Sulphur oxides (SOx) and Particulate Matter (PM)

Learn how SOx scrubbers reduce ship emissions to meet MARPOL Annex VI standards, with details on types, compliance, and environmental impacts.

The maritime industry plays a pivotal role in global trade, transporting over 80% of the world’s goods by volume. However, ships powered by heavy fuel oil release significant pollutants, including sulphur oxides (SOx) and particulate matter (PM), which harm air quality, human health, and marine ecosystems. To address these issues, the International Maritime Organization (IMO) introduced stringent regulations under MARPOL Annex VI, setting limits on sulphur content in marine fuels. SOx scrubbers, or Exhaust Gas Cleaning Systems (EGCS), have emerged as a key technology enabling ships to comply with these regulations while continuing to use high-sulphur fuel oil (HSFO). This article explores the mechanics of SOx scrubbers, their role in meeting MARPOL Annex VI requirements, their environmental implications, and the challenges surrounding particulate matter emissions.

Understanding Sulphur Oxides (SOx) and Particulate Matter (PM)

Sulphur oxides, primarily sulphur dioxide (SO2), are formed during the combustion of sulphur-containing fuels. These gases contribute to acid rain, respiratory issues, and environmental degradation. Particulate matter, consisting of tiny particles like soot and ash, is another byproduct of fuel combustion, posing risks to air quality and public health. Both SOx and PM are regulated under MARPOL Annex VI, which targets emissions from all shipboard fuel oil combustion equipment, including main engines, auxiliary engines, boilers, and inert gas generators.

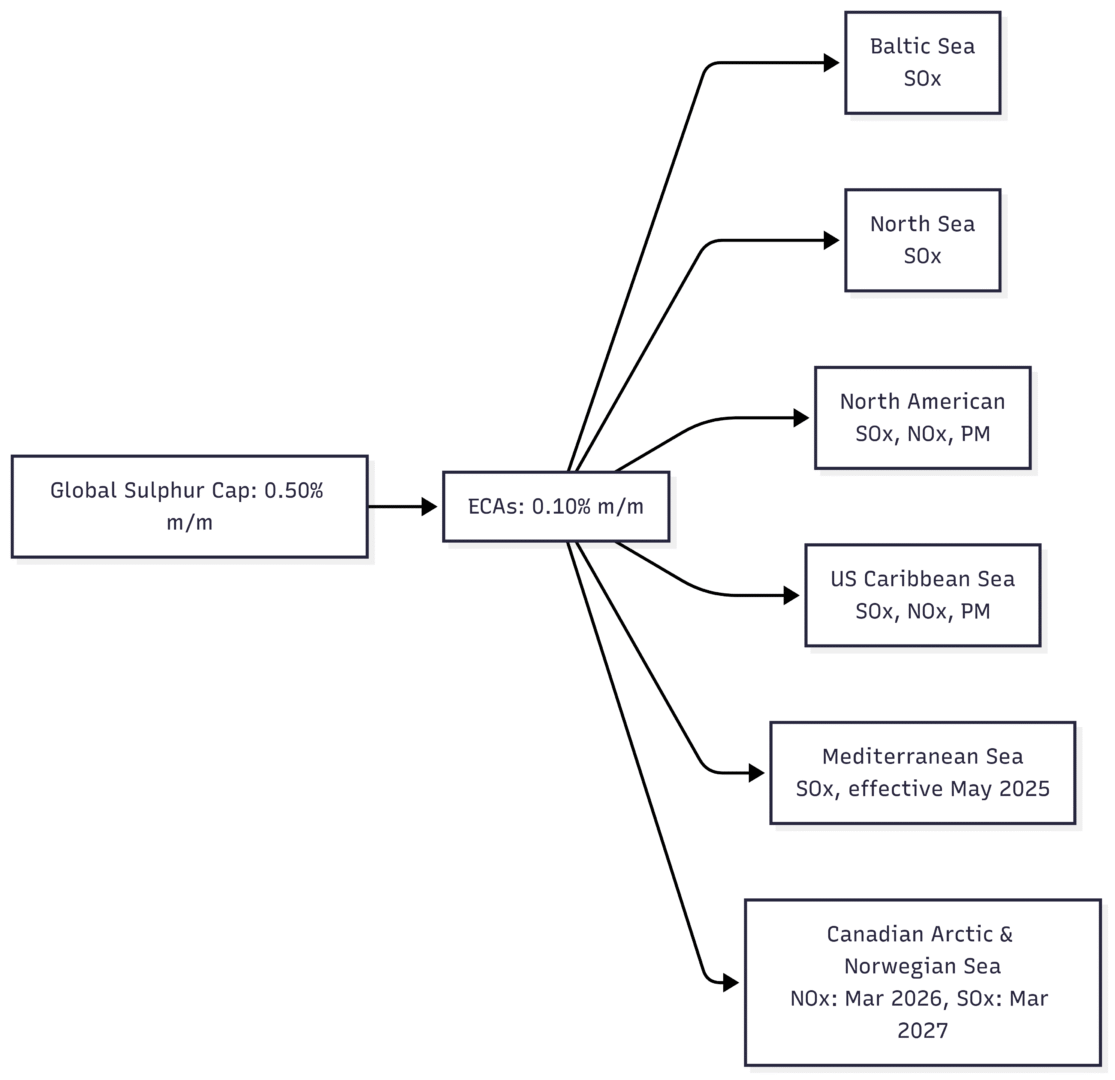

The IMO’s regulations divide emission controls into two categories: those applicable inside Emission Control Areas (ECAs) and those outside. ECAs, such as the Baltic Sea, North Sea, North American, and United States Caribbean Sea areas, enforce stricter sulphur limits to protect sensitive coastal ecosystems. The global sulphur cap, effective since January 1, 2020, reduced the allowable sulphur content in marine fuel from 3.50% to 0.50% by mass (m/m). In ECAs, the limit is even lower at 0.10% m/m.

The Role of SOx Scrubbers in Emission Compliance

SOx scrubbers offer an alternative to switching to low-sulphur fuel, allowing ships to use more cost-effective HSFO while meeting emission standards. These systems work by treating exhaust gases to remove sulphur compounds before they are released into the atmosphere. Scrubbers are particularly valuable in ECAs, where compliance with the 0.10% sulphur limit would otherwise require expensive low-sulphur fuel or distillates like marine gas oil (MGO).

How SOx Scrubbers Work

Scrubbers operate by spraying a liquid—either seawater or a chemical solution—into the ship’s exhaust gas stream. This process chemically binds sulphur dioxide, converting it into a less harmful compound. The resulting byproducts are either discharged into the sea (open-loop systems) or stored for disposal (closed-loop systems). There are three main types of scrubbers:

- Open-Loop Scrubbers: These systems use seawater to neutralize the sulfuric acid formed when SO2 reacts with water. The treated wash water, containing sulfates, is discharged back into the sea. Open-loop scrubbers are cost-effective and widely used due to the natural alkalinity of seawater, which neutralizes acidic compounds.

- Closed-Loop Scrubbers: These systems use a chemical solution, typically sodium hydroxide (caustic soda), to neutralize sulphur compounds. The resulting wash water is stored onboard and disposed of at designated port facilities. Closed-loop systems are suitable for areas with strict discharge regulations but require additional infrastructure for sludge handling.

- Hybrid Scrubbers: Combining features of both open- and closed-loop systems, hybrid scrubbers can switch between modes depending on operational needs or local regulations. They offer flexibility for ships operating in diverse regions.

The following table summarizes the key characteristics of scrubber types:

| Scrubber Type | Mechanism | Wash Water Handling | Advantages | Challenges |

|---|---|---|---|---|

| Open-Loop | Uses seawater to neutralize SO2 | Discharged into the sea | Cost-effective, simple operation | Environmental concerns over wash water discharge |

| Closed-Loop | Uses chemical solution (e.g., sodium hydroxide) | Stored onboard, disposed at port | No sea discharge, suitable for restricted areas | Higher operational costs, sludge disposal needs |

| Hybrid | Switches between open- and closed-loop modes | Flexible discharge or storage | Versatile for varying regulations | Complex design, higher installation costs |

Scrubber Installation and Costs

Installing a scrubber system involves significant upfront costs but can yield long-term savings by allowing the use of cheaper HSFO. The cost of scrubber installation varies depending on the ship’s size, engine type, and scrubber system. According to industry estimates, installation costs range from $2 million to $6 million per vessel for retrofit projects, with newbuild installations being slightly less expensive. Operating costs include maintenance, chemical supplies (for closed-loop systems), and sludge disposal fees.

| Component | Estimated Cost (USD) |

|---|---|

| Open-Loop Scrubber Installation | $2M–$4M |

| Closed-Loop Scrubber Installation | $3M–$6M |

| Hybrid Scrubber Installation | $4M–$6M |

| Annual Operating Costs | $100,000–$500,000 (depending on system and usage) |

These costs are offset by the price differential between HSFO and low-sulphur fuel oil (LSFO). For example, HSFO is typically 20–30% cheaper than LSFO, making scrubbers a financially viable option for ships with high fuel consumption.

MARPOL Annex VI: Regulatory Framework

MARPOL Annex VI, adopted by the IMO, sets global standards for controlling air pollution from ships. The regulation addresses SOx, nitrogen oxides (NOx), and PM emissions, with specific focus on sulphur content in fuel oil. The global sulphur cap of 0.50% m/m, implemented in 2020, marked a significant reduction from the previous 3.50% limit. In ECAs, the sulphur limit is 0.10% m/m, enforced in areas like the Baltic Sea, North Sea, North American, and United States Caribbean Sea regions.

The following table outlines the sulphur content limits over time:

| Period | Outside ECA (% m/m) | Inside ECA (% m/m) |

|---|---|---|

| Before 2010 | 4.50% | 1.50% |

| 2010–2012 | 3.50% | 1.00% |

| 2015–2020 | 3.50% | 0.10% |

| Post-2020 | 0.50% | 0.10% |

Regulation 4 of MARPOL Annex VI allows alternative compliance methods, such as scrubbers, provided they achieve equivalent SOx emission reductions. Ships using scrubbers must maintain a SOx Emissions Compliance Plan (SECP), detailing how compliance is achieved and monitored. The SECP includes records of fuel changeovers, scrubber operation, and wash water management.

Emission Control Areas (ECAs)

ECAs are designated regions with stricter emission controls to protect coastal environments. The current ECAs include:

- Baltic Sea Area (SOx only)

- North Sea Area (SOx only)

- North American Area (SOx, NOx, PM)

- United States Caribbean Sea Area (SOx, NOx, PM)

- Mediterranean Sea Area (SOx, effective May 1, 2025)

- Canadian Arctic and Norwegian Sea (NOx from March 1, 2026; SOx from March 1, 2027)

The following chart illustrates the global distribution of ECAs:

Fuel Changeover Procedures

Ships operating in and out of ECAs must switch between HSFO and ECA-compliant low-sulphur fuel (0.10% m/m) to meet regulations. This process, known as fuel changeover, requires careful planning to avoid contamination of fuel systems. Regulation 14.6 mandates that ships complete the changeover before entering an ECA and record details such as fuel quantities, date, time, and ship position in a logbook, typically the Annex I Oil Record Book.

The changeover process depends on the ship’s fuel system volume, sulphur content of fuels, and consumption rate. For example, a ship with a 500 m³ fuel system and a consumption rate of 10 m³/hour may require 50 hours to fully flush the system. Failure to properly manage changeovers can result in non-compliance and penalties.

Environmental and Operational Challenges

While scrubbers effectively reduce SOx emissions, they are not without controversy. The environmental and operational challenges associated with scrubbers include wash water discharge, sludge disposal, and their limited impact on particulate matter.

Wash Water Discharge

Open-loop scrubbers discharge wash water containing neutralized sulfates into the sea, raising concerns about marine ecosystem impacts. Studies suggest that wash water can alter seawater pH and introduce heavy metals, potentially harming marine life. Several countries, including Singapore and parts of Germany, have banned open-loop scrubber discharges in their ports, pushing operators toward closed-loop or hybrid systems.

Closed-loop scrubbers avoid sea discharge but produce sludge that must be stored and disposed of at port facilities. Improper sludge disposal can lead to environmental contamination, requiring robust waste management infrastructure.

Particulate Matter (PM) Emissions

Scrubbers are designed to target SOx, but their effectiveness in reducing PM is limited. Particulate matter, including black carbon and ultrafine particles, contributes to air pollution and climate change. While wet scrubbers can capture some PM through the washing process, they do not address all particle sizes, particularly ultrafine particles that pose significant health risks.

The IMO is exploring additional measures to control PM emissions, including black carbon, which is particularly relevant in Arctic regions. Ships operating in ECAs must consider complementary technologies, such as diesel particulate filters, to address PM emissions comprehensively.

Shifting Pollution from Air to Water

Critics argue that scrubbers shift pollution from the atmosphere to the ocean, particularly in open-loop systems. The discharge of acidic wash water and heavy metals can accumulate in marine environments, affecting water quality and biodiversity. This has led to calls for stricter regulations on scrubber use and wash water discharge, with some advocating for a global ban on open-loop systems.

Compliance and Enforcement

Compliance with MARPOL Annex VI is monitored through fuel oil sampling, bunker delivery notes (BDNs), and onboard inspections. The BDN, provided by the fuel supplier, must state the sulphur content of the fuel. Ships must ensure that ECA-compliant fuel is not contaminated with higher-sulphur fuel during storage or transfer operations.

In countries that have not ratified MARPOL Annex VI, shipowners must consult local regulations or their flag state to determine applicable sulphur limits. Even in ratifying countries, local regulations may impose stricter requirements, such as bans on open-loop scrubber discharges.

The IMO’s guidelines (MEPC.259(68) and MEPC.340(77)) provide detailed standards for scrubber operation, including monitoring of wash water pH, turbidity, and polycyclic aromatic hydrocarbons (PAHs). Non-compliance can result in fines, detentions, or operational restrictions.

Future Outlook and New ECAs

The maritime industry continues to evolve in response to environmental pressures. The designation of new ECAs, such as the Mediterranean Sea (effective May 1, 2025) and the Canadian Arctic and Norwegian Sea (NOx from March 1, 2026; SOx from March 1, 2027), reflects the IMO’s commitment to reducing ship emissions in sensitive regions.

Technological advancements are also shaping the future of emission control. Research into primary methods, such as onboard fuel blending or dual-fuel engines, could reduce reliance on scrubbers. Additionally, alternative fuels like liquefied natural gas (LNG), hydrogen, and ammonia offer potential pathways to zero-emission shipping, though their adoption is limited by infrastructure and cost.

Conclusion

SOx scrubbers have become a cornerstone of maritime emission control, enabling ships to comply with MARPOL Annex VI while using cost-effective high-sulphur fuel. Open-loop, closed-loop, and hybrid systems offer flexible solutions, but their environmental impact—particularly wash water discharge and limited PM reduction—remains a point of contention. As the IMO expands ECAs and explores new regulations, the maritime industry must balance compliance, cost, and environmental responsibility. Emerging technologies and alternative fuels may eventually reduce reliance on scrubbers, but for now, they remain a critical tool in the global effort to curb ship emissions.

Happy Boating!

Share Sulphur oxides (SOx) and Particulate Matter (PM) with your friends and leave a comment below with your thoughts.

Read Safe Working Practices in the Engine Room until we meet in the next article.