Understanding the Megger Test and its Importance on Ships

Learn about Megger testing, its importance on ships, and how it ensures electrical safety and reliability in marine environments.

Electrical systems are the backbone of modern maritime operations, powering critical components such as propulsion systems, navigation equipment, and communication devices. In the harsh marine environment, where equipment is exposed to saltwater, humidity, and temperature fluctuations, maintaining the integrity of these systems is paramount. One of the most effective tools for ensuring the reliability and safety of electrical systems on ships is the Megger test, also known as insulation resistance testing. This diagnostic technique assesses the condition of electrical insulation, helping to prevent failures, enhance safety, and ensure compliance with maritime regulations.

This article provides an in-depth exploration of Megger testing, its operational mechanics, its significance in the maritime industry, and best practices for implementation. We will also examine the types of Megger tests, their applications, and how they contribute to the longevity and safety of shipboard electrical systems.

What is a Megger Test?

The Megger test is a diagnostic procedure used to measure the insulation resistance of electrical components and systems. Named after the Megger company, a leading manufacturer of insulation resistance testers, the term “Megger” is often used generically to describe any insulation resistance testing device. The primary goal of the test is to evaluate the quality of insulation, which prevents unwanted current leakage that could lead to electrical faults, fires, or shocks.

Insulation resistance is measured in megohms (MΩ), with higher values indicating better insulation quality. Over time, insulation can degrade due to environmental factors like moisture, heat, or mechanical stress, particularly in the demanding conditions of a ship. The Megger test applies a high-voltage direct current (DC) to the insulation and measures the resulting leakage current to calculate resistance using Ohm’s Law:

[ R = \frac{V}{I} ]

Where:

- ( R ) is the insulation resistance (in ohms),

- ( V ) is the applied voltage (in volts),

- ( I ) is the leakage current (in amperes).

Why Insulation Resistance Matters

Insulation serves as a barrier that confines electrical current to its intended path. When insulation degrades, it can lead to:

- Electrical faults: Short circuits or ground faults that disrupt operations.

- Safety hazards: Increased risk of electrical shocks or fires.

- Reduced efficiency: Energy losses due to leakage currents.

- Equipment damage: Premature failure of critical components.

By detecting insulation weaknesses early, Megger testing enables proactive maintenance, reducing the likelihood of costly repairs or catastrophic failures.

How a Megger Tester Works

A Megger tester is a portable device that generates high-voltage DC, typically ranging from 250V to 5,000V, depending on the system being tested. The tester applies this voltage across the insulation material and measures the resistance to current flow. The process involves several key steps:

- Isolate the Equipment: The equipment or circuit must be disconnected from the power supply and locked out to ensure safety and prevent damage to sensitive electronics.

- Connect the Tester: One lead of the Megger tester is connected to the conductor, and the other to the insulation material or ground.

- Apply Test Voltage: The tester applies a controlled high-voltage DC to stress the insulation and reveal any weaknesses.

- Measure Resistance: The device measures the leakage current and calculates the insulation resistance in megohms.

- Analyze Results: The resistance value is compared to industry standards or historical data to determine the insulation’s condition.

Interpreting Megger Test Results

The results of a Megger test are interpreted based on the insulation resistance value:

- High Resistance (Megohms or higher): Indicates healthy insulation, capable of preventing unwanted current flow.

- Moderate Resistance: Suggests potential deterioration, warranting further investigation or maintenance.

- Low Resistance: Signals compromised insulation, requiring immediate repair or replacement.

For example, marine electrical standards often require insulation resistance to meet minimum thresholds, such as 1 MΩ for systems rated below 1,000V.

Importance of Megger Testing on Ships

Ships operate in some of the most challenging environments, where electrical systems are constantly exposed to moisture, salt, vibrations, and extreme temperatures. These conditions accelerate insulation degradation, making regular Megger testing critical for several reasons:

1. Ensuring Safety

Faulty insulation can lead to short circuits, ground faults, or electrical shocks, posing significant risks to crew and passengers. Megger testing identifies potential hazards before they escalate, preventing accidents and ensuring a safe operating environment.

2. Enhancing Reliability

Unplanned equipment failures at sea can disrupt operations and compromise mission-critical systems like propulsion or navigation. By detecting insulation issues early, Megger testing minimizes downtime and ensures the continuous operation of vital systems.

3. Extending Equipment Lifespan

Electrical equipment, such as motors, generators, and transformers, represents a significant investment for ship operators. Regular Megger testing helps maintain these assets by identifying and addressing insulation problems before they cause permanent damage, thereby extending equipment lifespan.

4. Ensuring Regulatory Compliance

Maritime regulations, such as those set by the International Maritime Organization (IMO) and classification societies like the American Bureau of Shipping (ABS), mandate regular testing of electrical systems. Megger testing ensures compliance with standards like IEC 60092-351, which governs electrical installations on ships.

5. Supporting Preventive Maintenance

Megger testing is a cornerstone of preventive maintenance programs. By integrating it into routine maintenance schedules, ship operators can proactively address insulation issues, reducing the risk of unexpected failures and optimizing maintenance planning.

6. Protecting Sensitive Systems

Modern ships rely on sophisticated electronic systems for navigation, communication, and automation. Insulation failures can damage these sensitive components, leading to costly repairs or operational disruptions. Megger testing safeguards these systems by ensuring insulation integrity.

Types of Megger Tests

Megger testing encompasses several methods, each suited to specific diagnostic needs:

- Spot Reading Test: Measures insulation resistance at a single point in time, providing a quick snapshot of insulation condition. This is ideal for routine checks.

- Time Resistance Test: Monitors insulation resistance over an extended period to detect issues like moisture ingress, which may cause resistance to drop gradually.

- Step Voltage Test: Applies increasing voltage levels to assess how insulation performs under varying stress conditions, revealing weaknesses that may not appear at lower voltages.

The following table summarizes the types of Megger tests and their applications:

| Test Type | Description | Best Use Case |

|---|---|---|

| Spot Reading Test | Measures insulation resistance at a specific moment | Routine maintenance checks |

| Time Resistance Test | Tracks resistance changes over time to detect moisture or contamination | Diagnosing environmental degradation |

| Step Voltage Test | Applies incremental voltages to evaluate insulation under stress | Assessing insulation under high voltages |

Applications of Megger Testing on Ships

Megger testing is applied to various shipboard electrical components to ensure their reliability and safety:

1. Generators and Motors

Generators and electric motors power critical systems like propulsion and auxiliary equipment. Insulation breakdown in these components can lead to overheating or failure. Regular Megger testing ensures the integrity of windings and cables.

2. Transformers

Transformers adjust voltage levels for different shipboard applications. Testing their insulation prevents arcing, shorts, or catastrophic failures that could disrupt power distribution.

3. Switchboards

Switchboards distribute power across the ship. Insulation testing ensures they operate safely and reliably, preventing power interruptions or electrical accidents.

4. Cabling and Wiring

Shipboard cables are exposed to harsh conditions, making them prone to insulation damage. Megger testing verifies their ability to conduct electricity without leakage.

5. Navigation and Communication Systems

Systems like radar, GPS, and radios are vital for safe navigation. Insulation testing protects these systems from faults that could impair their functionality.

Megger Testing Standards and Specifications

Marine electrical systems must adhere to strict standards to ensure safety and reliability. The following table outlines minimum insulation resistance requirements for various shipboard systems, based on maritime standards:

| Rated Voltage (Vr) | Minimum Test Voltage (V) | Minimum Insulation Resistance (MΩ) |

|---|---|---|

| Vr < 250V | 2 × Vr | 1 |

| 250V < Vr < 1,000V | 500 | 1 |

| 1,000V < Vr < 7,200V | 1,000 | (Vr / 1,000) + 1 |

| 7,200V < Vr < 15,000V | 5,000 | (Vr / 1,000) + 1 |

For power and lighting circuits, insulation resistance varies by load:

| Load (Amps) | Minimum Insulation Resistance (Ω) |

|---|---|

| Up to 5 | 2,000,000 |

| 10 | 1,000,000 |

| 25 | 400,000 |

| 50 | 250,000 |

| 100 | 100,000 |

| 200 | 50,000 |

| Over 200 | 25,000 |

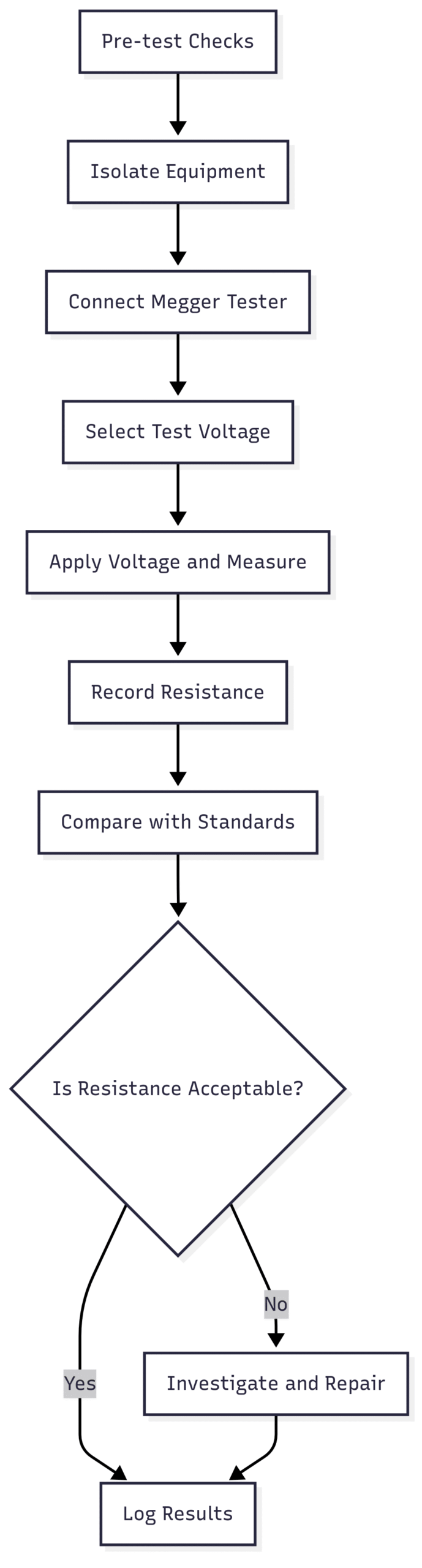

Flowchart: Megger Testing Process

This flowchart illustrates the systematic approach to conducting a Megger test, ensuring accurate results and effective follow-up actions.

Equipment Specifications and Pricing

Megger testers come in various models, each designed for specific applications. Below is a comparison of popular Megger testers suitable for marine use:

| Model | Test Voltage Range | Features | Approx. Price (USD) |

|---|---|---|---|

| Megger MIT525 | 250V–5,000V | Digital display, data storage, automatic testing | $4,000–$5,000 |

| Megger MIT410/2 | 50V–1,000V | Compact, rugged design, ideal for field use | $800–$1,200 |

| Megger MIT1025 | 500V–10,000V | Advanced diagnostics, suitable for high-voltage systems | $5,500–$7,000 |

Note: Prices are approximate and may vary based on supplier and region. For the latest pricing, visit Megger’s official website or authorized distributors.

Best Practices for Megger Testing

To maximize the effectiveness of Megger testing, follow these best practices:

- Regular Testing: Conduct tests during scheduled maintenance or after repairs to monitor insulation health.

- Proper Training: Ensure personnel are trained in Megger testing procedures and safety protocols.

- Equipment Calibration: Regularly calibrate Megger testers to maintain accuracy.

- Environmental Control: Perform tests in stable conditions to avoid skewed results due to temperature or humidity.

- Documentation: Maintain detailed logs of test results to track insulation trends over time.

Common Challenges and Solutions

- Inaccurate Readings: Verify test leads and connections; compensate for environmental factors like humidity.

- Complex Systems: Test complex circuits in segments to isolate issues.

- Safety Risks: Adhere to lockout/tagout procedures and wear appropriate PPE.

Conclusion

Megger testing is an indispensable tool for maintaining the safety, reliability, and efficiency of electrical systems on ships. By regularly assessing insulation resistance, ship operators can prevent electrical failures, ensure compliance with maritime regulations, and extend the lifespan of critical equipment. As ships become increasingly reliant on advanced electrical and electronic systems, the role of Megger testing will continue to grow, making it a vital component of modern maritime maintenance programs.

By integrating Megger testing into routine maintenance schedules and adhering to best practices, shipowners can mitigate risks, reduce operational costs, and ensure smooth operations at sea. Whether testing generators, transformers, or navigation systems, the Megger test remains a cornerstone of electrical safety and reliability in the maritime industry.

Share Understanding the Megger Test and its Importance on Ships with your friends and leave a comment below with your thoughts.

Read A Guide to the 4 Pillars of Maritime Law until we meet in the next article.