Steel Winch Cable Vs. Synthetic Rope

Explore the pros and cons of steel winch cable vs. synthetic rope for marine and off-road use. Learn which is best for durability, safety, and performance.

Winches are indispensable tools in industries like marine, off-road recovery, construction, and oil and gas, where they are used for towing, mooring, anchoring, and lifting heavy loads. The choice of winch line—steel cable or synthetic rope—can significantly impact performance, safety, and cost. Both materials have distinct advantages and drawbacks, and the decision hinges on specific operational needs, environmental conditions, and budget constraints. This article provides an in-depth comparison of steel winch cable and synthetic rope, focusing on their applications in marine and off-road environments, to help you make an informed choice.

Understanding Winch Lines: Steel Cable and Synthetic Rope

A winch operates by winding a rope or cable around a rotating drum to pull, haul, or lift objects. The two primary types of winch lines are:

- Steel Cable: Traditionally the industry standard, steel cable, often aircraft-grade, is known for its durability and strength in harsh environments.

- Synthetic Rope: Introduced in the mid-1990s, synthetic rope, typically made from high-tech polyethylene, offers a lighter and safer alternative, particularly in marine and off-road applications.

Each material has unique properties that make it suitable for specific scenarios. Below, we explore their characteristics, advantages, disadvantages, and ideal use cases, supported by expert insights and practical considerations.

Steel Winch Cable: The Durable Workhorse

Steel winch cable has been the go-to choice for decades due to its robustness and affordability. It is particularly well-suited for environments where durability is paramount.

Advantages of Steel Winch Cable

- Durability in Harsh Conditions: Steel cable excels in abrasive terrains, such as rocky, muddy, or sandy environments. Its resistance to abrasion, heat, and sharp edges makes it ideal for heavy-duty applications like construction, logging, or off-road recovery in rugged landscapes.

- Cost-Effective: Steel cable is generally more affordable than synthetic rope, making it a budget-friendly option for users who prioritize initial cost over long-term maintenance.

- UV Resistance: Unlike synthetic rope, steel cable is unaffected by prolonged sun exposure, ensuring consistent performance in outdoor settings.

- Low Maintenance: Steel requires less frequent cleaning compared to synthetic rope, especially in environments free of moisture or corrosive elements.

Disadvantages of Steel Winch Cable

- Weight: Steel cable is significantly heavier than synthetic rope, which can strain winch systems and make handling more cumbersome, particularly in marine applications where weight reduction is critical.

- Rust and Burrs: Steel is prone to rusting, especially in marine environments where exposure to saltwater is common. Over time, wear can cause sharp burrs to form, necessitating gloves for safe handling and regular maintenance to prevent corrosion.

- Kinking and Spooling Issues: Steel cable is less flexible, making it prone to kinking, which can weaken the line and complicate spooling on the winch drum. Improper spooling can reduce the cable’s strength and lifespan.

- Safety Risks: When steel cable breaks, it releases stored energy, creating a dangerous snap-back effect that can cause serious injury or damage. This makes it less safe in high-tension scenarios.

Maintenance Tips for Steel Cable

To maximize the lifespan of steel winch cable:

- Apply a light coating of chain oil or WD-40 to protect against rust and disperse moisture.

- Regularly inspect for burrs, kinks, or signs of wear, and replace damaged sections promptly.

- Ensure proper spooling to prevent kinks and maintain strength.

Synthetic Rope: The Lightweight Innovator

Synthetic rope, introduced as an alternative to steel cable, has gained popularity for its safety and ease of use. Made from materials like high-tech polyethylene, it is now a standard in many off-road competitions and marine applications.

Advantages of Synthetic Rope

- Lightweight: Synthetic rope is significantly lighter than steel cable, reducing the overall weight of the winch system. This is particularly beneficial for vehicles sensitive to front-axle weight, such as off-road rigs, and for marine applications where buoyancy is a factor.

- Buoyancy: Synthetic rope floats on water, making it ideal for marine environments or off-road recoveries involving water or mud.

- Flexibility: Its high flexibility allows for easier spooling and handling, especially in tight spaces, and it does not kink like steel cable.

- Safety: Synthetic rope stores less energy under tension, reducing the risk of dangerous snap-back if it breaks. This makes it safer for operators and bystanders.

- Repairability: Damaged synthetic rope can be repaired in the field using proper braiding techniques, such as with tools like the Factor55 Fast Fid, offering a practical advantage in remote locations.

- No Burrs: Unlike steel, synthetic rope does not develop sharp burrs, making it safer to handle without gloves.

Disadvantages of Synthetic Rope

- Susceptibility to Environmental Damage: Synthetic rope is vulnerable to UV exposure, abrasion, chemicals, and heat, which can weaken its fibers over time. Protective sleeves and coatings can mitigate these issues, but they add to the cost.

- Higher Cost: Synthetic rope is generally more expensive than steel cable, which may deter budget-conscious users.

- Maintenance Requirements: Synthetic rope requires regular cleaning and inspection, especially after use in sandy or muddy conditions, as debris can embed in the fibers and cause internal abrasion.

- Water Retention: Synthetic rope can absorb water, adding weight or freezing in cold weather, potentially rendering the winch unusable until thawed.

Maintenance Tips for Synthetic Rope

To ensure synthetic rope longevity:

- Regularly spool out and wash the rope to remove sand, dirt, or mud that can weaken the core.

- Store the rope away from prolonged UV exposure and chemicals.

- Use protective sleeves and heat-resistant coatings, especially for the section wrapped around the winch drum.

Comparative Analysis: Steel vs. Synthetic in Key Applications

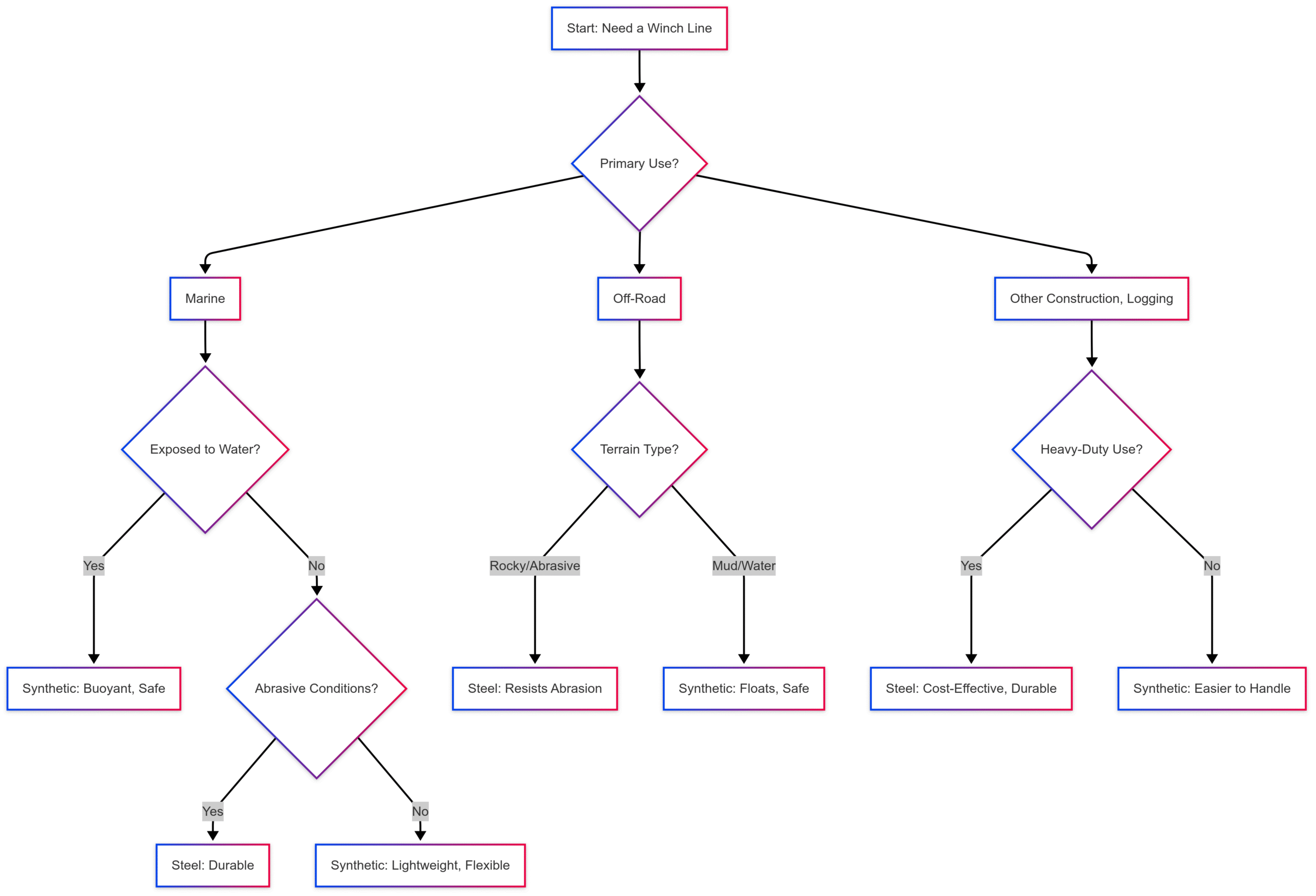

The choice between steel cable and synthetic rope depends on the specific application, environmental conditions, and user preferences. Below, we compare their performance in marine and off-road scenarios, supported by a detailed table and a decision-making flowchart.

Marine Applications

In marine environments, winches are used for towing, mooring, anchoring, and lifting heavy objects. The choice of winch line is influenced by factors like exposure to water, weight considerations, and safety.

- Synthetic Rope: Preferred for its buoyancy, lightweight nature, and flexibility, synthetic rope is ideal for marine applications. Its ability to float simplifies recoveries in water, and its lower snap-back risk enhances safety on deck. However, its susceptibility to UV and chemical degradation requires careful maintenance, especially on vessels exposed to harsh weather or corrosive substances.

- Steel Cable: Steel is more durable in abrasive or corrosive conditions, such as when dragging over rough surfaces or in saltwater environments. However, its weight and rust susceptibility make it less practical for frequent handling or prolonged water exposure.

Off-Road Recovery

Off-road enthusiasts often debate the merits of steel vs. synthetic for winch recovery, as each excels in different terrains.

- Synthetic Rope: Synthetic is favored for its safety, lightweight design, and ease of handling, making it the standard in many off-road competitions. It performs well in muddy or wet conditions due to its buoyancy and is easier to manage in tight trails. However, in rocky or abrasive terrains, such as those found in New England or Moab, synthetic rope can degrade quickly without proper care.

- Steel Cable: Steel is the go-to choice for rugged, abrasive terrains like rocky trails or logging operations. Its durability makes it reliable for heavy-duty recoveries, but its weight and potential for kinking or rusting can be drawbacks in less demanding environments.

Comparison Table

| Feature | Steel Cable | Synthetic Rope |

|---|---|---|

| Weight | Heavy, adds strain to winch system | Lightweight, reduces system weight |

| Buoyancy | Sinks in water | Floats on water |

| Flexibility | Less flexible, prone to kinking | Highly flexible, easy to spool |

| Safety | High snap-back risk if broken | Low snap-back risk, safer if broken |

| Durability | High resistance to abrasion, heat, UV | Susceptible to UV, abrasion, chemicals |

| Maintenance | Low, but requires rust prevention | High, needs regular cleaning and inspection |

| Cost | More affordable | More expensive |

| Repairability | Not field-repairable | Repairable with braiding techniques |

| Handling | Requires gloves due to burrs | Safe to handle without gloves |

Decision-Making Flowchart

To help visualize the decision process, the following flowchart outlines key considerations for choosing between steel cable and synthetic rope:

Specifications and Pricing

When selecting a winch line, specifications like diameter, breaking strength, and length are critical. Below are typical specifications and approximate price ranges for steel cable and synthetic rope, based on common winch sizes (e.g., 12,000 lb capacity).

Steel Cable Specifications

- Diameter: 5/16″ to 3/8″ (common for 12,000 lb winches)

- Breaking Strength: 12,000–15,000 lbs

- Length: 80–100 ft

- Material: Aircraft-grade galvanized steel

- Price Range: $50–$150 (depending on length and brand)

Synthetic Rope Specifications

- Diameter: 3/8″ to 1/2″ (common for 12,000 lb winches)

- Breaking Strength: 20,000–30,000 lbs (higher than steel for same diameter)

- Length: 80–100 ft

- Material: High-tech polyethylene (e.g., Dyneema or Spectra)

- Price Range: $150–$400 (depending on brand, protective coatings, and sleeves)

Price Considerations

- Steel Cable: More affordable upfront, ideal for budget-conscious users or those in abrasive environments where frequent replacement isn’t needed.

- Synthetic Rope: Higher initial cost but justified by safety, weight savings, and repairability. Premium brands like Masterpull or Warn offer protective sleeves, increasing costs but enhancing durability.

Marine Winch Drive Types: Impact on Line Choice

Marine winches are powered by pneumatic, hydraulic, or electric drives, each influencing the choice of winch line:

Pneumatic Drives:

- Pros: Spark-resistant, suitable for explosive environments; easy torque control.

- Cons: Noisy, less efficient, susceptible to debris in air supply.

- Line Preference: Steel cable is often used due to lower maintenance needs in harsh conditions, but synthetic is viable if safety is prioritized.

Hydraulic Drives:

- Pros: Compact, high power-to-size ratio, accurate speed/torque control.

- Cons: Prone to leaks, higher maintenance.

- Line Preference: Synthetic rope is preferred for its lightweight nature, reducing strain on hydraulic systems, but steel is used in abrasive conditions.

Electric Drives:

- Pros: Low operating costs, high efficiency, precise control.

- Cons: Expensive explosion-proof enclosures for marine use.

- Line Preference: Synthetic rope is ideal for its weight savings and safety, especially in variable-speed electric winches.

Direct Drive vs. Chain Drive

- Direct Drive: Couples the motor directly to the drum, reducing mechanical failure points. Preferred for reliability with either line type.

- Chain Drive: Uses a chain or belt, increasing maintenance but sometimes necessary due to space constraints. Synthetic rope’s flexibility makes it easier to manage in chain-driven systems.

Expert Insights and Community Perspectives

Online discussions, such as those on Reddit, reveal a divide among off-road enthusiasts. Some, like user trailtoy1993, favor steel for its toughness in abrasive terrains, citing experiences where synthetic rope failed over rotted logs or in muddy conditions. Others, like yourmomsblackdildo, advocate for synthetic rope, emphasizing its safety, strength, and ease of use, claiming it outperforms steel in most off-road scenarios. These perspectives highlight the importance of terrain and maintenance habits in decision-making.

For marine applications, experts emphasize synthetic rope’s buoyancy and safety, though steel remains relevant for heavy-duty tasks like towing or anchoring in corrosive environments. Companies like Atlas Winch Hire & Hoist Services recommend synthetic for water-intensive tasks and steel for abrasive conditions, aligning with industry trends toward synthetic in safety-critical applications.

The Verdict: Which Is Right for You?

The choice between steel winch cable and synthetic rope boils down to three key factors:

- Environment: Steel excels in abrasive, rocky, or high-heat conditions, while synthetic is ideal for water-intensive or muddy environments.

- Safety: Synthetic rope’s low snap-back risk makes it safer, especially in marine or crowded off-road settings.

- Budget and Maintenance: Steel is cheaper and requires less frequent cleaning, but synthetic’s repairability and weight savings may offset its higher cost for frequent users.

For marine applications, synthetic rope is often the better choice due to its buoyancy, flexibility, and safety, provided it is protected from UV and chemical exposure. For off-road recovery, synthetic is preferred for occasional use or muddy trails, while steel is better for rocky terrains or users who prioritize durability over maintenance. In construction or logging, steel’s cost-effectiveness and toughness often make it the default choice.

Practical Recommendations

- Beginners: Opt for synthetic rope for its ease of handling and safety, especially in off-road or marine settings. Invest in a quality brand with protective sleeves to mitigate abrasion and UV damage.

- Heavy-Duty Users: Choose steel cable for abrasive environments or when budget constraints are significant. Regular maintenance is key to preventing rust and burrs.

- Hybrid Approach: Some users, like patrick_schliesing, combine both, using steel for high-capacity winches (e.g., 15,000 lbs) and synthetic for lighter ones (e.g., 12,000 lbs).

Safety First: Winching Best Practices

Regardless of the line type, safe winching techniques are critical. Warn’s Basic Guide to Winching Techniques recommends:

- Always wear gloves when handling steel cable to avoid burrs.

- Use a winch dampener to reduce snap-back risk with either material.

- Regularly inspect the line for wear, kinks, or damage.

- Ensure proper spooling to maintain line strength and prevent jams.

Conclusion

Steel winch cable and synthetic rope each offer unique benefits tailored to specific needs. Steel’s durability and affordability make it a reliable choice for abrasive, heavy-duty tasks, while synthetic rope’s lightweight design, safety, and buoyancy shine in marine and off-road applications. By understanding your operational environment, maintenance capacity, and budget, you can select the winch line that best suits your needs. Whether you’re navigating rocky trails, recovering a vessel, or lifting heavy loads, the right choice will enhance performance, safety, and efficiency.

For further assistance, companies like Atlas Winch Hire & Hoist Services offer expert guidance and equipment tailored to your cabling needs. Contact their Scotland (01899 221 577) or Essex (01371 859 555) branches for support.

Share Steel Winch Cable Vs. Synthetic Rope with your friends and Leave a comment below with your thoughts.

Read How to Troubleshoot Common Issues with Boat Trailer Brakes? until we meet in the next article.