An Overview Of Sludge And Bilge Management Onboard Ships

Learn about sludge and bilge management on ships, including production, storage, treatment, and MARPOL-compliant disposal practices.

Maritime operations are intricate, involving complex machinery and systems that keep vessels running smoothly across the world’s oceans. Among the critical tasks onboard is the management of sludge and bilge water—byproducts of routine ship operations that, if mishandled, pose significant environmental risks. Governed by the International Maritime Organization’s (IMO) International Convention for the Prevention of Pollution from Ships (MARPOL), particularly Annex I, sludge and bilge management is a cornerstone of environmental compliance in the maritime industry. This article provides a comprehensive exploration of how sludge and bilge are generated, stored, treated, and disposed of onboard ships, ensuring adherence to stringent regulations while safeguarding the marine environment.

What Are Sludge and Bilge?

Sludge and bilge water are inevitable byproducts of ship operations. Sludge refers to oily residues generated from fuel and lubricating oil purification, engine operations, and other machinery-related activities. It typically consists of oil mixed with water, impurities, and other contaminants. Bilge water, on the other hand, is a mixture of water, oil, and other substances that accumulate in the lowest compartments of a ship, primarily due to leakages, condensation, and maintenance activities. Both substances must be managed carefully to prevent marine pollution, as outlined in MARPOL Annex I, which regulates the prevention of pollution by oil.

The importance of proper sludge and bilge management cannot be overstated. Mishandling these substances can lead to severe environmental damage, hefty fines, and even imprisonment for non-compliance with international regulations. This article delves into the sources of sludge and bilge, their storage, treatment methods, record-keeping requirements, and lawful disposal practices, providing a holistic understanding of these critical processes.

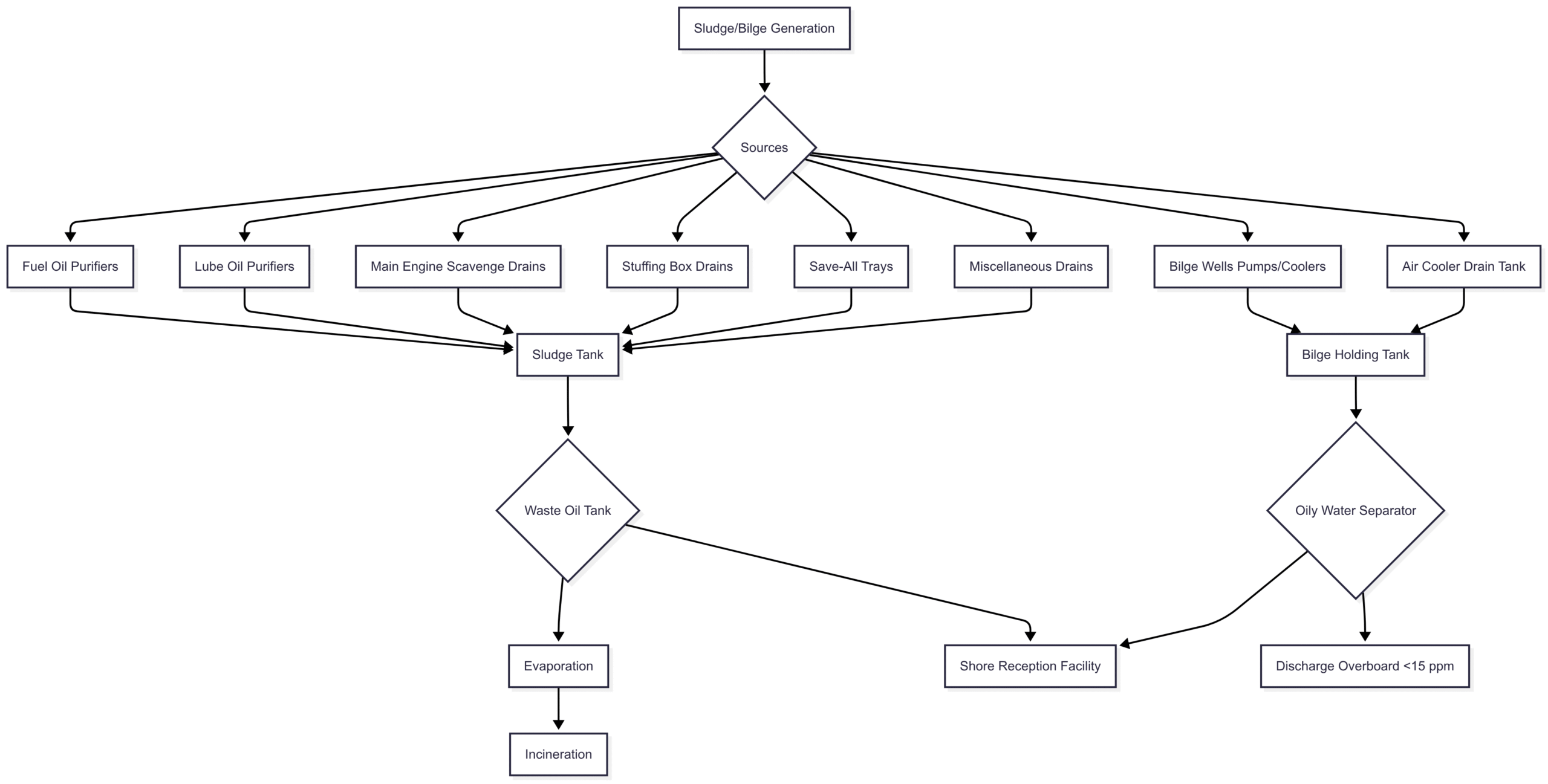

Sources of Sludge Production

Sludge is generated from multiple sources onboard a ship, primarily from the operation of machinery and fuel-handling systems. Below are the key contributors to sludge production:

1. Fuel Oil Purifiers

Fuel oil purifiers are essential for removing impurities from heavy fuel oil (HFO) before it is used in engines. These purifiers operate on a centrifugal principle, separating water and solid contaminants from the fuel. At regular intervals, determined by the quality of the fuel and operational parameters, the purifier’s bowl discharges accumulated sludge into a designated fuel oil purifier sludge tank. This sludge consists of oily water and impurities separated during the purification process.

2. Lube Oil Purifiers

Lubricating oil (LO) purifiers function similarly, removing contaminants from the lubricating oil used in the main engine and auxiliary generators. The discharge interval depends on the oil quality and engine running hours. The resulting sludge, containing oily water and impurities, is directed to a lube oil purifier sludge tank or a common sludge tank.

3. Main Engine Scavenge Drains

During the operation of a ship’s main engine, cylinder lubrication oil is scraped down from the cylinder liners and collected in the scavenge spaces. This oil residue is drained through scavenge drains for each engine unit and directed to a designated scavenge drain tank or a common sludge tank.

4. Main Engine Stuffing Box

The stuffing box, located around the piston rod, collects oil residue during engine operation. This oil is drained from each unit’s stuffing box and directed to a stuffing box drain tank or a common sludge tank.

5. Save-All Tray Drains

Fuel oil machinery, such as pumps, filters, and purifiers, is equipped with save-all trays to capture any leakages. These trays’ drains feed into sludge tanks, ensuring that oily residues are contained.

6. Miscellaneous Sources

Other sources of sludge include drains from air bottles, fuel oil settling and service tanks, and other engine room systems. These drains typically contain oily water, which is collected in sludge tanks for further processing.

The quantity of sludge generated is proportional to fuel consumption, with an industry average of approximately 1.5% of total fuel consumption. Excessive sludge production (beyond 1.5%) indicates inefficiencies or issues in fuel or machinery management, requiring investigation and optimization.

Sources of Bilge Water Production

Bilge water accumulates in the engine room’s bilge wells due to various operational and maintenance activities. The primary sources include:

1. Leakages from Pumps and Coolers

Freshwater and seawater pumps, as well as coolers, are prone to minor leakages during operation. These leakages collect in bilge wells located at strategic points, such as the forward tank top (port and starboard), the aft engine room, the recess bilge well under the flywheel, and the shaft tunnel bilge well (if applicable).

2. Condensation

Atmospheric air contains moisture, which is compressed in the turbocharger and cooled in the scavenge air coolers. This process causes condensation, forming water droplets that are directed to the air cooler drain tank. These droplets may contain oil due to oil vapor in the engine room air.

3. Maintenance Activities

Routine maintenance, such as cleaning or repairs, can introduce water and oil into bilge wells, further contributing to bilge water accumulation.

Bilge water is typically transferred to a bilge holding tank via an oily bilge pump, where it is stored for treatment or discharge. In some cases, it may be directed to a sludge tank or discharged ashore.

Storage of Sludge and Bilge

Sludge Tanks

The number and configuration of sludge tanks vary depending on the ship’s design, shipyard specifications, and engine room machinery. Some vessels have a single common sludge tank, while others use individual tanks for specific sources (e.g., fuel oil purifier sludge tank, lube oil purifier sludge tank). All sludge tanks must comply with MARPOL Annex I, Regulation 12, which mandates their inclusion in the ship’s International Oil Pollution Prevention (IOPP) Certificate. A sludge pump facilitates internal transfers between tanks or to shore reception facilities. Every transfer must be recorded in the Oil Record Book, as required by MARPOL Annex I, Regulation 17.

Bilge Tanks

Bilge water is stored in several specialized tanks, each serving a specific purpose:

- Bilge Holding Tank: Stores bilge water from bilge wells for discharge overboard (via an oily water separator) or to shore facilities.

- Bilge Primary Tank: A smaller tank used to separate oil from bilge water by gravity. The oil layer on top can be skimmed off, and the remaining water is transferred to the bilge holding tank.

- Bilge Evaporation Tank: Present on some ships, this tank allows bilge water to be heated and evaporated, reducing the volume of liquid to be processed.

- Air Cooler Drain Tank: Collects moisture from scavenge air coolers, which may contain oil due to engine room air vapor. This tank is discharged overboard via an oil content monitor or pumped to the bilge holding tank.

All bilge tanks are listed in the IOPP Certificate, and any transfers or discharges must be logged in the Oil Record Book.

Treatment of Sludge and Bilge

Sludge Treatment

Sludge typically contains water from purifiers, fuel oil settling tanks, and other sources. This water must be removed before incineration to ensure efficient burning. The process involves:

- Water Evaporation: Sludge is transferred from various sludge tanks to a waste oil tank, where it is heated to approximately 100°C using steam valves. At this temperature, water evaporates, leaving behind concentrated oily residue. If the tank temperature exceeds 100°C, it indicates that water evaporation is complete, and the oil is heating up. The volume of water evaporated is recorded in the Oil Record Book.

- Incineration Preparation: To prevent pressure buildup, the waste oil tank’s temperature must be kept below 90°C during sludge transfer. If an agitator is present, it is used to emulsify the sludge for even burning.

- Incineration Process:

- The incinerator is warmed up using diesel oil, following safety protocols and manufacturer guidelines.

- Once warmed, the waste oil feed valve is opened, allowing sludge to flow from the waste oil tank. Steam tracing ensures the waste oil line remains unclogged, and strainers are checked for blockages.

- The incinerator’s damper and temperature are adjusted per the manual, and the waste oil pump maintains a steady flow. The amount of sludge incinerated is logged in the Oil Record Book.

Incinerators must comply with MARPOL Annex VI, Regulation 16, which governs emissions from shipboard incineration.

Bilge Water Treatment

Bilge water is processed through an oily water separator (OWS), which separates oil from water to ensure the oil content is below 15 parts per million (ppm), as mandated by MARPOL Annex I, Regulation 15. The process involves:

- Transfer to Bilge Primary Tank: Bilge water is pumped from bilge wells to the bilge primary tank, where oil separates by gravity. The oil layer is skimmed off, and the water is transferred to the bilge holding tank.

- Oily Water Separator Operation: The OWS processes bilge water, and an oil content monitor (PPM monitor) ensures compliance with the 15 ppm limit. If the oil content exceeds 15 ppm, the discharge is automatically stopped.

- Discharge or Evaporation: Treated bilge water can be discharged overboard (beyond 12 nautical miles from land) or evaporated in a bilge evaporation tank, if available. All operations are recorded in the Oil Record Book, including the vessel’s position and discharge volume.

Cargo Hold Bilge Water Management

On container vessels, bilge wells in cargo holds (port and starboard) collect water from various sources, such as rainwater or condensation. These bilges are typically pumped overboard using a bilge eductor powered by the fire and general service (GS) pump, as they usually contain only water. However, a visual inspection is mandatory before pumping to ensure no oil is present. If oil is detected, the bilge water is diverted to a hold bilge collecting tank or an engine room tank for processing through the OWS.

Additional bilge wells in the bow thruster room, pipe duct, chain locker, and forepeak void space are also connected to the hold bilge line, with valves operable remotely from the ship’s office or engine control room. Direct overboard discharge is permitted only when the vessel is at sea and complies with local and international anti-pollution regulations.

Record-Keeping and Compliance

The Oil Record Book is a critical component of sludge and bilge management, ensuring transparency and compliance with MARPOL Annex I, Regulation 17. Key entries include:

- Transfers between sludge and bilge tanks.

- Water evaporation quantities.

- Incineration volumes and operational details.

- Bilge water discharges (overboard or to shore), including the vessel’s position, time, and volume.

- OWS operation details, including start/stop times and oil content readings.

Non-compliance with MARPOL regulations can result in severe penalties, including fines, vessel detention, or imprisonment. Port state control inspections verify adherence to these requirements, making accurate record-keeping essential.

Disposal Options

1. Incineration

Onboard incineration is a common method for sludge disposal, provided it meets MARPOL Annex VI emission standards. The process is tightly controlled to ensure safety and efficiency, with all incineration activities logged in the Oil Record Book.

2. Shore Reception Facilities

Sludge and bilge water can be offloaded to approved shore reception facilities, ensuring no oily residues enter the marine environment. This option is often used in ports with strict environmental regulations.

3. Overboard Discharge

Bilge water discharge is permitted under specific conditions:

- The vessel must be en route and beyond 12 nautical miles from the nearest land.

- The oil content must be below 15 ppm, as verified by the PPM monitor.

- The discharge must comply with local regulations and be recorded in the Oil Record Book.

Technological Advances in Sludge and Bilge Management

Advancements in technology are improving the efficiency and environmental impact of sludge and bilge management. Modern oily water separators are more effective at reducing oil content, while advanced incinerators produce fewer emissions. Some ships are equipped with automated monitoring systems that integrate with the Oil Record Book, streamlining record-keeping and ensuring compliance. Additionally, research into alternative fuels and lubricants aims to reduce sludge production, further minimizing the environmental footprint of maritime operations.

Diagram: Sludge and Bilge Management Workflow

Below is a flowchart illustrating the sludge and bilge management process onboard ships, created using syntax.

Table: Key MARPOL Regulations for Sludge and Bilge Management

| Regulation | Description | Key Requirements |

|---|---|---|

| MARPOL Annex I, Regulation 12 | Sludge Tank Requirements | Ships must have designated sludge tanks listed in the IOPP Certificate. |

| MARPOL Annex I, Regulation 15 | Bilge Water Discharge | Discharge permitted beyond 12 nautical miles with oil content <15 ppm. |

| MARPOL Annex I, Regulation 17 | Oil Record Book | All transfers, discharges, and incineration must be recorded. |

| MARPOL Annex VI, Regulation 16 | Incinerator Emissions | Incinerators must comply with emission standards. |

Conclusion

Effective sludge and bilge management is a cornerstone of responsible maritime operations, ensuring compliance with MARPOL regulations and protecting the marine environment. By understanding the sources, storage, treatment, and disposal processes, ship operators can minimize environmental risks and maintain operational efficiency. As technology continues to evolve, the maritime industry is poised to adopt more sustainable practices, reducing the environmental impact of sludge and bilge water. Through diligent record-keeping, adherence to international standards, and the use of advanced systems, ships can navigate the seas responsibly, safeguarding the oceans for future generations.

References

- MARPOL Annex I, “Regulations for the Prevention of Pollution by Oil”

- International Convention for the Prevention of Pollution from Ships (MARPOL)

- SOLAS (Safety of Life at Sea) Convention

- IMO Guidelines for the Implementation of MARPOL Annex I

- Marine Insight (marineinsight.com)

Happy Boating!

Share An Overview Of Sludge And Bilge Management Onboard Ships with your friends and leave a comment below with your thoughts.

Read Marine Fire Pumps: The Ultimate Guide until we meet in the next article.