Weathertight or watertight doors, that’ s the question

Explore watertight vs. weathertight doors on ships: their purpose, construction, and role in safety. Learn key differences and maintenance tips.

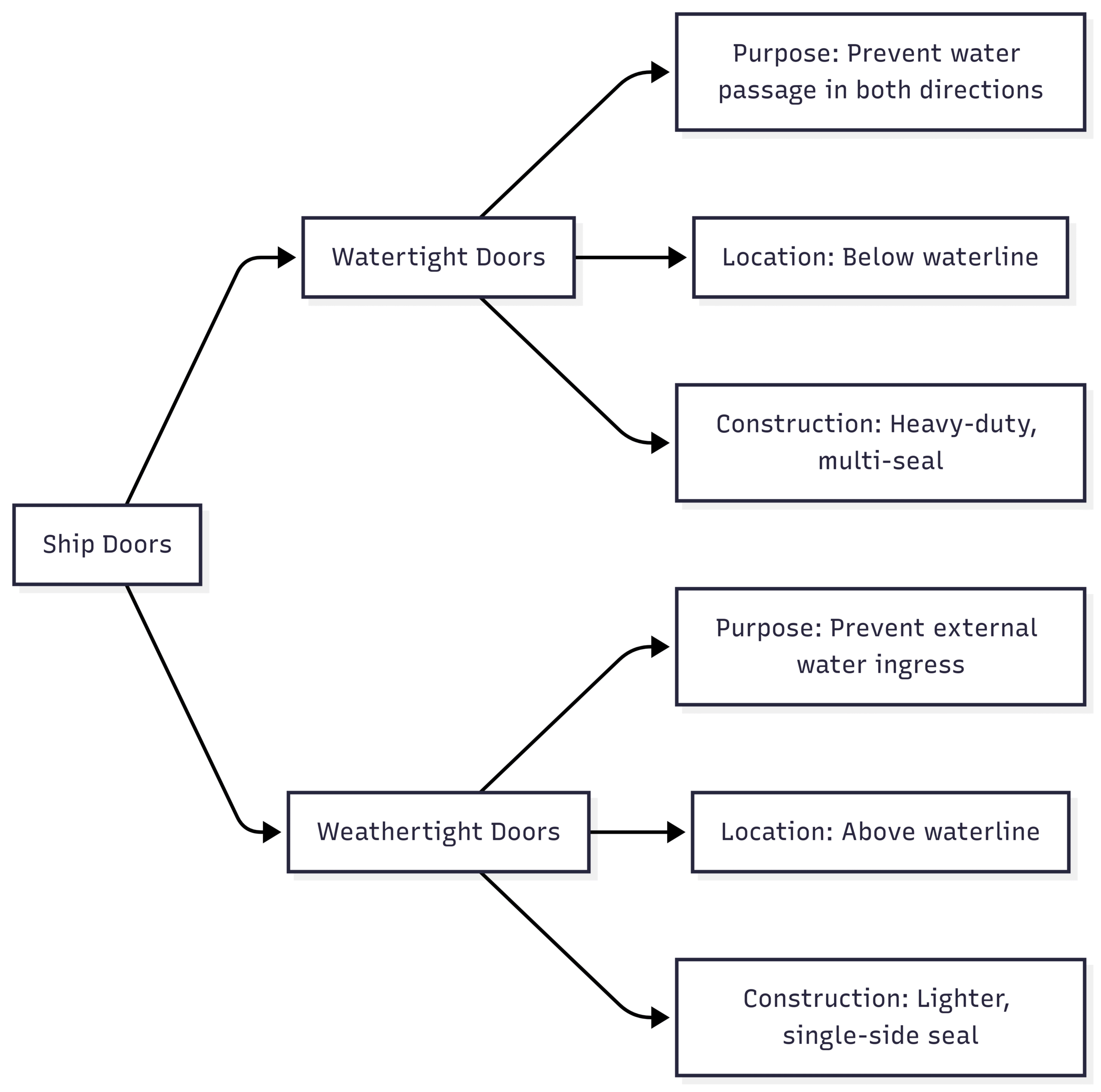

In the maritime industry, safety is paramount, and the choice between watertight and weathertight doors plays a critical role in protecting ships, crews, and passengers. These specialized doors, designed to address distinct environmental challenges, are integral to a vessel’s structural integrity and operational safety. While both serve to prevent water ingress, their purposes, locations, and construction differ significantly. This article delves into the differences between watertight and weathertight doors, their operational requirements, maintenance practices, and their importance in maritime safety, drawing from industry standards and real-world incidents.

Understanding Watertight Doors

Purpose and Functionality

Watertight doors are engineered to prevent water from passing between compartments, even under significant pressure, ensuring a ship’s stability and buoyancy during flooding. According to the International Convention for the Safety of Life at Sea (SOLAS), a watertight door must withstand water pressure from both sides, making it a critical component in maintaining a vessel’s watertight integrity. These doors are vital in scenarios where flooding could compromise a ship’s ability to stay afloat, such as in collisions, groundings, or hull breaches.

Location

Watertight doors are primarily installed below the waterline in areas like engine rooms, ballast tanks, shaft tunnels, and bow thruster compartments. These locations are prone to flooding during accidents, making the doors’ ability to contain water essential for compartmentalization. For example, a watertight door in a ballast tank must withstand a water column of up to 15 meters or more, preventing water from spreading to adjacent compartments.

Construction and Design

Watertight doors are built to endure extreme conditions. Key construction features include:

- Robust Materials: Typically constructed from steel or other high-strength materials to withstand significant water pressure.

- Sealing Mechanisms: Equipped with multiple rubber gaskets and locking mechanisms (often referred to as “dogs”) to ensure a tight seal.

- Operational Systems: Available in hinged or sliding configurations, with sliding doors often powered by hydraulic or electric systems for quick operation. Hinged doors may be manually operated but are designed for strength and reliability.

Watertight doors are tested rigorously, often in tanks where water pressure is applied from both sides to simulate flooding conditions. This ensures they can maintain integrity whether water pressure comes from inside or outside the compartment. Classification societies, such as Lloyd’s Register or DNV, mandate strict standards for these doors, requiring certification to ensure compliance.

Types of Watertight Doors

SOLAS categorizes watertight doors into four types based on their operational requirements:

| Type | Description | Usage |

|---|---|---|

| Type A | May remain open, closed only during emergencies. | Used in areas with infrequent access. |

| Type B | Must remain closed, opened only when personnel are working in adjacent compartments. | Common in high-risk areas like engine rooms. |

| Type C | Must remain closed at all times, opened briefly for personnel passage. | Used in critical compartments like ballast tanks. |

| Type D | Non-SOLAS compliant, must remain closed during navigation. | Found in older or less critical systems. |

Operational Requirements

SOLAS Chapter II-1 (Regulations 14–25) outlines specific requirements for watertight doors:

- Closure Time: Powered watertight doors must close within 20–40 seconds when operated remotely from the bridge or Ship Control Center (SCC), and within 60 seconds when closing all doors simultaneously.

- Emergency Operation: In case of power failure, doors must be closable within 90 seconds manually.

- Alarms and Indicators: A local audible alarm must sound for 5–10 seconds before a door closes remotely, and visual indicators (red for open, green for closed) must be present at remote operating stations.

- List Tolerance: Doors must function with the ship listed up to 15 degrees on either side.

These requirements ensure that watertight doors can be operated efficiently during emergencies, minimizing the risk of flooding.

Understanding Weathertight Doors

Purpose and Functionality

Weathertight doors are designed to prevent water ingress from external sources, such as waves, rain, or spray, protecting a ship’s interior from adverse weather conditions. Unlike watertight doors, they are not built to withstand continuous submersion or water pressure from both sides. Their primary role is to shield areas above the waterline, ensuring crew comfort and protecting equipment from environmental damage.

Location

Weathertight doors are typically found above the waterline, on decks, in wheelhouses, or in accommodation areas exposed to weather elements. For instance, a door leading to a ship’s deck must withstand green seas (solid waves hitting the deck) without allowing water to enter the interior.

Construction and Design

Weathertight doors are constructed with durability in mind but are less robust than watertight doors:

- Materials: Made from steel, aluminum, or composite materials, designed to resist corrosion from saltwater exposure.

- Sealing Mechanisms: Equipped with rubber gaskets and locking dogs to create a seal against external water pressure. Unlike watertight doors, they are not designed to handle internal pressure.

- Design Features: Often include drainage systems to manage water that may accumulate during heavy weather. They typically open outward to leverage water pressure for a tighter seal.

Weathertight doors are tested using high-pressure hoses directed at the seals to simulate wave impact, ensuring they can withstand brief submersion. Classification is generally not required, as their role is less critical to a ship’s survival than watertight doors.

Available Models

Manufacturers like July Marine offer weathertight doors in various configurations:

- Four-Dog Operating Door: Standard model with four locking points for secure sealing.

- Six-Dog Operating Door: Enhanced model with additional locking points for larger doors or harsher conditions.

- Quick-Acting Operating Door: Designed for rapid opening and closing, ideal for high-traffic areas.

These doors can be customized with options like square or radiused edges, different window types, and material choices to meet specific vessel requirements.

Key Differences Between Watertight and Weathertight Doors

To clarify the distinctions, the following table summarizes the key differences:

| Feature | Watertight Doors | Weathertight Doors |

|---|---|---|

| Purpose | Prevent water passage in both directions under pressure. | Prevent water ingress from external weather conditions. |

| Location | Below waterline (e.g., engine rooms, ballast tanks). | Above waterline (e.g., decks, accommodation areas). |

| Construction | Heavy-duty steel, multiple seals, designed for high pressure. | Lighter materials, single-side sealing, less pressure resistance. |

| Pressure Resistance | Can withstand water column (e.g., 15m) from both sides. | Resists brief external water pressure (e.g., waves). |

| Certification | Requires strict SOLAS compliance and classification. | Less stringent, often tested with hose pressure. |

| Operation | Hinged or sliding, often powered (hydraulic/electric). | Hinged, manual or quick-acting mechanisms. |

Fire Doors: A Brief Comparison

While the focus is on watertight and weathertight doors, fire doors are another critical component of maritime safety. They are designed to contain smoke and flames, preventing fire spread between compartments. Key features include:

- Fire Ratings: Rated for 30, 60, 90, or 120 minutes of fire resistance.

- Materials: Constructed from steel with intumescent seals that expand under heat.

- Operation: Equipped with self-closing mechanisms to ensure automatic closure during a fire.

Unlike watertight and weathertight doors, fire doors prioritize fire and smoke containment over water resistance, making them essential for crew and passenger safety in fire emergencies.

Importance in Maritime Safety

The significance of watertight and weathertight doors is underscored by historical maritime disasters:

- Herald of Free Enterprise (1987): The ferry capsized due to flooding through improperly closed bow doors, highlighting the critical role of watertight integrity. The disaster resulted in 193 deaths, emphasizing the need for proper door operation and crew training.

- Costa Concordia (2012): The partial sinking of this cruise ship demonstrated the consequences of inadequate watertight compartmentalization, with 32 lives lost due to flooding spreading beyond damaged areas.

- Titanic (1912): The ship’s sinking, with over 1,500 fatalities, exposed the limitations of early watertight door designs, leading to stricter SOLAS regulations.

These incidents highlight the necessity of robust door systems and crew preparedness to prevent catastrophic outcomes.

Operational Risks and Safety Protocols

Watertight doors, particularly powered sliding doors, pose significant risks if mishandled:

- Injury Risks: The heavy, high-force closure of powered doors can cause severe injuries, including crushed limbs or fatalities, if crew members are caught in the closing mechanism.

- Stability Risks: Leaving watertight doors open during flooding can compromise a ship’s stability, leading to capsizing or sinking.

- Fire and Smoke Spread: Open doors can allow fire or smoke to spread, endangering lives and equipment.

To mitigate these risks, SOLAS mandates regular drills and safety protocols:

- Weekly Drills: All watertight doors must be operated during weekly drills to ensure functionality.

- Daily Checks: Doors should be inspected during routine rounds, with operation tested from both local and remote controls.

- Crew Training: Crew members must be trained in safe operation, including avoiding passage through moving doors and understanding alarm systems.

- Clear Signage: Doors must display operating instructions and their SOLAS category (A, B, C, or D) in the ship’s working language.

Maintenance Practices

Proper maintenance is critical to ensure door functionality during emergencies. The ship’s Planned Maintenance System (PMS) should include:

- Routine Inspections: Monthly checks of seals, gaskets, and operational mechanisms for wear, corrosion, or damage.

- Cleaning: Regular cleaning of door frames and gaskets to prevent corrosion, with silicone oil lubrication for gaskets.

- Hydraulic/Electric Systems: Periodic checks for leaks, oil levels, and pump conditions, with oil and filter replacements as per PMS schedules.

- Structural Integrity: Inspections for cracks, indentations, or corrosion in door frames and steel structures.

- Testing: Regular testing of alarms, indicators, and self-closing mechanisms to ensure compliance with SOLAS standards.

Neglecting maintenance can lead to deficiencies noted by Port State Control inspectors, potentially resulting in vessel detention. Common issues include missing gaskets, hydraulic leaks, and faulty alarms.

Specifications and Pricing

While specific pricing varies by manufacturer and customization, typical specifications and cost ranges for watertight and weathertight doors are:

| Door Type | Specifications | Estimated Price Range (USD) |

|---|---|---|

| Watertight Door (Hinged) | Steel, 4–6 dogs, SOLAS-compliant, hydraulic/manual, 0.8m x 1.8m | $5,000–$15,000 |

| Watertight Door (Sliding) | Steel, hydraulic/electric, 1m x 2m, SOLAS-compliant | $10,000–$25,000 |

| Weathertight Door (Four-Dog) | Steel/aluminum, 4 dogs, 0.8m x 1.8m, hose-tested | $2,000–$7,000 |

| Weathertight Door (Quick-Acting) | Steel, quick-acting mechanism, 0.9m x 1.9m | $3,000–$9,000 |

Note: Prices are indicative and depend on size, material, and customization. Contact manufacturers like July Marine for precise quotes.

Industry Contributions

Manufacturers, classification societies, and flag administrations play a vital role in enhancing door safety:

- Manufacturers: Companies like July Marine produce doors to meet SOLAS and industry standards, offering customization to suit vessel needs.

- Classification Societies: Organizations like Lloyd’s Register ensure doors meet rigorous testing and certification requirements.

- Flag Administrations: Enforce compliance through inspections and regulations, ensuring vessels maintain safety standards.

Conclusion

Watertight and weathertight doors are indispensable for maritime safety, each serving a unique role in protecting ships from flooding and weather-related risks. Watertight doors, located below the waterline, ensure compartmentalization during flooding, while weathertight doors, positioned above the waterline, shield interiors from waves and rain. Adhering to SOLAS regulations, conducting regular maintenance, and training crew members are critical to ensuring these doors function effectively in emergencies. Historical incidents like the Herald of Free Enterprise and Costa Concordia underscore the catastrophic consequences of neglecting these systems. By prioritizing proper design, operation, and maintenance, the maritime industry can safeguard vessels, crews, and passengers, ensuring safer navigation across the world’s oceans.

Happy Boating!

Share Weathertight or watertight doors, that’ s the question with your friends and leave a comment below with your thoughts.

Read How to keep your boiler and cooling systems in top condition until we meet in the next article.