Top 10 Marine Diesel Engines

Marine diesel engines power a vast array of vessels, from commercial ships to high-speed ferries and yachts. These engines are engineered for durability in harsh marine environments, delivering reliable propulsion while balancing efficiency, emissions, and power.

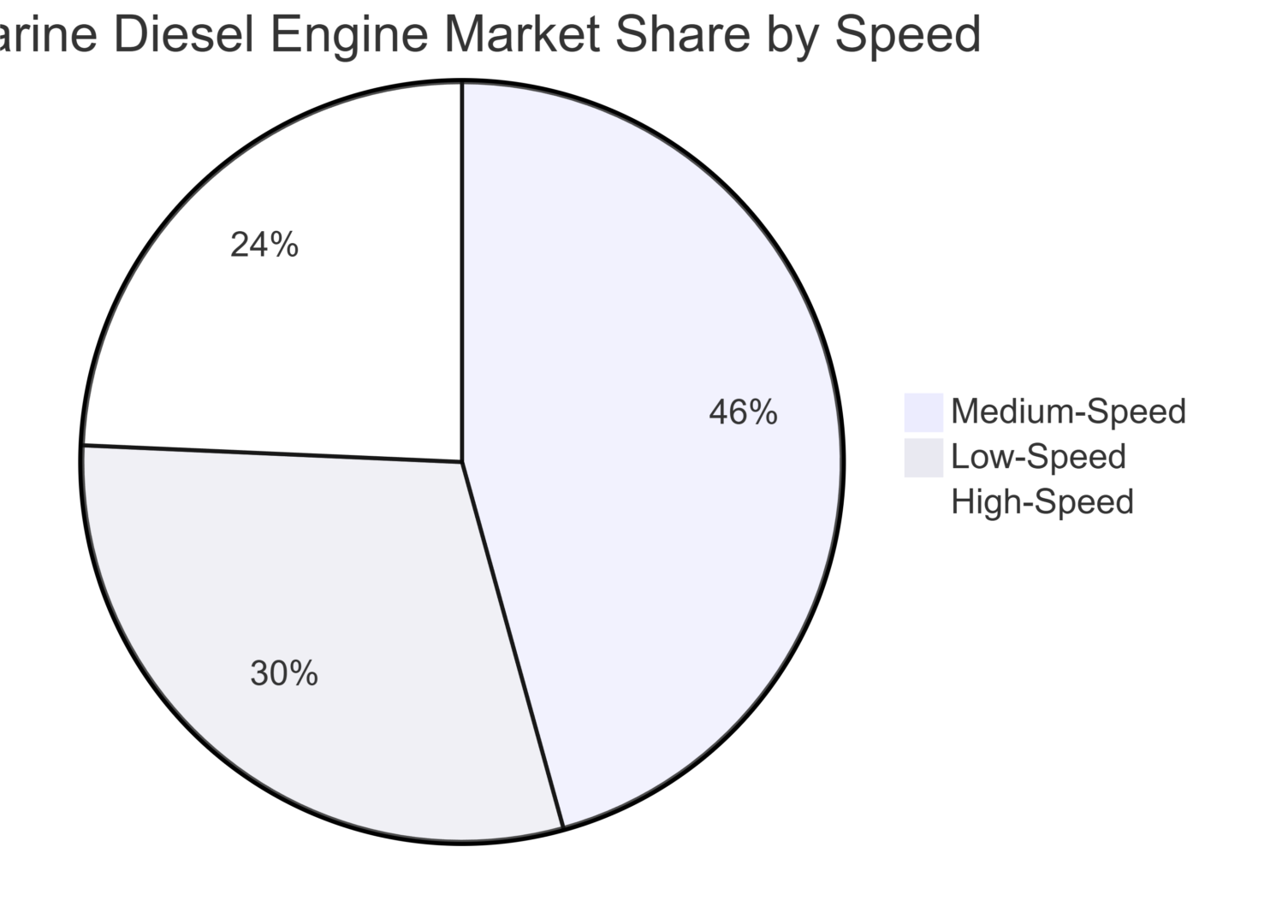

The global marine diesel engine market is valued at approximately USD 8.77 billion, with medium-speed engines holding about 45.7% market share due to their optimal balance of power and efficiency. Growth is driven by regulatory demands for lower emissions, fuel efficiency improvements, and digitalization, projecting a CAGR of 4-6% through 2033.

Understanding Marine Diesel Engines

Marine diesel engines are classified by speed (low, medium, high), cycle (two-stroke or four-stroke), fuel type, and construction. They operate on the diesel cycle, compressing air before injecting fuel for combustion, which drives pistons connected to a crankshaft for rotational power. Key components include the cylinder block, pistons, connecting rods, crankshaft, camshaft, fuel injection system, cooling system (often seawater-based), lubrication system, and exhaust system with turbochargers.

Two-Stroke vs. Four-Stroke Engines

Two-stroke engines complete a power cycle in two piston strokes, offering high power output and efficiency for large vessels like tankers and container ships. They are lighter with a higher power-to-weight ratio but produce higher NOx emissions, requiring systems like EGR or SCR. Advantages include simplicity and lower production costs; disadvantages are higher particulate emissions and frequent maintenance.

Four-stroke engines use four strokes (intake, compression, power, exhaust), providing lower NOx emissions and better fuel efficiency at low speeds. They are heavier and more complex but durable with longer service life. Ideal for smaller vessels, their drawbacks include lower power-to-weight ratio.

Here’s a comparison table:

| Feature | Two-Stroke Engines | Four-Stroke Engines |

|---|---|---|

| Cycle | Two strokes per power cycle | Four strokes per power cycle |

| Power Output | High, suited for large ships | Moderate, for varied applications |

| Weight & Complexity | Lighter, simpler | Heavier, more complex |

| Emissions | Higher NOx, particulates | Lower NOx |

| Efficiency | High at full load | Better at partial loads |

| Maintenance | Frequent filters | Less frequent, longer life |

Operation and Maintenance

Engines run continuously, monitored via controls for speed and performance. Maintenance includes oil changes, filter replacements, and inspections to prevent wear. Repairs may involve cylinder heads or fuel systems. Proper upkeep ensures peak efficiency and longevity.

Major Manufacturers

Key players include MAN Energy Solutions (dual-fuel engines), Wärtsilä (multi-fuel options), Rolls-Royce (MTU brand), Caterpillar, Cummins, Volvo Penta, Yanmar, Mitsubishi, and John Deere. These firms offer installation, maintenance, and repairs.

Top 10 Marine Diesel Engines

1. Caterpillar C32B

The Caterpillar C32B is a V12 engine with 32.1 liters displacement, delivering up to 2025 mhp (2000 bhp) at 2300 rpm. It features twin-turbo aspiration, a bore of 145 mm, and stroke of 162 mm. Weighing 3145 kg, it measures 2106 mm long, 1469 mm wide, and 1469 mm high (dry). Certified to EPA Tier 3 and IMO II, it offers 5% more power than predecessors with only 2% weight increase, plus 25% quieter low-speed operation via advanced injection. Reliability includes over 30,000 testing hours and unlimited-hour coverage for two years, extendable to 10. Prices vary; contact dealers for quotes, with used models around $60,000.

2. John Deere JD14 & JD18

John Deere’s JD14 is a 13.6-liter inline 6-cylinder engine, producing 400-803 hp (298-599 kW) at 1800-2100 rpm. The JD18 is an 18-liter inline 6-cylinder, offering 550-803 hp (410-599 kW). Both use high-pressure common-rail injection, hydraulic lash adjusters, and are compatible with renewable diesel/biodiesel. Certified to IMO Tier 2, EPA Tier 3, and EU RCD II, they feature 500-hour service intervals. The JD14 has a smaller footprint for easier integration, while JD18 suits heavy-duty applications. No standard prices available; expect commercial quotes based on configuration.

3. MAN Energy Solutions 20V32/44CR

This 20-cylinder four-stroke engine outputs 12,000 kW at 720-750 rpm, with a bore of 320 mm and stroke of 440 mm. It uses common-rail injection for efficiency and low emissions, meeting IMO Tier II/III. Dimensions support twin installations with 4000 mm centerline distance. It’s ideal for naval and large support ships, with dual-fuel options for methanol/ammonia. Weight and full specs vary by setup. Pricing is project-specific; recent orders indicate high-value contracts.

4. MTU Series 4000 M65L

The MTU 12V4000 M65L from Rolls-Royce delivers up to 1680 kW (2252 bhp) at 1800 rpm, powering vessels like 500-passenger ferries to 37 knots. It’s EPA Tier 4 certified with SCR and potential DPF for CARB compliance. The Series 4000 ranges up to 4300 kW overall. Features include common-rail injection and sequential turbocharging. Displacement is 57.2 liters for 12V models. No fixed prices; industrial quotes apply.

5. Yanmar 6GY135 Series

Yanmar’s 6GY135 is a 6-cylinder high-speed engine with outputs of 372-599 kW (499-803 hp) at 1800-2100 rpm. It uses common-rail for global emissions compliance (IMO Tier 3, EPA Tier 3). Emphasizing fuel economy and lifecycle value, it includes Smart-Assist for analysis. Replaces the 6KXZ series with cleaner exhaust and longevity. Dimensions: 1645 mm x 1055 mm x 1254 mm, weight 1825 kg without gear. Pricing unavailable; dealer inquiries recommended.

6. MAN V12X

The MAN V12X offers 2200 hp (1618 kW) at 2300 rpm from 29.6 liters, with 7350 Nm torque. Bore/stroke: 138/165 mm. It weighs 2720 kg, measuring 2335 mm long, 1153 mm wide, 1320 mm high. Advanced fuel and cooling systems enhance efficiency. Suited for yachts, it meets IMO II. Prices around $75,000 for similar V12 models.

7. MTU Series 2000

MTU Series 2000 includes 10V/12V/16V configurations from 1360-2600 hp. The new 12V2000 M96Z reaches 2222 mhp. Common-rail injection and sequential turbocharging provide efficiency. Displacement varies: 26.8 liters for 12V. Meets EPA Tier 3/IMO II. Compact for small engine rooms, with low fuel use. No standard pricing.

8. Northern Lights / Cummins Lugger L4105 & L6105

Lugger L4105 (4-cylinder) outputs 174-300 hp; L6105 (6-cylinder) 255-425 hp. Features wet liners, forged crankshafts, modular heads for durability. Built for longevity in commercial use, meeting emissions standards. Ideal for trawlers and workboats. Pricing varies by rating.

9. Cox Marine Diesel Outboard V8

Cox’s V8 outboard delivers 300-350 hp from 4.4 liters, twin-turbo, at 4000 rpm. Torque up to 1052 Nm, weight 393 kg. Gear ratio 1.46:1, shaft lengths 25-35 inches. EPA Tier 3/IMO II certified, with 30% better fuel economy than gas outboards. Prices around $50,000.

10. Hydrogen-Diesel Retrofits

Retrofit systems blend hydrogen with diesel, cutting fuel use by 20% and emissions. Compatible with existing engines, they offer a transition to cleaner ops. Costs range $100,000-$ millions depending on vessel size; Lomarlabs/Newlight pilots target IMO compliance.

Comparison Table

| Engine Model | Power Output (hp) | Displacement (L) | Emissions Standards | Key Features | Approx. Price (USD) |

|---|---|---|---|---|---|

| Caterpillar C32B | Up to 2025 | 32.1 | EPA Tier 3, IMO II | Quiet, high power density | Contact dealer |

| John Deere JD14/JD18 | 400-803 | 13.6/18 | EPA Tier 3, IMO II | Common-rail, biodiesel compat | Contact dealer |

| MAN 20V32/44CR | ~16,000 (12,000 kW) | Varies | IMO Tier II/III | Dual-fuel capable | Project-based |

| MTU 4000 M65L | Up to 2252 | 57.2 | EPA Tier 4 | SCR for low emissions | Contact dealer |

| Yanmar 6GY135 | 499-803 | Varies | IMO Tier 3 | Fuel-efficient, clean exhaust | Contact dealer |

| MAN V12X | 2200 | 29.6 | IMO II | High torque | ~$75,000 |

| MTU Series 2000 | 1360-2600 | 26.8 (12V) | EPA Tier 3 | Compact, efficient | Contact dealer |

| Lugger L4105/L6105 | 174-425 | Varies | Varies | Durable construction | Contact dealer |

| Cox V8 Outboard | 300-350 | 4.4 | EPA Tier 3 | High torque, efficient | ~$50,000 |

| Hydrogen Retrofits | Varies | N/A | Reduced emissions | 20% fuel savings | $100k+ |

Market Outlook and Trends

The market emphasizes higher horsepower, quieter ops, cleaner emissions via SCR/EGR, and hybrid/retrofit options. Dual-fuel engines support methanol/ammonia/hydrogen for sustainability. Digitalization aids monitoring and efficiency.

In summary, these top engines represent advancements in power, reliability, and eco-friendliness, catering to diverse maritime needs. Select based on vessel type, load, and regulations for optimal performance.

Happy Boating!

Share Top 10 Marine Diesel Engines with your friends and leave a comment below with your thoughts.

Read The Importance of Machinery Space on Ships: Types of Equipment and Systems until we meet in the next article.