Types of Governors for Engines Used On Ships

Explore types of marine diesel engine governors, their functions, and maintenance for optimal ship performance. Learn about mechanical, hydraulic, and electronic governors.

Marine diesel engines power the vast majority of ships, from cargo vessels to cruise liners, and their performance hinges on precise control mechanisms. Among these, governors play a critical role in regulating engine speed, ensuring safety, efficiency, and reliability under varying operational conditions. Governors control the fuel supply to maintain desired engine speeds, prevent overspeeding, and stabilize performance despite fluctuating loads. This article delves into the types of governors used in marine diesel engines, their operational principles, advantages, maintenance requirements, and key considerations for optimal performance. By understanding these systems, marine engineers and ship operators can enhance vessel reliability and safety.

What Are Marine Diesel Engine Governors?

Governors are mechanical, hydraulic, or electronic devices that automatically regulate an engine’s speed by controlling the fuel injected into the cylinders. They respond to changes in load or operating conditions, ensuring the engine operates within safe speed limits. In marine applications, governors are essential for both main propulsion engines and auxiliary engines (e.g., generators), as load variations caused by rough seas, vessel pitching, or structural changes can destabilize engine performance. Without governors, engines risk overspeeding, stalling, or suffering damage, which could lead to costly repairs or safety hazards.

Governors serve several key functions:

- Speed Control: Maintain consistent engine speed by adjusting fuel delivery based on load changes.

- Overspeed Protection: Prevent engine damage by cutting fuel supply if speed exceeds safe limits.

- Load Control: Ensure efficient operation under varying loads, avoiding stalls or speed fluctuations.

- Remote Operation: Allow speed adjustments from the bridge or engine control room in modern systems.

Types of Marine Diesel Engine Governors

Marine diesel engine governors are classified based on their design and construction into mechanical, hydraulic, electronic, and electro-hydraulic types. Each has unique mechanisms, advantages, and applications, catering to different engine sizes and operational needs.

1. Mechanical Governors

Mechanical governors are the simplest and most traditional type, relying on mechanical components like flyweights, springs, and linkages to regulate fuel delivery. These governors use centrifugal force generated by the engine’s crankshaft to adjust fuel injection.

How They Work

Mechanical governors feature flyweights mounted on a rotating ball head driven by the engine’s crankshaft. As the engine speed increases, centrifugal force pushes the flyweights outward, moving a control sleeve connected to the fuel injection racks. A speeder spring counteracts this force, balancing the system at the desired speed. When the engine speed decreases due to increased load, the flyweights move inward, increasing fuel delivery to restore speed. Conversely, reduced load increases speed, causing the flyweights to move outward and reduce fuel supply.

Advantages

- Cost-Effective: Mechanical governors are relatively inexpensive, making them suitable for smaller engines or budget-conscious applications.

- Simplicity: Their straightforward design with few components reduces complexity.

- Reliability: Robust construction ensures durability in harsh marine environments.

Disadvantages

- Limited Precision: Mechanical governors have a larger deadband (range where no correction occurs), making them less precise for applications requiring exact speed control.

- Maintenance Needs: Regular lubrication and inspection are required to prevent wear on moving parts.

- Limited Power Output: The centrifugal force generated is insufficient for controlling large engines’ fuel injection pumps.

Applications

Mechanical governors are typically used in smaller marine engines or older vessels where precise speed control is not critical. They are less common in modern ships due to advancements in hydraulic and electronic systems.

2. Hydraulic Governors

Hydraulic governors use hydraulic fluid to control fuel delivery, offering greater precision and power compared to mechanical governors. They are widely used in medium to large marine engines due to their ability to generate higher forces.

How They Work

In hydraulic governors, flyweights are connected to a pilot control valve rather than directly to the fuel racks. This valve directs hydraulic fluid to a power piston, which adjusts the fuel supply. A gear pump, driven by the governor’s drive shaft, supplies high-pressure oil from a sump, while a spring-loaded accumulator maintains consistent pressure. When engine speed decreases (e.g., due to increased load), the flyweights move inward, lowering the pilot valve to direct oil to the power piston, increasing fuel delivery. When speed increases, the flyweights move outward, raising the valve to drain oil, reducing fuel supply.

To enhance sensitivity and prevent overcorrection, hydraulic governors incorporate a compensating mechanism with actuating and receiving plungers. These plungers regulate oil flow to ensure the system stabilizes without overshooting the desired speed.

Advantages

- High Precision: Hydraulic governors offer accurate speed control, ideal for medium to large engines.

- High Power Output: They generate sufficient force to control larger fuel injection systems.

- Efficiency: Smooth operation reduces fuel wastage and wear.

- Ease of Maintenance: Hydraulic systems are easier to service compared to mechanical governors.

Disadvantages

- Complexity: More components increase the risk of hydraulic leaks or failures.

- Oil Quality Sensitivity: Requires specific oil types and viscosity for optimal performance.

Applications

Hydraulic governors are standard in modern marine vessels, particularly for main propulsion engines and auxiliary generators. Many older mechanical systems are retrofitted with hydraulic controls for improved performance.

3. Electronic Governors

Electronic governors represent the pinnacle of precision and flexibility, using sensors, control units, and actuators to manage fuel delivery. They are increasingly common in modern marine engines due to their integration with digital control systems.

How They Work

Electronic governors consist of three main components:

- Electro-Magnetic Pickup (MPU): A sensor installed near the engine’s flywheel, generating an AC voltage proportional to engine speed.

- Controller: Converts the MPU’s frequency into a DC voltage, compares it to a set value, and uses a PID (Proportional-Integral-Derivative) control algorithm to calculate adjustments.

- Actuator: Adjusts the fuel injection based on the controller’s output.

The MPU detects speed changes by sensing the flywheel’s teeth, and the controller adjusts fuel delivery to maintain the desired speed. Electronic governors support advanced functions like remote speed control, smoke suppression, and droop adjustment.

Advantages

- Fast Response: Rapidly adjusts to load changes, minimizing speed fluctuations.

- Automation: Integrates with engine control systems for remote operation and diagnostics.

- Flexibility: Programmable settings allow customization for specific applications.

- Remote Mounting: Can be installed away from the engine, reducing mechanical complexity.

Disadvantages

- Cost: Higher initial cost due to advanced electronics.

- Complexity: Requires skilled technicians for maintenance and troubleshooting.

- Dependence on Electronics: Susceptible to electrical failures or interference.

Applications

Electronic governors are used in modern marine engines, especially in vessels requiring precise control, such as cruise ships, ferries, and high-performance vessels. They are also common in auxiliary generators for stable power output.

4. Electro-Hydraulic Governors

Electro-hydraulic governors combine the precision of electronic control with the power of hydraulic systems, offering a hybrid solution for modern marine engines.

How They Work

These governors feature an electronic control unit paired with a hydraulic actuator. The electronic system monitors engine speed and sends signals to an actuator with both electric and mechanical-hydraulic components. In case of electronic failure, the mechanical-hydraulic backup ensures continued operation, albeit at a higher set speed. The system uses an electronic control box (ECB) to position a control valve via an electromagnetic field, regulating fuel delivery.

Advantages

- Reliability: Mechanical-hydraulic backup ensures operation during electronic failures.

- Precision: Combines electronic accuracy with hydraulic power.

- Versatility: Suitable for a wide range of engine sizes and applications.

Disadvantages

- Complexity: Dual systems increase maintenance requirements.

- Cost: More expensive than purely mechanical or hydraulic governors.

Applications

Electro-hydraulic governors are used in advanced marine propulsion systems and large auxiliary engines, where reliability and precision are paramount.

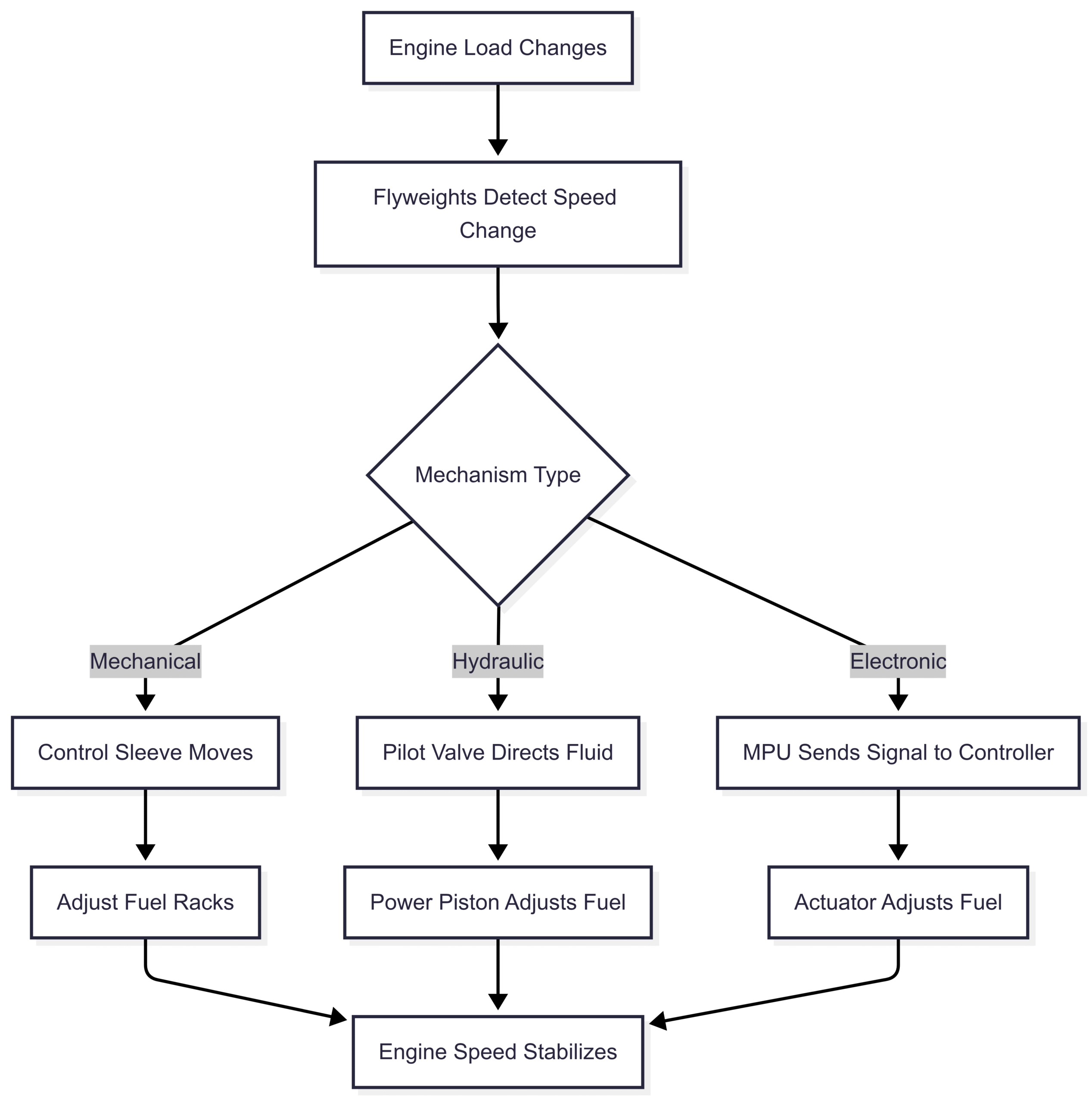

Operating Principles of Governors

Governors operate based on three primary mechanisms: flyweight assemblies, hydraulic control, and electronic systems. Understanding these principles is key to appreciating their functionality.

Flyweight Assembly

Most governors use flyweights mounted on a rotating ball head driven by the engine’s crankshaft. Centrifugal force causes the flyweights to move outward as speed increases, countered by a speeder spring. The flyweights’ movement adjusts a control sleeve, which actuates fuel pump controls to regulate fuel delivery. Under stable conditions, the spring and centrifugal forces balance, keeping the sleeve stationary. Load changes disrupt this balance, prompting adjustments to restore equilibrium.

Hydraulic Control

In hydraulic governors, flyweights control a pilot valve that directs hydraulic fluid to a power piston. The piston adjusts fuel delivery based on hydraulic pressure, which is regulated by a gear pump and accumulator. Compensating plungers enhance sensitivity, preventing overcorrection by temporarily closing oil ports to stabilize the system.

Electronic System

Electronic governors use an MPU to detect engine speed via the flywheel, generating a frequency converted into a DC voltage. The controller processes this signal using PID algorithms to adjust the actuator, which controls fuel delivery. This system supports advanced features like remote control and droop adjustment.

Chart: Governor Operation Flow

Key Features and Specifications

Governors vary in design and capacity, with leading manufacturers like Woodward and Regulateurs Europa offering robust solutions. Below is a table summarizing key product variants and their specifications:

| Governor Type | Work Output (ft-lb) | Applications | Key Features |

|---|---|---|---|

| Simple Governor (SG) | 5.7–40 | Small engines, auxiliary generators | Simple operation, reliable, uses engine’s oil supply (min. 25 psi) |

| Universal Governor (UG-25+) | 10.8–21.7 | Diesel, gas, steam turbines | Industry-standard, easy servicing, mechanical-hydraulic design |

| Governor (3161) | 18 | Medium engines | Precise speed control, reliable |

| Electronically Controlled Actuator (EGB) | 1–300 | Dual-fuel, diesel, gas turbines | Electronic control with mechanical backup, high reliability |

| Large Pressure-Compensated (PG) | 12–58 | Large engines, turbines | High work capacity, precise control |

Price Range: Prices vary based on application and complexity. Basic mechanical governors start at $500–$1,000, hydraulic governors range from $1,500–$5,000, and electronic/electro-hydraulic systems can cost $5,000–$15,000 or more, depending on customization and integration needs. For exact pricing, consult manufacturers like Woodward (https://www.woodward.com) or Regulateurs Europa.

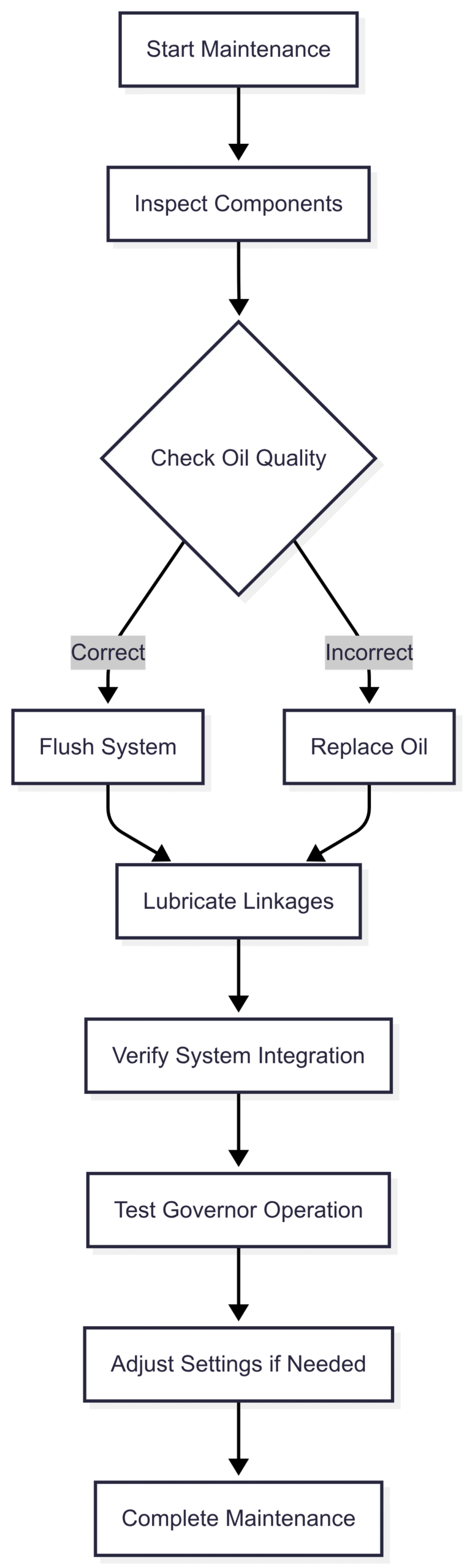

Maintenance of Marine Diesel Engine Governors

Proper maintenance ensures governors operate reliably, preventing engine damage and performance issues. Key maintenance practices include:

- Regular Inspections: Check for wear, leaks, or contamination in mechanical and hydraulic components.

- Oil Quality: Use manufacturer-specified hydraulic fluid or lubricating oil with correct viscosity. Maintain oil levels above 5/8 inch in the gauge glass.

- Cleaning and Flushing: Flush hydraulic systems every two weeks with clean fuel oil and every six months with carbon tetrachloride to remove contaminants.

- Professional Adjustments: Only qualified personnel should adjust governor settings to avoid improper calibration.

- Linkage Greasing: Lubricate mechanical linkages and joints to reduce friction and wear.

- System Integration: Ensure governors align with other engine control systems for seamless operation.

Neglecting maintenance can lead to issues like hunting (erratic speed fluctuations due to over-sensitive fuel control) or failure to respond to load changes, compromising safety and efficiency.

Key Concepts in Governor Operation

Droop

Droop is the percentage difference between no-load and full-load speeds, calculated as:

Droop% = (No Load Speed - Full Load Speed) / No Load Speed

Droop allows stable load sharing when multiple engines are connected to the same shaft, such as in generator sets. A smaller droop setting increases sensitivity but may cause hunting, while a larger droop results in slower responses.

Deadband

The deadband is the speed range within which the governor does not make corrections. A narrower deadband increases sensitivity but risks hunting, while a wider deadband reduces responsiveness.

Hunting

Hunting occurs when the governor overcorrects fuel supply, causing continuous speed fluctuations. This is mitigated by compensating mechanisms or precise electronic control.

Isochronous Governor

An isochronous governor maintains constant speed with zero hunting, ideal for applications requiring stable power output, such as generators. It uses proportional and reset controls to eliminate droop.

Overspeed Trip

An overspeed trip is a safety mechanism that cuts fuel supply if engine speed exceeds 110–115% of the rated speed, preventing damage. It requires manual resetting before restarting the engine.

Chart: Governor Maintenance Workflow

Why Governors Are Critical for Marine Engines

Marine environments are inherently challenging, with rough seas, vessel motion, and load variations posing constant risks to engine stability. Governors mitigate these risks by:

- Preventing Damage: Overspeed protection safeguards engine components from excessive wear or failure.

- Enhancing Efficiency: Precise fuel control optimizes fuel consumption, reducing operational costs.

- Ensuring Safety: Stable engine performance prevents accidents caused by sudden speed changes or engine failure.

- Supporting Automation: Modern governors integrate with digital control systems, enabling remote monitoring and operation.

Famous Governor Brands

- Woodward: A leading manufacturer offering hydraulic-mechanical and electronic governors for marine, power generation, and industrial applications. Their products range from 10.8 in-lbs to 500 ft-lbs in work output.

- Regulateurs Europa: Specializes in mechanical and electronic governors for marine and traction applications, known for robust control and monitoring solutions.

Conclusion

Marine diesel engine governors are indispensable for maintaining safe, efficient, and reliable vessel operation. Mechanical governors offer simplicity and cost-effectiveness for smaller engines, while hydraulic and electronic governors provide precision and power for modern, high-performance ships. Electro-hydraulic governors combine the best of both worlds, ensuring reliability even during electronic failures. By understanding the types, operating principles, and maintenance requirements of governors, marine engineers can optimize engine performance and prevent costly downtime. Regular maintenance, proper oil management, and professional adjustments are critical to ensuring governors function effectively in the demanding marine environment.

Happy Boating!

Share Types of Governors for Engines Used On Ships with your friends and leave a comment below with your thoughts.

Read The importance of ship maintenance and repair until we meet in the next article.