEP:

SOPEP Equipment: The Oil Spill Box

The SOPEP locker or oil spill box is a critical component of spill response. It contains specialized equipment to contain and clean up oil spills. Two common configurations are the 4-Barrel Oil Spill Box and the 7-Barrel Oil Spill Box, tailored to different vessel sizes and needs.

4-Barrel Oil Spill Box

| Item | Quantity | Specifications |

|---|---|---|

| Oil Boom (WB510SN) | 1 | 3m x 13m |

| Oil Sweep (WSWL100F) | 1 | 48 cm x 30 cm |

| Oil Socks (WSO410) | 6 | 120 cm x 7.5 cm |

| Oil Truckpack (KTO 100) | 2 | – |

| Oil Pads (WP200S) | 200 | 50 x 40 cm |

| Oil Pads (YPB200S) | 50 | 50 x 40 cm |

| PVC Protective Gloves | 1 | PPE105 |

| Disposal Bags (MTL103) | 2 | – |

7-Barrel Oil Spill Box

| Item | Quantity | Specifications |

|---|---|---|

| Oil Boom (WB510SN-03) | 4 | 3m x 14m |

| Oil Sweep (WSWL100F) | 1 | 48 cm x 30 cm |

| Oil Socks (WSO120-20) | 6 | 120 cm x 7.5 cm |

| Oil Truckpack (TP40) | 2 | 40 liters |

| Oil Pads (WP200) | 200 | 40 x 40 cm |

| Universal Pads (GBP100H) | 50 | 50 x 40 cm |

| PVC Protective Gloves | 1 | PPE105 |

| IMO Disposable Bags | 2 | OCS6012-100 |

| Safety Goggle | 1 | VB-0103 |

| Non-Sparking Hand Pump | 1 | – |

| 10 Steps Action Plan | 1 | – |

| Screwdriver | 1 | – |

These kits are designed to handle spills of varying sizes, with the 7-barrel box offering greater capacity for larger vessels or higher-risk operations.

Implementation and Maintenance

Implementing SOPEP requires ongoing commitment from shipowners, operators, and crews. Key practices include:

- Annual Review: Vessels must review their SOPEP annually within one month of the plan’s approval anniversary and submit a certification letter to the approving authority (e.g., Coast Guard).

- Reapproval: The entire plan must be resubmitted for reapproval six months before the approval period ends (e.g., every five years, as per the example approval valid until June 29, 2030).

- Updates: Non-mandatory changes, such as updated contact lists, do not require approval but must be documented. Mandatory changes require prior approval from the administration.

- Training and Drills: Regular training ensures crew readiness, with drills simulating spill scenarios to test response capabilities.

Environmental and Economic Impacts of Oil Spills

Oil spills have far-reaching consequences. Environmentally, they harm marine mammals, birds, and ecosystems, with long-term effects on biodiversity. Economically, cleanup costs vary based on spill size, oil type, and location. Factors include:

- Legal Claims and Penalties: Fines for non-compliance with MARPOL or national regulations.

- Cleanup Costs: Expenses for response teams, equipment, and shoreline restoration.

- Loss of Oil: Financial loss from spilled cargo or fuel.

- Repairs: Costs to fix damaged equipment or vessels.

- Ecosystem Damage: Incalculable losses to marine life and human health.

SOPEP minimizes these impacts by enabling rapid, effective response, reducing the scope and cost of spills.

Best Practices for SOPEP Compliance

To maximize SOPEP effectiveness, maritime professionals should:

- Ensure all crew members are trained and familiar with SOPEP procedures.

- Maintain an updated List of National Operational Contact Points.

- Conduct regular equipment checks to ensure SOPEP locker contents are functional.

- Perform spill response drills to simulate real-world scenarios.

- Keep detailed records of incidents and response actions for accountability.

Conclusion

The Shipboard Oil Pollution Emergency Plan (SOPEP) is an indispensable tool for maritime environmental protection. By outlining clear procedures, assigning roles, and specifying equipment, SOPEP ensures vessels are prepared to respond to oil spills effectively. Compliance with MARPOL and other regulations not only avoids penalties but also protects marine ecosystems and crew safety. For maritime professionals, understanding and implementing SOPEP is a critical responsibility, safeguarding both the environment and the industry’s operational integrity.

Happy Boating!

Share Shipboard Oil Pollution Emergency Plan (SOPEP) with your friends and leave a comment below with your thoughts.

Read What is Oil Discharge Monitoring and Control System on Ship until we meet in the next article.