What is a marine diesel engine overhaul?

Learn about marine diesel engine overhaul: process, benefits, and why it’s vital for vessel performance. Expert insights from Marine Diesel Specialists.

Marine diesel engines are the backbone of vessels, from small recreational boats to large commercial ships. These powerhouses endure extreme conditions—saltwater exposure, constant vibration, and high power demands—that lead to wear and tear over time. A marine diesel engine overhaul is a meticulous process designed to restore an engine to its original performance specifications, extending its lifespan and ensuring reliability. This guide explores the overhaul process, its importance, benefits, and why choosing expert services, like those from Marine Diesel Specialists, is critical for optimal results.

What is a Marine Diesel Engine Overhaul?

A marine diesel engine overhaul is a systematic procedure that involves disassembling, inspecting, cleaning, repairing, and replacing worn or damaged components to restore the engine to peak condition. Unlike a full engine replacement, an overhaul is a cost-effective solution that addresses wear, corrosion, and inefficiencies, ensuring the engine meets or exceeds manufacturer standards. Typically, marine diesel engines for generators require an overhaul after approximately 20,000 hours of operation, though this varies based on usage, maintenance history, and manufacturer guidelines.

The overhaul process is comprehensive, covering critical components like pistons, cylinder liners, crankshafts, bearings, and valves. It ensures the engine operates efficiently, delivers consistent power, and remains reliable under demanding marine conditions. By addressing issues proactively, an overhaul prevents costly failures and extends the engine’s service life.

Why is a Marine Diesel Engine Overhaul Necessary?

Marine engines operate in harsh environments, facing unique challenges compared to automotive engines. Here’s why overhauls are essential:

- High Operational Demands: Marine engines often run at or near full power for extended periods, unlike car engines, which typically operate below half throttle. For example, a 200hp marine outboard may consistently deliver 180hp, placing significant stress on components.

- Corrosive Environment: Saltwater exposure accelerates corrosion, particularly in cooling systems, even when heat exchangers are used to separate coolant from raw water.

- Wear and Tear: Constant vibration, high loads, and fluctuating conditions (e.g., propellers moving in and out of water in choppy seas) cause accelerated wear on pistons, bearings, and crankshafts.

- Preventive Maintenance: Regular overhauls, based on operating hours or manufacturer schedules, prevent unexpected breakdowns, ensuring safety and reliability during long voyages or commercial operations.

- Cost Efficiency: Overhauling an engine is significantly cheaper than replacing it, offering a like-new performance at a fraction of the cost.

Neglecting maintenance can lead to reduced performance, increased fuel consumption, and catastrophic engine failure, leaving vessels stranded or unsafe.

The Marine Diesel Engine Overhaul Process

The overhaul process is methodical and requires precision to ensure every component meets manufacturer specifications. Below is a detailed breakdown of the steps involved, as performed by expert marine rebuilders like Marine Diesel Specialists and Albion Marine Solutions.

Step-by-Step Overhaul Process

- Initial Assessment and Crankshaft Deflection Measurement

Before disassembly, technicians measure crankshaft deflection to assess alignment and identify potential issues. This ensures the crankshaft is not bent or stressed beyond acceptable limits. - Draining Crankcase Oil

All crankcase oil is drained to prepare the engine for disassembly and prevent contamination during the process. - Disassembly of Key Components

- Cylinder heads, pistons, piston rings, and main bearings are removed one by one for inspection.

- Connecting rod serrated ends are spray-checked for cracks, and bearings are visually inspected and measured with a micrometer for wear.

- Cylinder liners, gudgeon pins, and valves are removed for detailed evaluation.

- Inspection and Calibration

- Pistons and piston ring grooves are calibrated to check for wear or scoring.

- Cylinder liners are inspected for excessive wear or damage.

- Valves, valve seats, fuel injectors, air starting valves, and indicating cocks are cleaned and measured. Components exceeding manufacturer wear limits are replaced with genuine OEM parts.

- The crankshaft is checked for cracks, wear, or misalignment. If necessary, it is reground or replaced.

- Cleaning and Honing

- Cylinder liners are cleaned and honed to restore a smooth surface for optimal piston movement.

- Pistons and their grooves are thoroughly cleaned to remove carbon deposits and debris.

- The crankcase and oil filters are cleaned to ensure no contaminants remain.

- Replacement of Worn Components

- Worn pistons, piston rings, cylinder liners, bearings, gaskets, seals, and timing belts/chains are replaced with high-quality OEM or equivalent parts.

- New oil and compression rings are installed on pistons to ensure proper sealing and performance.

- Reassembly

- Pistons are lowered into honed cylinder liners.

- Connecting rod bearings are tightened to the manufacturer’s specified torque.

- Cylinder heads are reinstalled with new gaskets and tightened using a torque wrench to precise specifications.

- Tappet clearances for inlet and exhaust valves are adjusted for optimal performance.

- System Checks and Testing

- Jacket water circulation is opened to check for leaks, which are rectified if found.

- The fuel oil filter is cleaned or replaced.

- Fresh oil is added to the crankcase.

- All measurements, clearances, and replaced parts are documented for future reference.

- Running-In Procedure

After reassembly, the engine undergoes a manufacturer-recommended running-in procedure to ensure all components operate smoothly under load. This step verifies the overhaul’s success and prepares the engine for regular operation.

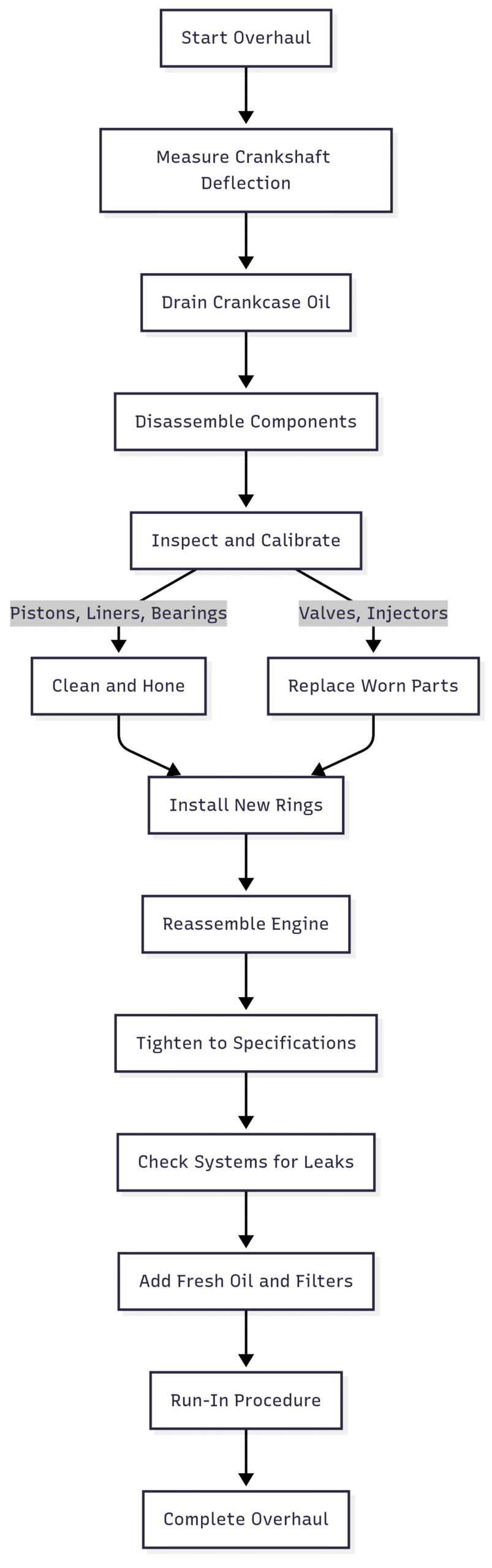

Chart: Marine Diesel Engine Overhaul Workflow

Below is a visual representation of the overhaul process using a flowchart:

This flowchart outlines the sequential steps, ensuring clarity for technicians and vessel owners.

Key Components Inspected and Replaced

The following table summarizes the critical components inspected during an overhaul, their purpose, and common actions taken:

| Component | Purpose | Inspection/Action |

|---|---|---|

| Pistons | Transfer power to crankshaft | Inspected for wear, scoring; replaced if needed |

| Piston Rings | Seal combustion chamber | Checked for sealing; replaced if worn |

| Cylinder Liners | House pistons | Inspected, cleaned, honed; replaced if worn |

| Connecting Rods | Link pistons to crankshaft | Checked for cracks, wear; replaced if needed18. |

Fuel System Maintenance

The fuel system—including injectors and filters—is critical for efficient combustion and power delivery. During an overhaul, fuel injectors are cleaned, tested, and recalibrated to ensure precise fuel delivery. Faulty injectors can lead to incomplete combustion, reduced power, and increased fuel consumption.

- Cleaning Fuel Oil Filter

The fuel oil filter is cleaned or replaced to prevent contaminants from entering the fuel system, which could cause blockages or damage. - Documentation

All measurements, clearances, and replaced parts are recorded for maintenance records. This documentation helps track engine health and plan future maintenance. - Running-In Procedure

The engine is run under controlled conditions to ensure all components work harmoniously. This step verifies the overhaul’s success and prepares the engine for regular operation.

Benefits of a Marine Diesel Engine Overhaul

- Restored Performance: The engine regains its original power output and efficiency, improving vessel speed and fuel economy.

- Extended Lifespan: Replacing worn components prevents further damage, potentially adding thousands of hours to the engine’s service life.

- Cost Savings: Overhauls are significantly cheaper than full engine replacements, offering like-new performance at a lower cost.

- Improved Reliability: Addressing wear and corrosion reduces the risk of unexpected breakdowns, ensuring safety during long voyages.

- Environmental Benefits: A well-maintained engine burns fuel more efficiently, reducing emissions and environmental impact.

Specifications and Costs

The specifications and costs of a marine diesel engine overhaul vary based on engine size, brand, and the extent of repairs needed. Below is an estimated cost breakdown for a typical medium-sized marine diesel engine (e.g., 200-500hp):

| Service/Item | Estimated Cost (USD) |

|---|---|

| Labor (50-100 hours) | $5,000 – $10,000 |

| OEM Parts (pistons, rings, etc.) | $2,000 – $5,000 |

| Crankshaft Grinding/Repair | $1,000 – $3,000 |

| Fuel System Servicing | $500 – $1,500 |

| Gaskets, Seals, and Filters | $500 – $1,000 |

| Total Estimated Cost | $9,000 – $20,000 |

Note: Costs vary based on engine complexity, vessel location, and labor rates. For precise pricing, contact professionals like Marine Diesel Specialists or Albion Marine Solutions.

Why Choose Professional Marine Engine Rebuilders?

Selecting a reputable service provider is critical for a successful overhaul. Marine Diesel Specialists and Albion Marine Solutions stand out for several reasons:

- Expertise: Both companies employ skilled technicians with extensive knowledge of marine diesel engines, including brands like MAN, Caterpillar, and Cummins.

- High-Quality Parts: They use OEM or equivalent parts, ensuring compatibility and durability.

- Precision Techniques: Advanced methods, such as crankshaft grinding and metal stitching, restore components to original specifications.

- Customer Focus: Personalized solutions and meticulous attention to detail ensure customer satisfaction.

- Proven Track Record: Both providers have a reputation for reliability, serving clients in Fort Lauderdale, Punta Gorda, and beyond.

Marine Diesel Specialists, for instance, is an authorized distributor of MAN diesel engines, known for their reliability and performance. Their Gulf Coast Diesel Service branch offers comprehensive maintenance, repair, and rebuild services, ensuring vessels are back on the water quickly.

Challenges and Considerations

While overhauls offer significant benefits, they come with challenges:

- Older Engines: Aging engines may be harder to start or operate due to wear on automatic starting systems, requiring additional repairs.

- Fuel System Issues: Contaminated fuel or clogged filters can reduce performance, necessitating regular maintenance.

- Corrosion: Saltwater exposure accelerates corrosion, particularly in cooling systems, even with heat exchangers.

- Downtime: Overhauls can take several weeks, depending on the engine’s condition and parts availability.

To mitigate these challenges, regular maintenance—such as oil changes, filter cleaning, and system flushes—can reduce the need for extensive repairs.

Comparison: Marine Diesel vs. Gasoline Engines

Marine diesel engines offer distinct advantages over gasoline engines, particularly for yachts and commercial vessels:

| Feature | Diesel Engine | Gasoline Engine |

|---|---|---|

| Fuel Efficiency | Higher, lower operating costs | Lower, higher fuel costs |

| Maintenance | Minimal, mainly oil changes | More frequent, complex repairs |

| Durability | Longer lifespan, robust design | Shorter lifespan, less robust |

| Power Output | Consistent high power for long trips | Variable, suited for shorter trips |

| Cost | Higher upfront, lower long-term costs | Lower upfront, higher maintenance |

Diesel engines are ideal for vessels requiring long-range travel and high power, while gasoline engines suit smaller, less frequent-use boats.

Expert Services at Marine Diesel Specialists

Marine Diesel Specialists offers a comprehensive suite of services, including:

- Engine Rebuilds: Full overhauls to restore performance and longevity.

- Routine Maintenance: Oil changes, filter replacements, and system checks.

- Repairs: Addressing specific issues like fuel system failures or corrosion damage.

- Engine Sales: Authorized distributor of MAN diesel engines, known for reliability and efficiency.

Their Fort Lauderdale and Punta Gorda teams provide personalized support, ensuring vessels meet operational demands. For more information, contact them at (954) 781-1464 or visit their marine engine blog for industry insights.

Conclusion

A marine diesel engine overhaul is a vital process for maintaining vessel performance, reliability, and longevity. By addressing wear, corrosion, and inefficiencies, an overhaul restores engines to like-new condition, saving costs compared to replacements. The meticulous process—disassembly, inspection, repair, and reassembly—requires expertise, high-quality parts, and adherence to manufacturer standards. Choosing professionals like Marine Diesel Specialists or Albion Marine Solutions ensures precision and durability, minimizing downtime and maximizing your boating experience. Whether for recreational or commercial vessels, a well-executed overhaul keeps your engine running smoothly, ensuring safety and efficiency on the water.

For expert marine diesel engine services, contact Marine Diesel Specialists or Albion Marine Solutions today to schedule an overhaul or explore their offerings.

Happy Boating!

Share What is a marine diesel engine overhaul? with your friends and leave a comment below with your thoughts.

Read Digital Resources for the Ship Engineering Department until we meet in the next article.