Understanding Ship Engine Room Pumps

Explore ship engine room pumps: centrifugal, positive displacement, and specialized types. Learn their functions, applications, and latest trends.

Ship engine rooms are the pulsating core of any vessel, orchestrating the movement of fluids that keep engines running, systems cool, and the ship stable. At the center of these operations are pumps—mechanical workhorses that transfer water, fuel, oil, and other liquids critical to a ship’s functionality. Without reliable pumps, a vessel risks propulsion failure, overheating, flooding, or environmental non-compliance. This article delves into the types of pumps used in ship engine rooms, their functions, applications, and the latest advancements shaping their role in modern maritime operations.

Why Pumps Are Essential in Ship Engine Rooms

Pumps in a ship’s engine room perform vital tasks that ensure operational efficiency and safety. They circulate fluids for cooling engines, transferring fuel, lubricating machinery, and managing bilge and ballast water. A failure in any pump can lead to catastrophic consequences, such as engine shutdowns, compromised stability, or environmental hazards like oil spills. For instance, a malfunctioning bilge pump could allow water accumulation, threatening the ship’s buoyancy, while a failed fuel pump might halt propulsion.

The importance of pumps extends beyond functionality to regulatory compliance. International Maritime Organization (IMO) standards, such as those for low-sulfur fuel systems and ballast water management, require pumps to meet stringent performance criteria. Understanding their types, applications, and maintenance is crucial for marine engineers, ship operators, and maritime enthusiasts.

Types of Ship Engine Room Pumps

Ship pumps are broadly classified into two categories based on their operating principles: positive displacement pumps and rotodynamic (centrifugal) pumps. Each type is suited to specific tasks, determined by the fluid’s characteristics (e.g., viscosity, density) and system requirements (e.g., flow rate, pressure).

1. Positive Displacement Pumps

Positive displacement pumps deliver a fixed volume of fluid per cycle, making them ideal for high-viscosity fluids like fuel oil or lubricants and applications requiring high pressure. They are self-priming, meaning they can start pumping without external assistance, and are used for precise fluid control.

a) Rotary Positive Displacement Pumps

Rotary pumps use rotating components to trap and move fluid, offering smooth, consistent flow with minimal pulsation.

- Gear Pumps

Working Principle: Meshing gears rotate to trap and transfer fluid, creating a steady flow.

Applications:- Fuel oil transfer (e.g., heavy fuel oil, marine gas oil).

- Lubrication of engine components like bearings and gears.

Advantages:- Handles high-viscosity fluids effectively.

- Reliable for consistent flow.

Example: A gear pump might transfer heavy fuel oil to the ship’s main engine at a steady rate of 10 m³/h.

- Screw Pumps

Working Principle: Rotating screws push fluid along the pump axis, delivering non-pulsating flow.

Applications:- Heavy fuel oil transfer and booster systems for fuel injection.

- Lubrication oil circulation.

Advantages:- Quiet operation.

- Excellent for viscous fluids.

Example: Screw pumps are used in large container ships to circulate lubrication oil at pressures up to 10 bar.

- Lobe Pumps

Working Principle: Rotating lobes gently move fluid with minimal shear, preserving fluid quality.

Applications:- Transfer of delicate or viscous fluids like lubricating oils.

Advantages:- Low shear, protecting sensitive fluids.

- Reversible flow capability.

- Transfer of delicate or viscous fluids like lubricating oils.

- Sliding Vane Pumps

Working Principle: Vanes slide in and out of a rotor to maintain consistent fluid movement.

Applications:- Handling fluids with varying viscosities, such as fuel oils.

Advantages:- Self-adjusting vanes for wear compensation.

- Versatile for different fluid types.

- Handling fluids with varying viscosities, such as fuel oils.

b) Reciprocating Positive Displacement Pumps

Reciprocating pumps use back-and-forth motion to displace fluid, excelling in high-pressure applications.

- Piston Pumps

Working Principle: A piston moves within a cylinder to generate fluid pressure.

Applications:- Hydraulic systems for winches and steering gears.

- High-pressure fuel injection.

Advantages:- High-pressure output (up to 200 bar).

- Precise fluid delivery.

- Plunger Pumps

Working Principle: Similar to piston pumps but with a smaller, high-pressure plunger.

Applications:- High-pressure cleaning systems.

- Hydraulic power systems.

Advantages:- Exceptional pressure capabilities (up to 500 bar).

- Durable for demanding conditions.

- Diaphragm Pumps

Working Principle: A flexible diaphragm displaces fluid, isolating it from moving parts.

Applications:- Handling abrasive or corrosive fluids, such as bilge water.

- Chemical dosing systems.

Advantages:- Leak-free operation.

- Suitable for hazardous fluids.

2. Rotodynamic (Centrifugal) Pumps

Rotodynamic pumps use rotating impellers to impart kinetic energy to fluids, creating flow. They are ideal for high-flow, low-viscosity fluids like seawater and are widely used in ship engine rooms.

- Centrifugal Pumps

Working Principle: A rotating impeller generates centrifugal force to move fluid radially outward.

Applications:- Cooling water systems for engines and generators.

- Ballast water transfer for stability.

- Firefighting systems for high-volume water delivery.

- Bilge water removal.

Advantages:- High flow rates (up to 5000 m³/h).

- Simple design with low maintenance.

Example: A centrifugal fire pump might deliver 1000 m³/h of water at 10 bar for firefighting.

- Axial Flow Pumps

Working Principle: Fluid moves parallel to the pump shaft, driven by a propeller-like impeller.

Applications:- Large-volume water circulation, such as flooding or de-ballasting.

Advantages:- High flow rates for low-pressure systems.

- Efficient for large-scale water movement.

- Large-volume water circulation, such as flooding or de-ballasting.

- Mixed Flow Pumps

Working Principle: Combines radial and axial flow for versatile performance.

Applications:- Ballast water transfer.

- General water circulation.

Advantages:- Balances flow and pressure.

- Adaptable to varying conditions.

- Turbine Pumps

Working Principle: Multi-stage impellers deliver high-pressure fluid flow.

Applications:- Boiler feedwater systems.

- High-pressure cooling systems.

Advantages:- High-pressure output (up to 100 bar).

- Compact design for high-pressure needs.

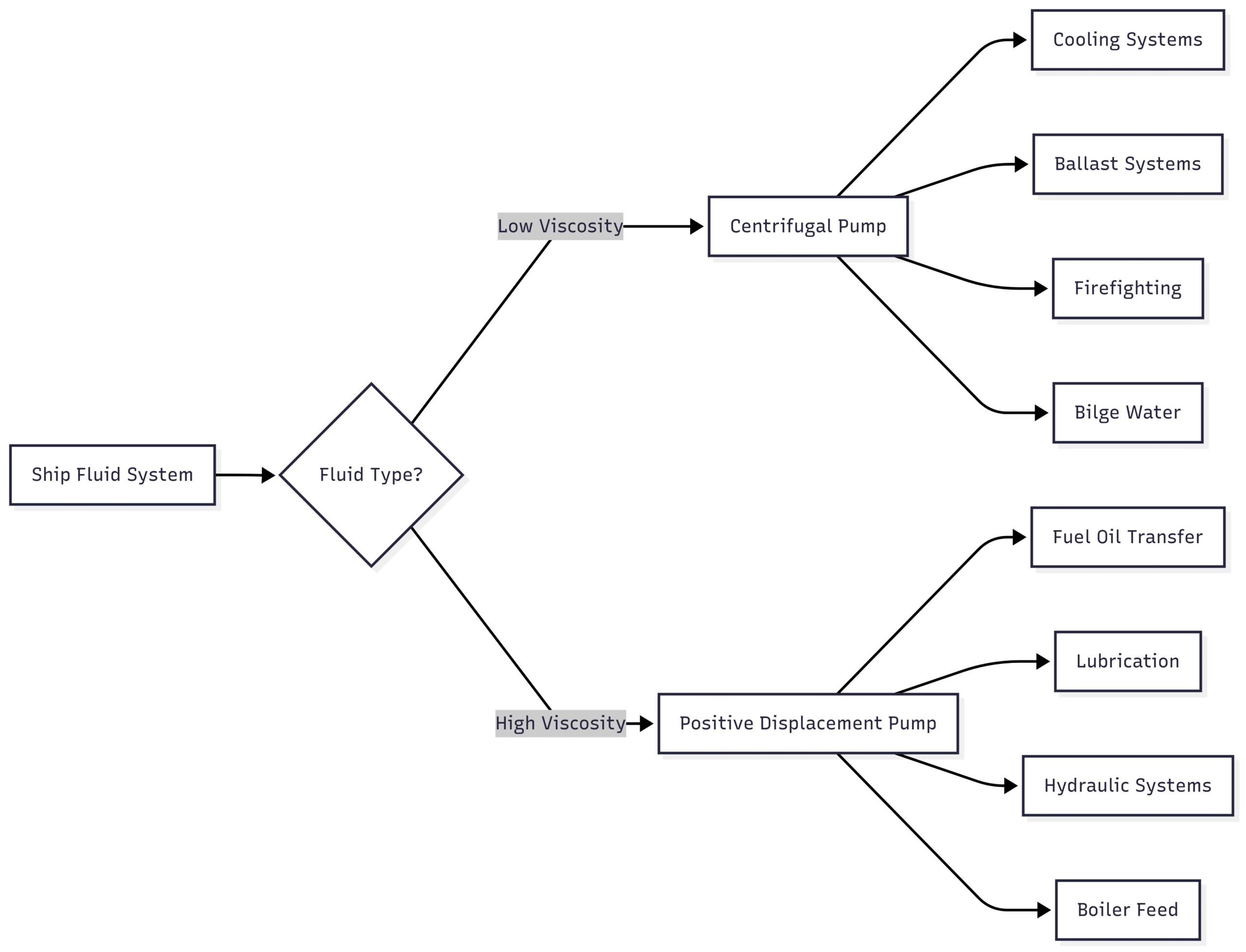

Key Differences Between Centrifugal and Positive Displacement Pumps

The choice between centrifugal and positive displacement pumps depends on the application’s requirements. The following table summarizes their differences:

| Feature | Centrifugal Pump | Positive Displacement Pump |

|---|---|---|

| Flow Nature | Continuous, varies with system resistance | Fixed, steady regardless of pressure |

| Fluid Type | Low-viscosity (e.g., seawater) | High-viscosity (e.g., fuel oil, lube oil) |

| Pressure Handling | Low to moderate (up to 100 bar) | High pressure (up to 500 bar) |

| Typical Applications | Cooling, ballast, firefighting | Fuel transfer, lubrication, hydraulics |

| Efficiency | High for large volumes | High for precise, high-pressure delivery |

Quick Tip: Use centrifugal pumps for high-volume, low-pressure tasks like cooling or ballast transfer, and positive displacement pumps for viscous fluids or high-pressure needs like fuel injection.

Application-Specific Pump Examples

Pumps are tailored to specific shipboard functions, ensuring optimal performance. The following table highlights common applications and their corresponding pump types:

| Application | Pump Type | Key Function |

|---|---|---|

| Bilge Water Removal | Centrifugal, Diaphragm | Removes accumulated water for stability |

| Firefighting Systems | Centrifugal | Delivers high-pressure water |

| Ballast Systems | Centrifugal, Mixed Flow | Adjusts ship trim and stability |

| Cooling Systems | Centrifugal | Regulates engine and machinery temperature |

| Boiler Feed | Turbine, Positive Displacement | Maintains boiler water levels |

| Fuel Oil Transfer | Gear, Screw | Ensures steady fuel delivery |

| Hydraulic Systems | Piston, Plunger | Powers winches, steering gears |

Chart: Pump Application Flow

Below is a flowchart illustrating how pump types are selected based on application requirements:

Factors Influencing Pump Selection

Choosing the right pump involves analyzing fluid and system characteristics:

- Fluid Properties: Viscosity, density, surface tension, and compressibility determine pump compatibility. For example, screw pumps handle high-viscosity fuel oil, while centrifugal pumps suit low-viscosity seawater.

- Flow Rate: Centrifugal pumps excel at high flow rates (e.g., 5000 m³/h for ballast), while positive displacement pumps are better for low to medium flows (e.g., 10 m³/h for fuel).

- Pressure Requirements: High-pressure applications (e.g., hydraulic systems) favor reciprocating pumps, while moderate-pressure tasks (e.g., cooling) use centrifugal pumps.

- System Conditions: Temperature, pressure, and corrosiveness influence material selection (e.g., stainless steel for seawater pumps).

- Operational Needs: Vessel size, type (e.g., cargo, passenger, naval), and mission profile dictate pump specifications.

Recent Trends in Marine Pump Technology

Advancements in pump technology are enhancing efficiency, reliability, and environmental compliance:

- Smart Pumps: Internet of Things (IoT) integration enables real-time monitoring of pump performance, predicting maintenance needs to prevent failures. For example, sensors on centrifugal pumps can detect cavitation early.

- Energy Efficiency: Optimized impeller designs and variable frequency drives (VFDs) reduce energy consumption by up to 20%, critical for meeting IMO’s Energy Efficiency Design Index (EEDI).

- Corrosion-Resistant Materials: Duplex stainless steels and advanced composites extend pump lifespan in harsh marine environments, reducing maintenance costs.

- IMO Compliance: Pumps are designed to handle low-sulfur fuels (per IMO 2020 regulations) and treat ballast water to prevent invasive species spread, as mandated by the Ballast Water Management Convention.

- Automation: Automated pump systems adjust flow and pressure dynamically, improving efficiency in variable conditions like changing sea states.

Maintenance and Operational Best Practices

Regular maintenance ensures pump reliability and longevity:

- Monthly Inspections: Check for leaks, vibrations, and wear on seals and bearings.

- Alignment and Lubrication: Ensure proper shaft alignment and lubricate moving parts to prevent friction-related failures.

- Dry-Docking Overhauls: Conduct comprehensive pump servicing during dry-docking, including impeller cleaning and seal replacement.

- Condition Monitoring: Use IoT sensors to track performance metrics like pressure and temperature, scheduling maintenance proactively.

- Crew Training: Train engineers on pump-specific troubleshooting to address issues like cavitation or priming failures swiftly.

Example: A centrifugal bilge pump may require impeller cleaning every six months to prevent clogging from debris, extending its service life.

Specifications and Pricing (Indicative)

Pump specifications and costs vary based on type, capacity, and materials. Below is a sample overview of common marine pumps:

| Pump Type | Flow Rate (m³/h) | Pressure (bar) | Material | Approx. Price (USD) |

|---|---|---|---|---|

| Centrifugal (Fire) | 1000–5000 | 8–12 | Stainless Steel | $10,000–$50,000 |

| Gear (Fuel Transfer) | 5–50 | 5–10 | Cast Iron/Steel | $5,000–$20,000 |

| Screw (Lubrication) | 10–100 | 5–15 | Stainless Steel | $8,000–$30,000 |

| Piston (Hydraulic) | 1–10 | 50–200 | Alloy Steel | $15,000–$60,000 |

| Diaphragm (Bilge) | 5–50 | 2–6 | Reinforced Polymer | $3,000–$15,000 |

Note: Prices are indicative and vary based on manufacturer, customization, and market conditions. For precise pricing, contact suppliers like Alfa Laval, Wärtsilä, or KSB.

FAQs About Ship Engine Room Pumps

What is the most common pump type in ship engine rooms?

Centrifugal pumps are the most common due to their high flow rates and suitability for seawater, cooling, and firefighting systems.

Why are positive displacement pumps preferred for fuel oil?

They deliver consistent flow and high pressure for viscous fluids like heavy fuel oil, ensuring reliable engine performance.

Can one pump handle multiple fluid types?

Versatile pumps like screw pumps can manage varying viscosities, but most are optimized for specific fluids to maximize efficiency.

How often should pumps be maintained?

Monthly inspections and maintenance during dry-docking cycles (every 2–5 years) are standard, with condition monitoring for proactive upkeep.

How do IMO regulations impact pump design?

Pumps must comply with low-sulfur fuel requirements and ballast water treatment standards, driving innovations in materials and automation.

Conclusion: Pumps as the Unsung Heroes of Maritime Operations

Ship engine room pumps are indispensable for safe and efficient vessel operation. From cooling engines to transferring fuel and managing stability, they ensure a ship’s systems run smoothly. By understanding the differences between centrifugal and positive displacement pumps, their applications, and emerging technologies, maritime professionals can optimize performance and comply with global regulations. Whether you’re a marine engineer, ship operator, or enthusiast, mastering pump systems is key to navigating the challenges of modern maritime operations.

Happy Boating!

Share Understanding Ship Engine Room Pumps with your friends and leave a comment below with your thoughts.

Read Interview Questions To Ask Marine Engineer Candidates until we meet in the next article.