Water Mist Fire Fighting Systems in Ship Engine Rooms

Discover how water mist fire fighting systems protect ship engine rooms with rapid, eco-friendly fire suppression. Learn their mechanisms, benefits, and regulations.

Ship engine rooms are critical areas where the risk of fire is elevated due to the presence of flammable liquids, high temperatures, and complex machinery. Water mist fire fighting systems have emerged as a highly effective, environmentally friendly solution for fire suppression in these high-risk environments. Unlike traditional sprinkler or gas-based systems, water mist systems use fine water droplets to suppress fires rapidly while minimizing damage to sensitive equipment and the environment. This article explores the operational principles, advantages, regulatory framework, installation considerations, and real-world applications of water mist systems in ship engine rooms, providing a comprehensive guide for maritime professionals.

Understanding Water Mist Fire Fighting Systems

Water mist fire fighting systems operate by dispersing microscopic water droplets, typically ranging from 50 to 200 microns in diameter, through high-pressure nozzles. These tiny droplets create a large surface area, enabling rapid heat absorption, oxygen displacement, and smoke suppression. The systems are designed to protect critical areas such as engine rooms, where fires can escalate quickly due to the presence of fuel, oil, and electrical equipment.

How Water Mist Systems Work

The effectiveness of water mist systems lies in their multi-faceted approach to fire suppression, which includes the following mechanisms:

- Heat Absorption: The fine water droplets evaporate quickly upon contact with flames, absorbing significant amounts of heat. This rapid evaporation cools the fire, reducing its temperature below the threshold required for combustion.

- Oxygen Displacement: As the water droplets evaporate, they produce water vapor, which displaces oxygen in the vicinity of the fire. This reduction in oxygen levels inhibits the combustion process, effectively starving the fire.

- Smoke Suppression: The mist captures and settles smoke particles, improving visibility and air quality during an emergency. This is particularly valuable in confined spaces like engine rooms, where smoke can hinder evacuation and firefighting efforts.

- Radiation Blocking: The mist forms a barrier that reduces radiant heat, preventing the fire from spreading to adjacent areas or equipment.

These mechanisms work synergistically to suppress fires quickly and efficiently, making water mist systems ideal for protecting high-risk areas on ships.

Key Components of Water Mist Systems

A typical water mist system comprises several critical components:

- Nozzles: Specially designed to atomize water into fine droplets at high pressure (4–10 MPa or 580–1,450 psi). Nozzle placement is critical to ensure complete coverage of protected areas.

- Water Supply: Systems typically draw from a dedicated fresh water tank, with the option to switch to seawater in emergencies. A reserve of fresh water sufficient for at least 20 minutes of operation is standard.

- Pumps: High-pressure pumps deliver water to the nozzles at the required pressure for effective mist formation.

- Detectors: Smoke and flame detectors trigger automatic activation, ensuring rapid response to fire incidents.

- Control Panels: Allow for both automatic and manual operation, providing flexibility in emergency situations.

- Valves: Solenoid valves isolate specific areas, enabling targeted water mist discharge.

Advantages of Water Mist Systems in Ship Engine Rooms

Water mist systems offer several advantages over traditional fire suppression methods like CO2, foam, or conventional sprinklers. These benefits make them particularly suited for maritime applications:

- Rapid Response: Water mist systems can be activated automatically within seconds of fire detection, minimizing the time between detection and suppression. This is critical in engine rooms, where fires can spread rapidly.

- Minimal Water Usage: Unlike traditional sprinklers, water mist systems use significantly less water, reducing the risk of water damage to sensitive equipment such as engines, generators, and electronics.

- Environmental Friendliness: Using potable water instead of chemical agents like Halon or foam, water mist systems are eco-friendly and align with international regulations aimed at reducing environmental impact.

- Versatility: These systems are effective against a wide range of fire types, including Class A (ordinary combustibles), Class B (flammable liquids), and Class E (electrical fires). They can be configured for total flooding of an entire compartment or localized protection of specific equipment.

- Reduced Equipment Damage: The fine mist minimizes water damage compared to traditional sprinklers, preserving critical machinery and reducing repair costs.

- Independent Operation: Water mist systems operate independently of other fire suppression systems, providing redundancy and enhancing overall fire safety.

Regulatory Framework for Water Mist Systems

The implementation of water mist systems in ship engine rooms is governed by international and national regulations to ensure safety and compliance. Key regulatory frameworks include:

International Maritime Organization (IMO) Standards

The International Convention for the Safety of Life at Sea (SOLAS) Chapter II-2 outlines requirements for fire protection systems on ships. Water mist systems are recognized as an acceptable alternative to traditional gas or foam systems for machinery space protection. IMO guidelines specify design, installation, and testing requirements to ensure system reliability and effectiveness.

NFPA 750

The National Fire Protection Association (NFPA) 750 standard provides comprehensive guidance on the design, manufacture, installation, and maintenance of water mist systems. It covers critical aspects such as nozzle spacing, pressure requirements, and system testing protocols.

National Regulations

Many countries align their maritime fire safety regulations with IMO standards but may impose additional requirements based on local conditions. Ship operators must ensure compliance with both international and national regulations to avoid penalties and ensure safety.

Compliance Requirements

To meet regulatory standards, water mist systems must undergo rigorous testing and certification. Regular inspections and maintenance are mandatory to ensure system readiness. Documentation of maintenance activities is essential for compliance with SOLAS and other regulations.

Installation Considerations

Installing a water mist system in a ship’s engine room requires careful planning to ensure optimal performance. Key considerations include:

- Nozzle Placement: Nozzles must be strategically positioned to provide complete coverage of protected areas. The distance between nozzles is critical to avoid gaps where fires could spread unnoticed. Computational fluid dynamics (CFD) modeling is often used to optimize nozzle placement.

- System Design: The system must be tailored to the specific layout and hazards of the engine room. This includes accounting for ventilation systems, which can affect mist dispersion, and identifying high-risk areas such as main engines, auxiliary generators, and purifiers.

- Integration with Other Systems: Water mist systems should be integrated with fire alarms, emergency lighting, and other safety systems to provide comprehensive protection. This ensures a coordinated response to fire emergencies.

- Water Supply: A reliable water supply, typically from a dedicated fresh water tank, is essential. Systems should be designed to switch to seawater if fresh water is depleted, ensuring continuous operation during prolonged emergencies.

- Pressure Requirements: High-pressure pumps must deliver water at 4–10 MPa to create the fine mist necessary for effective fire suppression. Regular testing of pump performance is critical.

Common Areas Protected by Water Mist Systems

Water mist systems are typically installed in the following engine room areas:

- Main engine cylinder head platform

- Auxiliary generators

- Auxiliary boiler room

- Purifier room

- Incinerator room

- Inert gas generator room

- Steering gear room

These areas are prone to fire hazards due to the presence of flammable liquids, high temperatures, and electrical equipment.

Operational Modes: Automatic and Manual

Water mist systems can operate in both automatic and manual modes, providing flexibility in emergency response.

Automatic Operation

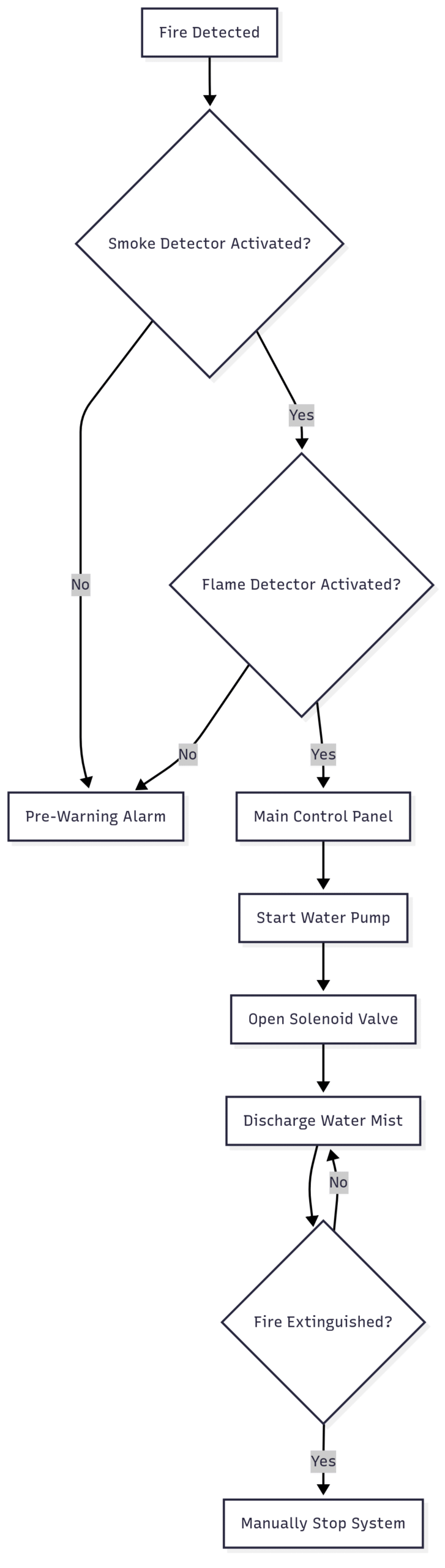

Automatic operation relies on a network of smoke and flame detectors installed in protected areas. When a single detector is activated, a pre-warning alarm alerts the crew, allowing them to assess the situation. If both smoke and flame detectors are triggered, the system initiates the following actions:

- Activation of Water Pump: The control panel starts the high-pressure pump, delivering water to the nozzles.

- Opening of Solenoid Valve: The valve for the affected area opens, allowing water to flow to the nozzles.

- Mist Discharge: Nozzles atomize water into a fine mist, which is sprayed over the fire-affected area.

The system continues to discharge water mist until manually stopped or the fire is extinguished. Regulations typically require a minimum discharge time of 20 minutes to ensure effective firefighting.

Manual Operation

In situations where automatic activation is not feasible or immediate intervention is required, crew members can manually activate the system by pressing the “START” button on the local or remote control panel. This triggers the same sequence of pump activation and valve opening as in automatic mode, allowing rapid response to fire threats.

Operational Readiness

To ensure the system is always ready for operation, the following conditions must be maintained:

- Adequate water level in the fresh water tank

- Uninterrupted power supply to the system

- Operational fire alarm system

- Closed drain and test valves

- Clear access to the water pump and control panels

Case Studies: Real-World Applications

Water mist systems have proven their effectiveness in several maritime fire incidents:

- MV Rena Incident: A container ship grounded off the coast of New Zealand experienced a fire in its engine room. The onboard high-pressure water mist system was activated, successfully controlling the blaze and minimizing damage to cargo and infrastructure. The system’s rapid response and minimal water usage were critical in preventing a more severe outcome.

- Passenger Ferry Fire: A ferry experienced an engine room fire while carrying passengers. The crew manually activated the water mist system, which suppressed the flames before they could spread to passenger areas. This incident highlighted the importance of crew training and system reliability in ensuring passenger safety.

These case studies demonstrate the critical role of water mist systems in maritime fire safety, particularly in high-risk engine rooms.

Maintenance and Crew Training

Regular maintenance and crew training are essential to ensure the reliability and effectiveness of water mist systems.

Maintenance Requirements

- Nozzle Cleaning: Nozzles must be cleaned regularly to prevent clogging, which could reduce mist formation efficiency.

- Filter Inspection: Filters should be checked and replaced as needed to ensure a clean water supply.

- Pressure Testing: Pumps and valves must be tested to verify they operate within the required pressure range (4–10 MPa).

- System Testing: Periodic full-system tests under simulated conditions help identify potential issues and ensure compliance with regulations.

Crew Training

Crew members should be trained in the following areas:

- System Operation: Familiarity with automatic and manual activation procedures.

- Emergency Procedures: Understanding when and how to engage the system safely.

- Maintenance Protocols: Knowledge of routine inspection and testing requirements.

Training programs should be conducted regularly and documented to comply with SOLAS regulations.

Example System: Marioff HI-FOG

One of the most widely used water mist systems in maritime applications is the Marioff HI-FOG system. This high-pressure system is designed for both total flooding and localized protection in engine rooms and other critical areas. Key specifications include:

- Pressure Range: 4–10 MPa

- Droplet Size: 50–200 microns

- Applications: Main engines, auxiliary generators, purifiers, boilers, and battery rooms

- Activation: Automatic (via detectors) or manual

- Water Usage: Up to 80% less than traditional sprinklers

The HI-FOG system is certified by major classification societies and complies with IMO and SOLAS regulations. Its modular design allows for customization based on the specific needs of the vessel.

Pricing (Approximate)

The cost of a water mist system like Marioff HI-FOG varies depending on the vessel size, system complexity, and installation requirements. Approximate costs include:

- System Components: $50,000–$150,000 (pumps, nozzles, control panels)

- Installation: $20,000–$50,000

- Maintenance (Annual): $5,000–$15,000

Chart: Water Mist System Workflow

Below is a flowchart illustrating the operational workflow of a water mist fire fighting system in automatic mode.

This chart outlines the sequence of events from fire detection to suppression, highlighting the dual-detector system and manual stopping mechanism.

Comparison Table: Water Mist vs. Traditional Systems

| Feature | Water Mist System | CO2 System | Foam System |

|---|---|---|---|

| Fire Suppression Mechanism | Heat absorption, oxygen displacement, smoke suppression | Oxygen displacement | Smothering, cooling |

| Water Usage | Low (up to 80% less than sprinklers) | None | Moderate |

| Environmental Impact | Eco-friendly (uses water) | Harmful (CO2 emissions) | Chemical-based, moderate |

| Equipment Damage | Minimal | High risk (corrosion) | Moderate |

| Activation Time | Immediate | Delayed (evacuation required) | Moderate |

| Applications | Engine rooms, cargo holds, passenger areas | Machinery spaces | Fuel-related fires |

This table highlights the advantages of water mist systems over traditional CO2 and foam systems, particularly in terms of environmental impact and equipment safety.

Future Trends and Innovations

As maritime safety regulations evolve, water mist systems are expected to see further advancements. Emerging trends include:

- Smart Detection Systems: Integration with AI-powered fire detection systems for faster and more accurate fire identification.

- Hybrid Systems: Combining water mist with other suppression methods (e.g., inert gas) for enhanced fire control in complex environments.

- Energy Efficiency: Development of low-energy pumps and nozzles to reduce power consumption while maintaining high-pressure performance.

These innovations will further enhance the reliability and efficiency of water mist systems in maritime applications.

Conclusion

Water mist fire fighting systems represent a significant advancement in maritime fire safety, particularly for protecting ship engine rooms. Their ability to suppress fires rapidly while minimizing water usage, environmental impact, and equipment damage makes them a preferred choice for modern vessels. By adhering to international regulations, ensuring proper installation, and prioritizing crew training and maintenance, ship operators can maximize the effectiveness of these systems. As technology continues to evolve, water mist systems will play an increasingly critical role in safeguarding lives, assets, and the environment in the maritime industry.

Happy Boating!

Share Water Mist Fire Fighting Systems in Ship Engine Rooms with your friends and leave a comment below with your thoughts.

Read Oily Water Separator: Construction and Working until we meet in the next article.