Stainless steel boat rails transform motorboat design

Discover how stainless steel boat rails enhance motorboat design with durability, safety, and style. Learn key considerations and real-world applications.

Stainless steel boat rails have become a cornerstone of modern motorboat design, blending functionality, safety, and aesthetic appeal. Their rise in popularity stems from unmatched durability, corrosion resistance, and a sleek, polished look that elevates any vessel’s appearance. Whether upgrading a recreational dayboat or outfitting a commercial fishing vessel, stainless steel railings offer a transformative solution for boat owners seeking reliability and style. This article explores the benefits, material options, design considerations, and real-world applications of stainless steel boat rails, with a focus on their role in enhancing motorboat design.

Why Stainless Steel Boat Rails?

Stainless steel stands out as a premium material for boat railings due to its unique properties. Unlike wood or aluminum, stainless steel combines strength, longevity, and low maintenance, making it ideal for the harsh marine environment. Here’s why it’s a preferred choice:

- Durability and Strength: Stainless steel railings withstand significant physical stress, from heavy wave impacts to constant passenger use. They resist bending, cracking, or warping, ensuring long-term reliability.

- Corrosion Resistance: Marine environments, especially saltwater, are notoriously corrosive. Stainless steel’s resistance to rust and pitting ensures railings remain functional and visually appealing for years.

- Aesthetic Appeal: The polished, mirror-like finish of stainless steel adds a modern, upscale look to any boat, enhancing its overall design and resale value.

- Low Maintenance: Unlike wooden rails, which require regular sealing and refinishing, stainless steel needs only periodic cleaning with mild soap and water to maintain its shine.

Stainless Steel Grades for Marine Applications

Not all stainless steel is created equal. The grade of stainless steel used in boat railings significantly impacts performance. The two most common grades are:

| Grade | Description | Best Use | Corrosion Resistance | Cost |

|---|---|---|---|---|

| 316 Stainless Steel | Marine-grade, with molybdenum for enhanced corrosion resistance. | Saltwater environments, coastal waters. | Excellent, resists pitting and rust in harsh conditions. | Higher, but justified by longevity. |

| 304 Stainless Steel | General-purpose, corrosion-resistant but less effective in saltwater. | Freshwater lakes and rivers. | Good, but prone to pitting in saline conditions. | More affordable than 316. |

316 Stainless Steel is the gold standard for marine applications. Its molybdenum content (2-3%) enhances resistance to chloride-induced corrosion, making it ideal for boats operating in saltwater. For example, a vessel navigating the coastal waters of Vancouver or British Columbia would benefit significantly from 316-grade rails. In contrast, 304 Stainless Steel is suitable for freshwater environments but may show signs of corrosion in saline conditions over time.

Cost Comparison

While stainless steel is more expensive than alternatives like aluminum, its long-term value is undeniable. Below is a cost comparison based on typical market prices for boat railings:

| Material | Initial Cost (per linear foot) | Maintenance Cost (Annual) | Lifespan (Years) |

|---|---|---|---|

| 316 Stainless Steel | $50–$100 | $5–$10 | 15–20 |

| 304 Stainless Steel | $40–$80 | $5–$10 | 10–15 |

| Marine-Grade Aluminum | $30–$60 | $10–$20 | 10–15 |

| Wood | $20–$50 | $20–$50 | 5–10 |

Stainless steel’s higher upfront cost is offset by its durability and minimal maintenance, making it a cost-effective choice over time.

Key Considerations for Choosing Stainless Steel Boat Rails

Selecting the right boat rails involves balancing safety, functionality, and aesthetics. Here are the critical factors to consider:

1. Safety First

Boat railings are primarily safety features, preventing falls and providing support during rough seas. The design must account for:

- Height and Spacing: Rails should be at least 30–36 inches high for adequate protection, with gaps no wider than 4 inches to prevent children or objects from slipping through.

- Grip Comfort: Oval or square rails, like those offered by Timeless Tube, provide better grip than round tubes, reducing slippage risks.

- Load-Bearing Capacity: Rails must withstand lateral forces, such as passengers leaning or waves hitting the boat.

2. Installation Options

Boat owners can choose between prefabricated kits or custom-fabricated rails:

- Prefabricated Kits: These are cost-effective and suitable for standard boats but may not fit unique deck curvatures or complex designs.

- Custom Rails: Tailored to the boat’s specifications, custom rails ensure perfect fit, enhanced safety, and seamless integration with the vessel’s aesthetics. They are ideal for high-end refits or boats with non-standard dimensions.

3. Maintenance Requirements

Stainless steel rails are low-maintenance but not maintenance-free. To preserve their appearance and integrity:

- Clean regularly with mild soap and water.

- Avoid abrasive cleaners or steel wool, which can scratch the surface and promote corrosion.

- Apply marine-grade stainless steel polish periodically to restore shine and protect against environmental damage.

4. Avoiding Galvanic Corrosion

When dissimilar metals (e.g., stainless steel and aluminum) are in contact in a saltwater environment, galvanic corrosion can occur. To prevent this:

- Use stainless steel fittings and fasteners to match the rail material.

- Apply insulating materials, such as nylon washers, at contact points with other metals.

5. Fabrication Techniques

Proper fabrication is critical for both functionality and aesthetics. Key techniques include:

- Bending: Use a tube bender designed for stainless steel, filled with sand to prevent kinks during complex curves.

- Welding: Employ TIG (Tungsten Inert Gas) welding for precise, clean joins that minimize heat-affected zones, preserving corrosion resistance.

- Polishing: Electropolishing or mechanical polishing enhances corrosion resistance and gives rails a mirror-like finish.

Case Study: Timeless Tube’s Oval Handrails on Botnia Targa 46

A real-world example of stainless steel boat rails transforming motorboat design is the refit of a Botnia Targa 46 Offshore Motorboat by a Jersey-based owner. The project, executed with Timeless Tube’s 316L stainless steel oval handrails, showcases the potential of innovative railing design.

Project Overview

The owner sought to replace the boat’s dated wooden handrails with modern, durable stainless steel rails. Working with Timeless Tube, marine fabricators Colin Kelly and Alan Worthington, and designer Paul Edmonson of PE Marine Designz, the owner transformed the Targa 46 into a standout vessel.

Why Oval Rails?

The owner chose Timeless Tube’s 71x45x2.77mm oval tubes for their tactile feel and unique aesthetic. Unlike standard round tubes, oval rails offer:

- Enhanced Grip: The flat surface provides a more secure hold, improving safety.

- Distinctive Look: Oval rails stand out, giving the boat a bespoke, luxurious appearance.

- Tactile Comfort: The owner noted that oval tubes feel “friendlier” and more ergonomic than round tubes.

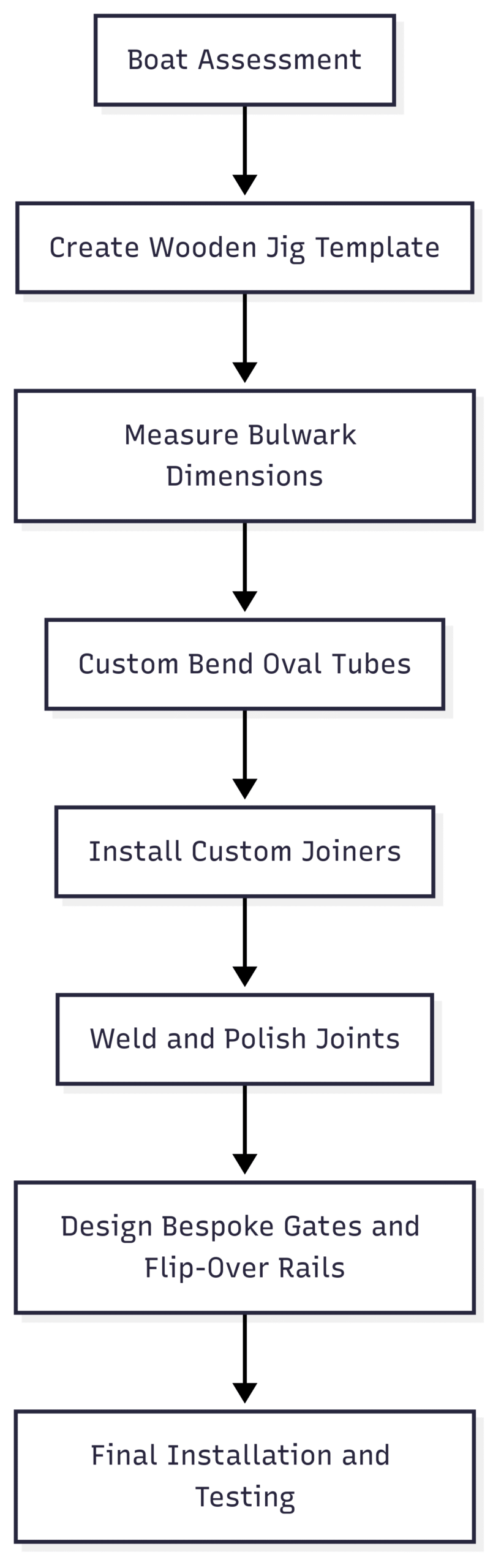

Fabrication Process

The refit required meticulous planning and execution:

- Template Creation: Wessex Marine, the UK agent for Botnia Targa, provided access to a Targa 46 for measurements. Fabricators built a wooden jig replicating the boat’s bulwark, ensuring accurate curves and dimensions.

- Custom Bending: Timeless Tube developed new rollers to create compound curves (bends in both x and y axes) in the oval tubing, ensuring a perfect fit.

- Joiners for Seamless Connections: Custom 316L stainless steel joiners were used to connect tubing at tight corners, both vertically and horizontally. Fabricators trimmed and welded joiners to achieve precise angles, ensuring strength and a polished finish.

- Bespoke Features:

- Stern Gates: Designer Paul Edmonson created self-closing gates with concealed hinges, using oval tubes for the handrail and round tubes for the gate doors to create contrast.

- Flip-Over Rails: Side rails with 180° hinges and spring-loaded latches were installed on port and starboard sides, enhancing accessibility and aesthetics.

Results

The owner described the transformation as “the most beautiful thing you can possibly imagine.” The oval rails elevated the Targa 46 from a standard production boat to a custom, head-turning vessel. The project highlights how stainless steel rails, when thoughtfully designed and fabricated, can redefine a boat’s identity.

Chart: Fabrication Process Flow

Broader Applications of Stainless Steel Rails

The Targa 46 refit is just one example of how stainless steel rails are transforming motorboat design. Across various vessel types—dayboats, fishing vessels, and luxury tenders—stainless steel rails offer versatile solutions:

- Safety Enhancements: Rails provide critical support for passengers, especially in rough waters or during boarding/disembarking.

- Functional Integration: Rails can support fishing rod holders, solar panels, or tie-down points for gear, maximizing utility.

- Aesthetic Upgrades: Polished stainless steel rails elevate the visual appeal of production boats, making them comparable to superyachts.

- Refurbishments: Replacing outdated wooden or aluminum rails with stainless steel is a growing trend, as seen in the Targa 46 project.

Timeless Tube’s Role in the Industry

Timeless Tube, a UK-based specialist in shaped stainless steel tubing, has seen increasing demand for its oval and square rails. Managing Director Tom McMillan notes, “Boat owners are discerning and want fittings that reflect their pride in their craft. Our oval rails offer a unique combination of safety, style, and durability, making them ideal for refits and new builds.”

Timeless Tube offers a range of services, including:

- Custom Fabrication: Tailored rails for unique boat designs.

- Polishing Services: Restoring scratched or dulled rails to a mirror finish.

- Onsite Installation: Skilled marine welders ensure precise, secure installation.

Practical Guide to Installing Stainless Steel Boat Rails

For boat owners considering stainless steel rails, here’s a step-by-step guide to ensure a successful installation:

1. Define Your Needs

Consider the vessel’s purpose, passenger demographics, and operating environment. For example:

- Fishing boats may need rails with rod holders.

- Family-oriented vessels require child-safe spacing and heights.

- Coastal boats demand 316-grade stainless steel for corrosion resistance.

2. Choose Between Prefabricated and Custom

Evaluate whether a prefabricated kit meets your needs or if custom fabrication is necessary. Custom rails are recommended for:

- Boats with unique deck curvatures.

- High-end aesthetics or complex designs.

- Enhanced safety requirements.

3. Inspect Structural Integrity

Before installation, ensure the deck and mounting surfaces are sound:

- Check for rot or weakness in fiberglass or wooden decks.

- Reinforce mounting zones if needed.

- Seal bolt holes to prevent water intrusion.

4. Work with Experienced Fabricators

Choose a fabricator with marine-specific expertise, such as Cedric Marina Ltd. in Vancouver or Timeless Tube in the UK. Look for:

- Experience with TIG welding and electropolishing.

- Knowledge of local marine conditions.

- Strong customer references and project portfolios.

5. Ensure Compliance

Verify that the railing design meets local regulations, such as Transport Canada guidelines for commercial vessels. Key considerations include rail height, spacing, and material standards.

6. Plan for Longevity

Invest in high-quality materials and finishes to maximize lifespan. Electropolished 316 stainless steel rails can last 15–20 years with minimal maintenance, even in aggressive saltwater environments.

Pricing for Stainless Steel Boat Rails

Costs vary based on material, customization, and installation complexity. Below is a rough estimate for a 30-foot motorboat:

| Component | Cost Range | Notes |

|---|---|---|

| 316 Stainless Steel Tubing (per linear foot) | $50–$100 | Oval or square tubing may cost more. |

| Custom Joiners and Fittings | $200–$500 | Depends on quantity and complexity. |

| Fabrication Labor | $500–$2,000 | Varies by region and project scope. |

| Installation | $300–$1,000 | Onsite welding increases costs. |

| Polishing/Finishing | $100–$300 | Optional for aesthetic enhancement. |

| Total (20–30 linear feet) | $1,500–$4,000 | Custom projects may exceed this range. |

Maintenance Tips for Stainless Steel Rails

To ensure longevity and maintain the polished look of stainless steel rails:

- Routine Cleaning: Wash with fresh water and mild soap after each trip to remove salt deposits.

- Polishing: Use marine-grade polish every 6–12 months to restore shine and protect against pitting.

- Inspection: Check for loose fittings or signs of corrosion annually, especially at welds or contact points with other metals.

- Avoid Harsh Chemicals: Steer clear of bleach or abrasive cleaners, which can damage the protective oxide layer.

Conclusion

Stainless steel boat rails are more than a functional necessity—they’re a transformative element in motorboat design. From enhancing safety to elevating aesthetics, rails like Timeless Tube’s oval handrails demonstrate the potential to turn a standard vessel into a standout. By choosing the right material (316 stainless steel for saltwater), prioritizing custom fabrication, and working with experienced marine fabricators, boat owners can achieve a balance of durability, safety, and style. Whether you’re refitting a dayboat or outfitting a commercial vessel, stainless steel rails are a worthwhile investment that delivers lasting value.

For those considering an upgrade, consult with specialists like Timeless Tube or Cedric Marina Ltd. to explore custom solutions tailored to your boat’s unique needs. With the right approach, stainless steel rails can redefine your vessel’s design and performance, ensuring years of safe and stylish boating.

Happy Boating!

Share Stainless steel boat rails transform motorboat design with your friends and leave a comment below with your thoughts.

Read V-Bottom Boats: A Comprehensive Guide until we meet in the next article.