Before You Buy: 17 Pros and Cons of Aluminium Boats

Explore the pros and cons of aluminum boats, from durability and lightweight design to noise and heat issues, to decide if they’re right for you.

Aluminum boats have surged in popularity among boating enthusiasts, offering a compelling mix of durability, lightweight construction, and versatility. Whether you’re a seasoned sailor planning long-distance cruising or a weekend angler seeking a reliable vessel for local waters, aluminum boats present a unique set of advantages and challenges. This comprehensive guide dives deep into the pros and cons of aluminum boats, providing detailed insights to help you make an informed decision. From their robust construction to potential drawbacks like noise amplification, we’ll explore every angle to ensure you understand what an aluminum boat brings to the table.

Why Choose an Aluminum Boat?

Aluminum boats have carved out a significant niche in the boating world, competing closely with fiberglass, the other dominant material. Their appeal lies in a combination of strength, longevity, and ease of maintenance, making them suitable for various boating activities, from fishing to bluewater cruising. However, no material is perfect, and aluminum boats come with trade-offs that potential buyers must consider. Below, we outline 17 key pros and cons, drawing from expert insights, user experiences, and industry analysis, to give you a clear picture of what to expect.

Pros of Aluminum Boats

1. Exceptional Durability and Strength

Aluminum is renowned for its resilience, making it an ideal material for boats operating in harsh conditions. Unlike fiberglass, which can crack under impact, aluminum’s high tensile strength allows it to absorb energy and withstand significant collisions without fracturing. This durability is particularly valuable for rough waters, rocky coastlines, or environments with debris. For example, aluminum boats are less likely to suffer catastrophic hull damage when striking objects like shipping containers, though they may dent.

2. Longevity

Aluminum boats are built to last, often enduring 30–50 years or more with proper care. Their resistance to osmosis, structural fatigue, and corrosion (when using marine-grade alloys like 5083 or 5086) ensures a long lifespan. This longevity makes aluminum boats a favorite for long-term investments, especially for cruisers who plan to keep their vessel for decades.

3. Lightweight Design

Aluminum is significantly lighter than steel (45–55% lighter) and about 30–40% lighter than fiberglass for the same volume. This reduced weight translates to several benefits:

- Improved Fuel Efficiency: Lighter boats require less power to move, reducing fuel consumption and operational costs.

- Easier Handling: Aluminum boats are easier to tow, launch, and retrieve, making them ideal for solo boaters or those with smaller tow vehicles.

- Enhanced Performance: The lightweight nature allows for smaller engines and faster speeds, improving maneuverability.

4. Easy Repairs

Aluminum hulls are relatively straightforward to repair compared to fiberglass. Dents and punctures can often be fixed by cutting out the damaged section and welding in a new piece. In remote locations, temporary repairs using rivets are also feasible, as noted by experienced boaters who’ve had welding done in places like Iceland and Chile. This ease of repair reduces downtime and repair costs, making aluminum boats practical for adventurous sailors.

5. Low Maintenance

Aluminum boats require minimal upkeep compared to fiberglass. They don’t need waxing or buffing, and their corrosion-resistant properties eliminate the need for frequent rust treatments. Regular cleaning and periodic corrosion checks, especially around fittings and welds, are typically sufficient to keep the boat in top condition.

6. Versatility

Aluminum’s flexibility in construction allows for extensive customization. Whether you’re building a racing yacht, a fishing boat, or a cruising vessel, aluminum can be tailored to meet specific needs. Manufacturers can weld together various components to create bespoke designs, accommodating extra storage, specialized equipment, or unique layouts.

7. High Resale Value

Due to their durability and low maintenance, aluminum boats tend to retain their value better than fiberglass counterparts. This makes them a smart choice for buyers who may want to resell their vessel in the future, as the boat’s condition is likely to remain strong over time.

8. Resistance to Solar Radiation

Aluminum is less susceptible to sun damage than fiberglass, which can suffer gel coat degradation or hull damage from prolonged UV exposure. Aluminum’s resistance to solar radiation ensures the boat maintains its structural integrity and appearance over time, even in sunny climates.

9. Eco-Friendliness and Recyclability

Aluminum is an environmentally friendly choice. Its production is less resource-intensive than fiberglass, and it’s fully recyclable, allowing retired boats to be repurposed. This eco-conscious aspect appeals to boaters who prioritize sustainability.

Cons of Aluminum Boats

10. Higher Upfront Cost

Aluminum boats often come with a higher initial purchase price compared to fiberglass boats. The cost stems from the intensive welding and riveting processes required during construction, as well as the use of high-quality marine-grade alloys. For budget-conscious buyers, this upfront investment can be a significant barrier, though long-term savings on maintenance and fuel may offset the cost.

11. Noise Amplification

One of the most cited drawbacks of aluminum boats is their tendency to amplify noise. The metal hull can create a loud slapping sound when hitting waves, which may disrupt relaxation or scare fish during angling. While insulation, such as spray foam used in models like the Jasper Marine Defender 22, can mitigate this issue, it remains a consideration for those seeking a quieter ride.

12. Heat Absorption

Aluminum’s high thermal conductivity means it absorbs heat quickly, making the deck uncomfortably hot in direct sunlight. This can be a challenge for barefoot boaters or those in warm climates. Decking materials or treatments can help, but they add to the cost and maintenance.

13. Additional Insulation Needs

Aluminum’s conductivity also makes it prone to condensation and cold temperatures in cooler climates. Without proper insulation, the interior can become uncomfortably cold or damp. Many modern aluminum boats, however, incorporate foam insulation (e.g., 3 inches of spray foam) to address this, improving comfort in both hot and cold conditions.

14. Paint and Anti-Fouling Challenges

Painting aluminum boats can be problematic. Standard bottom paints containing copper oxide are unsuitable, as they can trigger galvanic corrosion. Special non-copper paints are required, which are more expensive and harder to apply. Topside paints may also develop bubbles or blisters after a few years, even with meticulous preparation, as noted by experienced boaters.

15. Potential for Corrosion

While aluminum is corrosion-resistant, it’s not immune, especially in saltwater environments or marinas with stray electrical currents. Electrolysis, caused by improper electrical systems or dissimilar metals (e.g., copper coins in the bilge), can lead to significant damage if not monitored. Regular anode maintenance and metering devices are essential to prevent this.

16. Loose Rivets

Older aluminum boats or those with subpar construction may develop loose rivets over time, potentially leading to leaks. This issue is less common in modern welded designs but requires periodic inspection to ensure hull integrity.

17. Aesthetic Considerations

Aluminum boats often have an industrial appearance compared to the sleek, polished look of fiberglass yachts. While some owners appreciate the rugged aesthetic or opt for vinyl wraps to mimic traditional yacht designs, others may find aluminum less visually appealing.

Comparing Aluminum and Fiberglass Boats

To provide a clearer perspective, the table below compares key attributes of aluminum and fiberglass boats:

| Feature | Aluminum Boats | Fiberglass Boats |

|---|---|---|

| Weight | 30–40% lighter than fiberglass | Heavier, impacting fuel efficiency |

| Durability | High tensile strength, impact-resistant | Brittle, prone to cracking |

| Maintenance | Low, minimal upkeep | High, requires waxing and buffing |

| Repair Cost | Affordable, easy to weld or rivet | Expensive, requires specialists |

| Corrosion Resistance | High with proper alloys, anodes required | Moderate, susceptible to osmosis |

| Noise | Amplified, can be mitigated with insulation | Quieter operation |

| Initial Cost | Higher upfront cost | Generally lower upfront cost |

| Resale Value | High, retains value well | Lower, degrades faster |

| Customizability | Highly customizable | Moderate, limited by molding process |

| Eco-Friendliness | Recyclable, less resource-intensive | Non-recyclable, resource-heavy production |

Construction Considerations

Aluminum boats are constructed using marine-grade alloys like 5083 or 5086, which are specifically designed for marine environments. Unlike fiberglass, which is molded into a single piece, aluminum boats are built from multiple panels welded or riveted together. This process allows for greater customization but increases production complexity and cost. Proper construction techniques, such as blind-tapped plates for deck fittings, eliminate common issues like deck leaks, as highlighted by experienced boaters.

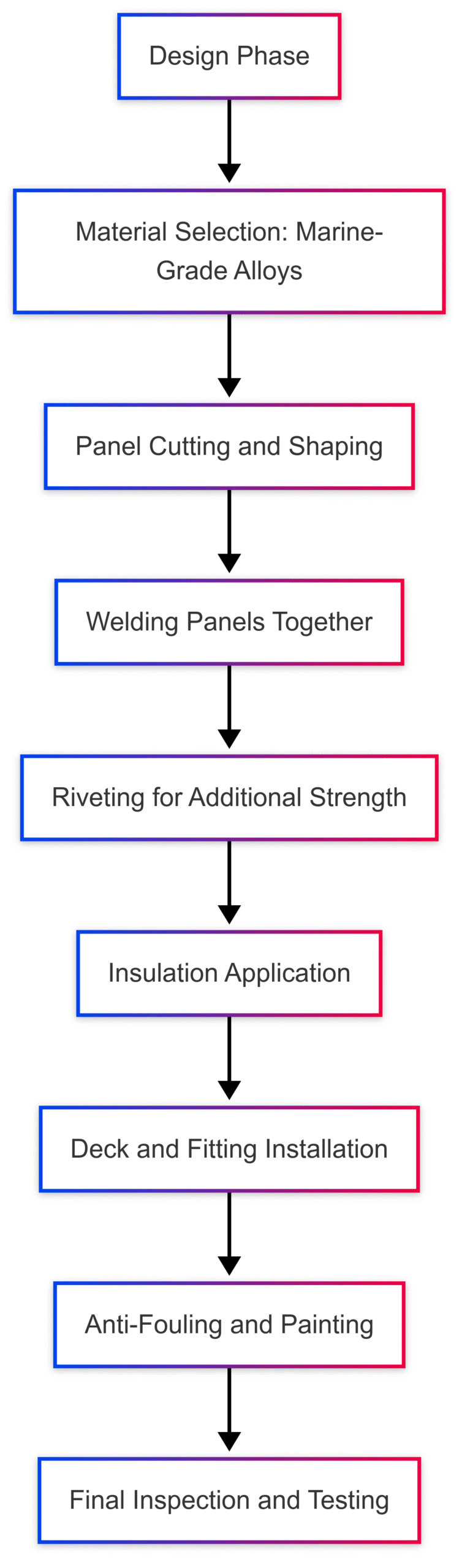

Chart: Aluminum Boat Construction Process

Below is a simplified flowchart of the aluminum boat construction process, illustrating key steps:

Real-World Insights from Boaters

User experiences from boating forums provide valuable context. For instance, owners of aluminum boats like the OVNI 385 and Trintella 51A praise their durability and ease of modification. One owner noted that their 1970s aluminum One Ton Cup winner, Wai Aniwa, remained in excellent condition due to meticulous corrosion monitoring. However, challenges like paint adhesion and the need for specialized anti-fouling paints were frequently mentioned. Another boater emphasized the importance of a robust electrical system to prevent electrolysis, citing a case where a faulty rubber engine mount caused an electrical issue.

Specifications and Pricing

Aluminum boats vary widely in size, purpose, and price. Below are examples of popular aluminum boat models with approximate specifications and pricing (based on typical market values for new boats, subject to change):

| Model | Length | Purpose | Key Features | Approx. Price (USD) |

|---|---|---|---|---|

| Jasper Marine Defender 22 | 22 ft | Fishing/Cruising | Spray foam insulation, welded hull | $50,000–$70,000 |

| OVNI 385 | 38 ft | Bluewater Cruising | Customizable layout, corrosion-resistant alloy | $200,000–$300,000 |

| Trintella 51A | 51 ft | Long-Distance Cruising | High resale value, robust construction | $400,000–$600,000 |

Note: Prices vary based on customization, location, and dealer. For SuperGrok or x.com subscription details, visit x.ai/grok or help.x.com.

Is an Aluminum Boat Right for You?

Choosing an aluminum boat depends on your boating needs, environment, and preferences. Here’s a quick guide to help you decide:

- Ideal For:

- Long-distance cruisers seeking durability and longevity.

- Boaters in harsh environments (e.g., rocky coasts, rough waters).

- Those prioritizing low maintenance and high resale value.

- Environmentally conscious buyers who value recyclability.

- Not Ideal For:

- Boaters who prioritize a quiet, smooth ride.

- Those in extremely hot climates without proper deck treatments.

- Budget-conscious buyers wary of higher upfront costs.

- Those who prefer the polished aesthetic of fiberglass.

Mitigating Drawbacks

Many of aluminum’s cons can be addressed with proper planning:

- Noise: Use spray foam insulation or non-skid deck coatings to dampen sound.

- Heat: Apply heat-resistant decking materials or vinyl wraps.

- Corrosion: Install anodes, use metering devices, and avoid dissimilar metals (e.g., copper).

- Paint Issues: Opt for unpainted topsides or use specialized non-copper paints.

Conclusion

Aluminum boats offer a compelling combination of durability, lightweight design, and versatility, making them a top choice for many boating enthusiasts. Their ability to withstand harsh conditions, resist corrosion, and maintain value over decades is unmatched, but challenges like noise, heat absorption, and higher upfront costs require careful consideration. By weighing these 17 pros and cons, you can determine whether an aluminum boat aligns with your boating goals. Whether you’re navigating coastal waters or embarking on a global adventure, aluminum boats provide a reliable, customizable, and eco-friendly option for your aquatic journey.

For those ready to explore aluminum boats, platforms like TheYachtMarket offer a wide selection of new and used vessels. Browse their listings to find the perfect aluminum boat for your needs, and set sail with confidence knowing you’ve made an informed choice.

Happy Boating!

Share Before You Buy: 17 Pros and Cons of Aluminium Boats with your friends and leave a comment below with your thoughts.

Read The Perfect Size Catamaran to Sail Around the World until we meet in the next article.