What are the Different Types of Marine Diesel Engines?

Discover the types of marine diesel engines, their features, and top manufacturers. Learn key factors to choose the best engine for your vessel.

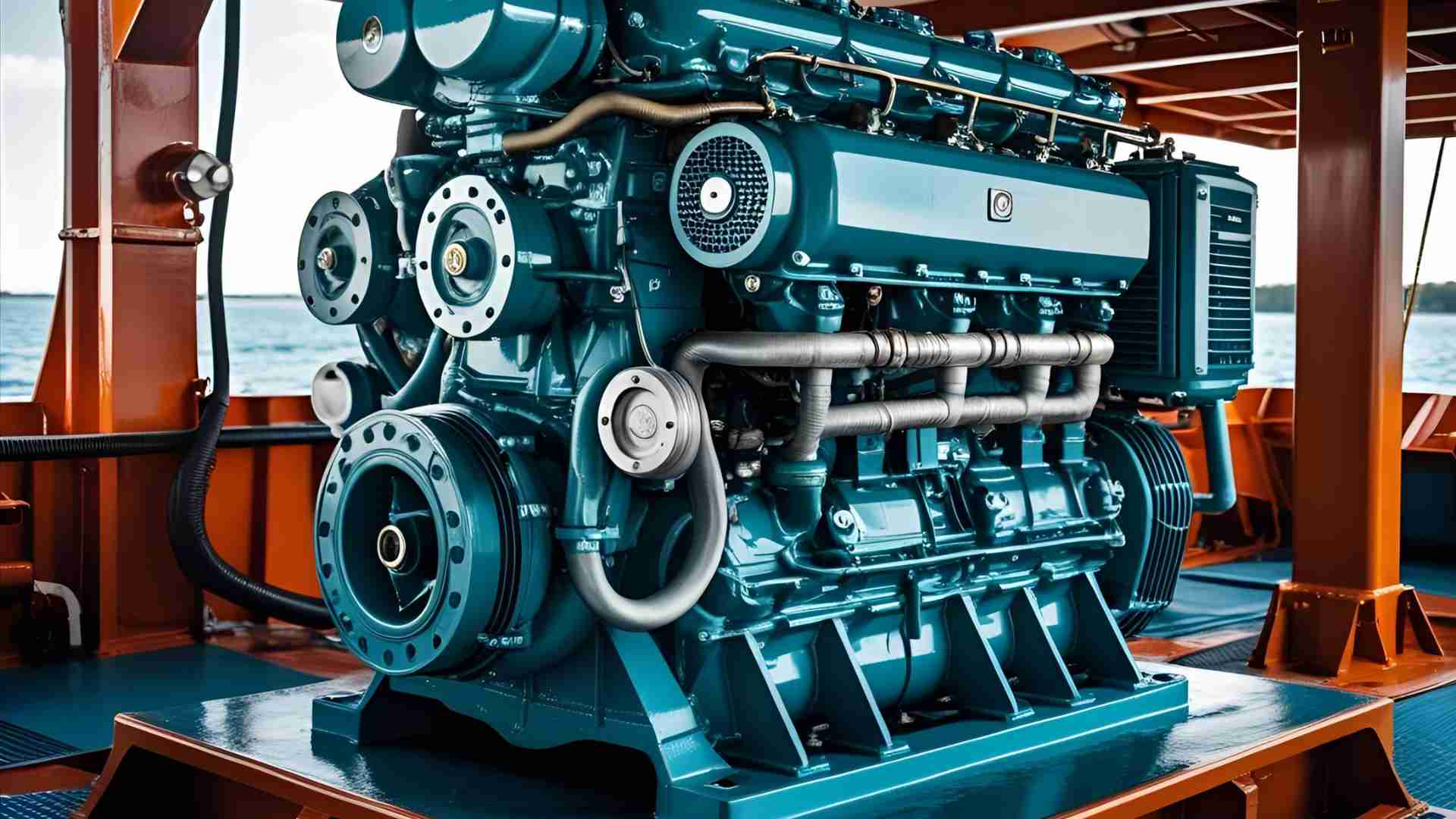

Marine diesel engines are the backbone of the maritime industry, powering everything from massive cargo ships to sleek yachts. Known for their durability, fuel efficiency, and reliability, these engines are designed to withstand the harsh marine environment while delivering consistent performance. Choosing the right marine diesel engine is critical for vessel owners, as it impacts performance, operating costs, and compliance with environmental regulations. This comprehensive guide explores the different types of marine diesel engines, their applications, key manufacturers, and essential factors to consider when selecting an engine.

Understanding Marine Diesel Engines

Marine diesel engines are internal combustion engines that run on diesel fuel, converting chemical energy into mechanical power to propel vessels. Unlike gasoline engines, diesel engines offer superior fuel efficiency and longevity, making them ideal for marine applications where reliability is paramount. They are classified based on operating speed (slow, medium, high) and cycle type (two-stroke or four-stroke), each tailored to specific vessel types and operational needs.

Why Choose Marine Diesel Engines?

Marine diesel engines stand out due to their:

- Durability: With proper maintenance, many engines can operate for over 20,000 hours without a major overhaul.

- Fuel Efficiency: Diesel engines consume less fuel per hour compared to gasoline engines, reducing operating costs.

- Reliability: Designed for continuous operation in challenging conditions, they are trusted by commercial and recreational vessels worldwide.

- Compliance: Modern engines meet stringent emissions standards like IMO Tier III and EPA Tier 4, reducing environmental impact.

Types of Marine Diesel Engines

Marine diesel engines are categorized by their operating speed and cycle type. Below, we explore each type, their applications, and performance characteristics.

By Operating Speed

Slow-Speed Diesel Engines

Slow-speed engines operate at 60–200 RPM and are primarily used in large vessels such as cargo ships, oil tankers, and bulk carriers. These engines, typically two-stroke, deliver immense torque to move heavy loads over long distances.

- Applications: Container ships, oil tankers, cruise liners.

- Advantages: Exceptional fuel efficiency, long service life, high torque.

- Disadvantages: Large size and weight, higher initial cost.

- Example: MAN B&W slow-speed engines power many of the world’s largest ships.

Medium-Speed Diesel Engines

Medium-speed engines run at 200–1,000 RPM and are versatile, used in ferries, tugboats, offshore supply vessels, and some yachts. They are usually four-stroke engines, balancing power and efficiency.

- Applications: Ferries, tugboats, offshore vessels, large yachts.

- Advantages: Compact size, good fuel efficiency, adaptable to various vessel types.

- Disadvantages: Higher maintenance frequency compared to slow-speed engines.

- Example: Caterpillar’s MaK series is popular for medium-speed applications.

High-Speed Diesel Engines

High-speed engines operate above 1,000 RPM and are found in smaller vessels like patrol boats, sportfishing boats, and pleasure yachts. These four-stroke engines prioritize speed and responsiveness.

- Applications: Patrol boats, yachts, fast ferries, pleasure boats.

- Advantages: Lightweight, compact, quick acceleration.

- Disadvantages: Higher fuel consumption, more frequent maintenance.

- Example: Volvo Penta’s high-speed engines are known for their performance in recreational boating.

By Cycle Type

Two-Stroke Engines

Two-stroke engines complete a power cycle in two piston strokes (one crankshaft revolution), delivering power with every downward stroke. They are favored in large ships due to their high power-to-weight ratio.

- Applications: Large commercial vessels like container ships and tankers.

- Advantages: High power output, simpler design, lighter weight.

- Disadvantages: Less fuel-efficient, higher emissions, noisier operation.

- Example: Detroit Diesel’s two-stroke engines are used in some marine applications.

Four-Stroke Engines

Four-stroke engines complete a power cycle in four piston strokes (two crankshaft revolutions): intake, compression, power, and exhaust. They are common in smaller vessels and auxiliary power systems.

- Applications: Yachts, ferries, fishing boats, auxiliary generators.

- Advantages: Better fuel efficiency, lower emissions, quieter operation.

- Disadvantages: Heavier and more complex than two-stroke engines.

- Example: Cummins’ four-stroke marine engines comply with EPA Tier III standards.

Turbocharged vs. Non-Turbocharged Engines

- Turbocharged Engines: Use a turbocharger to force extra air into the combustion chamber, boosting power without increasing engine size. Ideal for high-performance vessels like yachts and sportfishing boats.

- Advantages: Higher power output, improved fuel efficiency.

- Disadvantages: Increased maintenance complexity.

- Example: Mercury Marine’s turbocharged inboard engines.

- Non-Turbocharged Engines: Rely on natural aspiration for air intake, offering simplicity and reliability. Suitable for smaller boats or applications prioritizing low maintenance.

- Advantages: Easier maintenance, longer lifespan.

- Disadvantages: Lower power output.

- Example: Yanmar’s naturally aspirated inboard engines.

Key Manufacturers of Marine Diesel Engines

Several manufacturers dominate the marine diesel engine market, each offering unique strengths and specialties. Below is an overview of the top players:

| Manufacturer | Specialty | Notable Features | Sample Models |

|---|---|---|---|

| Caterpillar | Wide range of engines for all vessel types | High reliability, global service network | Cat C32, MaK M 46 DF |

| Cummins | EPA Tier III-compliant engines | Fuel efficiency, compact design | QSB6.7, B4.5L |

| MAN | Large vessel engines | High power output, IMO Tier III compliance | MAN B&W 6S90ME-C |

| Volvo Penta | Recreational and commercial engines | Advanced turbocharging, low noise | D13, IPS series |

| Yanmar | Inboard and outboard engines | Lightweight, reliable, fuel-efficient | 4JH, 6LY series |

| MTU | High-performance engines | High power density, advanced electronics | Series 4000 |

| John Deere | Durable engines for fishing boats | Simple design, easy maintenance | PowerTech 4045 |

| Scania | Medium- and high-speed engines | High efficiency, robust construction | DI16 |

| Mercury Marine | Inboard and sterndrive engines | Turbocharging, precision engineering | TDI 4.2L |

| Beta Marine | Small vessel engines | Reliable, customizable | Beta 50 |

Manufacturer Highlights

- Caterpillar: Known for its extensive range, from small yacht engines to massive slow-speed engines for tankers. Its global service network ensures easy access to parts and maintenance.

- Cummins: Focuses on fuel-efficient, environmentally compliant engines, particularly for fishing boats and recreational vessels.

- MAN: A leader in slow-speed engines for large commercial ships, offering high power and compliance with IMO Tier III standards.

- Volvo Penta: Popular in the recreational boating market, its engines feature advanced turbocharging and low noise levels.

- Yanmar: Offers lightweight, reliable engines for both commercial and pleasure boats, with a strong reputation for durability.

Performance Considerations

Selecting a marine diesel engine requires evaluating several performance factors to ensure it meets your vessel’s needs. Below are the key considerations:

Fuel Efficiency

Fuel efficiency is critical for reducing operating costs, especially for long voyages. Modern marine diesel engines, like the Wärtsilä 31, are designed for optimal fuel consumption. Turbocharged and four-stroke engines typically offer better fuel economy than two-stroke or non-turbocharged models.

- Example: Cummins QSB6.7 achieves up to 20% better fuel efficiency compared to older models.

- Tip: Regular maintenance, including fuel injection services, can further improve fuel economy.

Emissions Compliance

Stringent regulations like IMO Tier III and EPA Tier 4 aim to reduce nitrogen oxides (NOx) and particulate matter (PM) emissions. Most modern engines incorporate technologies like selective catalytic reduction (SCR) and exhaust gas recirculation (EGR) to meet these standards.

- Example: MAN’s SCR systems reduce NOx emissions by up to 80%.

- Tip: Ensure your engine complies with local and international emissions regulations to avoid fines.

Reliability and Longevity

Marine diesel engines are built for durability, with many lasting 5,000–20,000 hours before requiring a major overhaul. Brands like Detroit Diesel are renowned for their robust construction and interchangeable parts, simplifying maintenance.

- Example: Caterpillar’s Cat C32 engines are known to exceed 10,000 hours with proper care.

- Tip: Choose engines with accessible service points and a strong manufacturer support network.

Noise and Vibration

Modern engines incorporate noise-dampening technologies for a quieter boating experience, especially important for recreational vessels. Four-stroke engines generally produce less noise than two-stroke engines.

- Example: Volvo Penta’s D13 engines feature advanced insulation for reduced noise levels.

- Tip: Test drive engines to assess noise and vibration under operating conditions.

Maintenance and Serviceability

Ease of maintenance is crucial for minimizing downtime. Engines with accessible service points and interchangeable parts reduce repair costs and time. Manufacturers like Yanmar and John Deere design engines with maintenance in mind.

- Example: Beta Marine’s engines allow easy access to filters and belts.

- Tip: Verify the availability of spare parts and service centers in your boating area.

Key Factors to Consider When Choosing a Marine Diesel Engine

Choosing the right engine involves balancing performance, cost, and practical considerations. Below are the essential factors to evaluate:

- Power Requirements: Calculate the horsepower needed based on your vessel’s size, weight, and intended use. For example, a 50-hp difference can significantly impact performance when carrying heavy loads.

- Engine Size and Weight: Ensure the engine fits within your vessel’s space and weight capacity. Lightweight materials improve the power-to-weight ratio, enhancing performance.

- Fuel Efficiency: Opt for engines with proven fuel economy, especially for long-distance travel. Turbocharged and four-stroke engines are typically more efficient.

- Emissions Compliance: Verify that the engine meets IMO and EPA standards to avoid regulatory issues.

- Cooling System: Marine engines require robust saltwater cooling systems to operate reliably in ocean environments.

- Maintenance Needs: Choose engines with accessible service points and available spare parts. Review the manufacturer’s maintenance schedule.

- Brand Reputation: Select reputable brands like Caterpillar, Cummins, or Volvo Penta with strong after-sales support.

- Test Drive: Conduct sea trials to evaluate performance, noise, and handling under real-world conditions.

- Propulsion Type: Match the engine to your vessel’s hull type (displacement, semi-displacement, or planing) for optimal performance.

- Warranty and Service: Check warranty terms and the availability of service centers in your area.

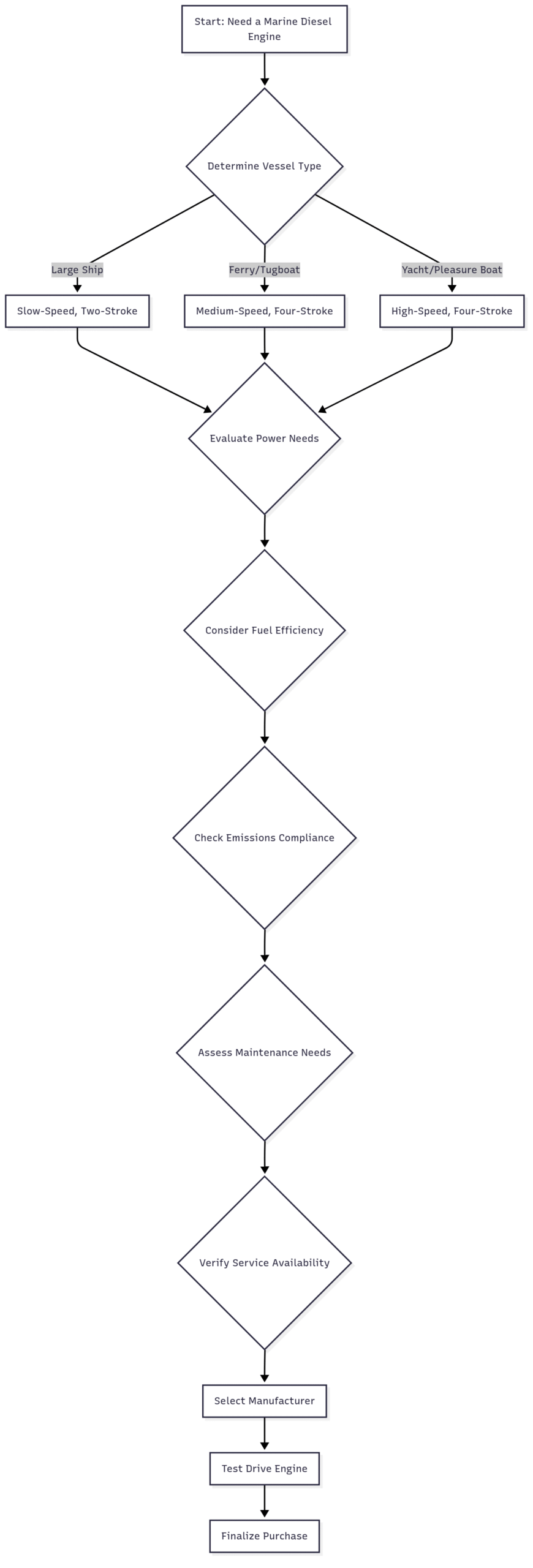

Sample Decision-Making Flowchart

Below is a flowchart to guide the engine selection process:

Comparing Marine Diesel vs. Gasoline Engines

When deciding between diesel and gasoline engines, consider the following:

| Feature | Marine Diesel Engines | Marine Gasoline Engines |

|---|---|---|

| Fuel Efficiency | Higher (less fuel per hour) | Lower (higher fuel consumption) |

| Longevity | Up to 20,000 hours with maintenance | Typically 1,500–3,000 hours |

| Cost | Higher initial cost, lower operating cost | Lower initial cost, higher operating cost |

| Emissions | Lower with modern technology | Higher, less regulated |

| Maintenance | More complex, requires specialized tools | Simpler, more DIY-friendly |

| Power Delivery | High torque, steady power | High speed, less torque |

Verdict: Diesel engines are ideal for vessels requiring long-range travel, heavy loads, or commercial use. Gasoline engines suit smaller, recreational boats prioritizing lower upfront costs.

Pricing and Specifications

Marine diesel engine prices vary based on power, type, and manufacturer. Below is a sample pricing guide for popular models:

| Engine Model | Manufacturer | Power (HP) | Type | Approx. Price (USD) |

|---|---|---|---|---|

| Cat C32 | Caterpillar | 1,600 | Medium-Speed | $150,000–$200,000 |

| QSB6.7 | Cummins | 480 | High-Speed | $40,000–$60,000 |

| D13 | Volvo Penta | 800 | High-Speed | $80,000–$100,000 |

| 6LY | Yanmar | 440 | High-Speed | $35,000–$50,000 |

| MAN B&W 6S90ME-C | MAN | 40,000+ | Slow-Speed | $1M–$2M+ |

Note: Prices are indicative and vary based on configuration, region, and dealer. Contact manufacturers for precise quotes.

Frequently Asked Questions

What is the most reliable marine diesel engine?

What is the difference between marine diesel and regular diesel?

What is the life expectancy of a marine diesel engine?

Conclusion

Choosing the right marine diesel engine is a critical decision that affects your vessel’s performance, efficiency, and longevity. By understanding the different types—slow-speed, medium-speed, high-speed, two-stroke, and four-stroke—you can select an engine tailored to your vessel’s needs. Key factors like fuel efficiency, emissions compliance, and maintenance requirements should guide your decision, alongside reputable manufacturers like Caterpillar, Cummins, and Volvo Penta.

For expert guidance, consult with marine engine specialists like RPM Diesel or CS Diesel Generators, who offer new and used engines, parts, and worldwide service. Conduct sea trials, verify service availability, and ensure compliance with emissions standards to make an informed investment. With the right marine diesel engine, you’ll enjoy reliable, efficient, and powerful performance on the water for years to come.

Happy Boating!

Share What are the Different Types of Marine Diesel Engines? with your friends and leave a comment below with your thoughts.

Read Segregated Ballast Tanks on Tankers until we meet in the next article.