Water-Mist And Sprinkler Systems On Passenger Ships

Discover water-mist and sprinkler systems on passenger ships, their components, advantages, and regulatory requirements for fire safety.

Fire safety on passenger ships is paramount due to the high number of lives at stake and the isolation of vessels at sea, far from shore-based assistance. Fixed fire suppression systems, such as water-mist and sprinkler systems, are critical for detecting and extinguishing fires, particularly in accommodation and technical spaces. These systems are designed to act swiftly, minimizing damage and protecting passengers and crew. This article explores the role, components, advantages, and operational details of water-mist and sprinkler systems on passenger ships, with a focus on their application, regulatory compliance, and technological advancements.

Importance of Fire Safety on Passenger Ships

Passenger ships, carrying thousands of passengers and crew, face unique fire safety challenges. A fire outbreak at sea can lead to catastrophic consequences, including loss of life, property damage, and environmental harm. Unlike cargo ships, where fire suppression may prioritize stability and cost, passenger ships require robust systems to protect human lives in densely populated areas like cabins, dining areas, and lounges. The engine room, with its high temperatures, flammable materials, and abundant oxygen supply, is a common fire risk area, making effective fire suppression systems indispensable.

Types of Fire Suppression Systems

Passenger ships employ a combination of fire suppression systems tailored to specific areas. The primary systems include:

- Water-Mist Systems: These use fine water droplets to suppress fires efficiently with minimal water usage, reducing damage and passenger inconvenience.

- Sprinkler Systems: Traditional systems that discharge larger water volumes, commonly used in older vessels’ accommodation areas.

- CO2 Systems: Used as a backup in technical spaces, such as engine rooms, for large, uncontrollable fires.

- Foam Systems: Applied in specific areas like machinery spaces or cargo holds, depending on the vessel’s needs.

- Inert Gas Systems: Used to reduce oxygen levels in cargo compartments to prevent combustion.

This article focuses on water-mist and sprinkler systems, which are the most prevalent in passenger ship accommodation and technical spaces.

Water-Mist Systems: Technology and Operation

Water-mist systems, such as the Marioff HI-FOG® system, are increasingly preferred on modern passenger ships for their efficiency and versatility. These systems discharge water as a fine mist, offering superior fire suppression compared to traditional sprinklers.

Components of Water-Mist Systems

A typical water-mist system, like the HI-FOG, includes:

- Freshwater Tank: Stores water with a level gauge and high/low-level float switches to monitor and replenish water levels.

- High-Pressure Pumps: Positive displacement pumps (8–10 per unit) that raise system pressure to 140–150 bar during fire events.

- Low-Pressure Diaphragm Pump: Maintains system pressure at 18–24 bar to compensate for minor leaks.

- Section Valves and Nozzles: Control water flow to specific areas, with dry lines in machinery spaces and wet lines in accommodation areas.

- Nitrogen Pilot Cylinders: Actuate additional water cylinders (50 liters each) for prolonged fire suppression.

- Seawater Supply Line: Provides backup water supply in emergencies, with valves normally closed to prevent corrosion.

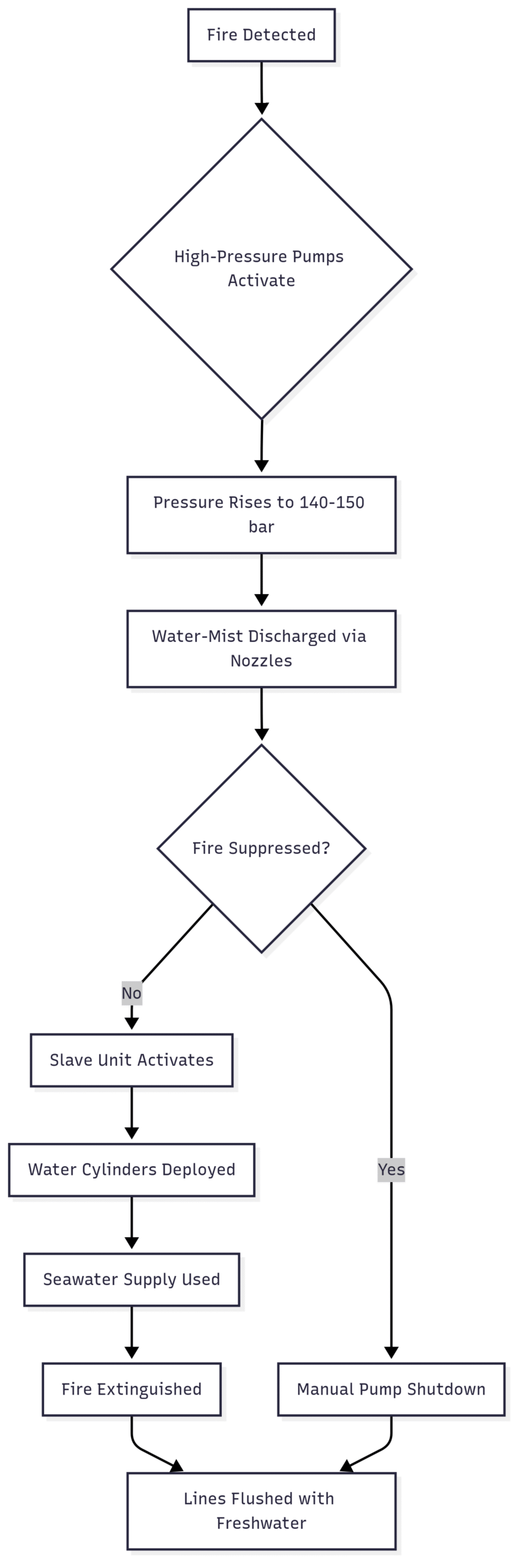

Operation of Water-Mist Systems

The system operates in two modes: Master (forward unit) and Slave (aft unit). In a fire event:

- Detection and Activation: Heat-sensitive nozzles or manual activation triggers the system. In accommodation areas, wet lines with bulb-type nozzles (containing heat-sensitive fluid) break automatically upon temperature increase, releasing mist.

- Pressure Management: If pressure drops below 18 bar, high-pressure pumps activate, raising it to 140–150 bar. Relief valves prevent overpressure damage.

- Water Supply: Freshwater is drawn from the tank. If depleted, additional water cylinders or seawater lines are used.

- Post-Fire Procedures: After extinguishing the fire, pumps are manually stopped, and lines are drained to restore normal pressure. If seawater is used, lines are flushed with freshwater to prevent corrosion.

Advantages of Water-Mist Systems

Water-mist systems offer several benefits over traditional sprinkler and CO2 systems:

- Efficient Coverage: Fine mist covers a larger area and penetrates the fire’s core, cooling it rapidly.

- Minimal Water Usage: Smaller droplet size reduces water consumption, minimizing damage to equipment and interiors.

- Rapid Fire Suppression: Mist evaporates into steam, starving the fire of oxygen and cooling the area.

- Safety: No risk to human life during discharge, unlike CO2 systems, which require evacuation and sealing.

- Ease of Maintenance: Refilling is simpler and less costly than CO2 systems, with no need for specialized shore-based support.

- Quick Activation: Mist can be released faster than CO2, reducing fire spread.

Chart: Water-Mist System Operation

Sprinkler Systems: Traditional Fire Protection

Sprinkler systems remain common in older passenger ships, particularly for accommodation areas. These systems use larger water volumes and are designed for automatic operation.

Components of Sprinkler Systems

Key components include:

- Surge Tank: A pressurized vessel maintaining 10–12 bar pressure, with an air column to stabilize pressure.

- Booster Pump: Supplies technical water to the topping-up pump.

- Topping-Up Pump: Maintains surge tank water levels, operating in series with the booster pump or independently.

- Seawater Pump: Activates automatically if system pressure drops below 5 bar, supplying seawater in emergencies.

- Non-Return Valves (NRVs): Prevent backflow to maintain system pressure.

- Line Valves (V1–V5): Butterfly valves with limit switches for remote monitoring.

- Pressure Gauge: Monitors system pressure.

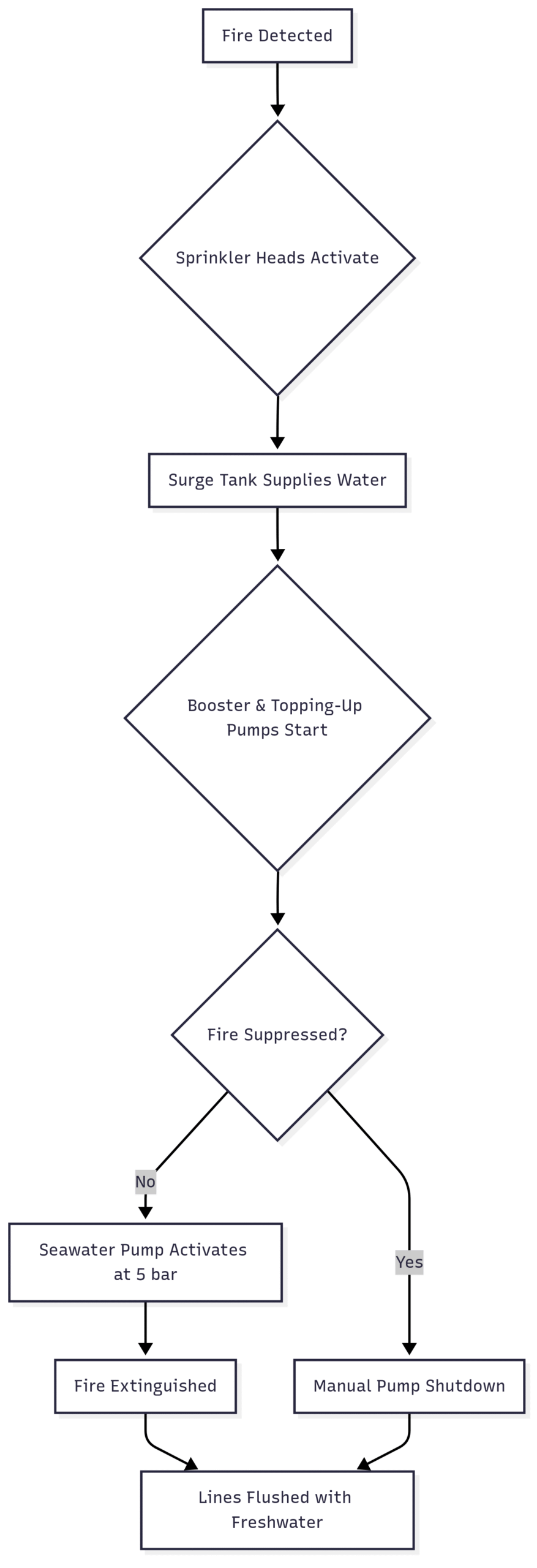

Operation of Sprinkler Systems

In normal conditions, the surge tank maintains a 3/4 water level, with valves V1–V4 open and V5 closed. During a fire:

- Activation: Heat-sensitive sprinkler heads break, releasing water to suppress the fire.

- Pump Operation: Booster and topping-up pumps start automatically as the surge tank level drops.

- Emergency Seawater Supply: If freshwater is depleted, the seawater pump activates at 5 bar, signaled by a pressure switch.

- Post-Fire Flushing: If seawater is used, lines are flushed with freshwater to prevent corrosion.

Advantages of Sprinkler Systems

- Automatic Operation: Quick response to fire detection.

- Cost-Effective Medium: Water is abundant and inexpensive.

- Ease of Testing: System can be tested per Planned Maintenance System (PMS) requirements.

Disadvantages of Sprinkler Systems

- Water Damage: Larger water volumes can damage interiors and equipment.

- Free Surface Effect: Excessive water in upper accommodation decks may affect ship stability.

- Maintenance Needs: Requires flushing after seawater use and regular water quality checks.

Chart: Sprinkler System Operation

Regulatory Requirements

Fire suppression systems on passenger ships are governed by international regulations, primarily the International Convention for the Safety of Life at Sea (SOLAS). Key requirements include:

- Accommodation Areas: Passenger ships must have automatic sprinkler or equivalent systems (e.g., water-mist) in cabins, corridors, and public spaces.

- Machinery Spaces: Systems like water-mist or CO2 must be installed, with CO2 as a backup for large fires.

- Maintenance and Testing: Systems must comply with manufacturer instructions and be regularly serviced to ensure functionality.

- Stability Considerations: Systems must not compromise the ship’s stability through excessive weight or water accumulation.

Comparison of Water-Mist and Sprinkler Systems

| Feature | Water-Mist System | Sprinkler System |

|---|---|---|

| Water Usage | Low (fine mist) | High (larger droplets) |

| Fire Suppression | Rapid cooling and oxygen starvation | Cooling and direct suppression |

| Damage to Equipment | Minimal | High due to water volume |

| Stability Impact | Low | Potential free surface effect |

| Maintenance | Simple, cost-effective | Requires flushing after seawater use |

| Cost | Higher installation, lower maintenance | Lower installation, higher maintenance |

| Application | Modern ships, all areas | Older ships, mainly accommodation |

Leading Solutions and Specifications

Marioff HI-FOG® Water-Mist System

- Application: Accommodation, machinery spaces, and technical areas.

- Pressure: 140–150 bar (high-pressure mode), 18–24 bar (standby).

- Components: Freshwater tank, high-pressure pumps, nitrogen cylinders, section valves.

- Price: Installation costs range from $500,000 to $2 million, depending on vessel size and system complexity (contact Marioff for precise quotes).

Johnson Controls Fire Suppression Systems

- Application: Offers water-mist, sprinkler, foam, and gaseous systems.

- Specifications: Customizable for specific vessel needs, with options for wet and dry pipe systems.

- Price: Varies widely; typically $300,000–$1.5 million for passenger ships.

DESMI Fire Systems

- Application: Tailored systems with customizable pump sizing.

- Specifications: Supports water-mist and sprinkler systems, with seawater backup options.

- Price: Approximately $400,000–$1.8 million, depending on configuration.

Note: Prices are estimates based on industry standards. For accurate pricing, contact suppliers directly.

Maintenance and Testing

Both systems require regular maintenance to comply with SOLAS and ensure reliability:

- Water-Mist Systems:

- Monthly pump tests to check pressure buildup and relief valve operation.

- Oil level checks in pumps and replacement per PMS.

- Water quality tests for pH, conductivity, and chloride levels.

- Sprinkler Systems:

- Test seawater pump operation by simulating pressure drop.

- Flush lines after seawater use to prevent corrosion.

- Monitor surge tank air column and water levels.

Retrofitting Older Vessels

Many older passenger ships retrofit water-mist systems in high-risk areas (e.g., engine rooms) due to their efficiency. However, high retrofitting costs ($1–3 million) and structural challenges limit their use in accommodation areas, where traditional sprinklers remain prevalent.

Future Trends

Water-mist systems are increasingly replacing sprinklers and CO2 systems due to their efficiency, safety, and lower environmental impact. Technological advancements, such as improved nozzle designs and automated monitoring, are driving adoption. As regulations tighten and passenger safety remains a priority, water-mist systems are likely to become the standard for new vessels.

Conclusion

Water-mist and sprinkler systems are vital for fire safety on passenger ships, protecting thousands of lives in the event of a fire. Water-mist systems, with their efficiency, minimal water usage, and versatility, are surpassing traditional sprinklers in modern vessels. Regulatory compliance, regular maintenance, and strategic system selection ensure these systems perform effectively. As technology evolves, water-mist systems will continue to dominate, offering a safer, more sustainable solution for fire suppression at sea.

Happy Boating!

Share Water-Mist And Sprinkler Systems On Passenger Ships with your friends and leave a comment below with your thoughts.

Read What Causes Oil Spills? – Learn About Their Causes and Impact until we meet in the next article.