Turbocharger Surging: What It Is and Why It Matters

Learn about turbocharger surging, its causes, symptoms, and solutions. Understand why it matters for engine performance and how to prevent costly damage.

Turbochargers are a cornerstone of modern engine design, boosting power and efficiency by forcing extra air into the combustion chamber. However, a phenomenon known as turbocharger surging can disrupt this process, leading to performance issues and potential damage. This article dives deep into turbocharger surging, exploring its causes, symptoms, consequences, and solutions to help vehicle and marine engine owners maintain optimal performance.

What Is Turbocharger Surging?

Turbocharger surging is an aerodynamic instability where airflow reverses direction within the turbocharger’s compressor, causing pressure fluctuations. This mismatch between the engine’s air demand and the turbocharger’s output results in the compressor accelerating and decelerating repeatedly, producing vibrations and noise. Surging can occur in automotive, marine, and industrial applications, particularly in low-speed diesel engines.

Surging disrupts the turbocharger’s ability to deliver consistent boost pressure, reducing engine efficiency and risking component damage. The phenomenon is often described as a “fluttering,” “gulping,” or “howling” sound, with terms like “compressor surge” or “turbo surge” used interchangeably. While the turbine (exhaust gas side) doesn’t directly cause surging, its performance can influence the compressor’s behavior.

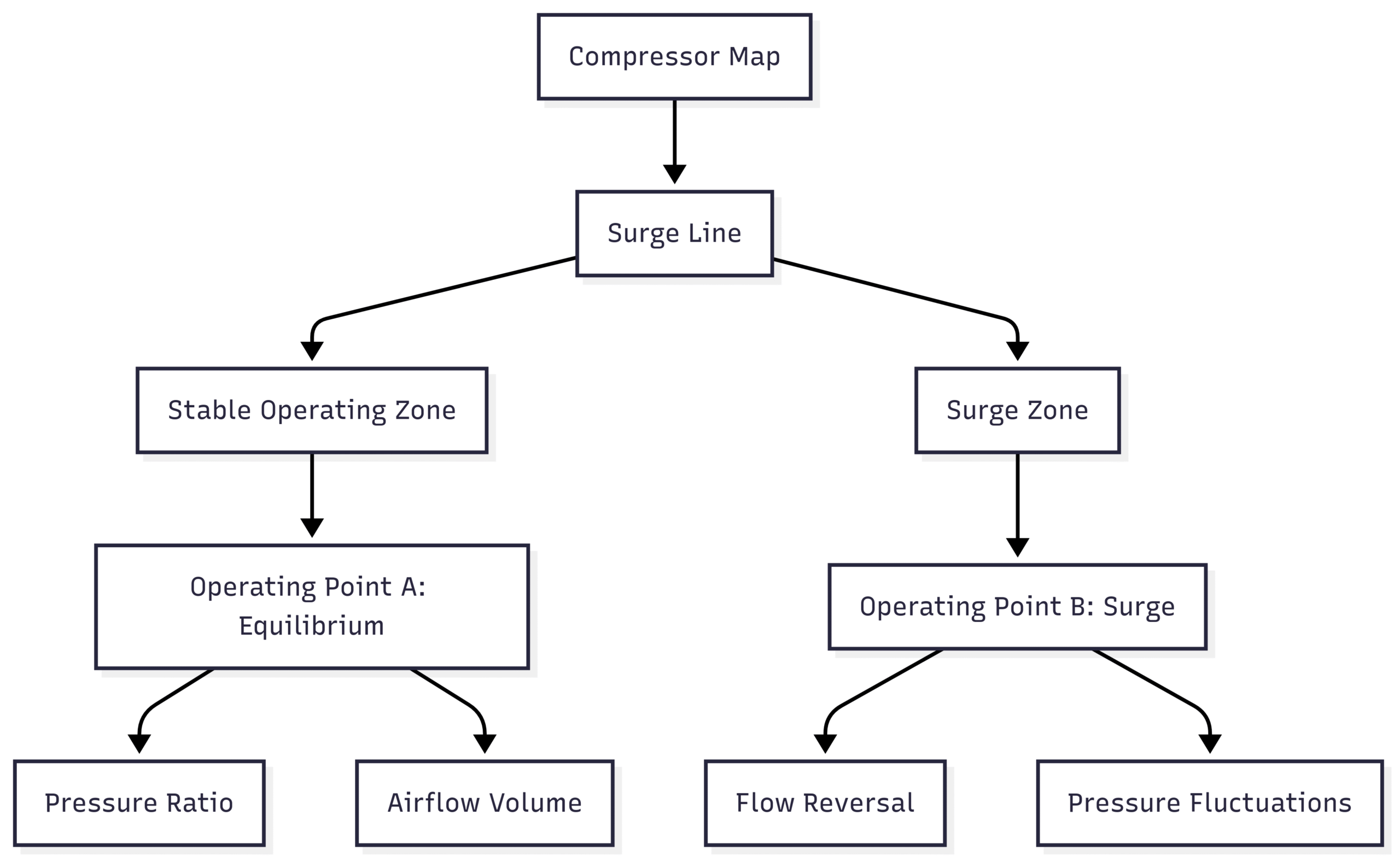

The Surge Line and Compressor Maps

A compressor map illustrates the turbocharger’s operating range, plotting airflow (volume) against pressure ratio. The surge line on the left side of the map marks the boundary where surging occurs. Operating to the left of this line means the compressor cannot maintain stable airflow, leading to flow reversal and pressure dips.

To maintain efficiency, the turbocharger’s operating point must stay to the right of the surge line with a safety margin. Tools like Accelleron’s Turbo Insights analyze operational data to monitor proximity to the surge line, providing actionable insights to prevent surging.

Causes of Turbocharger Surging

Surging arises from various factors that disrupt airflow or pressure balance. Below are the primary causes:

1. Airflow Restrictions

- Dirty Air Filters: Clogged filters reduce airflow, forcing the compressor to work harder and risking surge.

- Clogged Intercoolers: Fouled intercoolers increase backpressure, disrupting airflow dynamics.

- Intake/Exhaust Restrictions: Blockages in the intake or exhaust systems, such as carbon deposits or damaged silencers, limit airflow.

- Fouled Turbo Components: Dirt on compressor blades, nozzle rings, or turbine sides reduces efficiency, contributing to surging.

2. Improper Tuning or Modifications

- Modifying fuel or air management systems without recalibrating the turbocharger can disrupt the engine-turbo balance. For example, increasing fuel delivery without adjusting boost pressure may overwhelm the compressor, leading to surging.

3. Wastegate Malfunction

- The wastegate regulates boost pressure by diverting exhaust gases. A faulty wastegate can cause overboost or inconsistent pressure, triggering surging.

4. Engine Issues

- Fuel System Problems: Low fuel pressure, air/water in the fuel, or defective injectors disrupt combustion, affecting airflow and causing surging.

- Valve Timing Issues: Improper valve timing alters air intake, creating pressure imbalances.

- Worn Engine Components: Worn cylinders or piston rings reduce air consumption, misaligning with the turbocharger’s output.

5. Sudden Load Changes

- Rapid changes in engine load, such as emergency stops, start/stop operations, or abrupt maneuvering in marine applications, can overwhelm the turbocharger. In ships, rough seas or propeller movement in and out of water exacerbate this issue.

6. Environmental Factors

- Changes in ambient pressure or temperature can affect air density, altering the turbocharger’s performance and potentially causing surging.

Table: Common Causes of Turbocharger Surging

| Cause | Description | Impact |

|---|---|---|

| Airflow Restrictions | Dirty filters, clogged intercoolers, or exhaust blockages limit airflow. | Increases backpressure, triggers surge. |

| Improper Tuning | Uncalibrated modifications disrupt engine-turbo balance. | Causes pressure mismatches. |

| Wastegate Malfunction | Faulty wastegate fails to regulate boost pressure. | Leads to overboost or fluctuations. |

| Engine Issues | Fuel system or valve timing problems affect combustion and airflow. | Disrupts compressor stability. |

| Sudden Load Changes | Rapid load variations overwhelm turbo response. | Induces flow reversal. |

| Environmental Factors | Ambient pressure/temperature changes alter air density. | Affects turbo performance. |

Symptoms of Turbocharger Surging

Recognizing surging early is critical to preventing damage. Common symptoms include:

- Unusual Noises: Loud “gulping,” “howling,” or “fluttering” sounds from the turbocharger, often described as a high-pitched vibration.

- Pressure Fluctuations: Violent, repeated changes in boost pressure, observable on a boost gauge.

- Power Loss: Inconsistent airflow leads to sluggish acceleration and reduced engine power.

- Check Engine Light: The engine control unit (ECU) may detect pressure anomalies, triggering a warning light.

- Increased Exhaust Smoke: Inefficient combustion due to surging can produce visible smoke.

- Vibrations: Oscillations in the compressor cause noticeable vibrations in the engine bay.

In marine applications, surging is more audible due to the size of turbochargers and may occur during rough seas or crash stops. Mild surging may be tolerable in such cases, but frequent or severe surging requires immediate attention.

Consequences of Ignoring Turbocharger Surging

Neglecting surging can lead to severe consequences, including:

- Component Damage: Repeated stress on compressor blades, bearings, and shafts causes premature wear or catastrophic failure. Damaged bearings or a broken rotor can necessitate costly turbo replacement.

- Reduced Efficiency: Surging increases fuel consumption and emissions, undermining the turbocharger’s purpose.

- Engine Damage: Inconsistent airflow and pressure can strain engine components, leading to misfires, stalling, or cylinder damage.

- Operational Downtime: In marine or industrial applications, surging-related failures can halt operations, causing financial losses.

The cost of turbocharger repair or replacement varies by application. For automotive turbochargers, repairs range from $500 to $2,000, while marine turbochargers can cost $5,000 to $20,000 or more. Preventive maintenance is far more cost-effective.

Diagnosing Turbocharger Surging

Diagnosing surging requires careful observation and, in complex cases, professional tools. Steps include:

- Listen for Noises: Identify “whooshing,” “fluttering,” or “howling” sounds from the turbocharger.

- Monitor Performance: Note power loss, sluggish acceleration, or increased exhaust smoke.

- Check Boost Pressure: Use a boost gauge to detect fluctuations in pressure.

- Inspect Airflow Components: Examine air filters, intercoolers, and intake/exhaust systems for restrictions.

- Analyze Compressor Maps: Advanced tools like Turbo Insights map the turbocharger’s operating point relative to the surge line.

- Run ECU Diagnostics: Scan for error codes related to boost pressure or airflow anomalies.

- Consult a Specialist: For persistent issues, seek a turbocharger technician or marine engineer.

Preventing and Managing Turbocharger Surging

Preventing surging involves proactive maintenance and operational best practices. Below are actionable solutions:

1. Address Airflow Restrictions

- Replace Air Filters: Check and replace filters every 12,000–15,000 miles (automotive) or per manufacturer’s schedule (marine/industrial).

- Clean Intercoolers: Flush intercoolers annually to remove oil and debris.

- Inspect Intake/Exhaust: Ensure pipes, silencers, and exhaust manifolds are free of blockages.

- Water-Wash Turbo Components: Clean compressor and turbine sides per manufacturer guidelines to remove fouling.

2. Optimize Tuning and Modifications

- Work with a professional tuner to recalibrate fuel and air management systems after modifications. Ensure the turbocharger matches the engine’s air consumption rate.

3. Maintain Wastegate

- Inspect wastegates for proper operation and repair or replace faulty units. Regular lubrication and adjustment prevent sticking.

4. Diagnose Engine Issues

- Address fuel system problems, such as low pressure or defective injectors, promptly.

- Verify valve timing and cylinder condition to ensure consistent air demand.

5. Manage Load Changes

- Avoid abrupt throttle inputs or emergency stops when possible. In marine applications, gradual load adjustments during rough seas reduce surging risk.

6. Follow Maintenance Schedules

- Adhere to the manufacturer’s turbocharger service intervals, including bearing lubrication and component inspections.

- Use OEM parts (e.g., Garrett or Accelleron) for replacements to ensure compatibility.

7. Implement Design Modifications

- Anti-Surge Valves: Install blow-off valves to release excess pressure during load changes.

- Hybrid Turbochargers: These provide better torque distribution, reducing surging risk.

- Variable Geometry Turbochargers (VGT): VGTs adjust vane angles to operate closer to the surge margin without crossing it.

- Two-Stage Turbochargers: These use bypasses to suppress surging in high-pressure applications.

Table: Turbocharger Types and Surging Resistance

| Turbocharger Type | Description | Surging Resistance |

|---|---|---|

| Conventional | Fixed geometry, standard design. | Moderate; prone to classic surging. |

| Hybrid | Combines engine torque with turbo boost. | High; reduced surging risk. |

| Variable Geometry (VGT) | Adjustable vanes optimize airflow. | Very high; minimal surging. |

| Two-Stage | Dual compressors with bypasses. | High; designed to suppress surging. |

8. Use Monitoring Tools

- Employ compressor map analysis tools like Turbo Insights to track performance and predict surging risks.

- Install boost gauges and temperature sensors for real-time monitoring.

9. Seek Professional Help

- If surging persists, consult a turbocharger specialist or Accelleron service station. They can assess component damage and recommend repairs or upgrades.

Real-World Applications: Automotive vs. Marine

Automotive Turbochargers

In cars, surging often results from aftermarket modifications or neglected maintenance. For example, a tuned Subaru WRX with a dirty air filter may exhibit fluttering noises during rapid throttle changes. Regular filter replacements and professional tuning mitigate these issues. Garrett turbochargers, commonly used in performance cars, offer robust solutions with prices ranging from $800 to $3,000.

Marine Turbochargers

Marine engines, particularly low-speed diesels, experience surging due to load variations in rough seas or fouled components. A ship’s turbocharger, such as those from Accelleron, may cost $10,000–$50,000, with maintenance costs significantly lower. Regular water-washing and economizer cleaning prevent surging, ensuring efficient propulsion.

Cost Considerations

Automotive Turbocharger Costs

- Replacement: $800–$3,000 (e.g., Garrett G-Series).

- Repair: $500–$1,500.

- Maintenance: $100–$300 annually (filters, cleaning).

Marine Turbocharger Costs

- Replacement: $10,000–$50,000 (e.g., Accelleron models).

- Repair: $2,000–$10,000.

- Maintenance: $500–$2,000 per service interval.

Investing in preventive maintenance, such as cleaning and monitoring, saves significant costs compared to repairs or replacements.

Why Turbocharger Surging Matters

Turbocharger surging is more than a nuisance—it’s a threat to engine performance, efficiency, and longevity. Left unaddressed, it can lead to costly repairs, increased emissions, and operational downtime. By understanding its causes, recognizing symptoms, and implementing preventive measures, owners can protect their engines and maximize turbocharger benefits.

For automotive enthusiasts, surging undermines the thrill of boosted performance. For marine engineers, it jeopardizes vessel reliability and fuel efficiency. In both cases, proactive maintenance and modern turbocharger designs (e.g., VGT or two-stage systems) offer solutions to keep engines running smoothly.

Conclusion

Turbocharger surging is a complex but manageable issue that affects engine performance across applications. By addressing airflow restrictions, optimizing tuning, maintaining components, and using advanced monitoring tools, owners can prevent surging and its consequences. Regular maintenance, combined with modern turbocharger technologies, ensures efficient, reliable, and powerful engine operation. Whether you’re driving a performance car or operating a marine vessel, understanding and managing turbocharger surging is key to unlocking your engine’s full potential.

Happy Boating!

Share Turbocharger Surging: What It Is and Why It Matters with your friends and leave a comment below with your thoughts.

Read Crankcase Explosion: Causes, Prevention Strategies & Safety until we meet in the next article.