Understanding Boiler Safety on Ships – Common Risks

Learn about marine boiler safety on ships, common risks, safety valves, and systems to prevent explosions and ensure safe operations.

Marine boilers are critical components of a ship’s engine room, responsible for generating steam to power various systems, from propulsion in older vessels to heating fuel for modern main engines. However, their operation involves significant risks, including explosions, fires, and scalding injuries. Ensuring boiler safety is paramount to protect the crew, the vessel, and the environment. This comprehensive guide explores the common risks associated with marine boilers, the safety systems and instruments designed to mitigate these risks, and best practices for operational safety. By understanding these elements, ship operators and engineers can maintain safe and efficient boiler operations.

The Role of Marine Boilers in Ship Operations

Marine boilers have been integral to maritime operations since the advent of steam-powered ships. Historically, they powered propulsion systems via steam engines. Today, their role has evolved, with steam used for auxiliary functions such as heating heavy fuel oil for main engines, powering steam turbines, or supporting cargo operations like heating cargo tanks. Despite their reduced role in propulsion, marine boilers remain complex systems operating under high pressure and temperature, making safety a critical concern.

Boilers are often considered one of the most hazardous systems in the engine room due to the potential for catastrophic failures. A single oversight in operation or maintenance can lead to devastating consequences, including loss of life, vessel damage, or environmental harm. This article delves into the primary risks associated with marine boilers and the safety measures that mitigate them, focusing on safety valves, instrumentation, and operational protocols.

Common Risks Associated with Marine Boilers

Marine boilers pose several inherent risks due to their high-pressure, high-temperature operations and the flammable fuels they use. Below are the most prevalent hazards and their implications:

1. Boiler Explosions

Boiler explosions are among the most severe accidents in maritime history. They occur when excessive pressure builds up inside the boiler drum, often due to mismanaged fuel systems or unregulated steam pressure. If the pressure exceeds the boiler’s structural limits, it can rupture, releasing a destructive force capable of damaging the ship and endangering lives. Historical incidents, such as boiler explosions on early steamships, highlight the catastrophic potential of such failures.

2. Boiler Fires and Meltdowns

Fires within the boiler, often caused by improper fuel atomization or burner malfunctions, can destroy internal components like tubes and refractory linings. These fires may spread to other parts of the engine room, posing a significant risk to the vessel. A meltdown, where tubes overheat due to low water levels, can also lead to structural failure or explosions.

3. Scalding Injuries

Scalding, caused by exposure to high-temperature steam, is a common injury among seafarers working with boiler systems. Approximately 80% of seamen operating steam systems experience scalding incidents, ranging from minor burns to severe injuries, during their careers. These incidents often occur during maintenance or when handling steam pipes and valves.

4. Hot Surface Burns

The external surfaces of boilers, pipes, and associated valves often reach temperatures exceeding 200°C. Direct contact with these surfaces can cause severe burns, especially if insulation (lagging) is damaged or inadequate. These injuries are preventable with proper maintenance and protective measures.

5. Other Hazards

Additional risks include handling high-pressure components, exposure to harmful chemicals used in water treatment, and injuries from moving machinery like fuel pumps or forced draught fans. These hazards, while less severe than explosions or fires, still require careful management to ensure crew safety.

Boiler Safety Systems and Instruments

To mitigate these risks, modern marine boilers are equipped with advanced safety systems and instruments. These are designed to monitor critical parameters, provide early warnings, and prevent accidents. The safety systems can be categorized based on the boiler’s subsystems: steam, water, and fuel.

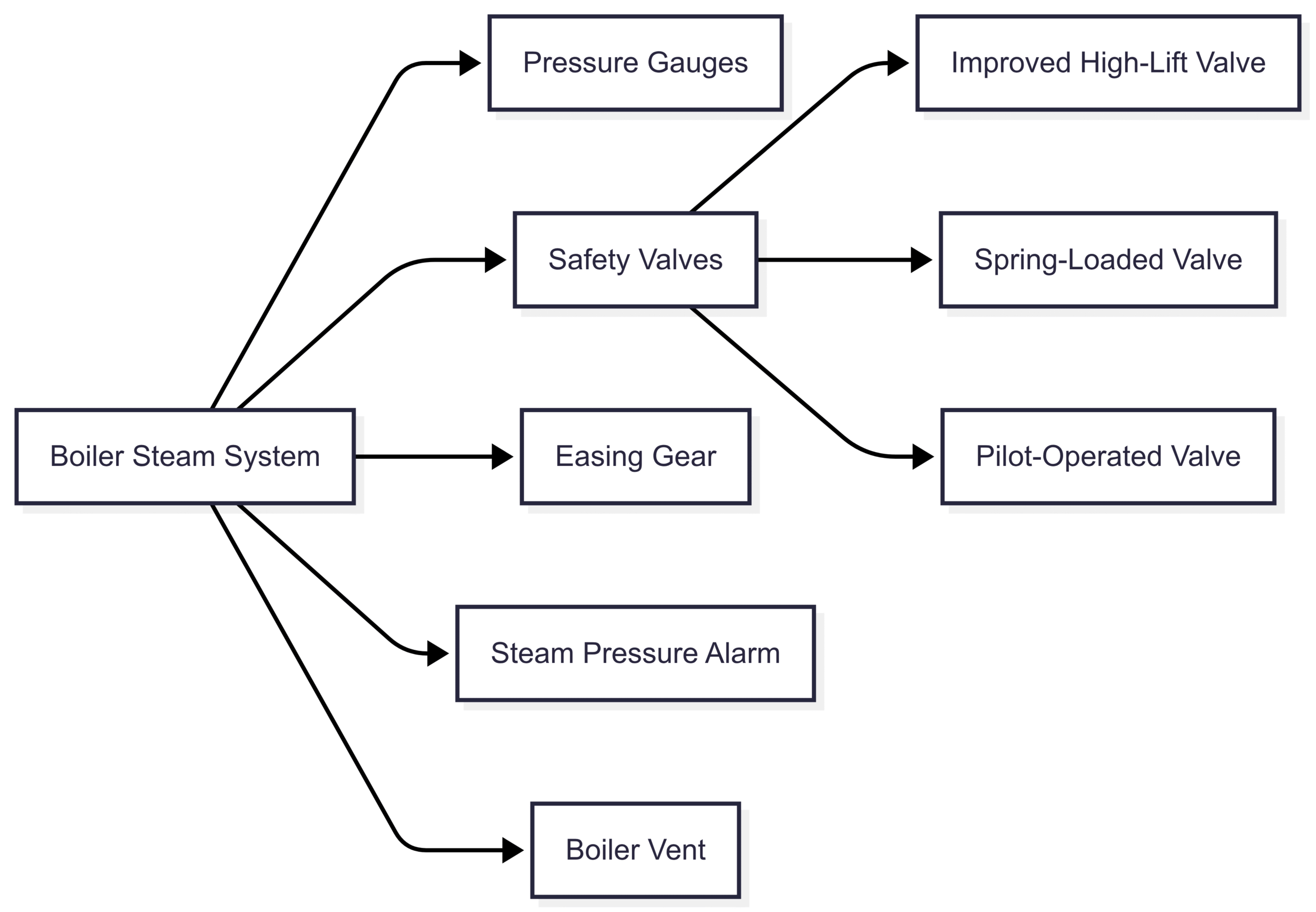

Steam Safety System

The steam system operates under high pressure and temperature, making it the most critical area for safety. Key safety features include:

- Pressure Gauges: Multiple pressure gauges are installed on the boiler to monitor steam pressure in real time. Typically, two gauges are fitted on the boiler itself, with an additional line to the engine control room for remote monitoring. These gauges are integrated with automation systems to control the burner. When pressure reaches a preset high limit, the burner stops firing; when it drops to a lower limit, the burner restarts to maintain optimal pressure.

- Safety Valves: Safety valves are the cornerstone of boiler safety, mandated by SOLAS Chapter II-1, which requires at least two safety valves on every steam boiler. These valves are set to open at a pressure slightly above the boiler’s normal working pressure (typically 3% higher) and close when pressure returns to a safe level. The most common type is the improved high-lift safety valve, designed to lift at the blow-off pressure with a lift of one-twelfth of the valve diameter. These valves must have sufficient capacity to relieve more energy than the boiler can produce, preventing overpressure.

- Easing Gear: Each safety valve is equipped with an easing gear—a pulley-and-wire system connected to a lever on the valve. This allows operators to manually lift the valve for testing or in emergencies without approaching the valve directly, reducing the risk of scalding or injury.

- Steam Pressure Alarm and Cutout: An audio-visual alarm alerts operators when steam pressure approaches unsafe levels. If the pressure continues to rise or fall beyond safe limits, a cutout system halts the burner. The high-pressure cutout is non-overridable to prevent catastrophic overpressure, while the low-pressure cutout can be overridden in specific scenarios.

- Boiler Vent: A vent on the boiler drum is opened when the pressure drops below 0.5 bar during shutdown to prevent implosion due to vacuum formation.

Water Safety System

The water system is critical for maintaining boiler efficiency and preventing damage from overheating or contamination. Safety features include:

- Low/High Water Level Alarm and Cutout: A level sensor in the boiler drum continuously monitors water levels. High water levels can cause carryover, reducing efficiency, while low levels risk tube overheating, potentially leading to fires or meltdowns. Alarms provide early warnings, and a secondary “too low” water level cutout stops the burner to prevent damage.

- Water Level Indicators: Multiple indicators, including local duplex gauge glasses and remote sensors (e.g., differential pressure or probe sensors), allow operators to monitor water levels from the boiler platform and engine control room. These ensure redundancy and reliability in level monitoring.

- Salinity Sensor: A salinity sensor monitors dissolved solids in the boiler water. Excessive salinity, often due to condenser leaks, can damage tubes and internals. If salinity exceeds safe limits, the sensor triggers an alarm and may trip the boiler, prompting the operator to blow down the boiler and feed fresh water.

Fuel Safety System

The fuel system, which supplies heavy or marine gas oil to the burner, is another critical area for safety. Key features include:

- Low Fuel Oil Pressure Alarm: Two fuel pumps (one active, one standby) ensure continuous fuel supply. If pressure drops below the required level, atomization fails, leading to fuel dripping and potential blow-back, which can injure operators. An alarm prompts immediate action to restore pressure.

- Low/High Fuel Oil Temperature Alarm: Fuel temperature affects viscosity and combustion efficiency. Alarms sound if the temperature deviates from the optimal range for the fuel grade, allowing operators to adjust conditions before restarting the burner.

- Flame Failure Alarm: A photocell (flame eye) detects the burner flame. If the flame fails during startup or operation, an audio-visual alarm alerts the operator to prevent unburned fuel accumulation.

- Smoke Density Alarm: A sensor in the exhaust monitors smoke density, especially during startup or low-load conditions. High smoke density indicates poor combustion, triggering an alarm for operator intervention.

- Forced Draught Fan Stop Alarm: The forced draught fan supplies air for combustion. If it stops, an alarm ensures the operator addresses the issue to maintain efficient combustion.

| Safety System | Component | Function | Key Specification |

|---|---|---|---|

| Steam System | Pressure Gauge | Monitors steam pressure | Multiple units, remote display in ECR |

| Steam System | Safety Valve | Relieves excess pressure | Min. 2 valves, 3% above working pressure |

| Steam System | Easing Gear | Manual valve operation | Pulley-and-wire system for testing |

| Water System | Level Sensor | Monitors water level | Low/high and too-low alarms |

| Water System | Salinity Sensor | Detects dissolved solids | Trips boiler on high salinity |

| Fuel System | Fuel Pressure Alarm | Ensures proper atomization | Dual pumps for redundancy |

| Fuel System | Flame Eye | Detects burner flame | Audio-visual alarm on failure |

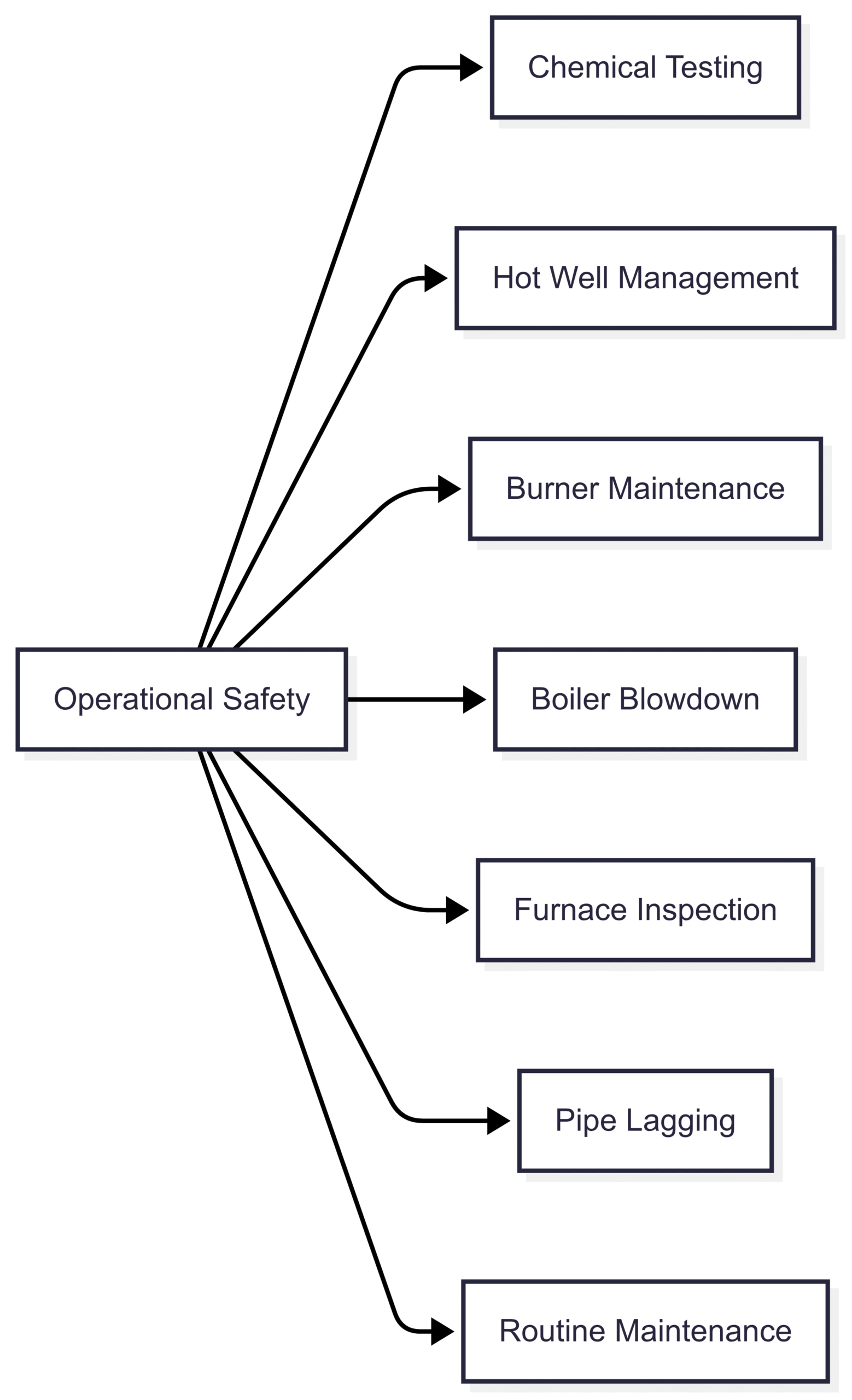

Operational Safety Practices

While automation and safety systems are critical, human expertise and adherence to best practices are equally important for boiler safety. Operational safety focuses on proactive measures to prevent accidents and maintain efficiency. Key practices include:

1. Chemical Testing and Dosing

Regular testing of boiler water for pH, alkalinity, and contaminants ensures it does not corrode or damage internal components. Chemical dosing corrects water chemistry to prevent scaling or corrosion.

2. Efficient Hot Well/Cascade Tank Operation

Maintaining the correct temperature in the hot well or cascade tank reduces the time required to generate steam, improving efficiency and reducing thermal stress on the boiler.

3. Burner Maintenance

A well-maintained burner ensures proper fuel atomization, preventing backfires and ensuring efficient combustion. Regular cleaning and inspection are essential.

4. Boiler Blowdown

Periodic blowdown removes impurities and maintains water alkalinity, preventing tube damage and improving steam quality.

5. Furnace Inspection

Regular inspection of the furnace refractory ensures it contains heat effectively, reducing surface heat loss and maintaining efficiency.

6. Pipe and Valve Lagging

Proper insulation (lagging) on steam pipes and valves prevents heat loss and protects crew from burns. Damaged lagging must be repaired promptly.

7. Routine Maintenance

Scheduled maintenance, including safety valve testing, tube cleaning, and pump inspections, ensures the boiler operates safely and efficiently.

Regulatory Compliance and Standards

Marine boiler safety is governed by international regulations, primarily SOLAS Chapter II-1, which mandates the installation of at least two safety valves with adequate capacity. The International Maritime Organization (IMO) and American Society of Mechanical Engineers (ASME) codes provide additional standards for design, testing, and maintenance. Compliance ensures boilers meet safety and performance requirements, reducing the risk of accidents.

The Importance of a Safety-First Mindset

The adage “prevention is better than cure” is particularly relevant for marine boiler operations. While modern safety systems provide robust protection, human vigilance is critical. Engineers must prioritize regular maintenance, adhere to operational protocols, and respond promptly to alarms. Training and awareness are essential to ensure all crew members understand the risks and safety procedures associated with boilers.

Conclusion

Marine boilers are vital to ship operations but pose significant risks if not managed properly. Boiler explosions, fires, scalding, and burns are preventable through a combination of advanced safety systems, regular maintenance, and strict adherence to operational protocols. Safety valves, pressure gauges, water level sensors, and fuel system alarms form the backbone of boiler safety, while practices like chemical testing, blowdown, and burner maintenance enhance reliability and efficiency. By fostering a safety-first mindset and complying with international regulations, ship operators can mitigate risks and ensure the safe operation of marine boilers, protecting both the crew and the vessel.

Happy Boating!

Share Understanding Boiler Safety on Ships – Common Risks with your friends and leave a comment below with your thoughts.

Read An Introduction to Ship’s Turbine Generator until we meet in the next article.