The importance of ship maintenance and repair

Discover why ship maintenance and repair are vital for safety, efficiency, and compliance in the maritime industry. Learn key practices and benefits.

The maritime industry is the backbone of global trade, with over 100,000 vessels facilitating the movement of goods, from oil to food, across the world’s oceans. These ships operate in harsh environments, facing constant exposure to corrosive seawater, extreme weather, and heavy operational demands. To ensure these vessels remain safe, reliable, and efficient, ship maintenance and repair are critical. This article explores the multifaceted importance of ship maintenance and repair, covering operational and maintenance practices, their impact on safety, efficiency, compliance, and environmental responsibility, and the role of ship management in sustaining a vessel’s lifecycle. Through structured maintenance programs, shipowners can enhance crew safety, extend vessel lifespan, reduce costs, and meet stringent regulatory standards.

Understanding Ship Operations and Maintenance

Ship operations and maintenance are interconnected disciplines that ensure a vessel’s functionality and safety. Operations involve the day-to-day management of the ship, while maintenance focuses on preserving its physical and mechanical integrity.

Key Areas of Ship Operations

Ship operations encompass a range of activities critical to a vessel’s functionality:

- Crew Management: Ensuring the crew is trained, certified, and adequately staffed for safe operations. This includes compliance with the International Convention on Standards of Training, Certification, and Watchkeeping for Seafarers (STCW).

- Cargo Handling: Coordinating the loading, securing, and unloading of cargo, working with port agents and stevedores to ensure efficiency and safety.

- Voyage Planning: Charting optimal routes based on weather, traffic, and port regulations to minimize fuel use and delays.

- Navigation: Using charts, GPS, radar, and communication systems to ensure safe passage.

- Port Operations: Managing interactions with port authorities, pilots, and tugboats for smooth docking and undocking.

- Fuel and Provisions: Monitoring fuel consumption, bunkering, and provisioning to sustain long voyages.

- Safety and Security: Enforcing safety protocols, emergency procedures, and security measures to protect the crew and cargo.

- Financial Management: Budgeting and controlling costs to ensure the voyage’s economic viability.

- Compliance: Adhering to international regulations like the International Safety Management (ISM) Code, the International Convention for the Safety of Life at Sea (SOLAS), and the International Convention for the Prevention of Pollution from Ships (MARPOL).

Key Areas of Ship Maintenance

Maintenance is a proactive process to keep a vessel in optimal condition. Key maintenance areas include:

- Hull and Structural Maintenance: Regular inspections to detect and repair corrosion, cracks, or structural damage caused by environmental stress.

- Machinery and Equipment Maintenance: Servicing engines, pumps, generators, and other systems to prevent failures.

- Electrical and Automation Systems: Maintaining control systems, navigation equipment, and safety devices like fire suppression systems.

- Preventive Maintenance: Scheduled tasks, such as oil changes and filter replacements, to address issues before they escalate.

- Condition-Based Maintenance: Using sensors and data analytics to monitor equipment health and schedule maintenance based on real-time conditions.

- Corrective Maintenance: Addressing unexpected breakdowns to restore functionality.

- Dry Docking: Major overhauls conducted in dry docks, typically every 2.5 to 5 years, for extensive repairs and inspections.

- Record Keeping: Documenting maintenance activities for regulatory compliance and historical reference.

Why Ship Maintenance and Repair Are Essential

Ship maintenance and repair are non-negotiable for ensuring safety, profitability, compliance, and environmental stewardship. Below are the five primary reasons why these practices are indispensable.

1. Crew Safety

The safety of the crew is the top priority in maritime operations. Ships operate in challenging conditions, and equipment failures can lead to accidents, injuries, or fatalities. Regular maintenance ensures that critical systems—such as the hull, lifeboats, navigation equipment, fire suppression systems, and emergency power—are in optimal condition.

For example, hull inspections can identify corrosion or cracks that could compromise structural integrity, while regular testing of lifeboats ensures they are ready for emergencies. According to the International Maritime Organization (IMO), proactive maintenance reduces the risk of accidents by addressing potential issues early. A well-maintained vessel mitigates risks, boosts crew confidence, and fosters a safer working environment.

2. Vessel Lifespan and Profitability

A ship is a significant capital investment, often costing tens of millions of dollars. Regular maintenance extends a vessel’s operational life, maximizing its return on investment (ROI). Routine tasks like hull cleaning, engine servicing, and alignment checks prevent wear and tear, reducing the likelihood of costly breakdowns.

For instance, cleaning the hull and propellers reduces drag, improving fuel efficiency and extending the lifespan of propulsion systems. A well-maintained vessel can operate for decades, generating revenue through cargo transport or passenger services. Conversely, neglecting maintenance can lead to premature scrapping, as seen in cases where corrosion or engine failures render ships uneconomical to repair.

| Maintenance Task | Impact on Vessel Lifespan | Frequency |

|---|---|---|

| Hull Cleaning | Reduces drag, prevents corrosion | Every 6–12 months |

| Engine Servicing | Prevents wear, ensures efficiency | Every 3–6 months |

| Propeller Maintenance | Improves fuel efficiency | Annually or as needed |

| Dry Docking | Comprehensive overhaul | Every 2.5–5 years |

3. Regulatory Compliance

The maritime industry is governed by stringent international and national regulations. Non-compliance can result in fines, detentions, or reputational damage. Regular maintenance ensures that vessels meet standards set by organizations like the IMO, including SOLAS, MARPOL, and the ISM Code.

- Safety Compliance: Inspections of safety equipment, such as lifeboats and fire suppression systems, ensure compliance with SOLAS requirements.

- Environmental Compliance: Maintaining emissions control systems and waste management equipment helps vessels meet MARPOL standards, reducing the risk of environmental violations.

- Insurance Requirements: Insurers often require proof of regular maintenance before issuing policies or settling claims. Comprehensive maintenance logs demonstrate due diligence.

- Record Keeping: Accurate documentation of maintenance activities is mandatory for audits and inspections by port state control authorities.

Non-compliance can lead to penalties ranging from thousands to millions of dollars, depending on the severity of the violation. For example, failing to maintain emissions systems could result in fines under MARPOL Annex VI, which regulates air pollution from ships.

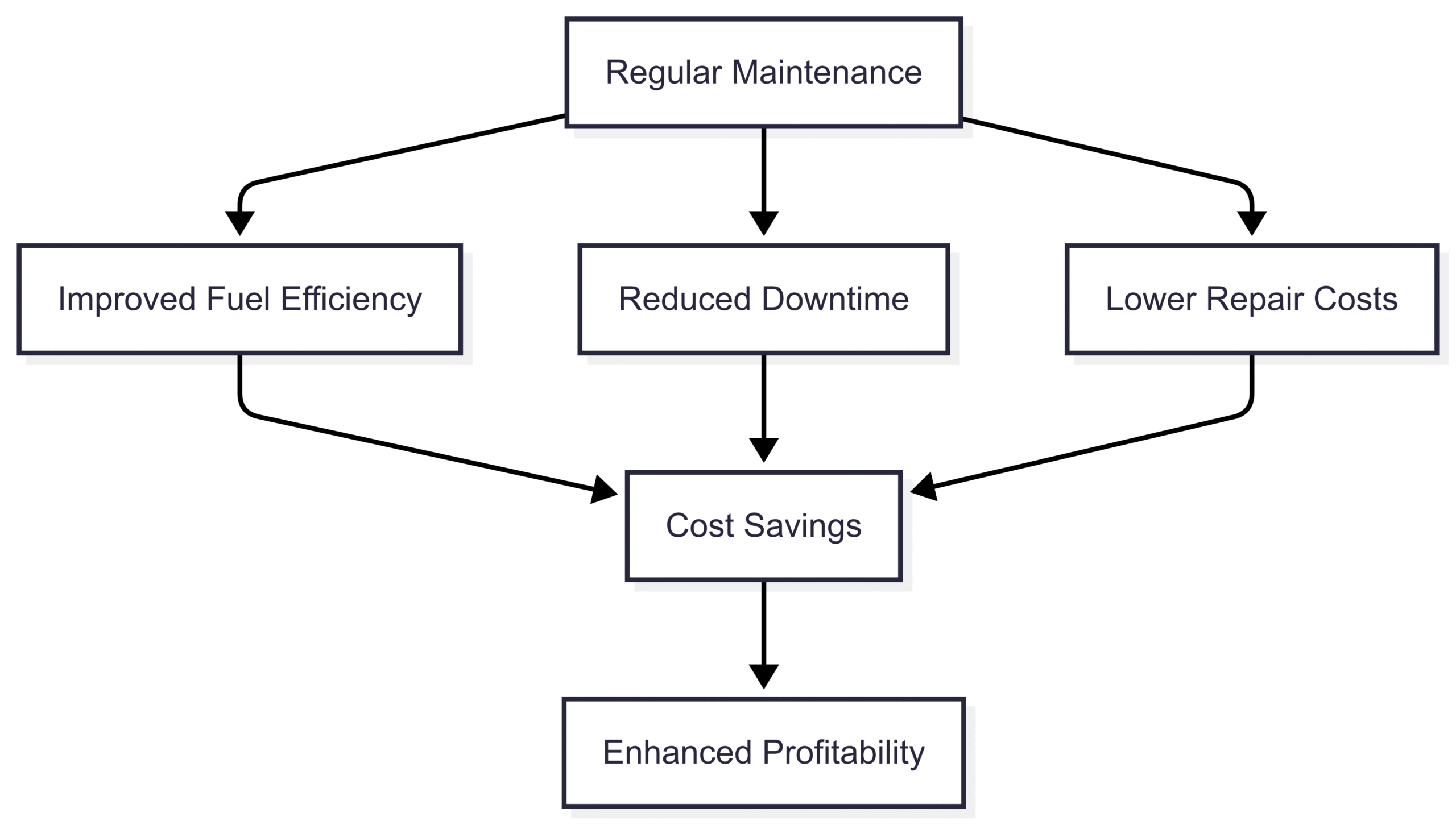

4. Operational Efficiency

Efficient operations are critical for profitability and sustainability. Regular maintenance optimizes the performance of key systems, reducing fuel consumption and minimizing downtime.

- Fuel Efficiency: Hull and propeller cleaning can reduce fuel consumption by up to 5–10%, according to maritime studies. A clean hull minimizes drag, allowing the ship to maintain speed with less power.

- Equipment Reliability: Regular servicing of propulsion, electrical, and HVAC systems prevents unexpected failures, ensuring continuous operations.

- Cost Savings: Preventive maintenance reduces the need for expensive corrective repairs. For instance, replacing a worn bearing during routine maintenance is far cheaper than repairing a damaged engine.

The following chart illustrates the relationship between maintenance frequency and operational efficiency:

5. Environmental and Corporate Responsibility

The maritime industry is under increasing pressure to reduce its environmental footprint. Maintenance plays a pivotal role in supporting the industry’s “green transition” by minimizing emissions, preventing pollution, and ensuring compliance with environmental regulations.

- Reduced Emissions: Maintaining energy-efficient systems, such as propulsion and lighting, lowers greenhouse gas emissions. For example, optimizing engine performance can reduce CO2 emissions by up to 15%.

- Pollution Prevention: Regular checks on waste management systems, such as oily water separators and sewage treatment plants, prevent accidental discharges that could harm marine ecosystems.

- Green Technologies: Upgrading to eco-friendly technologies during maintenance, such as low-friction hull coatings or hybrid propulsion systems, further reduces environmental impact.

| Environmental Measure | Maintenance Action | Impact |

|---|---|---|

| Emissions Reduction | Engine optimization | Up to 15% lower CO2 emissions |

| Pollution Prevention | Waste system checks | Prevents oil spills, sewage discharge |

| Green Technology Adoption | Hull coating upgrades | 5–10% fuel savings |

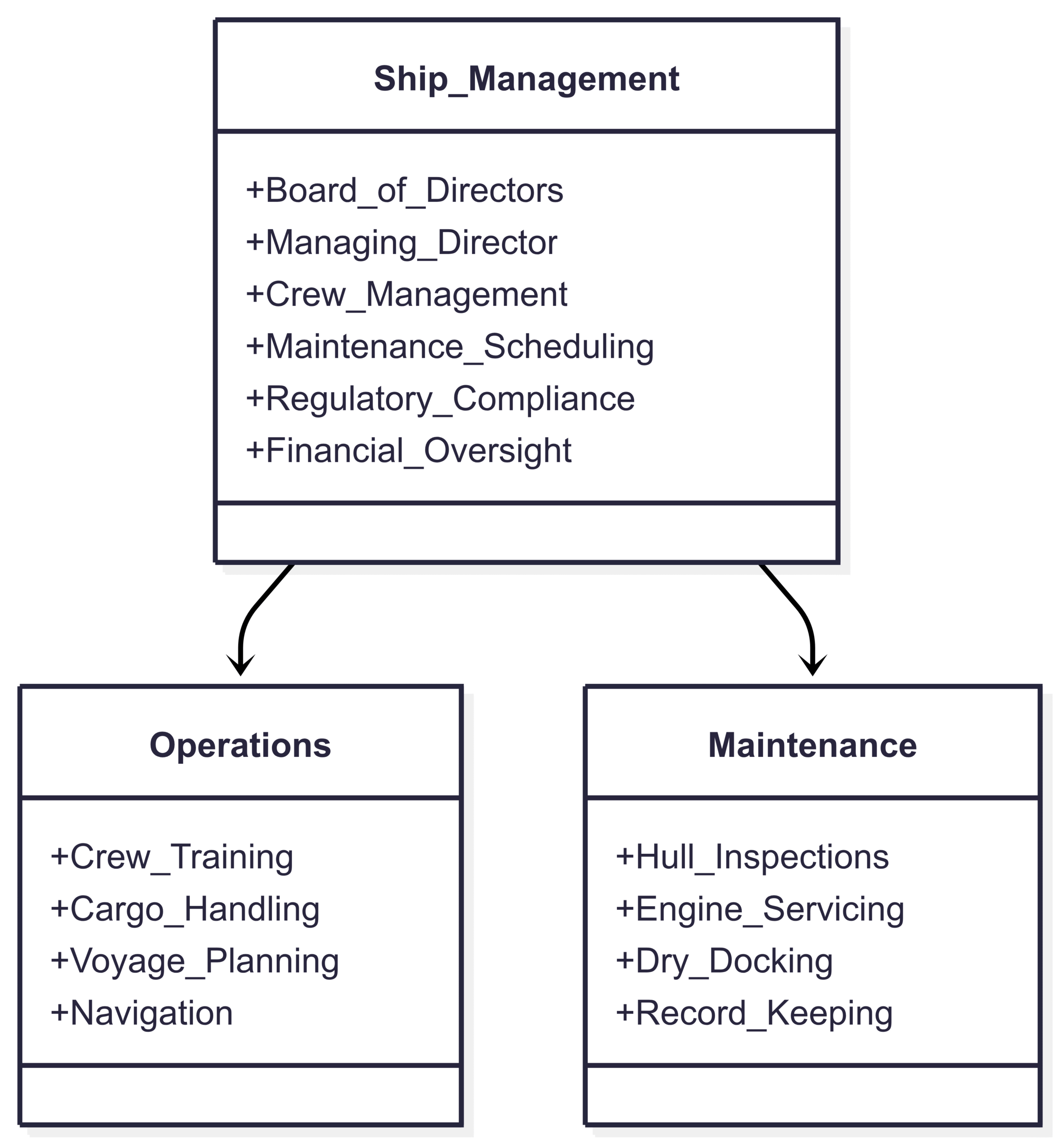

Ship Management: The Backbone of Maintenance and Operations

Effective ship management integrates operations and maintenance to ensure vessels are safe, compliant, and profitable. Ship managers, whether in-house or third-party firms, oversee critical tasks such as:

- Crew Training and Safety: Ensuring crew members are trained in safety protocols and emergency procedures.

- Maintenance Scheduling: Coordinating preventive and corrective maintenance to minimize disruptions.

- Regulatory Compliance: Maintaining records and ensuring adherence to international standards.

- Financial Oversight: Managing budgets, fuel costs, and insurance claims to optimize profitability.

The organizational structure of ship management typically includes a board of directors, led by a chairperson or managing director, who sets strategic goals. Operational tasks may be handled internally or outsourced to specialized firms, depending on the shipowner’s resources.

Best Practices for Ship Maintenance

To maximize the benefits of maintenance, shipowners should adopt the following best practices:

- Implement a Preventive Maintenance Schedule: Regular inspections and servicing prevent minor issues from becoming major problems.

- Leverage Condition-Based Monitoring: Use sensors and data analytics to monitor equipment health and schedule maintenance based on real-time data.

- Conduct Regular Dry Docking: Schedule dry dock visits every 2.5–5 years for comprehensive inspections and repairs.

- Train Crew in Maintenance Procedures: Equip crew members with the skills to perform routine maintenance tasks and identify potential issues.

- Maintain Detailed Records: Keep accurate logs of all maintenance activities to ensure compliance and facilitate audits.

- Invest in Green Technologies: Upgrade to energy-efficient systems and eco-friendly coatings to reduce environmental impact.

Costs and Specifications of Ship Maintenance

The cost of ship maintenance varies depending on the vessel’s size, type, and operational demands. Below is a table outlining typical maintenance costs and specifications for a medium-sized cargo vessel (e.g., 40,000 DWT):

| Maintenance Type | Estimated Cost (USD) | Frequency | Key Specifications |

|---|---|---|---|

| Hull Cleaning | $50,000–$100,000 | 6–12 months | Removes biofouling, reduces drag |

| Engine Servicing | $20,000–$50,000 | 3–6 months | Oil changes, filter replacements |

| Dry Docking | $500,000–$2,000,000 | 2.5–5 years | Full inspection, repairs, repainting |

| Electrical Systems | $10,000–$30,000 | Annually | Testing navigation, safety systems |

| Green Upgrades | $100,000–$500,000 | As needed | Low-friction coatings, hybrid systems |

Note: Costs are approximate and vary based on vessel size, location, and service provider. For precise pricing, consult shipyard or maintenance service providers.

The Role of Ship Registration and Risk Management

Ship registration establishes a vessel’s nationality and ensures compliance with international maritime law, as outlined in the UN Convention on the Law of the Sea (UNCLOS). Registration grants a ship the right to fly a state’s flag and imposes obligations to maintain safety and environmental standards.

Risk management, often through insurance, protects shipowners from financial losses due to damage, liability, or crew injuries. Key insurance types include:

- Hull Insurance: Covers damage to the vessel.

- Protection and Indemnity (P&I): Covers third-party liabilities, such as cargo damage or environmental pollution.

- Crew Insurance: Protects against crew injuries or fatalities.

Effective maintenance reduces insurance premiums by demonstrating a commitment to safety and reliability.

Challenges in Ship Maintenance and Operations

Despite its importance, ship maintenance faces several challenges:

- High Costs: Dry docking and major repairs can cost millions, straining budgets.

- Downtime: Maintenance activities can disrupt operations, leading to revenue losses.

- Regulatory Complexity: Keeping up with evolving international standards requires constant vigilance.

- Skilled Labor Shortages: Finding qualified technicians for specialized repairs can be difficult.

- Environmental Pressures: Balancing operational efficiency with environmental compliance is increasingly complex.

Conclusion

Ship maintenance and repair are the cornerstones of safe, efficient, and sustainable maritime operations. By prioritizing crew safety, extending vessel lifespan, ensuring compliance, optimizing efficiency, and reducing environmental impact, maintenance programs deliver significant benefits to shipowners, crews, and the global ecosystem. Through proactive strategies, such as preventive maintenance, condition-based monitoring, and green technology adoption, the maritime industry can navigate the challenges of modern shipping while maintaining its critical role in global trade. Investing in robust maintenance and management practices is not just a regulatory necessity but a strategic imperative for long-term success.

Happy Boating!

Share The importance of ship maintenance and repair with your friends and leave a comment below with your thoughts.

Read Career Development for Seafarers: Building Skills until we meet in the next article.