Top 10 Engine Room Procedures for New Cadets

Discover the top 10 engine room procedures for new cadets to ensure safety, efficiency, and career growth in marine engineering.

The engine room is the pulsating core of any maritime vessel, a complex ecosystem of machinery that powers the ship and ensures its operational integrity. For new engine cadets stepping into this high-stakes environment, mastering standard operating procedures (SOPs) is not just a requirement—it’s a lifeline. These procedures, aligned with International Maritime Organization (IMO) standards like the STCW Code, transform theoretical knowledge into practical skills, ensuring safety, efficiency, and career progression. This guide outlines the top 10 engine room procedures every cadet must prioritize, offering actionable insights, real-world applications, and essential tips to excel in marine engineering.

Why Engine Room Procedures Matter

The engine room is a high-pressure environment where errors can lead to catastrophic consequences—equipment failure, environmental violations, or even loss of life. SOPs provide a structured framework for cadets to navigate this complexity, fostering discipline and competence. By internalizing these procedures, cadets contribute to the vessel’s safety, comply with global regulations like MARPOL and SOLAS, and lay the groundwork for a rewarding career as marine engineers.

1. Conducting Daily Engine Room Rounds and Logkeeping

Daily rounds are the backbone of engine room operations, allowing cadets to monitor the health of machinery and detect anomalies early.

Key Tasks:

- Check temperatures, pressures, and fluid levels in main engines, generators, and auxiliary systems.

- Listen for unusual noises or vibrations and inspect for leaks.

- Record findings in logbooks or digital systems, ensuring accuracy for noon logs.

Practical Tips:

- Use a checklist to ensure consistency, starting from the lowest platform and working upward.

- Track trends over time, such as a gradual increase in lube oil temperature, which may signal issues like clogged filters.

- Always carry a notebook to jot down observations and questions for senior engineers.

IMO Reference: STCW A-III/1 mandates competency in watchkeeping and machinery monitoring.

Real-World Insight: A cadet’s diligent rounds on a bulk carrier identified rising exhaust temperatures, preventing a mid-sea blackout by alerting the second engineer in time.

2. Starting and Stopping the Main Engine

The main engine powers the vessel’s propulsion, and its startup and shutdown require precision to avoid failures or delays.

Key Tasks:

- Perform pre-start checks: verify cooling water flow, lube oil levels, and air starting pressure.

- Disengage the jacking gear and monitor warm-up via remote systems.

- Follow emergency stop protocols, ensuring fuel and air systems are secure.

Practical Tips:

- Never initiate startup without the chief engineer’s authorization.

- Ensure proper fuel system purging to avoid failure-to-start alarms, critical during port maneuvers.

- Familiarize yourself with the engine’s control panel layout during downtime.

Safety Note: Inadequate cooling water supply during startup can cause overheating, risking engine seizure.

Real-World Insight: A cadet’s oversight in purging air from the fuel system delayed a port departure, underscoring the need for thorough pre-start checks.

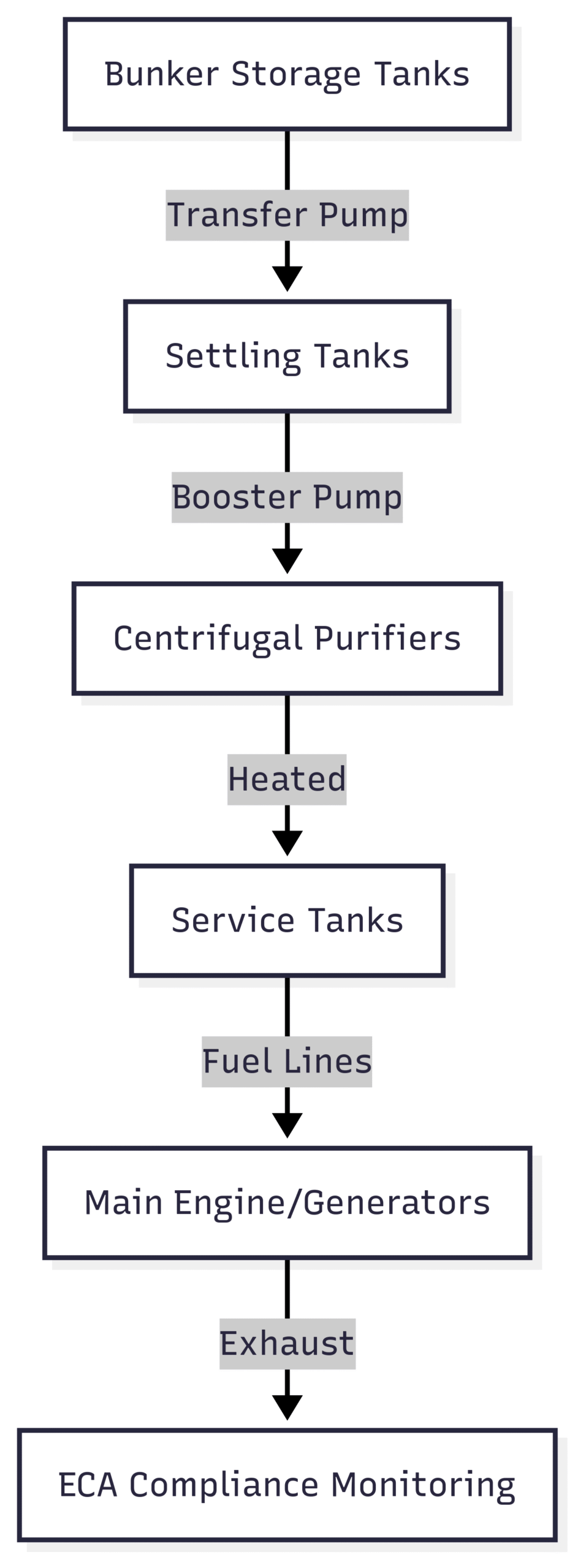

3. Operating and Changing Over the Fuel Oil System

Managing the fuel oil system ensures efficient combustion and compliance with environmental regulations, particularly in Emission Control Areas (ECAs).

Key Tasks:

- Operate fuel transfer pumps, booster systems, and centrifugal purifiers.

- Handle bunker storage and settling tanks, ensuring proper segregation.

- Execute fuel changeovers from heavy fuel oil (HFO) to marine gas oil (MGO) in ECAs.

Practical Tips:

- Monitor purifier performance to prevent fuel contamination.

- Record changeover times and sulfur content to comply with MARPOL Annex VI (sulfur limit: 0.10% m/m in ECAs).

- Practice valve line-ups under supervision to master system flow.

Compliance Note: A 2018 California port state detention resulted from a delayed HFO-to-MGO changeover, highlighting the importance of timely execution.

Chart: Fuel Oil System Flow

4. Maintaining Lube Oil Purifiers

Lube oil purifiers extend machinery life by removing contaminants, and cadets assist in their operation and maintenance.

Key Tasks:

- Select the correct gravity disc based on oil viscosity and throughput.

- Perform bowl cleaning and desludging during scheduled maintenance.

- Log running hours to schedule preventive maintenance.

Practical Tips:

- Double-check bowl assembly to prevent vibrations, referring to the manufacturer’s manual.

- Monitor oil clarity post-purification to ensure purifier efficiency.

- Wear PPE during desludging to avoid burns from hot oil.

Pro Tip: Incorrect gravity disc selection can reduce purification efficiency, leading to premature wear in engine components.

5. Starting and Synchronizing Generators

Generators provide critical power redundancy, and cadets learn to start and synchronize them to prevent blackouts.

Key Tasks:

- Initiate standby generators in manual or auto mode.

- Synchronize alternator output by matching voltage, frequency, and phase sequence.

- Ensure load sharing between online generators.

Practical Tips:

- Practice synchronization on simulation trainers to build confidence.

- Monitor synchroscope readings to avoid reverse power trips.

- Report any load-sharing imbalances to the duty engineer immediately.

Safety Alert: Improper synchronization can trigger blackouts, especially during high-demand maneuvers.

IMO Reference: STCW A-III/1 requires knowledge of shipboard electrical systems.

6. Managing Bilge Pumping and Tank Sounding

Bilge systems prevent flooding and pollution, and cadets assist in their operation and monitoring.

Key Tasks:

- Operate bilge pumps or ejectors to transfer wastewater to holding tanks.

- Sound bilge wells and drain tanks, recording levels accurately.

- Ensure oily water separator (OWS) compliance with MARPOL’s 15 ppm discharge limit.

Practical Tips:

- Check for oil sheen in bilge water to avoid environmental violations.

- Use sounding tapes correctly, accounting for ship trim and list.

- Report high bilge levels promptly to prevent pump overload.

MARPOL Note: A cadet’s misidentification of an oily bilge valve during an audit led to a non-compliance penalty, emphasizing the need for vigilance.

7. Maintaining Cooling Water Systems

Cooling water systems prevent engine overheating, and cadets support their maintenance and monitoring.

Key Tasks:

- Backflush seawater strainers to remove debris.

- Maintain jacket water treatment levels to prevent corrosion.

- Inspect pumps and pipelines for leaks or air locks.

Practical Tips:

- Check strainer baskets regularly, especially in coastal waters with high debris.

- Test jacket water samples for pH and nitrite levels weekly.

- Report air lock symptoms (e.g., fluctuating pressures) immediately.

Pro Insight: Clogged strainers or untreated water can cause corrosion in cylinder liners, leading to costly repairs.

8. Operating Boilers and Performing Blowdown

Boilers supply steam for fuel heating and domestic use, and cadets assist in their safe operation.

Key Tasks:

- Monitor fuel valve opening, firing sequence, and flame stability.

- Test low water alarms and safety valves regularly.

- Perform blowdown to remove sludge and total dissolved solids (TDS).

Practical Tips:

- Follow blowdown checklists to avoid scalding or system damage.

- Monitor boiler water chemistry to prevent scale buildup.

- Never bypass low water alarms, as they prevent catastrophic explosions.

Safety Note: Boiler explosions are among the deadliest engine room incidents, making adherence to SOPs critical.

IMO Reference: STCW A-III/1 and A-III/4 cover boiler operations.

9. Testing Emergency Generators and Fire Pumps

Emergency systems ensure safety during power or fire incidents, and cadets participate in their regular testing.

Key Tasks:

- Manually start emergency generators and verify auto-start functionality.

- Check fire pump pressure and hydrant conditions.

- Log test results for SOLAS compliance.

Practical Tips:

- Time emergency generator startups to ensure activation within 45 seconds.

- Inspect fire hoses for leaks or blockages during drills.

- Familiarize yourself with emergency switchboard connections.

SOLAS Compliance: A 2017 port state detention cited a non-functional emergency generator, partly due to cadet oversight during checks.

10. Adhering to Safe Working Practices and Permit to Work (PTW)

Safe work practices prevent accidents, and cadets learn to follow PTW systems for high-risk tasks.

Key Tasks:

- Conduct risk assessments before tasks like enclosed space entry or hot work.

- Use appropriate PPE, including helmets, safety shoes, and ear plugs (mandatory in noisy engine rooms).

- Follow lockout/tagout procedures for equipment isolation.

Practical Tips:

- Verify PTW signatures from senior officers before starting work.

- Report unsafe conditions, even if not directly involved.

- Practice confined space rescue drills to prepare for emergencies.

STCW & ISM Code: PTW is mandatory for safety-critical tasks, ensuring accountability and oversight.

Real-World Insight: A cadet’s adherence to PTW during a welding job prevented a fire hazard, earning commendation from the chief engineer.

Essential Skills for Cadets

Beyond technical procedures, cadets must cultivate soft skills to thrive:

- Attention to Detail: Spotting minor leaks or temperature anomalies prevents major failures.

- Problem-Solving: Diagnosing issues like purifier vibrations builds confidence.

- Adaptability: Adjusting to dynamic conditions, like sudden maneuvers, is crucial.

- Teamwork: Collaborating with ratings and senior engineers ensures smooth operations.

- Communication: Clear reporting of issues or task completion enhances safety.

Career Progression and Learning Opportunities

Pathway:

- After cadetship, passing STCW exams qualifies cadets for 4th or 3rd engineer roles.

- Experience gained as a cadet forms the foundation for chief engineer positions.

Learning Strategies:

- Observe ratings during tasks like sea chest cleaning to learn practical skills.

- Study equipment manuals before overhauls to understand procedures.

- Participate actively in drills to showcase leadership and teamwork.

Pro Tip: Preparing work permits or job analyses in advance impresses senior engineers and saves time.

Table: Key Engine Room Equipment and Cadet Responsibilities

| Equipment | Cadet Tasks | Safety Considerations |

|---|---|---|

| Main Engine | Pre-start checks, monitoring | Ensure cooling water flow, chief’s approval |

| Fuel Oil Purifiers | Gravity disc selection, bowl cleaning | Wear PPE, check assembly |

| Generators | Synchronization, load sharing | Avoid reverse power trips |

| Bilge Pumps | Sounding, operation | Comply with MARPOL 15 ppm limit |

| Boilers | Blowdown, water testing | Monitor alarms, follow checklists |

Challenges for Cadets and How to Overcome Them

- Overwhelm: The engine room’s complexity can intimidate. Use system diagrams to trace pipelines and ask senior engineers for guidance.

- Limited Supervision: Senior engineers may be busy, leaving cadets to learn independently. Take initiative by shadowing experienced ratings.

- Cultural Differences: Working with diverse crew members can be tricky. Show respect by learning basic phrases in their languages and engaging with their cultures.

- Accountability: Cadets may face scrutiny for errors. Always report anomalies, even if minor, to avoid liability and demonstrate responsibility.

FAQ: Cadet Responsibilities in the Engine Room

Can cadets operate machinery independently?

How can cadets prepare for rounds?

Are these skills relevant for future roles?

What’s the best learning method?

Conclusion: Building a Career at Sea

For new engine cadets, the engine room is both a challenge and a classroom. Mastering these top 10 procedures—daily rounds, main engine startups, safe work practices, and more—equips cadets with the skills, discipline, and confidence to excel. By prioritizing safety, seeking mentorship, and embracing every task as a learning opportunity, cadets lay the foundation for a successful career in marine engineering.

Happy Boating!

Share Top 10 Engine Room Procedures for New Cadets with your friends and leave a comment below with your thoughts.

Read Top 10 Engine Types Used in Commercial Vessels until we meet in the next article.