Types of Propulsion System in Ship

Explore types of ship propulsion systems, from diesel to hydrogen fuel cells, and their impact on efficiency and sustainability in maritime transport.

The maritime industry, a cornerstone of global trade and transportation, relies heavily on advanced propulsion systems to navigate the world’s waterways. These systems convert energy into mechanical force, propelling vessels ranging from small ferries to massive cargo ships across vast oceans. Over time, ship propulsion technologies have evolved dramatically, driven by the need for efficiency, reliability, and environmental sustainability. From the sails of antiquity to cutting-edge hydrogen fuel cells, this article delves into the diverse types of propulsion systems, their characteristics, applications, advantages, and challenges, while exploring their role in shaping a sustainable maritime future.

The Evolution of Ship Propulsion

Ship propulsion has a rich history, reflecting humanity’s ingenuity in harnessing natural and technological resources. Before the Industrial Revolution, ships relied on human power (oars) and wind (sails). Greek triremes and Roman galleys used oars for maneuverability in naval warfare, while sail-powered merchant vessels dominated commercial routes until the late 19th century. The advent of steam engines marked a turning point, enabling ships to travel faster and more reliably, independent of wind conditions. By the early 20th century, diesel engines began to replace steam, offering superior fuel efficiency and reliability. Today, the industry is shifting toward greener technologies like LNG engines, fuel cells, and hybrid systems to meet stringent environmental regulations, such as the International Maritime Organization’s (IMO) goal to reduce CO2 emissions by 50% by 2050 compared to 2018 levels.

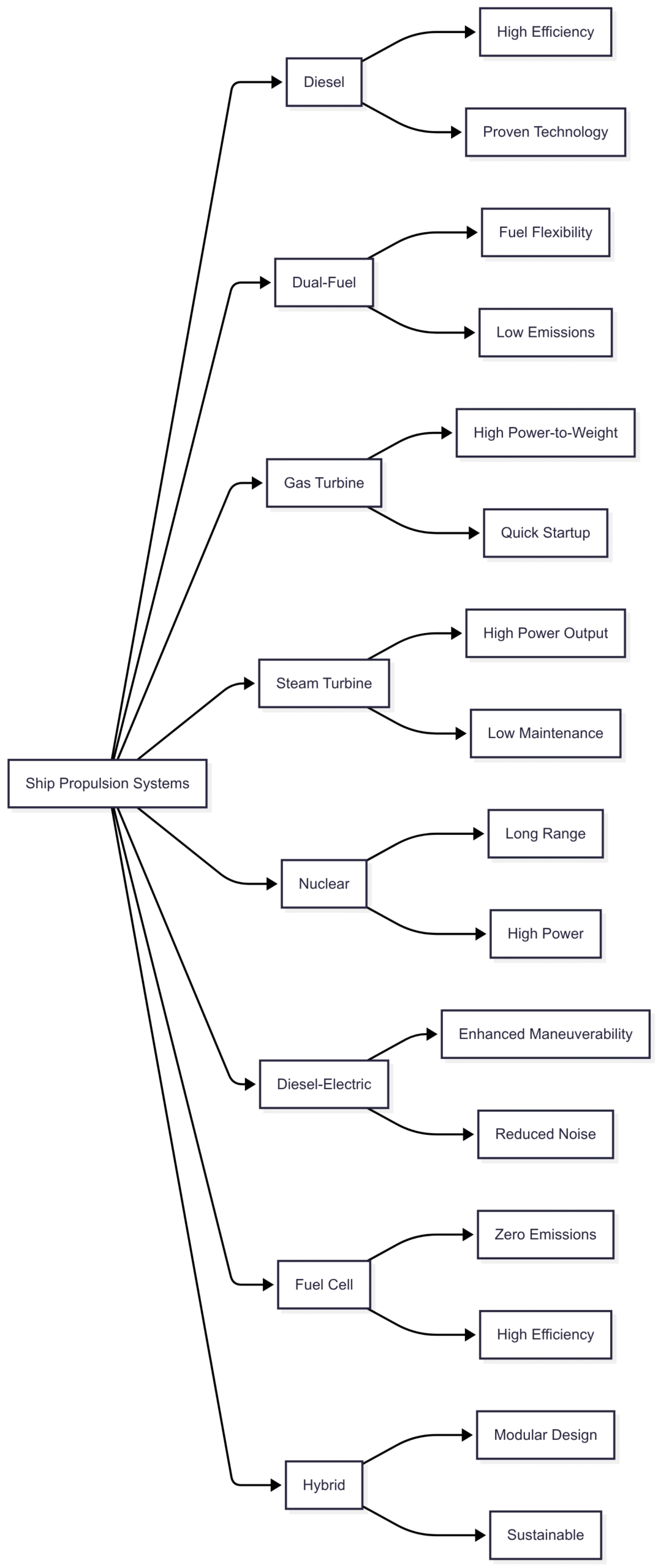

Key Types of Ship Propulsion Systems

The maritime industry employs a variety of propulsion systems, each tailored to specific vessel types and operational needs. Below, we explore the primary systems in use today, their technical specifications, applications, and their role in the future of shipping.

1. Diesel Propulsion

Overview: Diesel propulsion is the most prevalent system in the maritime industry, powering vessels from small boats to large container ships. It operates on the principle of compression ignition, where air is compressed to ignite injected fuel, producing mechanical energy to drive propellers.

Types of Diesel Engines:

- Two-Stroke Engines: Complete a power cycle in two piston strokes, delivering high power output per cycle. They are lighter, more compact, and ideal for large vessels like cargo ships and tankers.

- Four-Stroke Engines: Operate in four strokes (intake, compression, power, exhaust), offering versatility for medium-sized vessels like ferries and cruise ships.

- High-Speed Engines: Exceed 1000 rpm, suitable for smaller, high-performance vessels.

Key Characteristics:

- Efficiency: Two-stroke engines achieve high thermal efficiency, reducing fuel consumption.

- Power-to-Weight Ratio: Compact designs maximize cargo capacity.

- Fuel Flexibility: Can operate on heavy fuel oil (HFO), marine diesel oil (MDO), or biofuels.

- Scavenging: Two-stroke engines use port scavenging or piston porting to replace exhaust gases with fresh air, enhancing performance.

Applications: Cargo ships, tankers, passenger ferries, and offshore vessels.

Advantages:

- Proven reliability and durability.

- High fuel efficiency compared to steam systems.

- Wide fuel compatibility.

Disadvantages:

- Significant CO2, NOx, and SOx emissions.

- Dependency on fossil fuels, challenging IMO emission targets.

Specifications (Example: MAN B&W Two-Stroke Engine):

- Power Output: Up to 80,000 kW.

- Fuel Consumption: ~170 g/kWh.

- Weight: ~1,000-2,000 tons (depending on size).

- Cost: $10-20 million (varies by engine size and vessel type).

2. Dual-Fuel Engines

Overview: Dual-fuel engines represent an evolution in diesel technology, capable of operating on two fuel types, typically HFO and natural gas, with some models supporting biofuels or LPG. These engines switch seamlessly between fuels, optimizing cost and emissions.

Key Characteristics:

- Fuel Flexibility: Operators can choose fuels based on availability, cost, or environmental regulations.

- Environmental Benefits: Natural gas reduces SOx by ~90%, NOx by ~80%, and particulate matter significantly.

- Efficiency: Higher thermal efficiency than traditional diesel engines, often exceeding 45%.

- Reliability: Seamless fuel switching ensures uninterrupted operation.

Applications: Container ships, LNG carriers, and ferries.

Advantages:

- Reduced emissions, aligning with IMO regulations.

- Cost savings through fuel flexibility.

- High efficiency lowers operational costs.

Disadvantages:

- Higher initial investment (~20-30% more than standard diesel engines).

- Limited bunkering infrastructure for alternative fuels like LNG.

Specifications (Example: Wärtsilä Dual-Fuel Engine):

- Power Output: 6,000-20,000 kW.

- Fuel Types: HFO, LNG, MDO, biofuels.

- Efficiency: ~48-50%.

- Cost: $8-15 million.

3. Gas Turbine Propulsion

Overview: Gas turbines, akin to jet engines, burn gas or liquid fuel to generate thrust, offering high power in a compact form. They are often used in hybrid configurations like Combined Diesel or Gas (CODOG) or Combined Gas or Gas (COGAG).

Key Characteristics:

- High Power-to-Weight Ratio: Ideal for fast vessels requiring rapid acceleration.

- Quick Startup: Operational within minutes, unlike diesel engines.

- Hybrid Systems: CODOG uses diesel for cruising and gas turbines for high-speed operations, while COGAG leverages waste heat for efficiency.

Applications: Naval ships, high-speed ferries, luxury yachts, and LNG carriers.

Advantages:

- Rapid response and high power output.

- Lower emissions in sensitive areas (with cleaner fuels).

- Compact design saves space.

Disadvantages:

- Lower fuel efficiency (30-35% thermal efficiency) compared to diesel (45%).

- Higher operating costs due to expensive fuels.

Specifications (Example: GE LM2500 Gas Turbine):

- Power Output: 25,000-35,000 kW.

- Fuel Consumption: ~220 g/kWh.

- Weight: ~20-30 tons.

- Cost: $5-10 million.

4. Steam Turbine Propulsion

Overview: Steam turbines generate mechanical work by using high-pressure steam to rotate blades on a shaft. Once dominant, they are now largely obsolete in commercial shipping but remain in use for specialized vessels like LNG carriers.

Key Characteristics:

- Continuous Rotation: Smooth operation compared to reciprocating engines.

- High Power Output: Suitable for large vessels requiring sustained power.

- Fuel Source: Typically powered by burning fossil fuels or nuclear reactors (in naval applications).

Applications: LNG carriers, naval vessels, and some icebreakers.

Advantages:

- Reliable for high-power, continuous operation.

- Low maintenance for steady-state operations.

Disadvantages:

- Inefficient at low speeds (~25-30% thermal efficiency).

- High maintenance complexity and costs.

- Phased out due to environmental concerns.

Specifications (Example: Mitsubishi Marine Steam Turbine):

- Power Output: 20,000-50,000 kW.

- Efficiency: ~30%.

- Weight: ~100-200 tons.

- Cost: $10-15 million.

5. Nuclear Propulsion

Overview: Nuclear propulsion uses reactors to generate steam, driving turbines for propulsion. It is primarily used in military vessels due to its high energy density and long operational range.

Key Characteristics:

- Energy Density: Allows years of operation without refueling.

- High Power: Suitable for large, high-speed vessels.

- Safety Protocols: Requires stringent safety measures and specialized crew.

Applications: Submarines, aircraft carriers, and icebreakers.

Advantages:

- Extended operational range without refueling.

- High power output for large vessels.

Disadvantages:

- Extremely high costs (~$500 million-$1 billion per reactor system).

- Complex safety and regulatory requirements.

- Limited to military applications.

Specifications (Example: Naval Nuclear Reactor):

- Power Output: 100,000-200,000 kW.

- Fuel: Enriched uranium.

- Operational Life: 20-30 years.

- Cost: $500 million-$1 billion.

6. Diesel-Electric Propulsion

Overview: Diesel-electric systems use diesel engines to generate electricity, which powers electric motors driving propellers. This setup enhances efficiency and maneuverability.

Key Characteristics:

- Flexibility: Precise control over power distribution.

- Reduced Noise: Ideal for submarines and cruise ships.

- Efficiency: Optimized fuel use through variable power allocation.

Applications: Cruise ships (e.g., Wonder of the Seas), submarines, icebreakers.

Advantages:

- High fuel efficiency (~40-45%).

- Enhanced maneuverability and quiet operation.

- Reduced emissions compared to direct diesel propulsion.

Disadvantages:

- High initial costs (~$15-25 million for large systems).

- Complex integration and maintenance.

Specifications (Example: Wärtsilä Diesel-Electric System):

- Power Output: 10,000-50,000 kW.

- Efficiency: ~45%.

- Weight: ~50-100 tons.

- Cost: $15-25 million.

7. Fuel Cell Propulsion

Overview: Fuel cell propulsion generates electricity through a chemical reaction between hydrogen and oxygen, producing only water vapor as a byproduct. This emerging technology is highly sustainable.

Key Characteristics:

- Zero Emissions: No CO2, NOx, or SOx emissions.

- High Efficiency: ~50-60% electrical efficiency.

- Challenges: Hydrogen storage and bunkering infrastructure.

Applications: Experimental use in ferries, small cargo ships, and research vessels.

Advantages:

- Environmentally friendly with zero emissions.

- High efficiency and low noise.

Disadvantages:

- High costs (~$1,000-$2,000 per kW installed).

- Limited hydrogen infrastructure.

- Scalability challenges for large vessels.

Specifications (Example: Ballard Power Fuel Cell):

- Power Output: 100-1,000 kW (scalable).

- Efficiency: ~55%.

- Fuel: Hydrogen or methanol (with reformer).

- Cost: $500,000-$2 million (system-dependent).

8. Hybrid Propulsion Systems

Overview: Hybrid systems combine multiple energy sources (e.g., diesel, electric, fuel cells, or batteries) to optimize efficiency and reduce emissions. These systems are modular and adaptable.

Key Characteristics:

- Modularity: Combines batteries, fuel cells, or combustion engines.

- Flexibility: Adapts to operational needs (e.g., electric for ports, diesel for open sea).

- Sustainability: Reduces emissions through optimized power use.

Applications: Ferries, tugs, and offshore vessels.

Advantages:

- Enhanced fuel efficiency and lower emissions.

- Flexible operation for varying conditions.

- Future-proof with integration of new technologies (e.g., methanol engines, fuel cells).

Disadvantages:

- High initial costs (~$20-30 million for large systems).

- Complex system integration and maintenance.

Specifications (Example: Rolls-Royce mtu Hybrid System):

- Power Output: 5,000-20,000 kW.

- Components: Diesel engines, batteries, electric motors.

- Efficiency: ~45-50%.

- Cost: $20-30 million.

Emerging Trends in Ship Propulsion

The maritime industry is undergoing a transformation driven by environmental regulations and technological advancements. Key trends include:

1. Sustainable Fuels

- Methanol: Rolls-Royce is developing methanol-based engines (mtu Series 4000) for launch by 2026. Methanol offers high energy density, easy storage, and compatibility with existing infrastructure, reducing CO2 emissions when sourced sustainably.

- LNG: LNG engines reduce CO2 by ~20% and SOx/NOx significantly, with growing bunkering infrastructure supporting adoption.

- Biofuels: Compatible with diesel and dual-fuel engines, biofuels offer a drop-in solution for reducing emissions.

2. Electrification and Batteries

Battery-powered electric propulsion is gaining traction for short-range vessels like tugs and ferries. Batteries provide zero-emission operation in ports, with systems like those from Corvus Energy offering 1-10 MWh storage capacity.

3. Fuel Cells

Rolls-Royce plans to launch mtu fuel cell systems by 2028, leveraging hydrogen or methanol for zero or near-zero emissions. These systems offer 50-60% efficiency and low noise, ideal for environmentally sensitive areas.

4. Wind-Assisted Propulsion

Modern wind technologies, such as rotor sails and kites, are being integrated to enhance fuel efficiency. For example, Norsepower’s rotor sails can reduce fuel consumption by 5-20% on cargo ships.

5. Automation and Digitalization

Automation systems like Rolls-Royce’s mtu NautIQ monitor propulsion and ship operations, optimizing performance and reducing emissions through real-time data analytics.

Comparative Analysis of Propulsion Systems

| Propulsion Type | Efficiency | Emissions | Applications | Cost (USD) | Key Advantage |

|---|---|---|---|---|---|

| Diesel | 45% | High CO2, NOx | Cargo ships, tankers | $10-20M | Proven reliability |

| Dual-Fuel | 48-50% | Low NOx, SOx | Container ships, LNG carriers | $8-15M | Fuel flexibility |

| Gas Turbine | 30-35% | Moderate | Naval ships, ferries | $5-10M | High power-to-weight ratio |

| Steam Turbine | 25-30% | High CO2 | LNG carriers, naval | $10-15M | High power output |

| Nuclear | N/A | Zero | Submarines, carriers | $500M-$1B | Long operational range |

| Diesel-Electric | 40-45% | Moderate | Cruise ships, submarines | $15-25M | Enhanced maneuverability |

| Fuel Cell | 50-60% | Zero | Ferries, research vessels | $0.5-2M (per system) | Zero emissions |

| Hybrid | 45-50% | Low | Ferries, tugs | $20-30M | Flexible and sustainable |

Chart: Propulsion System Comparison

The Future of Ship Propulsion

The maritime industry is at a crossroads, balancing operational efficiency with environmental responsibility. The IMO’s 2050 emissions target is driving innovation in propulsion technologies. Key developments include:

- Methanol and LNG: Sustainable fuels like methanol and LNG are bridging the gap to zero-emission technologies, with companies like Rolls-Royce leading the charge.

- Fuel Cells: Hydrogen and methanol fuel cells offer a path to zero-emission shipping, with pilot projects underway for ferries and cargo vessels.

- Hybrid Systems: Modular hybrid systems, combining batteries, fuel cells, and combustion engines, provide flexibility and future-proofing.

- Wind-Assisted Technologies: Rotor sails and kites are reducing fuel consumption, particularly for cargo ships on transoceanic routes.

As Tobias Kohl, Director of Application Engineering Marine at Rolls-Royce, notes, “The question of the propulsion system of the future is complex.” Vessel type, range, and infrastructure dictate the optimal solution. Short-range tugs may rely on batteries, while long-range ferries and cargo ships will integrate sustainable fuels and fuel cells. Automation systems like mtu NautIQ will further enhance efficiency by monitoring and optimizing propulsion performance.

Conclusion

Ship propulsion systems are the backbone of maritime transport, enabling global trade and connectivity. From the workhorse diesel engines to the promising hydrogen fuel cells, each system offers unique advantages tailored to specific applications. The industry’s shift toward sustainability is evident in the rise of dual-fuel engines, LNG, and fuel cell technologies, all aimed at meeting stringent environmental regulations. As innovations like methanol engines, hybrid systems, and wind-assisted propulsion gain traction, the maritime sector is poised to achieve greater efficiency and reduced emissions, ensuring a sustainable future for global shipping.

FAQs

- What is a ship propulsion system?

A propulsion system generates the mechanical force to move a ship through water, using engines, turbines, or alternative technologies. - What are the main types of marine propulsion systems?

Diesel, dual-fuel, gas turbines, steam turbines, nuclear, diesel-electric, fuel cells, and hybrid systems. - What are the benefits of dual-fuel engines?

They offer fuel flexibility, reduced emissions, and high efficiency, making them cost-effective and environmentally friendly. - Why are gas turbines used in naval ships?

Gas turbines provide high power-to-weight ratios and rapid startup, ideal for high-speed and agile naval operations. - How do fuel cells contribute to sustainable shipping?

Fuel cells produce zero emissions, using hydrogen or methanol to generate electricity, making them a key technology for green maritime transport.

Happy Boating!

Share Types of Propulsion System in Ship with your friends and leave a comment below with your thoughts.

Read How to Synchronize Generators on a Ship? until we meet in the next article.