What is an Inert Gas or IG System on Ships?

Discover the Inert Gas System (IGS) on ships, a critical safety feature preventing explosions in cargo tanks by controlling oxygen levels. Learn its components, types, and regulations.

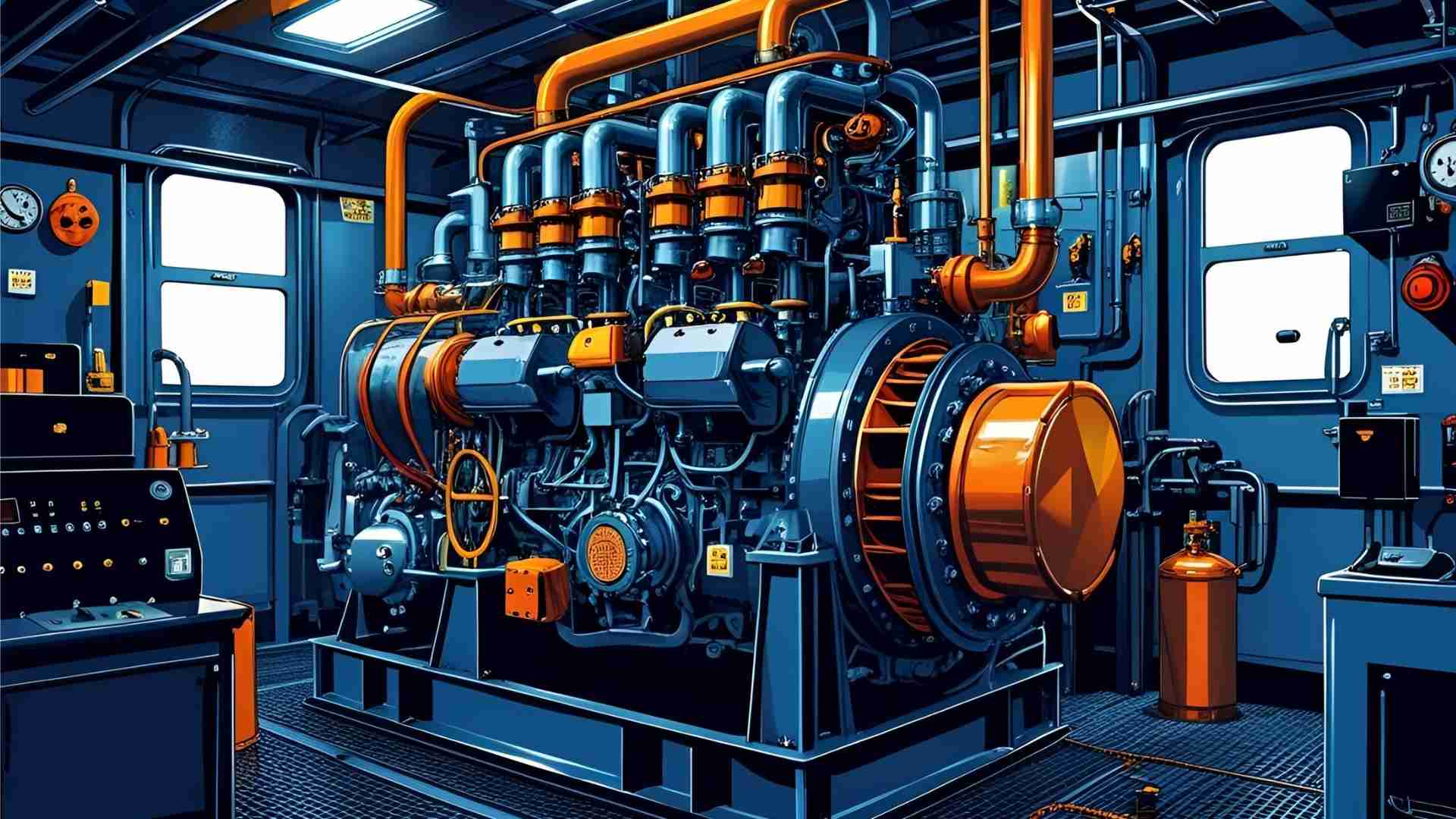

The maritime industry, particularly oil and gas tankers, handles some of the most hazardous cargo in the world—flammable liquids like crude oil and liquefied gases. These cargoes release hydrocarbon vapors that, when mixed with oxygen in specific concentrations, create a volatile environment prone to catastrophic explosions. To mitigate this risk, the Inert Gas System (IGS) has become an indispensable safety mechanism on ships, particularly oil tankers and gas carriers. By replacing oxygen-rich air in cargo tanks with inert gases, IGS ensures a non-flammable atmosphere, safeguarding the vessel, crew, and environment. This comprehensive guide explores the purpose, functionality, components, types, safety considerations, and regulatory requirements of IGS, emphasizing its critical role in maritime safety.

What is an Inert Gas System?

An Inert Gas System (IGS) is a sophisticated safety mechanism designed to prevent explosions in cargo tanks by maintaining a non-flammable atmosphere. It achieves this by displacing oxygen-rich air with an inert gas, typically a mixture of nitrogen and carbon dioxide, reducing the oxygen content to below 8%—a level insufficient to support combustion. This process, known as inerting, ensures that even if flammable hydrocarbon vapors are present, the risk of ignition is eliminated. The IGS is a vital component on oil tankers, chemical tankers, and gas carriers, protecting against the devastating consequences of explosions, such as loss of life, property damage, and marine pollution.

The primary purpose of the IGS is threefold:

- Explosion Prevention: By reducing oxygen levels, the system eliminates one side of the fire triangle (oxygen, fuel, ignition source), making combustion impossible.

- Tank Integrity: The system maintains slight positive pressure in cargo tanks to prevent air ingress, preserving structural integrity.

- Cargo Protection: Inerting minimizes oxidation and contamination of sensitive cargoes, ensuring product quality during transport.

How Does an Inert Gas System Work?

The operation of an IGS involves a series of carefully orchestrated steps to produce, clean, and distribute inert gas to cargo tanks. Below is a detailed breakdown of the process:

- Inert Gas Production:

- The primary source of inert gas is flue gas from the ship’s boiler or a dedicated inert gas generator. Flue gas, primarily composed of nitrogen (approximately 80%) and carbon dioxide, is generated during fuel combustion.

- For vessels requiring high-purity inert gas, such as gas tankers, nitrogen is produced using membrane or cryogenic separation systems.

- Gas Scrubbing and Cooling:

- Flue gas is passed through a scrubbing tower, where it is sprayed with seawater to cool it and remove impurities like sulfur dioxide (SO2) and soot. This process reduces SO2 levels by up to 90%, ensuring the gas is clean and safe for tank use.

- A demister, often made of polypropylene, removes moisture from the gas, reducing the dew point to prevent corrosion in cargo tanks.

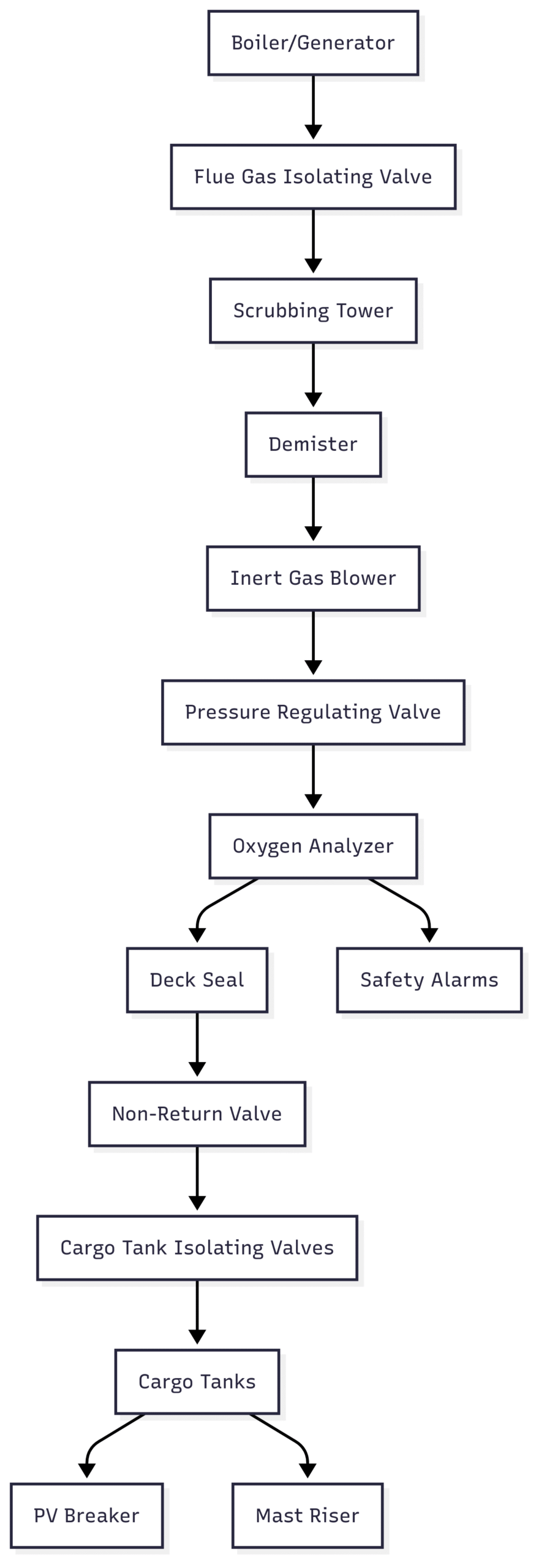

- Gas Distribution:

- Inert gas blowers, typically steam-driven or electrically powered, compress and distribute the gas to cargo tanks via a piping system.

- The system maintains a slight positive pressure (typically 100–200 mm water gauge) to prevent air ingress, which could reintroduce oxygen.

- Safety and Monitoring:

- Oxygen analyzers continuously monitor the gas’s oxygen content, ensuring it remains below 8%. If levels exceed this threshold, alarms are triggered, and the system may shut down to prevent unsafe conditions.

- A deck seal, usually a wet-type seal using water or oil, prevents backflow of flammable vapors from cargo tanks to the machinery space.

- Pressure/Vacuum (PV) breakers protect tanks from over-pressurization or vacuum collapse by automatically venting excess pressure or admitting air when needed.

- Operational Modes:

- Inerting: Before loading cargo, tanks are filled with inert gas to displace oxygen-rich air.

- Purging: During loading, unloading, or tank cleaning, inert gas flushes out flammable vapors, creating a safe atmosphere.

- Gas-Freeing: When tanks need to be accessed for maintenance or inspection, inert gas is replaced with fresh air, ensuring safe entry for personnel.

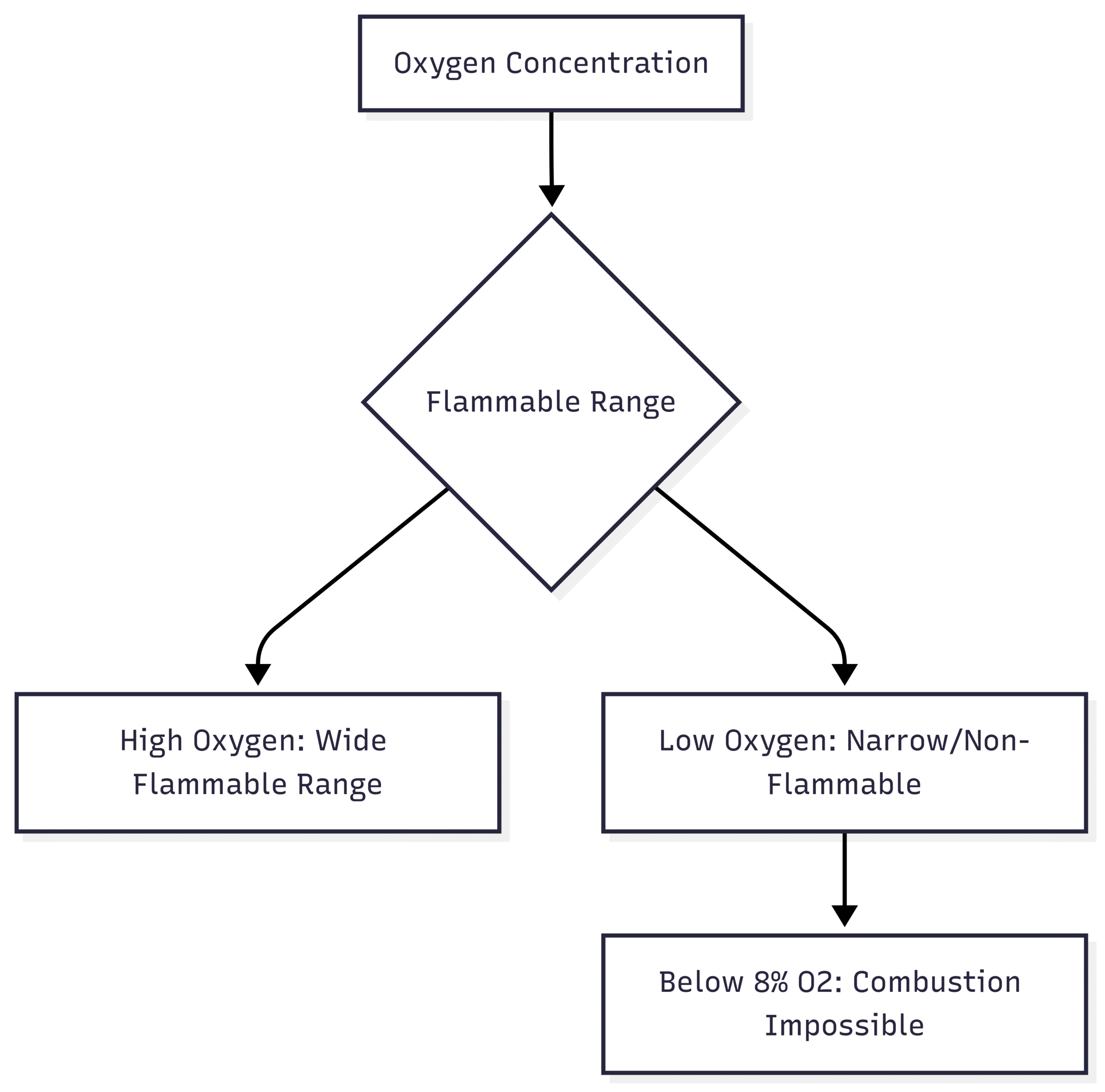

Flammability and the Role of Inert Gas

The flammability of hydrocarbon vapors is determined by their concentration in air, defined by the Lower Flammable Limit (LFL) and Upper Flammable Limit (UFL). These limits represent the minimum and maximum concentrations of vapor that can ignite when mixed with air. For most hydrocarbons, an oxygen content below 10–12% renders the mixture non-flammable. The International Maritime Organization (IMO) mandates a stricter threshold of less than 8% oxygen to provide a safety margin.

Inert gas narrows the flammable range by reducing oxygen levels, increasing the energy required for ignition. For example, at 5% oxygen, combustion is impossible regardless of vapor concentration. This principle is illustrated in the flammability diagram below, created using syntax:

This diagram highlights how reducing oxygen concentration shifts the tank atmosphere outside the flammable range, ensuring safety during cargo operations.

Components of an Inert Gas System

The IGS comprises several critical components working together to produce, clean, and distribute inert gas. Below is a detailed overview of each component:

| Component | Description |

|---|---|

| Inert Gas Source | Flue gas from the ship’s boiler or a dedicated inert gas generator (e.g., nitrogen generator). |

| Scrubbing Tower | Cools and cleans flue gas using seawater sprays and baffle plates, removing SO2 and soot. |

| Demister | Removes moisture from scrubbed gas to prevent corrosion in cargo tanks. |

| Inert Gas Blowers | Compress and distribute inert gas to cargo tanks; available in steam-driven or electric models. |

| Deck Seal | Prevents backflow of flammable vapors from cargo tanks to machinery spaces. |

| PV Breaker | Protects tanks from over-pressurization or vacuum collapse by venting or admitting air. |

| Oxygen Analyzers | Monitor oxygen content in the inert gas, triggering alarms if levels exceed 8%. |

| Pressure Regulating Valve | Recirculates excess gas to maintain optimal pressure in the system. |

| Cargo Tank Isolating Valves | Control inert gas flow to individual cargo tanks, operated by authorized personnel. |

| Mast Riser | Maintains positive pressure during cargo loading by venting excess gas. |

| Safety and Alarm Systems | Include alarms for high oxygen, low pressure, high temperature, and power failure. |

These components are integrated into a cohesive system, as shown in the following flowchart:

This flowchart illustrates the sequential flow of inert gas through the system, highlighting the critical role of each component in maintaining a safe tank atmosphere.

Types of Inert Gas Systems

IGS designs vary based on the vessel’s requirements, cargo type, and operational constraints. The three primary types are:

- Flue Gas Inert Gas System:

- Description: Utilizes exhaust gases from the ship’s boilers as the inert gas source. The gas is scrubbed and cooled before distribution.

- Advantages: Cost-effective, leveraging existing boiler infrastructure; suitable for older vessels.

- Disadvantages: Limited control over gas purity; requires regular maintenance to manage impurities.

- Applications: Commonly used on crude oil tankers.

- Nitrogen Inert Gas System:

- Description: Produces high-purity nitrogen using membrane or cryogenic separation, ideal for sensitive cargoes.

- Advantages: High gas purity, precise control, and reduced corrosion; widely used in modern vessels.

- Disadvantages: Higher initial cost and complexity.

- Applications: Preferred for gas tankers carrying ammonia or polymerizing cargoes.

- Membrane Inert Gas System:

- Description: Employs semi-permeable membranes to separate nitrogen from air, producing inert gas.

- Advantages: Compact, lightweight, and energy-efficient; ideal for smaller vessels.

- Disadvantages: Limited capacity compared to flue gas systems.

- Applications: Suitable for smaller tankers or vessels with space constraints.

The choice of system depends on factors like vessel size, cargo type, and budget. Below is a comparison table:

| System Type | Cost | Purity | Complexity | Best Suited For |

|---|---|---|---|---|

| Flue Gas System | Low | Moderate | Low | Crude oil tankers |

| Nitrogen System | High | High | High | Gas tankers, sensitive cargo |

| Membrane System | Medium | High | Medium | Smaller vessels |

Safety Considerations

Operating an IGS requires stringent safety measures to ensure effectiveness and compliance with international standards. Key considerations include:

- Gas Monitoring: Continuous monitoring of oxygen levels, pressure, and temperature is critical. Oxygen analyzers must be calibrated regularly to ensure accuracy.

- Leak Detection: Regular inspections of piping systems and deck seals prevent leaks that could compromise the inert atmosphere.

- Emergency Shutdown: Systems are equipped with automatic shutdown mechanisms triggered by conditions like high oxygen levels, low pressure, or power failure.

- Fire Prevention: While IGS prevents fires, complementary measures like proper tank cleaning and ventilation are essential.

- Crew Training: Operators must be trained to handle IGS equipment, respond to alarms, and follow emergency procedures.

The following table summarizes key safety alarms and their triggers:

| Alarm Condition | Threshold | Action |

|---|---|---|

| High Oxygen Content | >8% | Alarm and system shutdown |

| High Inert Gas Temperature | >70°C | Alarm and blower shutdown |

| Low Seawater Pressure (Scrubber) | <0.7 bar | Alarm and blower shutdown |

| Low Seawater Pressure (Deck Seal) | <1.5 bar | Alarm and gas delivery stop |

| Low Pressure After Blower | <250 mm WG | Alarm and blower shutdown |

| Low Deck Seal Level | Below minimum | Alarm and gas delivery stop |

| Power Failure | N/A | Alarm and system shutdown |

Regulatory Requirements

IGS operations are governed by international regulations to ensure safety and environmental protection. Key frameworks include:

- SOLAS Convention (Chapter II-2): Mandates IGS on oil tankers and vessels carrying flammable cargoes, specifying design and operational standards.

- IGC Code: Provides requirements for gas carriers, including inert gas systems for safe handling of liquefied gases.

- IBC Code: Outlines standards for chemical tankers, ensuring IGS compatibility with hazardous cargoes.

- Classification Society Rules: Organizations like Lloyd’s Register and DNV GL enforce IGS standards for class certification.

- Flag State and Port State Control: Ensure compliance through inspections and adherence to national regulations.

Non-compliance can result in port detentions, fines, or operational restrictions, underscoring the importance of adhering to these standards.

Benefits of Inert Gas Systems

Beyond explosion prevention, IGS offers several operational and environmental benefits:

- Reduced Corrosion: Low oxygen levels minimize corrosion in tank structures, extending vessel lifespan.

- Efficient Tank Cleaning: Inerting allows the use of larger tank-washing machines, reducing cleaning time.

- Lower Fuel Consumption: Inerted tanks require less fuel for cleaning compared to gas-freeing methods.

- Environmental Protection: By preventing explosions, IGS reduces the risk of oil spills and marine pollution.

Challenges and Maintenance

While IGS is highly effective, it faces challenges that require diligent maintenance:

- System Complexity: Multiple components demand regular inspections to ensure functionality.

- Impurity Management: Flue gas systems must effectively remove SO2 and soot to prevent tank contamination.

- Crew Expertise: Operators need specialized training to manage IGS and respond to emergencies.

Routine maintenance includes cleaning scrubbers, calibrating oxygen analyzers, and inspecting deck seals and PV breakers. A well-maintained IGS ensures compliance and safety throughout the vessel’s operations.

Conclusion

The Inert Gas System is a cornerstone of maritime safety, particularly for vessels transporting flammable cargoes. By maintaining a low-oxygen, non-flammable atmosphere in cargo tanks, IGS prevents catastrophic explosions, protects tank integrity, and ensures cargo quality. Its sophisticated components—ranging from scrubbers and blowers to oxygen analyzers and safety alarms—work in harmony to create a safe operational environment. With various system types like flue gas, nitrogen, and membrane systems, ship operators can choose the best fit for their vessel’s needs. Strict adherence to international regulations, such as those from the IMO, ensures that IGS remains a reliable safeguard against the inherent risks of maritime transport. As technology advances, IGS continues to evolve, offering greater efficiency, reliability, and environmental benefits, solidifying its role as an essential component of modern maritime operations.

Happy Boating!

Share What is an Inert Gas or IG System on Ships? with your friends and leave a comment below with your thoughts.

Read How to Troubleshoot Marine Engineering Problems? until we meet in the next article.