Ways of starting and testing emergency generator on a Ship

Learn how to start and test an emergency generator on a ship, ensuring safety and compliance with maritime regulations.

Emergency generators are the unsung heroes of maritime operations, acting as a critical lifeline when a ship’s main power supply fails. These robust systems ensure that essential equipment—such as navigation aids, communication devices, and emergency lighting—remains operational during a blackout, safeguarding the vessel and its crew. This article provides an in-depth exploration of how to start and test emergency generators on ships, their key components, maintenance requirements, and compliance with international maritime regulations. Designed for ship engineers, crew members, and maritime professionals, this guide offers practical insights and technical details to ensure these systems perform reliably in critical situations.

The Role of Emergency Generators on Ships

Emergency generators are standalone power sources designed to activate automatically when a ship’s main generators fail, preventing a complete blackout. Positioned outside the main machinery spaces and above the uppermost continuous deck, they are strategically placed to avoid damage from incidents like engine room fires or flooding. Their primary role is to supply power to critical systems, including:

- Navigation Equipment: Radar, GPS, and navigation lights to ensure safe maneuvering.

- Communication Systems: VHF, MF, and MF/HF radio installations for emergency communication.

- Emergency Lighting: Illumination for alleyways, stairways, muster stations, and engine rooms.

- Safety Systems: Fire detection, alarms, emergency fire pumps, and watertight doors.

- Steering Gear: Ensures the ship remains controllable during power loss.

Without a functional emergency generator, a ship could face catastrophic consequences, including loss of navigation, inability to communicate, or failure to operate critical safety systems. International maritime regulations, such as those set by the International Maritime Organization (IMO) under the SOLAS (Safety of Life at Sea) convention, mandate that all passenger and cargo ships be equipped with reliable emergency power sources.

Key Components of an Emergency Generator

Understanding the components of an emergency generator is essential for effective operation and maintenance. Below are the critical parts of a typical marine emergency generator:

| Component | Description |

|---|---|

| Marine Diesel Oil (MDO) Tank | Stores fuel with a flashpoint of at least 43°C, sufficient for 18–36 hours of operation. |

| Air Filters | Cleans combustion air using oil bath or dry-type (cartridge or dust collector) filters. |

| Fuel Filters | Ensures clean diesel enters the engine, preventing clogs or damage. |

| Mechanical Spring Starter | Initiates engine cranking during power failure, often backed by a small electric motor. |

| Engine Sump Oil | Lubricates the engine; regular checks ensure no contamination by carbon or soot. |

| Radiator | Cools the engine with water to maintain optimal operating temperatures. |

| Pump System | Delivers diesel fuel to the engine for combustion. |

| Leak-Off Mechanism | Detects fuel leaks, triggering alarms if oil levels rise abnormally. |

| Main Control Panel | Displays critical parameters like RPM, lube oil pressure, and coolant temperature. |

These components work together to ensure the generator starts reliably and operates efficiently during emergencies. For example, the MDO tank must always have enough fuel to meet regulatory requirements (18 hours for cargo ships, 36 hours for passenger ships), and the sump oil must be checked regularly to maintain engine health.

Starting an Emergency Generator: Step-by-Step Procedures

Emergency generators are designed to start automatically within 45 seconds of a main power failure, but manual and hydraulic starting modes are also required as backups. Below are the detailed procedures for each starting method.

Battery Start Procedure

The battery start mode is the primary method for most emergency generators, relying on a charged battery to crank the engine. Here’s how to perform a battery start:

- Locate the Control Panel: Access the emergency generator room and find the control panel.

- Switch to Test Mode: Move the mode selector switch from “Automatic” to “Test.” This starts the generator without connecting it to the load.

- Monitor Parameters: Check the voltage and frequency on the panel’s meters to ensure they are within acceptable ranges (typically 440V or 220V, 50/60 Hz).

- Run the Generator: Allow the generator to run for 10–15 minutes, monitoring exhaust temperature, lube oil pressure, and other parameters.

- Check Sump Oil Level: Verify the oil level in the sump to ensure it’s adequate and free of contaminants.

- Stop the Generator: Switch the mode selector to “Manual” and press the stop button to shut down the generator.

Hydraulic/Pneumatic Start Procedure

The hydraulic or pneumatic start is a secondary mode, using stored pressure to crank the engine. This is critical if the battery fails. The procedure is as follows:

- Set to Manual Mode: Switch the control panel to “Manual” mode.

- Check Oil Pressure: Ensure the hydraulic accumulator has sufficient pressure (check the pressure gauge).

- Open the Valve: Open the valve connecting the accumulator to the generator.

- Activate the Starter: Push the spring-loaded valve to start the generator.

- Monitor Parameters: Verify voltage and frequency, and run the generator for 10–15 minutes while checking exhaust temperature and other parameters.

- Check Sump Oil Level: Confirm the oil level and condition.

- Stop the Generator: Press the manual stop button, then repressurize the hydraulic accumulator and close the valve.

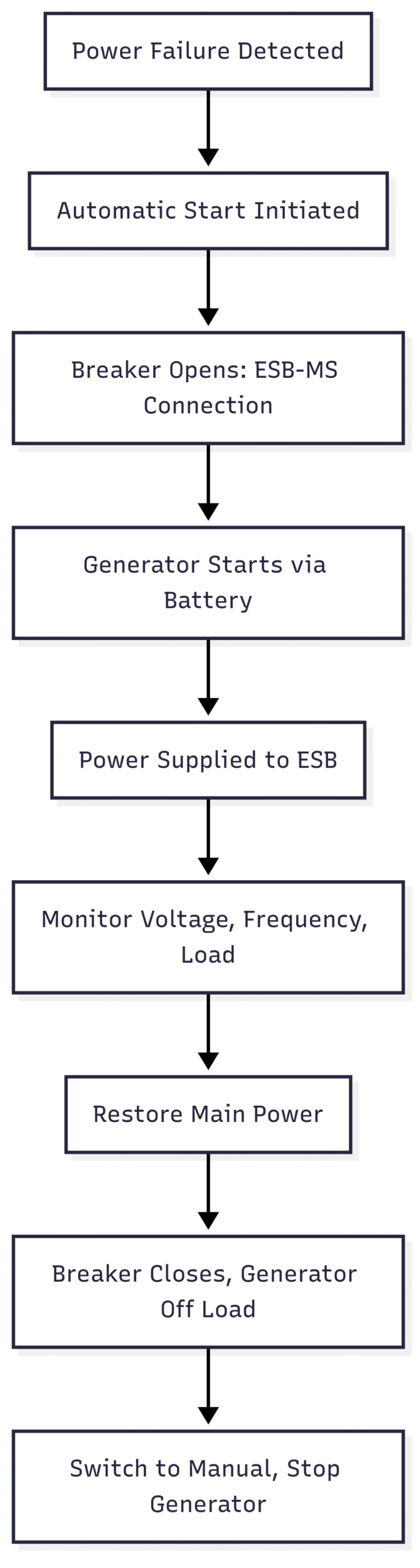

Automatic Start Procedure

The automatic start is the default mode, triggered by a power failure. It relies on an interlock system to prevent simultaneous operation with the main power supply. Here’s how it works:

- Simulate Power Failure: Open the breaker connecting the Emergency Switch Board (ESB) to the Main Switch Board (MSB) from either panel.

- Automatic Activation: The generator starts automatically using the battery and connects to the ESB to supply power to essential systems.

- Monitor Operation: Ensure the generator is supplying power correctly, checking voltage, frequency, and load distribution.

- Stop the Generator: Close the breaker to restore main power. The interlock will take the generator off load. Switch to “Manual” mode and press the stop button.

Testing the Emergency Generator

Regular testing ensures the emergency generator is ready for operation. Tests are conducted weekly, monthly, and quarterly, each focusing on different aspects of performance.

Weekly Testing

- Purpose: Verify battery start functionality.

- Procedure: Run the generator unloaded in test mode for 10–15 minutes. Check voltage, frequency, and general operation.

- Key Checks: Battery charge, sump oil level, and exhaust temperature.

Monthly Testing

- Purpose: Test hydraulic/pneumatic start and automatic operation.

- Procedure: Perform a hydraulic start as described above and simulate a power failure to test automatic start. Ensure the generator comes on load.

- Key Checks: Hydraulic pressure, interlock functionality, and load distribution.

Quarterly Load Testing

- Purpose: Verify performance under load.

- Procedure: Run the generator on load for an extended period (e.g., 1–2 hours) to test the prime mover, circuit breakers, and fuel system.

- Key Checks: Monitor fuel consumption, engine temperature, and electrical output stability.

| Test Type | Frequency | Duration | Key Parameters Checked |

|---|---|---|---|

| Weekly Test | Weekly | 10–15 minutes | Battery start, voltage, frequency, sump oil |

| Monthly Test | Monthly | 10–15 minutes | Hydraulic start, automatic operation, interlock |

| Quarterly Load Test | Every 3 months | 1–2 hours | Load performance, fuel system, circuit breakers |

Maintenance of Emergency Generators

Regular maintenance is critical to ensure reliability. The following tasks should be performed:

- Fuel System: Check the MDO tank level to ensure it’s above the minimum mark for 18–36 hours of operation. Inspect fuel filters for clogs and replace as needed.

- Air Filters: Clean or replace air filters (oil bath or dry type) to ensure proper combustion.

- Sump Oil: Check oil levels weekly and inspect for contamination. Change oil if carbon or soot is present.

- Cooling System: Verify radiator water levels and treat with antifreeze in cold climates. Ensure heating arrangements are functional for temperatures below 0°C.

- Batteries: Ensure batteries are fully charged and capable of at least three consecutive starts without recharging.

- Control Panel: Regularly inspect for accurate readings of RPM, lube oil pressure, and coolant temperature.

- Emergency Lighting: Test emergency lights weekly to ensure they function during a blackout.

Emergency Switchboard and Load Distribution

The Emergency Switch Board (ESB) distributes power from the emergency generator to critical systems. It has two sections:

- 440V Section: Powers high-voltage equipment like emergency bilge pumps, sprinkler systems, and steering gear.

- 220V Section: Supplies navigation equipment, radio communication, battery chargers, and emergency lighting.

Under normal conditions, the ESB draws power from the MSB via a circuit breaker. During a power failure, the breaker trips, and the emergency generator supplies power through another breaker. An interlock prevents simultaneous operation of both power sources.

Equipment Powered by the Emergency Generator

The following systems are typically connected to the ESB:

| Equipment | Voltage | Purpose |

|---|---|---|

| Emergency Bilge Pump | 440V | Removes water from flooded compartments |

| Sprinkler System | 440V | Fire suppression |

| Steering Gear | 440V | Maintains ship control |

| Navigation Equipment | 220V | GPS, radar, and other navigation aids |

| Radio Communication | 220V | VHF, MF, MF/HF for emergency communication |

| Emergency Lighting | 220V | Illuminates critical areas |

| Battery Chargers | 220V | Recharges transitional power batteries |

| Fire Detection/Alarms | 220V | Detects and alerts for fire hazards |

| Watertight Doors | 220V | Ensures compartment integrity |

Regulatory Requirements for Emergency Power Sources

The IMO’s SOLAS convention outlines strict requirements for emergency power sources on ships:

- Automatic Start: Emergency generators must start and connect to the ESB within 45 seconds of a power failure.

- Operational Duration:

- Passenger ships: 36 hours.

- Cargo ships: 18 hours.

- Independent Fuel Supply: Must use fuel with a flashpoint of at least 43°C, stored separately from main fuel tanks.

- Cold Weather Operation: Must start reliably at 0°C, with antifreeze and heating arrangements for colder climates.

- Location: Must be above the uppermost continuous deck, outside main machinery spaces, and aft of the collision bulkhead.

- Battery Systems: Must maintain voltage within 12% of nominal during discharge and support essential loads for 30 minutes.

Specific Requirements for Passenger and Cargo Ships

| Requirement | Passenger Ships | Cargo Ships |

|---|---|---|

| Start Time | Within 45 seconds | Within 45 seconds |

| Operational Duration | 36 hours | 18 hours |

| Services Supported | Emergency lighting, navigation, fire systems, watertight doors, etc. | Same as passenger ships, minus watertight doors |

| Battery Backup | 30 minutes for critical systems | 30 minutes for critical systems |

Common Issues and Troubleshooting

Emergency generators can fail due to issues like poor fuel quality, battery failure, or hydraulic system malfunctions. Common problems include:

- Fuel Contamination: Water or impurities in the fuel can prevent starting. Regular fuel filter checks and fuel quality tests are essential.

- Battery Failure: Insufficient charge or degraded batteries can hinder starting. Ensure batteries are charged and tested weekly.

- Hydraulic Pressure Loss: Low pressure in the accumulator can prevent hydraulic starts. Check and repressurize monthly.

- Interlock Malfunctions: Faulty interlocks may prevent automatic switching. Test the interlock system during monthly checks.

Port State Control (PSC) inspections may detain a ship if the emergency generator’s secondary start mode (hydraulic/pneumatic) is non-functional, emphasizing the importance of regular maintenance.

Specifications and Pricing (Approximate)

Emergency generators vary in size and specifications based on the ship’s requirements. Below are typical specifications for a marine emergency generator:

| Specification | Details |

|---|---|

| Power Output | 50–500 kW (varies by ship size) |

| Voltage | 440V (3-phase), 220V (single-phase) |

| Fuel Type | Marine Diesel Oil (flashpoint ≥ 43°C) |

| Start Modes | Battery, hydraulic/pneumatic |

| Cooling System | Radiator with water, antifreeze for cold climates |

| Dimensions | 2–4 m (L) x 1–2 m (W) x 1.5–2.5 m (H) |

| Weight | 1,000–5,000 kg |

Approximate Pricing:

- Small emergency generators (50–100 kW): $20,000–$50,000.

- Medium generators (100–300 kW): $50,000–$100,000.

- Large generators (300–500 kW): $100,000–$200,000.

Note: Prices vary based on manufacturer, ship specifications, and additional features like advanced control systems. For precise pricing, consult manufacturers like Caterpillar, Cummins, or MAN Energy Solutions.

Best Practices for Reliability

To ensure the emergency generator remains operational:

- Adhere to Maintenance Schedules: Follow weekly, monthly, and quarterly testing and maintenance routines.

- Train Crew Members: Ensure all relevant personnel are trained in starting, testing, and troubleshooting procedures.

- Document Tests: Maintain a logbook of all tests, including parameters like voltage, frequency, and fuel levels.

- Prepare for Inspections: Regularly verify compliance with SOLAS and PSC requirements to avoid detentions.

Conclusion

Emergency generators are a cornerstone of maritime safety, providing critical power during main power failures. By understanding their components, mastering starting and testing procedures, and adhering to strict maintenance and regulatory requirements, ship operators can ensure these systems remain reliable. Regular testing, proper maintenance, and crew training are non-negotiable for compliance and safety. For those seeking deeper insights, resources like the Merchant Navy Decoded Combo package offer detailed video explanations to enhance understanding of this critical system.

Happy Boating!

Share Ways of starting and testing emergency generator on a Ship with your friends and leave a comment below with your thoughts.

Read Do’s and Don’ts for Efficient Boiler Operations On Ships until we meet in the next article.