what is the purpose of a boats ventilation system

Discover the purpose of a boat ventilation system, ensuring safety by removing flammable gases and enhancing comfort with fresh air circulation.

Boat ventilation systems are essential for maintaining safety and comfort on the water. These systems serve a dual purpose: preventing dangerous explosions by removing flammable gases and ensuring a pleasant onboard environment by circulating fresh air and reducing humidity. This comprehensive guide explores the purpose, types, components, and regulations of boat ventilation systems, emphasizing their importance for both recreational and commercial vessels. With safety as the cornerstone, we’ll also cover practical maintenance tips, system specifications, and compliance with boating regulations to help boat owners make informed decisions.

Why Boat Ventilation Systems Are Essential

Boats, especially those powered by gasoline engines, face unique risks due to the potential accumulation of flammable vapors in enclosed spaces like engine compartments and bilges. A ventilation system mitigates these risks while improving the onboard environment. The primary purposes of a boat ventilation system are:

- Safety: Preventing explosions by removing flammable gasoline vapors from enclosed areas.

- Comfort: Circulating fresh air to reduce humidity, prevent mold, and eliminate odors.

- Engine Protection: Dissipating heat and exhaust fumes to maintain optimal engine performance.

- Structural Integrity: Reducing moisture buildup to prevent damage to the boat’s interior.

Without proper ventilation, boats risk catastrophic fires, health hazards from poor air quality, and costly damage from mold and mildew. Let’s dive into each purpose and how ventilation systems achieve these goals.

Safety: Mitigating Explosion Risks

Gasoline-powered boats are particularly vulnerable to explosions due to the volatility of gasoline vapors. These vapors are heavier than air and can accumulate in low-lying areas like the bilge or engine compartment. A single spark from starting the engine can ignite these fumes, leading to devastating consequences.

Ventilation systems address this by:

- Removing Flammable Vapors: Exhaust ducts and blowers extract gasoline vapors from the bilge and engine compartments, ensuring they don’t reach dangerous concentrations.

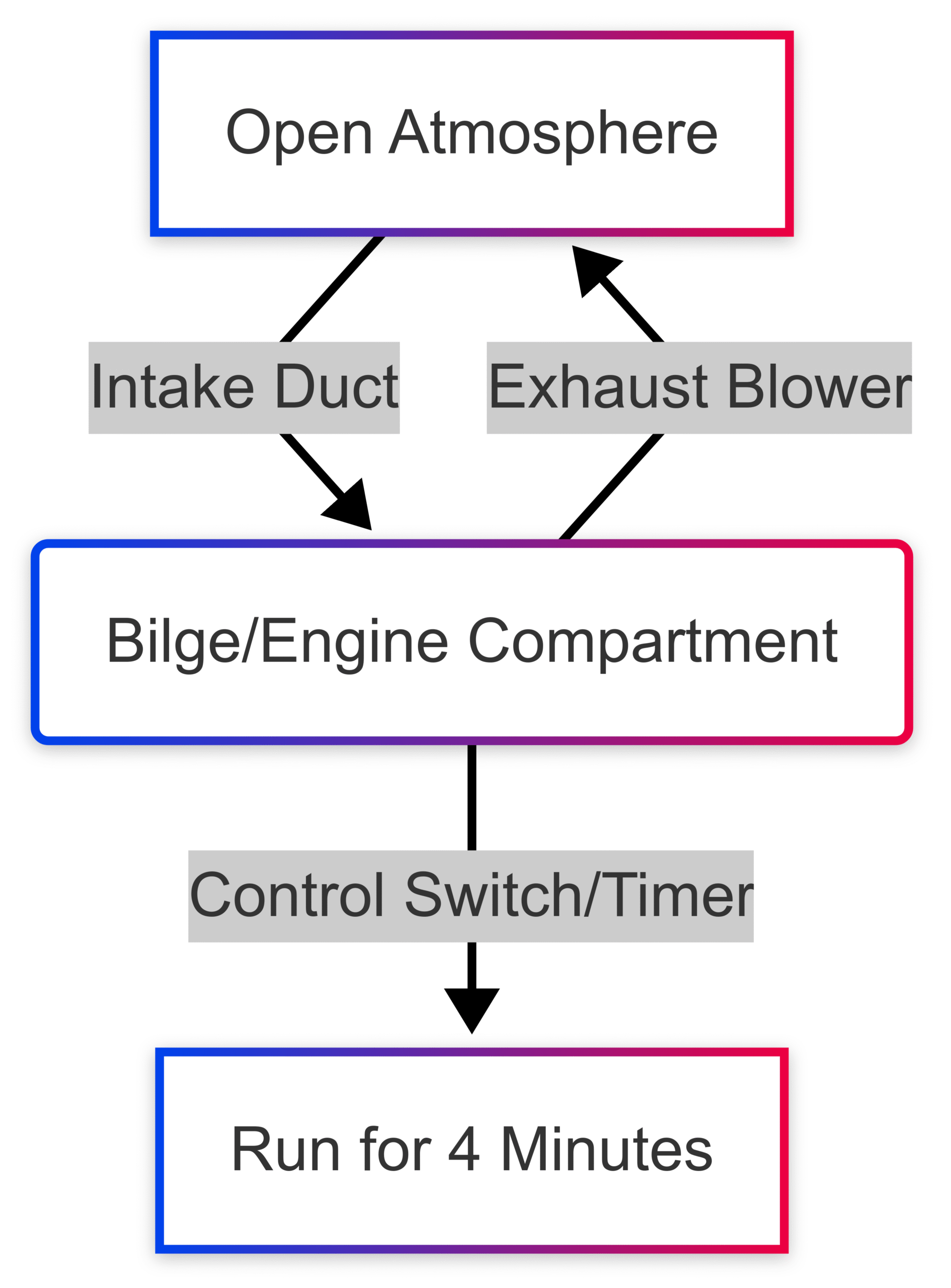

- Pre-Ignition Safety Checks: Regulations require running powered ventilation systems for at least four minutes before starting the engine to clear out any accumulated fumes. Boaters are also advised to sniff for gasoline odors as an additional precaution.

- Legal Compliance: Boats built after 1940 (in the U.S.) and those with enclosed gasoline engines (in Canada) must have ventilation systems to meet safety standards.

For example, U.S. regulations, such as those enforced in Iowa state waters, mandate that all powerboats (except open boats) using volatile fuels must have efficient ventilation for engine and fuel tank compartments. Similarly, Canadian Small Vessel Regulations require at least two ventilation ducts with cowls to remove vapors from enclosed spaces.

Real-World Impact

A study by the U.S. Coast Guard found that improper ventilation contributes to a significant percentage of boating accidents involving fires or explosions. Ensuring a functional ventilation system can reduce the risk of such incidents by up to 90%, making it a non-negotiable feature for gasoline-powered vessels.

Comfort and Environmental Control

Beyond safety, ventilation systems enhance onboard comfort by addressing humidity, odors, and air quality. Enclosed spaces on boats, such as cabins, galleys, and heads, can become stifling without proper airflow. Ventilation systems tackle these issues by:

- Reducing Humidity: Excess moisture can lead to mold and mildew, which damage interiors and pose health risks. Ventilation systems circulate fresh air to keep humidity levels in check.

- Eliminating Odors: Stale air, fuel smells, and cooking odors can make the boating experience unpleasant. Ventilation ensures a steady supply of fresh air to keep the cabin smelling clean.

- Improving Air Quality: By removing stale air and introducing fresh air, ventilation systems create a healthier environment for passengers and crew.

For example, a well-ventilated galley prevents the buildup of cooking fumes, while proper airflow in the head reduces the risk of mold growth in damp conditions.

Engine Room Ventilation: Protecting Performance

Engines generate significant heat and exhaust fumes, which can compromise performance and safety if not properly managed. Ventilation systems in engine rooms serve critical functions:

- Heat Dissipation: Marine engines, especially in powerboats, produce intense heat during operation. Ventilation systems remove hot air, preventing overheating and extending engine life.

- Fume Extraction: Exhaust blowers remove harmful fumes, protecting the crew from carbon monoxide exposure and maintaining a safe engine room environment.

- Cooling After Use: Strategically placed vents allow cooler outside air to enter the engine room after the boat has stopped, aiding in post-operation cooling.

High-performance blowers, such as those from Jabsco and Rule, are designed for engine room applications. Jabsco’s heavy-duty flangemount blowers, for instance, feature corrosion-resistant materials and a 5,000-hour motor life, making them ideal for continuous operation in demanding environments.

Bilge Ventilation: Keeping the Boat Dry

The bilge, the lowest part of a boat’s hull, is prone to collecting water, debris, and fuel residues. Without proper ventilation, this area becomes a breeding ground for mold, mildew, and corrosion. Bilge ventilation systems:

- Remove Moisture: By circulating air, these systems dry out the bilge, reducing the risk of mold and structural damage.

- Extract Vapors: Exhaust ducts positioned low in the bilge remove gasoline vapors, enhancing safety.

- Maintain Cleanliness: Proper airflow prevents the buildup of debris and contaminants, keeping the bilge clean and functional.

For smaller boats, compact inline blowers like those from Rule are popular for bilge ventilation due to their high airflow and low power consumption.

Types of Boat Ventilation Systems

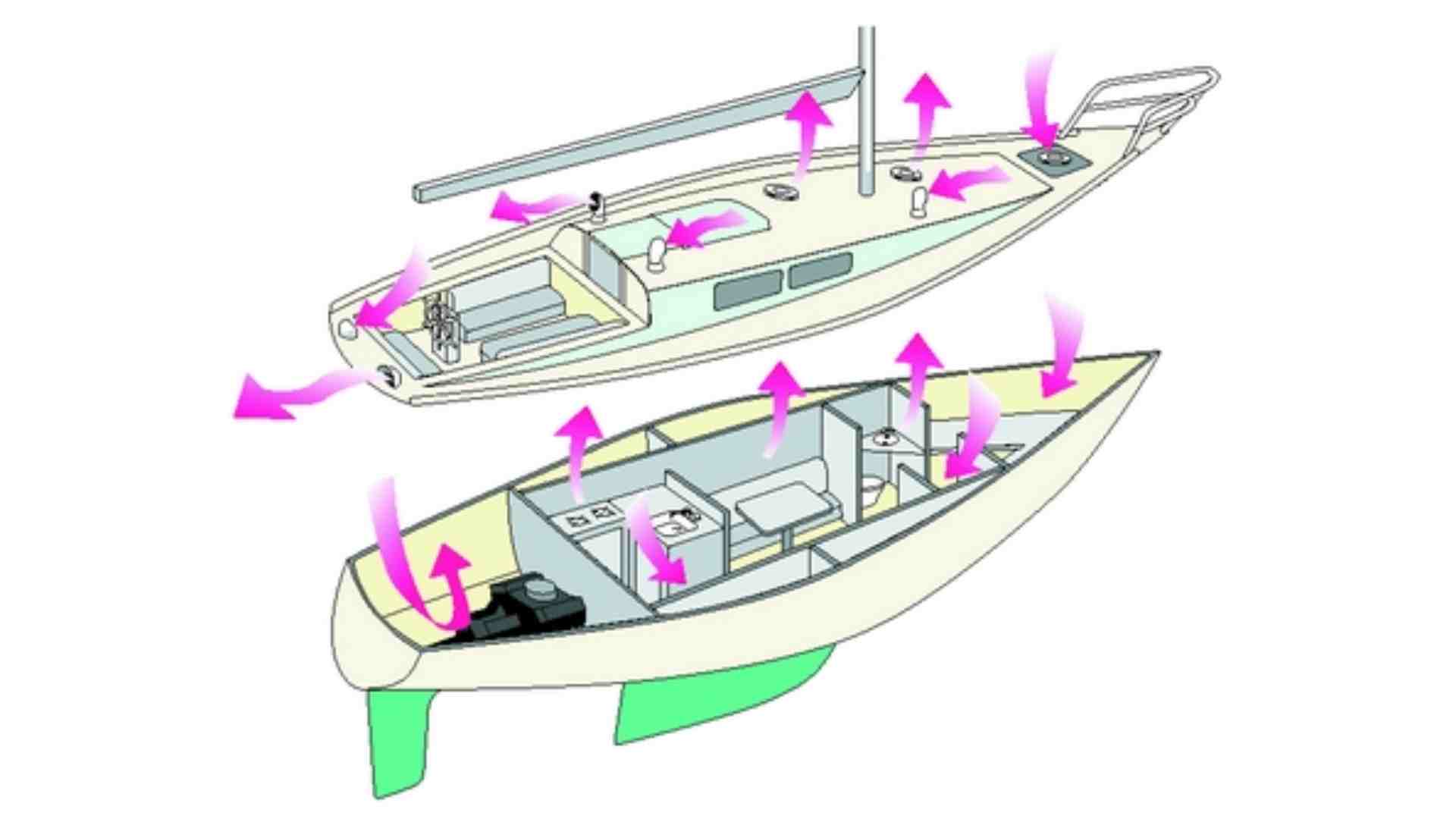

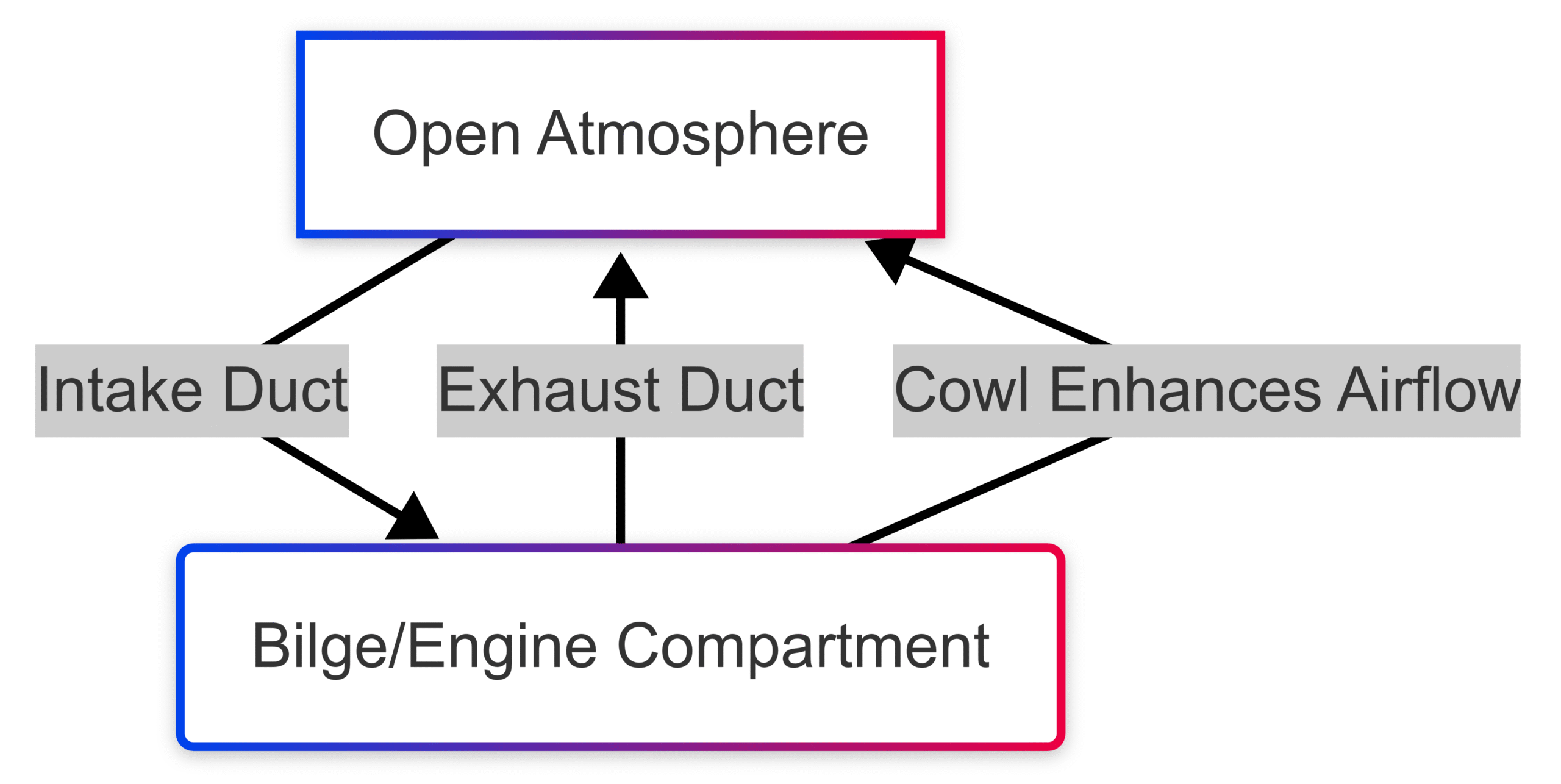

Boat ventilation systems fall into two main categories: natural (passive) and powered (active). Each has distinct mechanisms, advantages, and applications.

Natural Ventilation Systems

Natural ventilation relies on the boat’s motion and wind to circulate air. Key components include:

- Intake Duct: Draws fresh air from outside into the bilge or engine compartment. It must extend at least midway to the bilge or below the carburetor air intake level.

- Exhaust Duct: Removes stale air and fumes from the lower bilge to the open atmosphere.

- Cowls: Hood-shaped covers on ducts that enhance airflow by catching wind.

Advantages:

- No power consumption, making it energy-efficient.

- Simple design with fewer components to maintain.

- Suitable for smaller boats or those with minimal ventilation needs.

Limitations:

- Less effective when the boat is stationary or in calm conditions.

- Limited airflow compared to powered systems.

Diagram: Natural Ventilation System

Powered Ventilation Systems

Powered ventilation uses electric blowers to actively move air through ducts. These systems are required for boats built after 1982 with enclosed engines or fuel tanks.

Key Components:

- Exhaust Blowers: High-output motors that pull air and fumes from the lower bilge or engine compartment.

- Intake Ducts: Positioned to draw in fresh air, typically above the normal bilge water level.

- Control Systems: Timers or switches to ensure blowers run for at least four minutes before engine ignition.

Advantages:

- Highly effective at removing fumes, even when the boat is stationary.

- Greater airflow for larger or more complex vessels.

- Meets stringent regulatory requirements for enclosed gasoline engines.

Limitations:

- Requires power, increasing energy consumption.

- More complex maintenance due to electrical components.

Diagram: Powered Ventilation System

Regulatory Requirements for Boat Ventilation

Boating regulations in the U.S. and Canada emphasize the importance of ventilation systems for safety. Below are key requirements:

U.S. Regulations

- Iowa State Waters: All powerboats (except open boats) using volatile fuels must have ventilation systems to remove flammable gases from engine and fuel tank compartments.

- Post-1940 Boats: Gasoline-powered boats must have either natural or powered ventilation.

- Post-1980 Boats: Those with powered exhaust blowers in gasoline engine compartments must display a warning sticker near the instrument panel:

“WARNING: Gasoline vapors can explode. Before starting engine, operate blower for 4 minutes and check engine compartment for gasoline vapors.”

Canadian Small Vessel Regulations

- Boats with enclosed spaces containing gasoline engines or fuel tanks must have at least two ventilation ducts with cowls:

- One exhaust duct extending to the lower bilge.

- One intake duct extending at least midway to the bilge or below the carburetor air intake.

- Boats with powered ventilation must run blowers for four minutes after fueling and before starting the engine.

- A safety notice must be posted at each ignition switch to remind operators of the blower requirement.

Table: Ventilation System Requirements by Region

| Region | Boat Type | Ventilation Type | Key Requirements |

|---|---|---|---|

| U.S. (Iowa) | Gasoline-powered, non-open boats | Natural or Powered | Ventilation for engine/fuel compartments; warning sticker for post-1980 boats |

| Canada | Enclosed gasoline engine boats | Powered | Two ducts with cowls; blower operation for 4 minutes; safety notice at ignition switch |

Popular Ventilation System Brands and Specifications

Several manufacturers offer high-quality marine ventilation systems. Below are two leading brands with their specifications and approximate pricing (based on general market trends):

Jabsco Blowers

- Heavy-Duty Flangemount Blowers:

- Use: Commercial or high-use engine rooms.

- Features: Corrosion-resistant materials, Delrin rotors, 5,000-hour motor life, direct bulkhead mounting.

- Airflow: Up to 250 CFM (Cubic Feet per Minute).

- Power: 12V or 24V DC.

- Price: $150–$300 (depending on model and retailer).

- Flexmount Blowers:

- Use: Engine rooms, fuel compartments, galleys, heads.

- Features: Rotatable mounting for flexible ducting, corrosion-resistant, high output.

- Airflow: 150–200 CFM.

- Price: $100–$200.

Rule Blowers

- Compact Inline Blowers:

- Use: Small boats, bilges, galleys, heads.

- Features: Front/rear shaft seals, corrosion-resistant motor housing, low amp draw.

- Airflow: 100–150 CFM.

- Power: 12V DC.

- Price: $50–$100.

Table: Comparison of Jabsco and Rule Blowers

| Feature | Jabsco Flangemount | Jabsco Flexmount | Rule Inline |

|---|---|---|---|

| Airflow (CFM) | Up to 250 | 150–200 | 100–150 |

| Power | 12V/24V DC | 12V/24V DC | 12V DC |

| Motor Life | 5,000 hours | 5,000 hours | 3,000–4,000 hours |

| Mounting | Direct bulkhead | Rotatable collar | Flat surface |

| Price Range | $150–$300 | $100–$200 | $50–$100 |

| Best For | Commercial/heavy use | Versatile spaces | Small boats |

Note: Prices are approximate and may vary by retailer or region. Check with marine suppliers like West Marine or Defender for current pricing.

Maintenance Tips for Boat Ventilation Systems

To ensure optimal performance and compliance, boat owners must maintain their ventilation systems. Here are practical tips:

- Inspect Ducts and Openings:

- Check for blockages, debris, or damage in intake and exhaust ducts.

- Ensure cowls are free of obstructions to maximize airflow.

- Test Blowers:

- Run powered blowers to confirm they operate smoothly without unusual noises.

- Verify that blowers achieve the required airflow (check manufacturer specs).

- Replace Worn Parts:

- Use marine-grade replacement parts to maintain system integrity.

- Replace damaged ducts or corroded components promptly.

- Check Electrical Connections:

- Ensure wiring for powered blowers is secure and free of corrosion.

- Test control switches and timers for proper operation.

- Follow Pre-Start Procedures:

- Run powered ventilation for at least four minutes before starting the engine.

- Sniff for gasoline vapors in the engine compartment, especially on boats without powered systems.

Common Issues and Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Weak airflow | Blocked ducts or cowls | Clear obstructions; inspect for damage |

| Blower not working | Faulty motor or wiring | Test motor; check connections |

| Persistent gasoline odors | Inadequate ventilation time | Run blower for 4+ minutes; check ducts |

| Mold/mildew in bilge | Poor ventilation or drainage | Increase airflow; inspect bilge pump |

The Bigger Picture: Ventilation and Boat Longevity

A well-maintained ventilation system not only ensures safety and comfort but also extends the lifespan of the boat. By preventing moisture-related damage, reducing engine wear, and maintaining a clean bilge, ventilation systems protect the vessel’s structural and mechanical integrity. For boat owners, investing in a reliable ventilation system—whether natural or powered—is a small price to pay for the safety and enjoyment of life on the water.

Conclusion

Boat ventilation systems are indispensable for safety, comfort, and compliance. By removing flammable vapors, they prevent explosions, while fresh air circulation enhances onboard comfort and protects the vessel from moisture damage. Whether opting for natural or powered ventilation, boat owners must prioritize proper installation, maintenance, and adherence to regulations. With trusted brands like Jabsco and Rule offering robust solutions, equipping your boat with an effective ventilation system is a critical step toward safe and enjoyable boating.

Happy Boating!

Share what is the purpose of a boats ventilation system with your friends and leave a comment below with your thoughts.

Read What Are Pontoon Boats Used For: Guide until we meet in the next article.