Common Symptoms of Johnson Optical Sensor Issues

Learn common Johnson optical sensor issues, symptoms like misfires, hard starting, and no spark, plus troubleshooting tips for your outboard engine.

Johnson outboard engines, particularly models like the 1996 and 2001 Johnson 150 Ocean Runner with Optical Ignition Systems (OIS), are renowned for their reliability and performance in marine environments. However, like any complex mechanical system, they can develop issues, one of the most critical being problems with the optical sensor. This component is integral to the ignition system, and its failure can lead to a range of performance issues, from misfires to complete engine failure. This comprehensive guide explores the common symptoms of Johnson optical sensor issues, their impact on engine performance, troubleshooting steps, and practical solutions for boat owners and marine mechanics. We’ll also address specific user concerns, such as engines stuck in SLOW mode or hard starting, and provide actionable advice to restore optimal performance.

What is the Johnson Optical Sensor?

The optical sensor in a Johnson outboard engine, part of the Optical Ignition System (OIS), is a precision component that uses light to detect the position of the crankshaft. This information is relayed to the power pack, which controls the timing of the spark plugs’ firing sequence. Unlike traditional mechanical ignition systems, the OIS offers greater precision and reliability, but it’s not immune to wear, environmental factors, or electrical issues. When the optical sensor malfunctions, it disrupts the ignition timing, leading to a cascade of performance problems.

The optical sensor, often referred to as the “optical eye,” is typically located near the flywheel and works in tandem with other components like the stator, power pack, and spark plugs. Its failure can cause intermittent or complete loss of spark, making it a critical point of focus when diagnosing engine issues.

Common Symptoms of Optical Sensor Issues

When the optical sensor fails, it manifests in several noticeable symptoms that affect engine performance. Below is a detailed breakdown of these symptoms, their causes, and their impact on the engine.

1. Engine Misfires and Rough Idling

The optical sensor’s primary role is to ensure precise ignition timing. A malfunctioning sensor can cause inconsistent spark plug firing, leading to misfires. This results in a rough idle, where the engine vibrates excessively or feels unsteady at low RPMs. Misfires occur because the sensor fails to accurately detect the crankshaft’s position, sending incorrect signals to the power pack.

Impact: Rough idling can reduce fuel efficiency, increase wear on engine components, and make the boating experience uncomfortable. Persistent misfires may also damage the spark plugs or power pack over time.

2. Hard Starting, Especially When Cold

A faulty optical sensor can disrupt the spark timing, making it difficult to start the engine, particularly in cold conditions. Cold starts require precise fuel and spark delivery, and a failing sensor may not provide the power pack with accurate data, delaying or preventing ignition.

Impact: Hard starting can strand boaters, especially in remote locations, and repeated cranking can drain batteries or overheat the starter motor.

3. No Spark on Some or All Cylinders

In severe cases, a completely failed optical sensor can prevent spark generation across one or more cylinders. This is often due to a total loss of signal from the sensor to the power pack, halting the ignition process entirely.

Impact: Without spark, the engine will not run, leaving the boat inoperable. This is one of the most critical symptoms, requiring immediate attention.

4. Intermittent Issues, Especially When Warm

Optical sensor issues often worsen as the engine heats up. The sensor’s internal components or wiring may degrade under heat, causing intermittent spark loss. Boaters may notice the engine runs fine initially but stumbles or stalls after extended operation.

Impact: Intermittent issues are challenging to diagnose because they may not appear consistently during testing. They can lead to unpredictable engine behavior, posing safety risks on the water.

5. Engine Stuck in SLOW Mode

On some Johnson models, like the 1996 Johnson 150, a failing optical sensor can trigger the engine’s SLOW (Safe Low Operating Mode) mode. This protective feature limits engine RPMs to prevent damage when the Engine Control Module (ECM) detects a fault, such as incorrect timing signals from the sensor.

Impact: SLOW mode severely restricts boat speed, making it difficult to navigate efficiently. It can be frustrating for boaters and may indicate deeper electrical or sensor issues.

6. Damage to the Power Pack

A shorted or damaged optical sensor wire can send incorrect voltage to the power pack, potentially frying this critical component. The power pack amplifies the sensor’s signal to fire the spark plugs, and any disruption can cause it to malfunction.

Impact: A damaged power pack is costly to replace, with prices ranging from $200 to $500 depending on the model, and it can exacerbate other ignition issues.

| Symptom | Possible Cause | Impact |

|---|---|---|

| Misfires/Rough Idling | Inconsistent spark due to sensor failure | Reduced efficiency, increased wear |

| Hard Starting | Disrupted spark timing | Stranded boaters, battery drain |

| No Spark | Complete sensor failure | Engine inoperable |

| Intermittent Issues | Heat-related sensor degradation | Unpredictable performance, safety risks |

| SLOW Mode Activation | Faulty timing signals to ECM | Limited speed, navigation issues |

| Power Pack Damage | Shorted sensor wiring | Costly repairs, extended downtime |

Real-World Examples: User Experiences with Optical Sensor Issues

To illustrate the practical implications of optical sensor issues, let’s examine two user scenarios involving Johnson 150 outboard engines.

Case 1: 1996 Johnson 150 Stuck in SLOW Mode

A boater reported their 1996 Johnson 150 entering SLOW mode despite replacing the fuel line, filter, power pack, and spark plugs, and disconnecting the temperature sensors. The engine’s alarm system functioned for low oil levels, but the boater was unsure if it activated during SLOW mode.

Analysis: SLOW mode is often triggered by the ECM detecting a fault in the ignition system, such as incorrect signals from the optical sensor. Replacing the power pack and spark plugs rules out those components, but persistent issues suggest wiring problems, corrosion in connectors, or a failing optical sensor. Disconnecting temperature sensors may not resolve the issue if the sensor or its wiring is faulty.

Next Steps:

- Inspect Wiring and Connectors: Check for corrosion or shorts in the optical sensor wiring and ECM connectors.

- Test the Optical Sensor: Use a multimeter to verify the sensor’s output. A replacement sensor costs approximately $50-$100.

- Verify ECM Functionality: Ensure the ECM is receiving accurate signals. A marine mechanic may need to use diagnostic software.

- Check Kill Switch and Throttle Linkage: Faulty switches or linkages can mimic sensor issues.

Case 2: 2001 Johnson Ocean Runner 150 Hard Starting

Another boater described a 2001 Johnson Ocean Runner 150 that struggled to start after sitting unused for a week or more, requiring up to 15 minutes of cranking. The engine would flood, indicating fuel delivery but no spark. Once started, it ran perfectly, and frequent use prevented the issue. The boater suspected the optical sensor but lacked diagnostic tools.

Analysis: The hard-starting issue, particularly after long periods of inactivity, points to a potential optical sensor failure or related ignition system issues. Weak batteries (11.88V, below the recommended 12.6V) and old fuel further complicate the problem. The fact that the engine runs fine once started suggests the sensor may be intermittently failing, possibly due to dirt, grease, or heat sensitivity.

Next Steps:

- Replace Batteries: Ensure batteries are fully charged (12.6V or higher) to support consistent cranking.

- Use Fresh Fuel: Drain old fuel and replace it with fresh, stabilized fuel to prevent flooding and improve combustion.

- Clean Optical Sensor: Use denatured alcohol and a Q-tip to clean the sensor lens, as other cleaners can damage it.

- Test Ignition Components: Use a spark tester ($10-$20) to confirm spark presence and a multimeter to check stator and power pack output.

- Follow Proper Cold Start Procedure: Prime the fuel bulb, hold the key in for 8 seconds to prime the carbs, and crank without advancing the throttle.

Troubleshooting Johnson Optical Sensor Issues

Diagnosing optical sensor issues requires a systematic approach to rule out other potential causes. Below is a step-by-step guide to troubleshooting, incorporating advice from marine mechanics and user experiences.

Step 1: Verify Spark Presence

Use a spark tester to check for spark on all cylinders. If no spark is present or it’s inconsistent, the issue may lie with the optical sensor, power pack, or stator.

Tools Needed:

- Spark tester: $10-$20 (available at auto parts stores)

- Screwdriver for plug removal

Step 2: Inspect Optical Sensor and Wiring

Examine the optical sensor for dirt, grease, or damage. Clean it with denatured alcohol and a Q-tip. Check the wiring for shorts, corrosion, or loose connections. A shorted wire can damage the power pack, so ensure all connections are secure and free of corrosion.

Tools Needed:

- Denatured alcohol and Q-tips

- Multimeter for continuity testing

Step 3: Test Battery Voltage

Measure battery voltage at rest (should be 12.6V or higher) and during cranking (should not drop below 11V). Weak batteries can cause insufficient power to the ignition system, mimicking sensor issues.

Tools Needed:

- Multimeter: $20-$50

- Battery charger with boost function: $100-$200

Step 4: Check Stator and Power Pack

Use a peak voltage multimeter to test the stator’s output (typically 150-300V depending on the model). A faulty stator can cause no spark or weak spark. Similarly, test the power pack’s output to ensure it’s amplifying the sensor’s signal correctly.

Tools Needed:

- Peak voltage multimeter: $80-$150

- DVA adapter for standard multimeters: $30-$50

Step 5: Verify Cold Start Procedure

Improper starting techniques can exacerbate issues. For Johnson OIS engines:

- Prime the fuel bulb until firm.

- Press and hold the key for 8-10 seconds to prime the carburetors.

- Crank the engine without advancing the throttle (QuickStart system adjusts timing automatically).

- If flooding occurs, advance the throttle to wide-open throttle (WOT) in neutral and crank for 4-5 seconds to clear the fuel.

Step 6: Check Additional Components

- Voltage Regulator/Rectifier: Disconnect and test for spark. A faulty regulator can cause electrical issues. Replacement costs: $200-$300.

- Tachometer: A non-functional tachometer may indicate a rectifier or stator issue. Check connections and set the range dial to #6.

- Fuel System: Inspect fuel filters, lines, and the VRO pump for leaks or clogs. A deteriorated VRO pump diaphragm can introduce oil into the fuel system, causing hard starting.

Step 7: Consult a Marine Mechanic

If troubleshooting doesn’t resolve the issue, consult a qualified marine mechanic. They can use diagnostic software to read ECM codes and perform advanced tests on the ignition system.

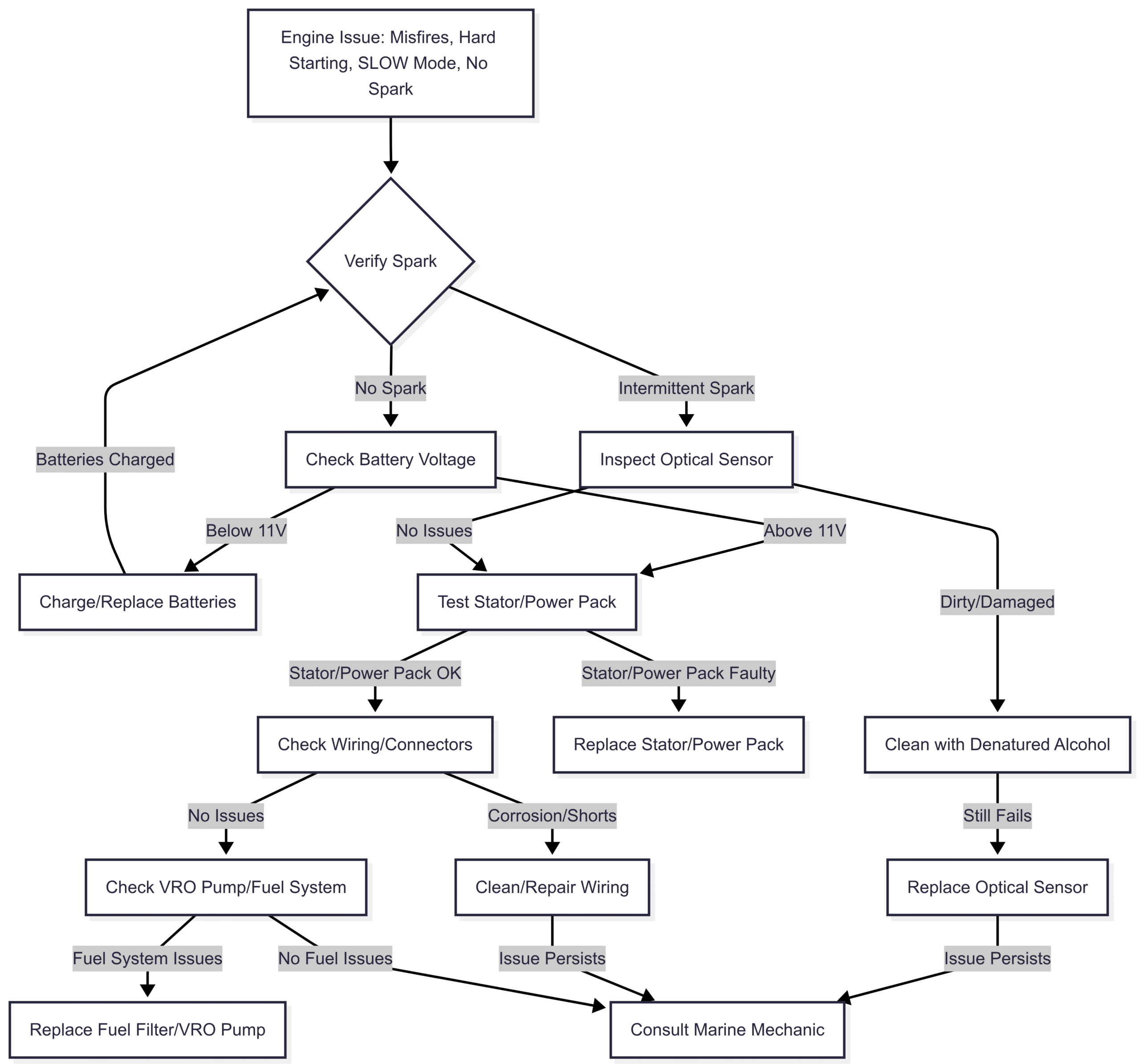

Chart: Troubleshooting Workflow

Below is a flowchart to guide the troubleshooting process for Johnson optical sensor issues.

Maintenance Tips to Prevent Optical Sensor Issues

Preventing optical sensor issues requires regular maintenance and attention to the engine’s electrical and fuel systems. Here are key tips:

- Clean Electrical Connections: Use CRC electrical spray and lithium grease to protect connectors from corrosion.

- Use Fresh Fuel: Replace old fuel with fresh, stabilized fuel to prevent carburetor clogs and flooding.

- Maintain Batteries: Ensure batteries are fully charged and test them annually. Replace if voltage drops below 12.6V at rest.

- Inspect the Optical Sensor Regularly: Clean the sensor lens with denatured alcohol during routine maintenance.

- Follow Proper Starting Procedures: Adhere to the manufacturer’s cold start sequence to avoid flooding or stressing the ignition system.

- Schedule Annual Tune-Ups: Have a marine mechanic inspect the ignition system, fuel system, and cooling system annually.

Replacement Costs and Specifications

If the optical sensor needs replacement, here are the typical costs and specifications for Johnson 150 outboard engines:

| Component | Approximate Cost | Specifications |

|---|---|---|

| Optical Sensor (OIS Eye) | $50-$100 | OEM part, compatible with 1996-2001 Johnson 150 models |

| Power Pack | $200-$500 | 12V input, controls spark timing |

| Stator | $150-$300 | 150-300V output, model-specific |

| Voltage Regulator/Rectifier | $200-$300 | Water-cooled, 12-14.5V output |

| Spark Tester | $10-$20 | Inline tester for spark verification |

| Peak Voltage Multimeter | $80-$150 | Measures stator and power pack output |

Note: Prices vary based on region, supplier, and whether OEM or aftermarket parts are used. Always consult a marine parts supplier like iboats.com or boats.net for exact pricing.

Conclusion

Johnson optical sensor issues can significantly impact outboard engine performance, manifesting as misfires, hard starting, no spark, or SLOW mode activation. By understanding the symptoms—such as rough idling, intermittent spark loss, or power pack damage—boaters can systematically troubleshoot the problem using tools like spark testers and multimeters. Real-world cases, like the 1996 and 2001 Johnson 150 engines, highlight the importance of checking batteries, fuel quality, and wiring alongside the optical sensor. Regular maintenance, proper starting procedures, and timely repairs can prevent costly downtime and ensure reliable performance on the water. If issues persist, consulting a marine mechanic with diagnostic tools is the best course of action. By following the steps outlined in this guide, boaters can diagnose and resolve optical sensor issues efficiently, keeping their Johnson outboards running like champs.

Share Common Symptoms of Johnson Optical Sensor Issues with your friends and leave a comment below with your thoughts.

Read 6 Symptoms to Detect a Bad Coil on Your Mercury Outboard until we meet in the next article.