Top 10 Marine equipment manufacturer in the World

Discover the top 10 marine equipment manufacturers globally, their innovative products, and key specifications for maritime excellence.

The maritime industry, a backbone of global trade, relies on advanced equipment to ensure safety, efficiency, and sustainability. From propulsion systems to mooring solutions, marine equipment manufacturers play a critical role in equipping vessels for diverse applications, including commercial shipping, recreational boating, and offshore operations. This article explores the top 10 marine equipment manufacturers worldwide, highlighting their products, technical specifications, applications, and contributions to the industry. Whether you’re a maritime professional, student, or enthusiast, understanding these leaders will enhance your perspective on marine technology.

Why Marine Equipment Matters

Marine equipment encompasses a wide range of systems, including engines, navigation tools, deck machinery, and environmental solutions. These components ensure vessels operate reliably in harsh marine environments, comply with international regulations like SOLAS and MARPOL, and support sustainable practices. Choosing the right manufacturer is crucial for optimizing performance, reducing operational costs, and meeting environmental standards.

Top 10 Marine Equipment Manufacturers

Below, we delve into the leading manufacturers, their flagship products, and their impact on the maritime sector. Each company is evaluated based on product quality, innovation, and global reach.

1. Wärtsilä Corporation

Country: Finland

Known For: Engines, hybrid propulsion, scrubbers

Website: wartsila.com

Wärtsilä is a global leader in smart marine technologies, offering lifecycle solutions for propulsion, power generation, and environmental compliance. Their portfolio includes dual-fuel engines, hybrid propulsion systems, and exhaust gas cleaning systems (scrubbers) that reduce emissions to meet IMO standards.

Key Products:

- Wärtsilä 46DF Engine: A dual-fuel engine for commercial vessels, offering fuel flexibility (LNG, diesel) and compliance with Tier III emission standards.

- Hybrid Propulsion Systems: Combine electric and diesel power for fuel efficiency and reduced emissions.

- Scrubbers: Remove sulfur oxides from exhaust gases, ensuring MARPOL compliance.

Technical Specifications:

- Power Output: 6–18 MW (46DF engine)

- Fuel Efficiency: Up to 50% reduction in fuel consumption with hybrid systems

- Emission Compliance: IMO Tier III, MARPOL Annex VI

Applications:

- Commercial shipping

- Offshore support vessels

- Cruise and ferry operations

Pros:

- High fuel efficiency

- Comprehensive after-sales support

- Focus on sustainability

Cons:

- High initial investment

- Complex maintenance for hybrid systems

Innovation Highlight: Wärtsilä’s digital solutions, such as remote diagnostics and predictive maintenance, leverage IoT and analytics to optimize vessel performance.

2. MAN Energy Solutions

Country: Germany

Known For: Two-stroke and four-stroke engines

Website: man-es.com

MAN Energy Solutions specializes in high-performance marine engines for commercial vessels, including container ships and bulk carriers. Their engines are renowned for durability, fuel efficiency, and compliance with stringent emission regulations.

Key Products:

- MAN B&W 6G95ME-C10.5: A two-stroke engine for large vessels, optimized for low-speed operation and fuel efficiency.

- Four-Stroke Engines: Compact engines for yachts and workboats.

- Retrofit Solutions: Upgrades for existing engines to meet emission standards.

Technical Specifications:

- Power Range: 10–90 MW (two-stroke engines)

- Fuel Types: HFO, MGO, LNG

- Emission Standards: IMO Tier II/III

Applications:

- Container ships

- Bulk carriers

- LNG carriers

Pros:

- Robust and reliable engines

- Fuel flexibility

- Global service network

Cons:

- High maintenance costs

- Limited focus on smaller vessels

Innovation Highlight: MAN’s ME-GI engine supports LNG as a fuel, reducing CO2 emissions by up to 25% compared to traditional fuels.

3. Alfa Laval

Country: Sweden

Known For: Heat exchangers, fuel systems, ballast water management systems (BWMS)

Website: alfalaval.com

Alfa Laval provides critical systems for thermal management, fuel treatment, and environmental protection. Their products enhance energy efficiency and ensure compliance with international regulations.

Key Products:

- PureBallast 3: A UV-based ballast water management system.

- Plate Heat Exchangers: Compact and efficient for cooling and heating applications.

- Fuel Conditioning Modules: Optimize fuel quality for engine performance.

Technical Specifications:

- BWMS Capacity: 150–3,000 m³/h

- Heat Exchanger Efficiency: Up to 90% heat recovery

- Material: Stainless steel, titanium for corrosion resistance

Applications:

- Tankers

- Cruise ships

- Offshore platforms

Pros:

- Energy-efficient solutions

- Compact designs

- Strong focus on environmental compliance

Cons:

- High upfront costs

- Specialized maintenance required

Innovation Highlight: Alfa Laval’s PureSOx scrubber system reduces sulfur emissions, supporting compliance with IMO 2020 regulations.

4. Kongsberg Maritime

Country: Norway

Known For: Navigation, automation, control systems

Website: kongsberg.com

Kongsberg Maritime, incorporating Rolls-Royce Marine’s former operations, excels in integrated bridge systems, propulsion, and deck machinery. Their solutions enhance vessel safety and operational efficiency through automation.

Key Products:

- K-Pos Dynamic Positioning System: Maintains precise vessel positioning for offshore operations.

- Integrated Bridge Systems: Combine navigation, radar, and control functions.

- Azipull Thrusters: High-efficiency propulsion for maneuverability.

Technical Specifications:

- DP Accuracy: ±0.1 m

- Thruster Power: 1–5 MW

- Automation: IoT-enabled for remote monitoring

Applications:

- Offshore supply vessels

- Ferries

- Research vessels

Pros:

- Advanced automation reduces crew workload

- High precision and reliability

- Global support network

Cons:

- Complex systems require training

- High installation costs

Innovation Highlight: Kongsberg’s digital twin technology enables real-time simulation of vessel systems for predictive maintenance.

5. ABB Marine

Country: Switzerland

Known For: Electric propulsion, switchboards

Website: abb.com

ABB Marine pioneers electric and hybrid propulsion systems, reducing fuel consumption and emissions. Their solutions are ideal for ferries, cruise ships, and environmentally sensitive areas.

Key Products:

- Azipod Propulsion: Electric podded propulsion for maneuverability and efficiency.

- Onboard DC Grid: Distributes power efficiently, reducing fuel use.

- Switchboards: Safe and reliable power distribution.

Technical Specifications:

- Azipod Power: 1–22 MW

- Efficiency: Up to 20% fuel savings

- Compliance: Designed for IMO and DNV standards

Applications:

- Cruise ships

- Ferries

- Icebreakers

Pros:

- Significant fuel and emission reductions

- Enhanced maneuverability

- Scalable solutions

Cons:

- High capital expenditure

- Requires skilled engineers for maintenance

Innovation Highlight: ABB’s Onboard DC Grid supports integration with battery storage for fully electric operations.

6. Misea Machinery

Country: China

Known For: Winches, capstans, cranes, pumps

Website: miseamachinery.com

Misea Machinery manufactures durable deck equipment for anchoring, mooring, and cargo handling. Their products are designed for reliability in harsh marine environments.

Key Products:

- Marine Winches: Electric and hydraulic winches for towing and mooring.

- Capstans: For efficient line handling at docks.

- Cranes: Compact designs for cargo operations.

Technical Specifications:

- Lifting Capacity: 5–100 tons (winches)

- Power Source: Electric or hydraulic

- Material: Corrosion-resistant alloys

Applications:

- Cargo vessels

- Mooring operations

- Offshore platforms

Pros:

- Cost-effective solutions

- Durable construction

- Versatile configurations

Cons:

- Hydraulic systems require complex installation

- Electric winches may overheat under heavy loads

Innovation Highlight: Misea’s modular winch designs allow for easy customization to meet project-specific needs.

7. DMT Marine Equipment

Country: Netherlands

Known For: Winches, deck machinery

Website: dmt-winches.com

DMT Marine Equipment provides custom-engineered winches and deck machinery, certified to European standards. Their products are tailored for dredging and offshore applications.

Key Products:

- Custom Winches: Designed for specific vessel requirements.

- Deck Machinery: Includes anchor handling systems.

- Control Systems: Automated for precision.

Technical Specifications:

- Load Capacity: Up to 200 tons

- Certification: CE, DNV, ABS

- Material: High-strength steel

Applications:

- Dredging vessels

- Offshore wind farms

- Fishing vessels

Pros:

- High reliability

- Extensive customization options

- Certified quality

Cons:

- Higher costs for bespoke solutions

- Limited availability in some regions

Innovation Highlight: DMT’s in-house engineering ensures compliance with stringent safety and performance standards.

8. Sinostar Marine Equipment

Country: China

Known For: Mooring products, anchors, chains

Website: smemarine.com

Sinostar Marine Equipment specializes in mooring solutions, offering anchors, chains, and deck fittings built for durability in saltwater environments.

Key Products:

- Marine Anchors: High-holding power for secure mooring.

- Mooring Chains: Alloy-grade for corrosion resistance.

- Deck Fittings: Customizable for various vessels.

Technical Specifications:

- Anchor Weight: 100 kg–20 tons

- Chain Material: Grade 2/3 alloy steel

- Corrosion Resistance: Galvanized coatings

Applications:

- Aquaculture

- Cargo vessels

- Offshore mooring

Pros:

- High durability

- Comprehensive after-sales support

- Competitive pricing

Cons:

- Limited product dimension details

- Custom solutions may be costly

Innovation Highlight: Sinostar’s focus on eco-friendly materials supports sustainable maritime operations.

9. Thordon Bearings Inc. (DiSalvo Marine Equipment)

Country: Canada

Known For: Oil- and grease-free bearing systems

Website: disalvomarine.com

Thordon Bearings, distributed through DiSalvo Marine, manufactures environmentally friendly bearing systems for marine and industrial applications. Their oil- and grease-free designs reduce pollution risks.

Key Products:

- Thordon SXL Bearings: For propeller shafts and rudders.

- Seals: High-performance, non-polluting seals.

- Shaft Line Products: Enhance propulsion efficiency.

Technical Specifications:

- Load Capacity: Up to 50 MPa

- Material: Polymer composites

- Lifespan: 20+ years in marine conditions

Applications:

- Naval vessels

- Cruise ships

- Hydropower plants

Pros:

- Environmentally friendly

- Low maintenance

- High reliability

Cons:

- Limited to specific applications

- Higher initial costs

Innovation Highlight: Thordon’s bearings eliminate the need for lubricants, reducing environmental impact and maintenance costs.

10. CorPower Ocean

Country: Sweden

Known For: Wave energy converters

Website: corpowerocean.com

CorPower Ocean develops innovative wave energy technology, converting ocean waves into electricity. Their compact devices are ideal for sustainable marine energy solutions.

Key Products:

- CorPower C4: A wave energy converter with high efficiency.

- Control Systems: Optimize energy capture in varying wave conditions.

- Mooring Systems: Designed for harsh offshore environments.

Technical Specifications:

- Power Output: 300 kW per unit

- Efficiency: Up to 30% wave-to-wire

- Survivability: Designed for 50-year storm conditions

Applications:

- Offshore renewable energy

- Remote island power supply

- Research platforms

Pros:

- High energy efficiency

- Compact and scalable

- Environmentally sustainable

Cons:

- Niche application

- High development costs

Innovation Highlight: CorPower’s phase control technology maximizes energy extraction, outperforming traditional wave energy systems.

Comparison Table

| Manufacturer | Key Products | Applications | Pros | Cons |

|---|---|---|---|---|

| Wärtsilä | Engines, hybrid propulsion, scrubbers | Commercial shipping, cruises | Fuel-efficient, sustainable | High cost, complex maintenance |

| MAN Energy Solutions | Two/four-stroke engines | Container ships, LNG carriers | Reliable, fuel-flexible | High maintenance costs |

| Alfa Laval | Heat exchangers, BWMS | Tankers, offshore platforms | Energy-efficient, compact | High upfront costs |

| Kongsberg Maritime | Navigation, automation, thrusters | Offshore vessels, ferries | Precise, automated | Requires training, costly |

| ABB Marine | Electric propulsion, switchboards | Cruise ships, ferries | Fuel-saving, maneuverable | High capital expenditure |

| Misea Machinery | Winches, cranes, pumps | Cargo vessels, mooring | Cost-effective, durable | Complex installation |

| DMT Marine Equipment | Custom winches, deck machinery | Dredging, offshore wind | Reliable, customizable | Higher costs for bespoke solutions |

| Sinostar Marine | Anchors, chains, deck fittings | Aquaculture, cargo vessels | Durable, competitive pricing | Limited dimension details |

| Thordon Bearings | Oil-free bearings, seals | Naval vessels, cruise ships | Eco-friendly, low maintenance | Niche applications |

| CorPower Ocean | Wave energy converters | Offshore renewable energy | Efficient, sustainable | High development costs |

Trends and Innovations in Marine Equipment

The marine equipment industry is evolving rapidly, driven by regulatory pressures and technological advancements. Key trends include:

Green Technologies:

- Hybrid and electric propulsion systems reduce fuel consumption and emissions.

- Energy-saving devices like propeller boss cap fins improve efficiency.

- Scrubbers and SCR systems ensure compliance with IMO 2020 sulfur caps.

Digitalization:

- IoT sensors enable condition-based maintenance, reducing downtime.

- Digital twins provide real-time simulations for performance optimization.

- Remote diagnostics enhance operational efficiency.

Automation:

- Integrated bridge systems streamline navigation and control.

- Automated deck machinery reduces crew workload and enhances safety.

Cybersecurity:

- Compliance with IMO 2021 Cyber Risk Management resolution protects digital systems.

- Secure IoT platforms safeguard critical equipment.

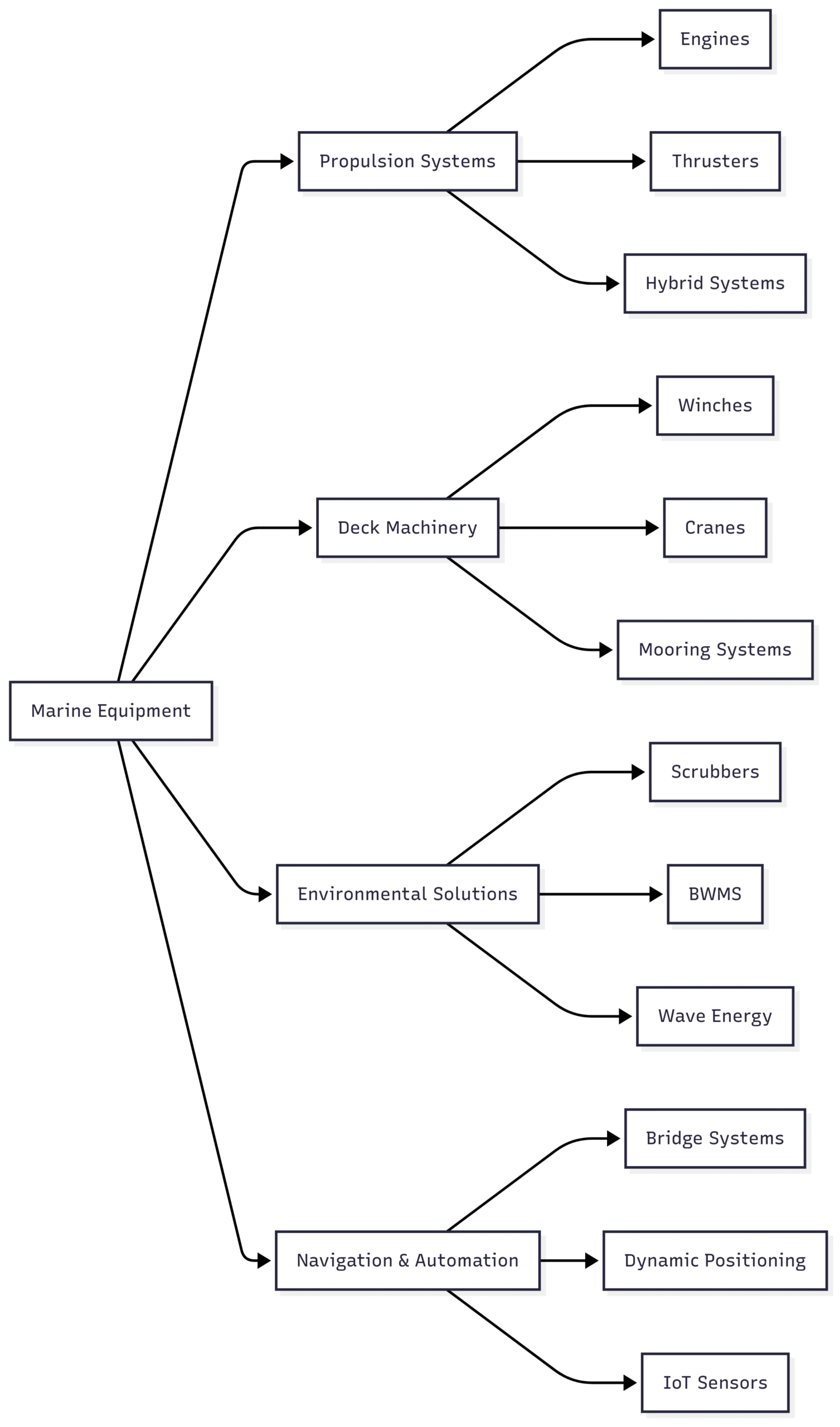

Mermaid Chart: Marine Equipment Ecosystem

This chart illustrates the interconnected categories of marine equipment, highlighting the diversity of systems provided by top manufacturers.

Pricing Insights

Pricing varies significantly based on product type, specifications, and customization. Below are approximate ranges for key equipment:

- Marine Engines: $500,000–$5 million (Wärtsilä, MAN)

- Winches: $10,000–$500,000 (Misea, DMT)

- BWMS: $200,000–$1 million (Alfa Laval)

- Wave Energy Converters: $1–$3 million per unit (CorPower)

- Electric Propulsion Systems: $1–$10 million (ABB)

For precise pricing, contact manufacturers directly, as costs depend on vessel size, application, and regional factors.

Choosing the Right Manufacturer

When selecting a marine equipment manufacturer, consider:

- Reputation: Check certifications (ISO 9001, DNV, ABS) and customer reviews.

- Product Range: Ensure the manufacturer meets your specific needs (e.g., commercial vs. recreational).

- Support: Evaluate after-sales service, spare parts availability, and global reach.

- Compliance: Verify adherence to IMO, SOLAS, and class society standards.

- Cost: Balance upfront costs with long-term savings from efficiency and durability.

FAQs

What types of marine equipment are most critical?

How do manufacturers ensure equipment durability?

What are the benefits of green marine technologies?

How can I find reliable suppliers?

Conclusion

The top 10 marine equipment manufacturers—Wärtsilä, MAN Energy Solutions, Alfa Laval, Kongsberg Maritime, ABB Marine, Misea Machinery, DMT Marine Equipment, Sinostar Marine, Thordon Bearings, and CorPower Ocean—drive innovation and reliability in the maritime industry. Their products, from engines to wave energy converters, support global trade, safety, and sustainability. By understanding their offerings and trends like green technologies and digitalization, maritime professionals and enthusiasts can make informed decisions to enhance vessel performance and compliance.

Next Steps:

- Explore manufacturer websites for detailed specifications.

- Download marine equipment inspection checklists from industry resources.

- Stay updated on green marine technologies for future-proofing your operations.

Happy Boating!

Share Top 10 Marine equipment manufacturer in the World with your friends and leave a comment below with your thoughts.

Read Essential Instruments in a Ship’s Engine Room until we meet in the next article.