What is Oil Discharge Monitoring and Control System on Ship

Discover the Oil Discharge Monitoring and Control System (ODMCS) on ships, its components, functionality, and MARPOL compliance to prevent marine pollution.

The maritime industry plays a pivotal role in global trade, with oil tankers transporting vast quantities of crude oil and petroleum products across oceans. However, the operational necessity of discharging ballast and bilge water from these vessels poses a significant environmental risk due to potential oil contamination. To mitigate this, the Oil Discharge Monitoring and Control System (ODMCS), also known as Oil Discharge Monitoring Equipment (ODME), is a critical technology mandated for oil tankers under international regulations. This system ensures that oily water discharges comply with stringent environmental standards, protecting marine ecosystems from pollution. This article explores the ODMCS in detail, covering its components, functionality, regulatory framework, operational principles, and significance in maritime environmental protection.

The Role of ODMCS in Maritime Operations

Oil tankers, designed to carry liquid cargoes such as crude oil or refined petroleum, often sail without cargo after unloading at a port. To maintain stability and achieve optimal draught during these voyages, they take on seawater as ballast, typically stored in cargo tanks previously used for oil. Before loading new cargo, this ballast water, which may contain residual oil, must be discharged at sea. Similarly, bilge water from engine rooms and other spaces can also become contaminated with oil. Uncontrolled discharge of such oily mixtures can severely harm marine ecosystems, leading to the development of the ODMCS.

The ODMCS is an automated system designed to monitor and control the discharge of oily water from oil tankers, ensuring compliance with the International Convention for the Prevention of Pollution from Ships (MARPOL) Annex I. By measuring oil content, flow rate, and other parameters, the system prevents illegal discharges and minimizes environmental impact, making it an indispensable tool for sustainable maritime operations.

Key Components of the ODMCS

The ODMCS is a sophisticated system comprising several interconnected components that work together to monitor and regulate oily water discharge. Below are the primary components and their functions:

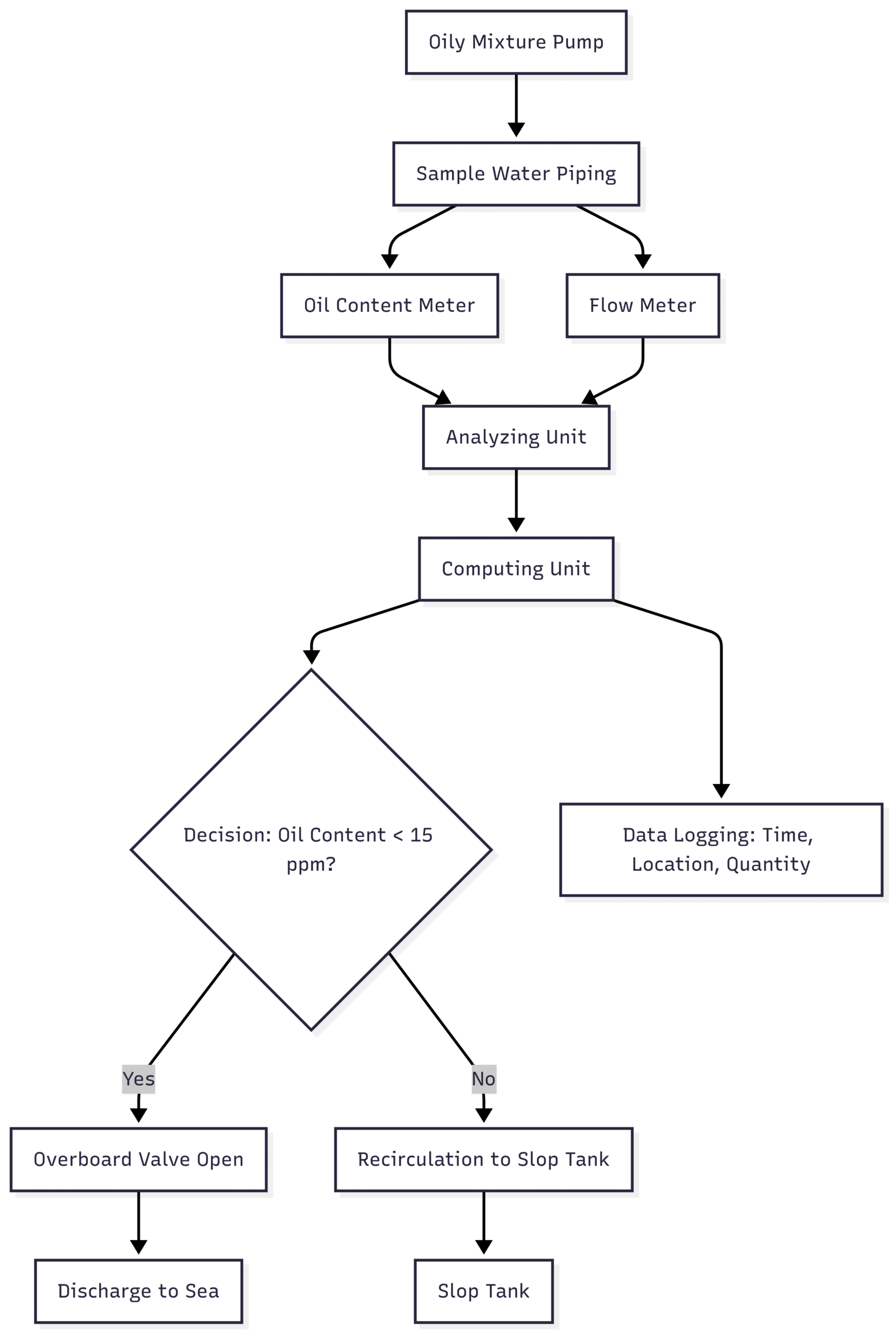

Oil Content Meter:

- The oil content meter is the heart of the ODMCS, measuring the concentration of oil in the discharged water in parts per million (ppm). It uses advanced analytical techniques, such as infrared spectroscopy or ultraviolet fluorescence, to detect oil traces accurately.

- Typically, the meter is designed to detect oil content as low as 15 ppm, aligning with MARPOL’s permissible discharge limits.

Flow Meter:

- Installed at the discharge pipe, the flow meter measures the rate at which oily water is discharged, typically in liters per second or cubic meters per hour.

- This data is crucial for calculating the instantaneous discharge rate and ensuring it remains within regulatory limits.

Computing Unit:

- Located in the cargo control room, the computing unit processes data from the oil content meter and flow meter. It calculates critical parameters, such as the total oil discharged (in liters per nautical mile) and the cumulative discharge quantity.

- The unit also logs essential data, including the date, time, and ship’s position (via GPS integration), for regulatory compliance.

Overboard Valve Control System:

- This system includes an automated valve installed at the overboard discharge point. If the oil content exceeds the permissible limit (typically 15 ppm), the valve closes automatically, stopping the discharge.

- Simultaneously, the system diverts the oily mixture to the ship’s slop tank or recirculates it for further treatment.

Sample Water Piping:

- A sampler probe, connected to the discharge pipe, draws a representative sample of the oily water for analysis by the oil content meter.

- The piping system includes a flowmeter to monitor sample flow and ensure accurate measurements.

Analyzing Unit:

- The analyzing unit houses the oil content meter, a fresh water valve for periodic cleaning, and a pressure transmitter to monitor sample flow through the measuring cell.

- The fresh water valve ensures the system remains free of oil residues, reducing maintenance needs and ensuring measurement accuracy.

Diagram: ODMCS Component Flow

Below is a simplified flowchart illustrating the interaction of ODMCS components during oily water discharge:

How the ODMCS Works

The ODMCS operates as an integrated system to ensure that oily water discharges comply with MARPOL Annex I regulations. The process begins when an oily mixture, such as ballast water from cargo tanks or bilge water, is pumped out for discharge at sea. The operational workflow is as follows:

Sampling and Measurement:

- A sampler probe extracts a continuous sample from the discharge pipe, which is analyzed by the oil content meter to determine the oil concentration in ppm.

- Simultaneously, the flow meter measures the discharge rate, providing data on the volume of water being discharged.

Data Processing:

- The computing unit receives inputs from the oil content meter and flow meter, calculating the instantaneous oil discharge rate (in liters per nautical mile) and the total oil discharged.

- The system integrates GPS data to record the ship’s location and logs the date and time of the discharge.

Discharge Control:

- If the oil content exceeds the permissible limit (typically 15 ppm) or the discharge rate exceeds 30 liters per nautical mile, the computing unit triggers the overboard valve control system.

- The overboard valve closes, and the oily mixture is redirected to the slop tank or recirculated for further treatment, preventing non-compliant discharge.

Data Recording:

- All relevant data, including oil content, discharge rate, total quantity discharged, ship’s position, and timestamp, are recorded in the system’s memory.

- These records are stored for at least three years, as required by MARPOL, and are available for inspection by port state control authorities.

Self-Maintenance:

- The analyzing unit periodically flushes the oil content meter with fresh water to prevent oil residue buildup, ensuring consistent accuracy with minimal crew intervention.

This automated process ensures that discharges are continuously monitored and controlled, reducing the risk of human error and ensuring compliance with environmental regulations.

Regulatory Framework Governing ODMCS

The ODMCS is mandated by MARPOL Annex I, which sets out regulations to prevent pollution by oil from ships. Key regulatory requirements include:

- Applicability:

- All oil tankers of 150 gross tonnage (GT) and above must be equipped with an approved ODMCS, as per MARPOL Regulation 31.

- The system must include a manual operating mode to ensure functionality in case of automation failure.

- Design and Installation Standards:

- The Marine Environment Protection Committee (MEPC) resolution MEPC.108(49) provides detailed guidelines for the design, installation, and operation of ODMCS.

- The system must be approved by the ship’s flag state administration, and an operational manual must be provided on board.

- Operational Requirements:

- Discharges are permitted only when the tanker is en route, at least 50 nautical miles from land, and outside designated special areas (e.g., the Mediterranean Sea, Baltic Sea, or Antarctic area).

- The instantaneous oil discharge rate must not exceed 30 liters per nautical mile.

- The total oil discharged must not exceed 1/30,000 of the total quantity of the residue formed from the previous cargo.

- Record-Keeping:

- The ODMCS must record the following:

- Discharge rate (liters per second or cubic meters per hour).

- Oil content of the discharge (ppm).

- Total quantity discharged (liters).

- Ship’s position (latitude and longitude).

- Date and time of the discharge.

- These records must be retained on board for at least three years and be readily available for inspection.

- The ODMCS must record the following:

Table: MARPOL Annex I Discharge Criteria

| Parameter | Requirement |

|---|---|

| Vessel Status | Must be en route |

| Distance from Land | At least 50 nautical miles |

| Special Areas | Discharge prohibited |

| Instantaneous Oil Discharge Rate | ≤ 30 liters per nautical mile |

| Total Oil Discharged | ≤ 1/30,000 of residue formed cargo |

| ODMCS Status | Must be operational and approved |

| Record Retention Period | Minimum 3 years |

Importance of ODMCS in Marine Environmental Protection

The ODMCS plays a critical role in safeguarding marine ecosystems and ensuring compliance with international environmental standards. Its key benefits include:

- Prevention of Illegal Discharges: By automatically controlling the overboard valve, the ODMCS prevents discharges that exceed permissible oil content limits, reducing the risk of illegal pollution.

- Protection of Marine Ecosystems: Oil pollution can devastate marine life, including fish, seabirds, and coral reefs. The ODMCS ensures that oily water discharges are within safe limits, minimizing environmental harm.

- Regulatory Compliance: Compliance with MARPOL Annex I is mandatory for oil tankers operating internationally. The ODMCS provides accurate monitoring and data logging, enabling ships to demonstrate compliance during inspections.

- Operational Efficiency: The system supports efficient management of slop tanks by diverting non-compliant oily water for further treatment, optimizing onboard waste management processes.

- Data Transparency: The ODMCS’s comprehensive data logging facilitates accurate reporting in the Oil Record Book, enhancing transparency and accountability in maritime operations.

Technical Specifications and Costs

The technical specifications of ODMCS vary depending on the manufacturer and the tanker’s size, but typical features include:

- Oil Content Meter Sensitivity: Detects oil concentrations as low as 0–100 ppm, with an accuracy of ±5 ppm.

- Flow Meter Range: Measures flow rates from 0.1 to 100 cubic meters per hour, depending on the discharge pump capacity.

- Computing Unit: Equipped with a user-friendly interface, GPS integration, and data storage capacity for at least three years.

- Valve Control System: Automated, with fail-safe mechanisms to close the overboard valve within seconds of detecting non-compliance.

- Power Supply: Typically 110–220V AC or 24V DC, compatible with shipboard power systems.

- Material: Corrosion-resistant materials (e.g., stainless steel) for durability in harsh marine environments.

Cost Considerations

The cost of an ODMCS depends on the tanker’s size, system complexity, and manufacturer. Approximate costs include:

- Basic Systems: $50,000–$100,000 for smaller tankers (150–5,000 GT).

- Advanced Systems: $100,000–$200,000 for larger tankers (>5,000 GT) with enhanced automation and data integration features.

- Installation and Commissioning: $10,000–$30,000, depending on shipyard rates and system integration requirements.

- Maintenance: Annual maintenance costs range from $5,000 to $15,000, covering calibration, sensor cleaning, and software updates.

These costs are offset by the system’s role in ensuring regulatory compliance, avoiding fines, and protecting the shipowner’s reputation.

Challenges and Future Developments

While the ODMCS is highly effective, it faces certain challenges:

- Calibration and Maintenance:

- The oil content meter requires regular calibration to maintain accuracy, which can be time-consuming and costly.

- Crew training is essential to operate the system effectively, especially in manual mode during automation failures.

- Evolving Regulations:

- As environmental standards become stricter, ODMCS designs must adapt to meet new requirements, such as lower permissible oil content limits or integration with emerging technologies.

- Data Integration:

- Modern ODMCS systems are increasingly integrated with shipboard data management systems, requiring compatibility with digital platforms for real-time monitoring and reporting.

Future developments in ODMCS technology may include:

- Enhanced Sensors: Next-generation oil content meters with improved sensitivity and resistance to fouling.

- IoT Integration: Real-time data transmission to shore-based authorities for remote compliance monitoring.

- Automation Upgrades: Fully autonomous systems with minimal crew intervention, reducing operational errors.

Conclusion

The Oil Discharge Monitoring and Control System (ODMCS) is a cornerstone of environmental protection in the maritime industry. By monitoring and controlling oily water discharges, the system ensures that oil tankers comply with MARPOL Annex I regulations, minimizing the risk of marine pollution. Its key components – oil content meter, flow meter, computing unit, and valve control system – work seamlessly to provide accurate measurements, automated control, and comprehensive data logging. As environmental concerns grow and regulations evolve, the ODMCS will continue to play a vital role in promoting sustainable maritime operations, protecting marine ecosystems, and ensuring compliance with international standards. For shipowners and operators, investing in a reliable ODMCS is not only a regulatory necessity but also a commitment to environmental stewardship.

Happy Boating!

Share What is Oil Discharge Monitoring and Control System on Ship with your friends and leave a comment below with your thoughts.

Read Marine Propulsion Systems | Types and Uses Explained until we meet in the next article.