Watertight Doors on Ships: Types, Drills, Maintenance & SOLAS Regulations

Watertight doors serve as critical barriers on ships, preventing water ingress between compartments during flooding or accidents. These specialized doors maintain vessel integrity by limiting water spread, ensuring stability and buoyancy.

Found in high-risk areas like engine rooms, shaft tunnels, ballast tanks, and bow thruster compartments, they are indispensable on container vessels, passenger ships, offshore platforms, and oil exploration rigs. Crew familiarity with their locations and operations is essential for emergency response and daily safety.

Understanding the distinction between watertight and weathertight is foundational. According to SOLAS, watertight means capable of preventing water passage in any direction under anticipated heads in intact or damaged states. These doors withstand pressure from both sides and continuous submersion, typically positioned below the waterline. Weathertight, conversely, ensures no water penetration in sea conditions, designed for brief submersion and located above the waterline to resist external weather forces.

This article delves into the functions, types, operational requirements, risks, drills, SOLAS regulations, and maintenance of watertight doors, providing a comprehensive guide for maritime professionals.

Functions and Operational Requirements

Watertight doors primarily function to compartmentalize the ship, enhancing survivability in flooding scenarios. By sealing off sections, they prevent progressive flooding that could lead to capsizing or sinking. Operationally, these doors must integrate with the ship’s control systems, allowing local and remote activation from the bridge or ship control center (SCC). Remote closure ensures swift response during emergencies, while local controls provide flexibility for routine access.

In practice, doors operate under specific conditions to mitigate hazards. They must close in restricted visibility, high-traffic areas, shallow waters (less than three times the draft), or when the master deems conditions dangerous. This proactive closure maintains the ship’s watertight integrity.

Watertight doors are powered by hydraulic or electric systems, making them robust but potentially hazardous if mishandled. Hydraulic systems use cylinders for smooth motion, while electric motors offer precise control. Specifications vary by manufacturer, but common features include corrosion-resistant materials like stainless steel or galvanized steel frames, with door thicknesses ranging from 6-12 mm. Sealing is achieved via rubber gaskets, often neoprene or EPDM, rated for pressures up to 10-15 bar depending on the door’s location.

Prices for watertight doors fluctuate based on size, type, and customization. Standard hinged models start at $5,000-$10,000, while powered sliding doors can range from $15,000-$50,000 per unit, excluding installation. High-end versions for offshore vessels may exceed $100,000, incorporating advanced sensors and automation.

Types of Watertight Doors

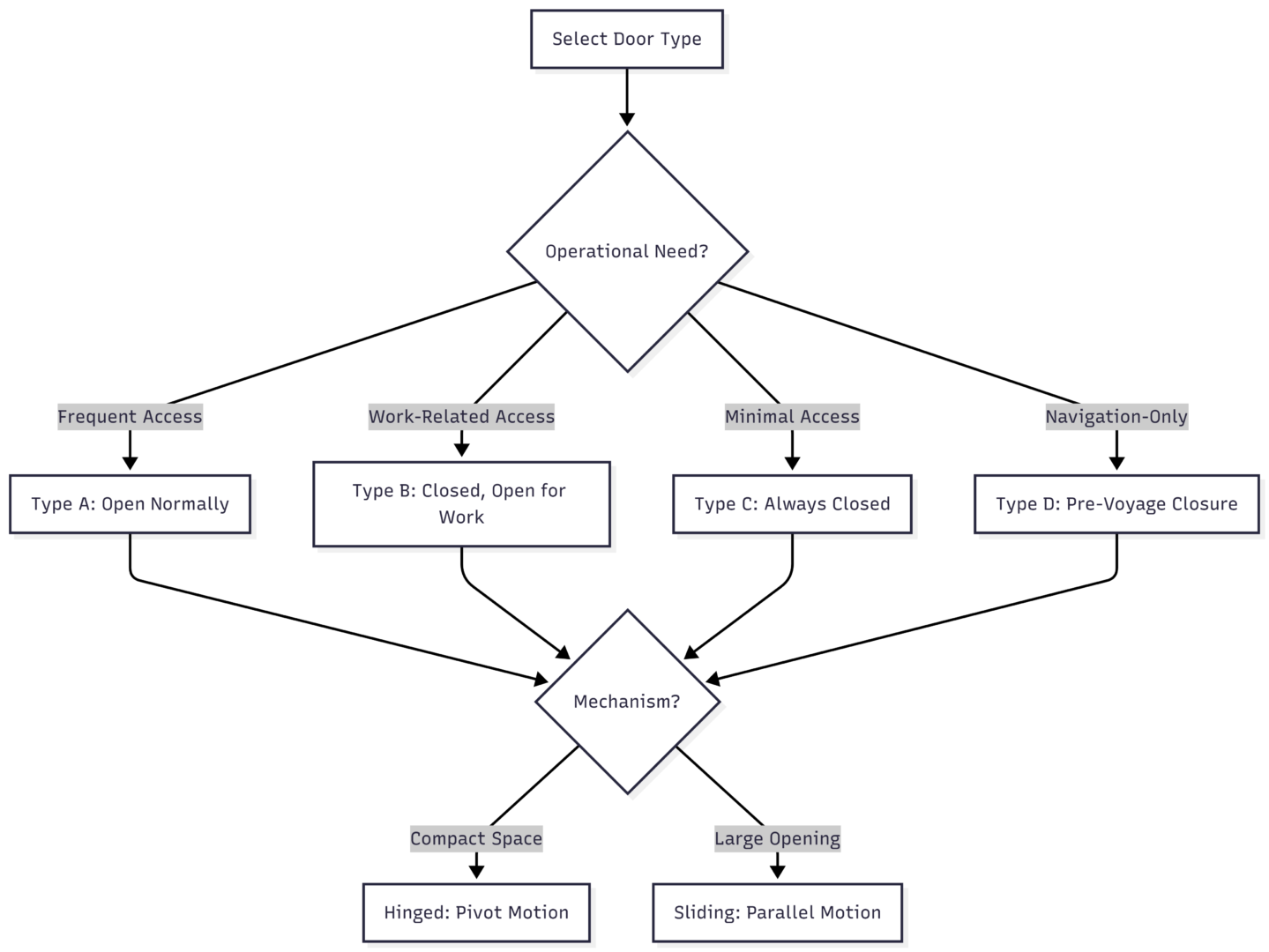

Watertight doors are categorized by operational protocols and mechanisms, ensuring compliance with safety standards.

Operational Categories

- Type A: These doors may remain open during normal operations and close only in emergencies. Ideal for low-risk passages where frequent access is needed.

- Type B: Kept closed generally, opening only when personnel work in adjacent compartments. This balances accessibility with security.

- Type C: Must stay closed at all times, opening briefly for passage. Suited for high-risk zones like engine rooms.

- Type D: Non-SOLAS compliant, these close before voyages and remain shut during navigation. They cannot upgrade to other categories and are used in specific, controlled applications.

| Type | Operational Protocol | Typical Use Cases | Closure Frequency |

|---|---|---|---|

| A | Open normally; close in emergencies | Fore and aft passageways | Low |

| B | Closed; open for work in adjacent areas | Engine room access | Medium |

| C | Closed always; brief openings for passage | Shaft tunnels, ballast tanks | High |

| D | Closed pre-voyage; remain shut | Non-critical, navigation-only zones | Constant during sail |

Mechanical Classifications

Doors are also classified by movement:

- Hinged Type: Pivot on vertical or horizontal edges, operated manually or powered. Compact and reliable for smaller openings, with closing forces up to 5-10 kN. Specifications include leaf sizes up to 1.5m x 2m, weight 200-500 kg.

- Sliding Type: Move horizontally or vertically parallel to the plane, powered by hydraulics or motors. Handle larger openings (up to 3m x 3m), with weights exceeding 1,000 kg. Hydraulic pressure ranges 100-200 bar, ensuring closure against lists up to 15 degrees.

Sliding doors dominate in modern ships due to space efficiency and automation.

To visualize the decision process for door types:

This flowchart aids in selecting appropriate doors based on ship design and risk assessment.

Risks Associated with Watertight Doors

Powered watertight doors pose significant risks due to their force and weight. Improper use can lead to injuries, such as crushed limbs or fatalities. Key risks include:

- Stability Loss: Open or leaking doors during flooding compromise buoyancy, allowing water spread.

- Fire and Smoke Spread: Unsecured doors facilitate fire propagation, endangering lives and the vessel.

- Entrapment: Lack of awareness during remote closure can trap crew.

- Human Injury: Reports highlight finger amputations from mishandling. Doors close with forces over 10 kN, crushing obstacles.

- Operational Failure: Debris near doors causes malfunctions, exacerbating emergencies.

Most incidents stem from procedural lapses, like passing through moving doors or ignoring alarms. Training emphasizes one-handed operation, vigilance during bridge-activated closures, and ensuring full opening before passage. Loose items must be secured to prevent jams.

Drills for Watertight Doors

Regular drills ensure crew proficiency and system reliability. SOLAS mandates weekly drills, with pre-port departure checks.

- Weekly Drills: Operate all doors, verifying local and remote functionality.

- Daily Operations: Hinged and powered doors activated during rounds.

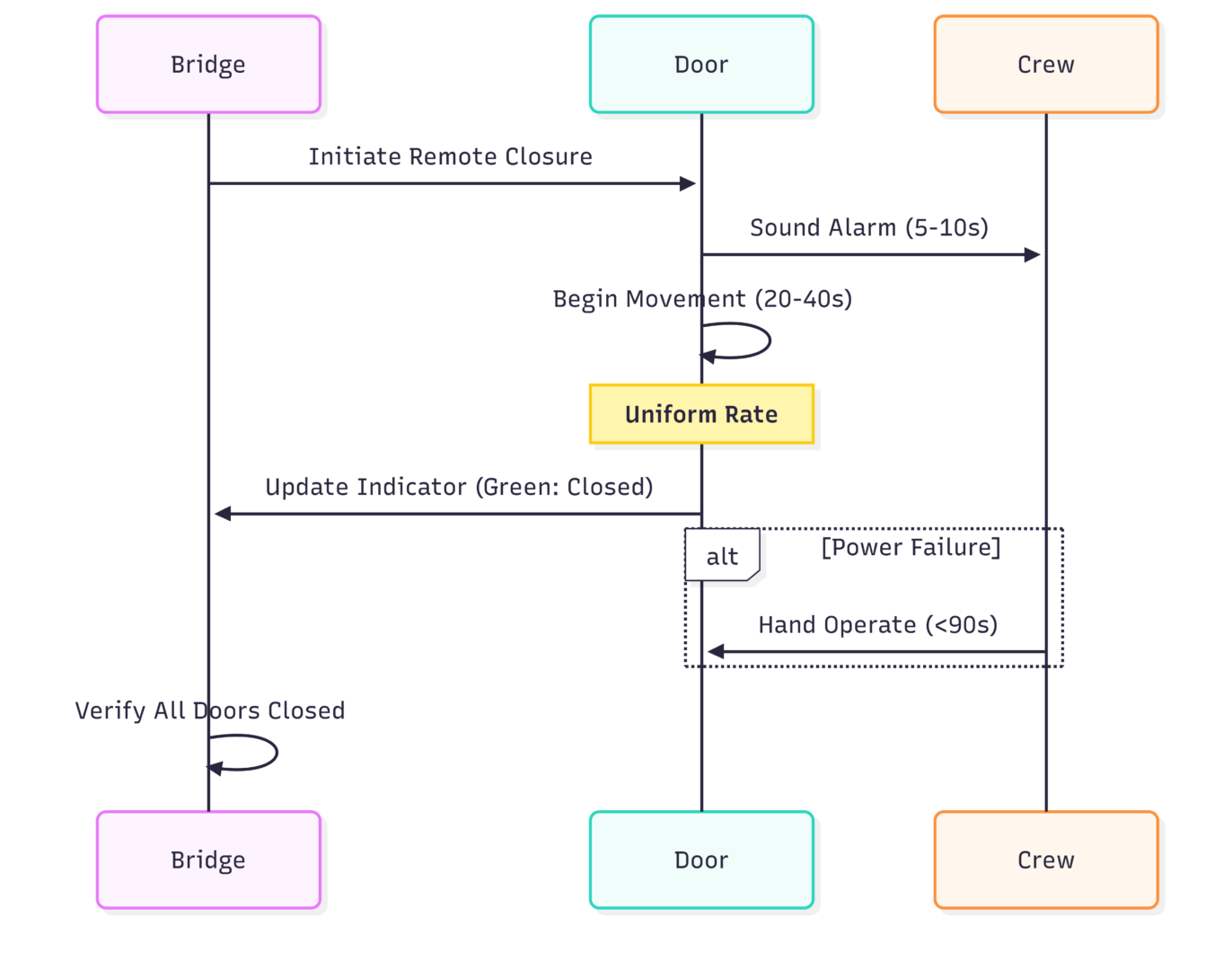

- Remote Operation: Audio-visual alarms sound during closure; indicators show open/closed status.

Drills simulate emergencies, testing simultaneous closure from bridge and SCC within 60 seconds. Hand operation during power failure must close doors in 90 seconds.

A sample drill procedure table:

| Step | Action | Responsible Party | Verification |

|---|---|---|---|

| 1 | Announce drill | Bridge Officer | Log entry |

| 2 | Activate remote closure | Bridge/SCC | Alarm sounds 5-10s before movement |

| 3 | Check local controls | Deck Crew | Doors respond, no jams |

| 4 | Verify indicators | All Stations | Green for closed, red for open |

| 5 | Simulate failure | Engineering | Hand close in <90s |

| 6 | Debrief | Master | Address issues |

Incorporating drills into onboard training reduces risks and ensures compliance.

SOLAS Regulations for Watertight Doors

SOLAS Chapter II-1, Regulations 14-25, governs watertight doors to uphold ship safety.

- Closure Times: Powered doors close simultaneously from bridge/SCC in ≤60 seconds upright. Individual closure: 20-40 seconds.

- List Capability: Close with 15-degree list either side.

- Alarms: Local audible alarm (5-10 seconds) before remote closure, continuing until shut.

- Controls: Available on both door sides and bridge console, ≥1.6m above floor on passenger ships.

- Indicators: Bridge visuals: red (open), green (closed). Direction markings at all positions.

- Secondary Station: Above bulkhead deck for fire/flood scenarios.

- Hand Operation: ≤90 seconds during failure.

These regulations ensure doors function in adverse conditions, with pilot panels displaying LED statuses.

For operational flow under SOLAS:

This diagram outlines the regulated sequence, emphasizing safety features.

Maintenance of Watertight Doors

Maintenance follows the ship’s planned maintenance system (PMS) and manufacturer guidelines, focusing on system integrity.

- Inspections: Routine checks for alarms, mechanisms, valves, fluid levels, seals, and lights.

- Cleaning: Remove dirt from frames and gaskets; lubricate with silicone oil.

- Components: Inspect wheels, bearings, rails for wear; check hydraulic systems for leaks, oil levels, and filters.

- Avoidances: No painting on gaskets or pistons; post warnings during work.

- Lubrication: Mechanical parts like cleats, locks, wheels.

- Structural Checks: Frames for cracks, corrosion.

- Markings: Clear instructions in ship’s language, category labels.

Deficiencies like gasket damage or alarm faults can lead to detentions. Treat doors as safety-critical; avoid modifications.

Maintenance schedule example:

| Component | Frequency | Action | Specifications |

|---|---|---|---|

| Gaskets | Monthly | Clean/Lubricate | Neoprene, 5-10mm thick, pressure-rated |

| Hydraulics | Quarterly | Check Leaks/Oil | Oil: ISO VG 32-68, Filter: 10-20 micron |

| Alarms | Weekly | Test Functionality | Audible >70dB, Visual LEDs |

| Rails/Wheels | Bi-annual | Inspect Wear | Stainless steel, Bearings: Sealed ball |

| Full System | Annually | Overhaul | Per Manufacturer, Cost: $2,000-$5,000/door |

Regular maintenance prevents failures, preserving ship safety.

Conclusion

Watertight doors are vital for maritime safety, integrating types, drills, regulations, and maintenance to protect against flooding. Adhering to SOLAS and best practices ensures vessel integrity and crew safety. Prioritize training and inspections to mitigate risks, recognizing these doors as guardians of buoyancy and stability. By maintaining vigilance, ships can navigate hazards effectively, upholding the highest safety standards.

Happy Boating!

Share Watertight Doors on Ships: Types, Drills, Maintenance & SOLAS Regulations with your friends and leave a comment below with your thoughts.

Read Top 10 Marine Diesel Engines until we meet in the next article.