Sikaflex 291 vs 295: A Comprehensive Comparison

Compare Sikaflex 291 vs. 295 UV: key features, applications, performance, and costs for marine sealants. Find the best choice for your boat!

In the marine industry, sealants are critical for ensuring the durability, safety, and aesthetics of boats. Among the top contenders, Sikaflex, a trusted name in polyurethane sealants, offers two standout products: Sikaflex 291 and Sikaflex 295 UV. While both are designed to withstand the harsh marine environment, they cater to different applications and needs. This article provides an in-depth comparison of Sikaflex 291 and Sikaflex 295 UV, covering their features, applications, performance, costs, and more to help boat owners and builders make an informed choice.

Understanding Sikaflex and Marine Sealants

Marine sealants are engineered to endure extreme conditions such as saltwater exposure, UV radiation, temperature fluctuations, and constant mechanical stress. Sikaflex, manufactured by Sika, is a polyurethane-based adhesive and sealant renowned for its versatility, durability, and ease of use. Its ability to bond with various substrates and maintain flexibility makes it a preferred choice for marine applications, from sealing deck fittings to bonding windows.

Marine sealants serve multiple purposes:

- Preventing Water Ingress: They create watertight seals to protect against corrosion, rot, and mold.

- Structural Integrity: Sealants maintain the boat’s structural strength by bonding components securely.

- Aesthetic Enhancement: They provide a clean, professional finish, enhancing the boat’s appearance.

Sikaflex stands out due to its exceptional resistance to harsh marine conditions, ease of application via standard caulking guns, and availability in various colors to match boat finishes. However, choosing between Sikaflex 291 and 295 UV requires understanding their specific strengths and applications.

Sikaflex 291: The All-Purpose Marine Sealant

Sikaflex 291 (now often labeled as Sikaflex 291i, indicating a reformulated version) is a versatile, non-structural polyurethane sealant designed primarily for above-the-waterline applications. It is widely regarded as the “default” Sikaflex for marine DIY projects due to its balance of sealing and adhesive properties.

Key Features of Sikaflex 291

- Superior Adhesion: Bonds effectively to a wide range of substrates, including fiberglass, wood, metal, and most plastics (excluding acrylic and polycarbonate due to potential chemical reactions).

- Flexibility and Elasticity: Accommodates movement without compromising the seal, ideal for dynamic marine environments.

- UV Resistance: Resists degradation from sunlight, ensuring long-term performance.

- Ease of Application: Smooth, creamy consistency allows for easy application and tooling for a professional finish.

- Saltwater Resistance: Engineered to withstand corrosive saltwater, preventing deterioration over time.

- Versatility: Suitable for sealing deck fittings, hull joints, hatches, and portholes.

Applications

Sikaflex 291 is ideal for above-the-waterline tasks such as:

- Sealing deck hardware (cleats, winches, rope clutches).

- Bonding hull joints and deck fittings.

- General-purpose sealing in areas not constantly submerged.

Pros and Cons

Pros:

- Strong adhesion across diverse substrates.

- Flexible and elastic, accommodating boat movement.

- Excellent resistance to UV, saltwater, and weathering.

- Easy to apply and tool for a clean finish.

- Versatile for a range of non-structural applications.

Cons:

- Longer curing time compared to some alternatives (e.g., 3M 4200 Fast Cure).

- Requires proper surface preparation for optimal adhesion.

- Not suitable for below-the-waterline applications.

- Incompatible with acrylic and polycarbonate, potentially causing cracking.

Performance Insights

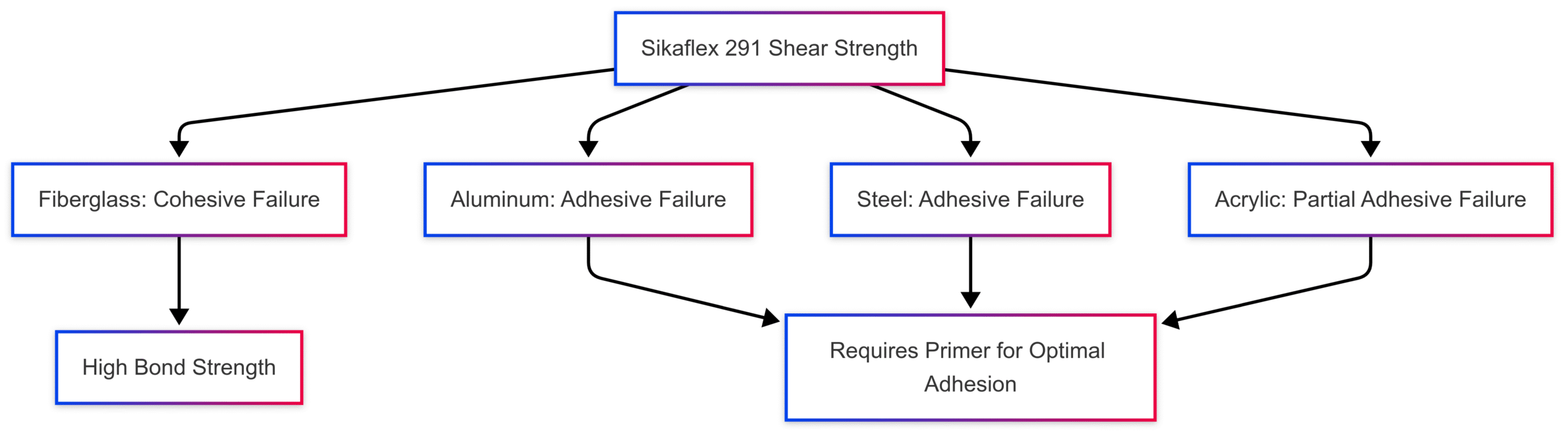

Sikaflex 291 performs exceptionally well in shear tests, often failing cohesively (the sealant tears rather than peels from the substrate), indicating strong adhesion. Testing by Practical Sailor showed it bonding well to fiberglass and wood but less effectively to metals like aluminum and steel without priming. Its elasticity ensures it can handle the stresses of boat movement, making it a reliable choice for above-the-waterline sealing.

Sikaflex 295 UV: The Specialist for Glazing and Below-the-Waterline

Sikaflex 295 UV (sometimes labeled as 295i UV, with potential regional naming variations) is a high-performance polyurethane adhesive and sealant formulated for below-the-waterline applications and bonding plastic glazing materials like acrylic and polycarbonate. Its UV resistance and strong bonding capabilities make it ideal for demanding tasks.

Key Features of Sikaflex 295 UV

- Excellent Water Resistance: Provides a watertight seal, critical for below-the-waterline applications.

- Superior Bonding Strength: Offers robust adhesion, suitable for high-stress environments.

- Enhanced UV Resistance: Specifically designed to resist UV degradation, making it ideal for exposed applications like windows.

- Compatibility with Plastics: Safe for bonding acrylic and polycarbonate without causing crazing or cracking.

- Ease of Application: Similar to 291, it has a smooth consistency for easy application and professional finishing.

Applications

Sikaflex 295 UV is tailored for:

- Bonding acrylic and polycarbonate windows directly to gelcoat or other substrates without mechanical fasteners.

- Sealing keel joints, through-hull fittings, and hull-to-deck joints below the waterline.

- Applications requiring high UV resistance and strong adhesion.

Pros and Cons

Pros:

- Exceptional water resistance for below-the-waterline use.

- Strong bonding strength for high-stress applications.

- Superior UV resistance, ideal for glazing and exposed areas.

- Compatible with acrylic and polycarbonate.

- Easy to apply and tool for a neat finish.

Cons:

- Not suitable for above-the-waterline applications where flexibility is prioritized over adhesion.

- Requires careful surface preparation for optimal performance.

- Shorter shelf life compared to some sealants.

- Slightly higher cost due to specialized formulation.

Performance Insights

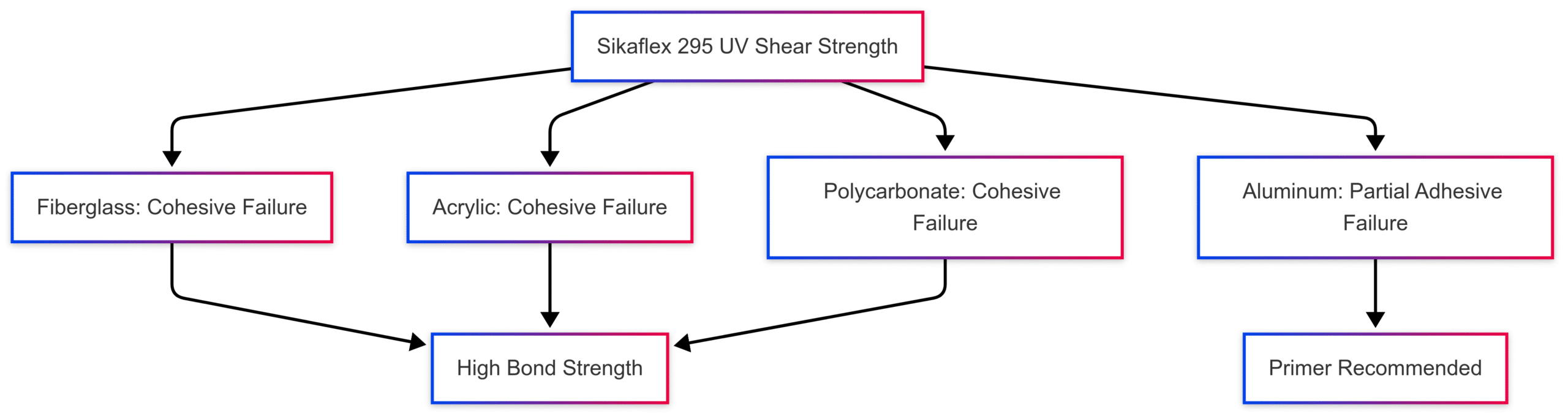

Sikaflex 295 UV excels in below-the-waterline applications, offering cohesive failure in shear tests across most substrates, including fiberglass and acrylic. Its compatibility with plastics makes it the go-to choice for glazing, as it avoids the chemical reactions that Sikaflex 291 may cause with acrylic or polycarbonate. Practical Sailor tests confirmed its strong adhesion to fiberglass and acrylic, though metal bonding may require priming.

Sikaflex 291 vs. 295 UV: Head-to-Head Comparison

To choose between Sikaflex 291 and 295 UV, it’s essential to compare their performance, applications, and costs directly.

Performance Comparison

Both sealants are polyurethane-based, offering excellent flexibility and durability in marine environments. However, their intended applications differ significantly:

- Sikaflex 291: Best for above-the-waterline sealing, such as deck fittings and hull joints. It provides a strong, elastic bond but is not suitable for continuous submersion or bonding acrylic/polycarbonate due to potential chemical reactions.

- Sikaflex 295 UV: Designed for below-the-waterline applications and glazing, with enhanced UV resistance and compatibility with plastics. Its stronger adhesive properties make it suitable for high-stress bonding tasks.

Table 1: Performance Comparison

| Feature | Sikaflex 291 | Sikaflex 295 UV |

|---|---|---|

| Primary Use | Above-the-waterline sealing | Below-the-waterline, glazing |

| Adhesion Strength | Moderate (non-structural) | High (structural) |

| Flexibility | High | Moderate (prioritizes adhesion) |

| UV Resistance | Good | Excellent |

| Water Resistance | Good (not for continuous submersion) | Excellent |

| Substrate Compatibility | Fiberglass, wood, metal, most plastics | Fiberglass, acrylic, polycarbonate, metal |

| Curing Time | 3-5 days (full cure ~1 month) | 3-5 days (full cure ~1 month) |

Cost Analysis

Pricing for Sikaflex products varies by region and supplier, but Sikaflex 295 UV is generally more expensive due to its specialized formulation for glazing and below-the-waterline use.

Table 2: Cost Comparison (Approximate RRP per 300ml Cartridge)

| Product | Price (USD) | Notes |

|---|---|---|

| Sikaflex 291 | $12.70 | Widely available, cost-effective |

| Sikaflex 295 UV | $15.50 | Higher cost due to UV and plastic compatibility |

While Sikaflex 295 UV has a higher upfront cost, its durability in demanding applications (e.g., below-the-waterline or glazing) may reduce maintenance costs over time. Sikaflex 291, being more affordable, is ideal for general-purpose sealing where extreme conditions are not a factor.

Application Techniques

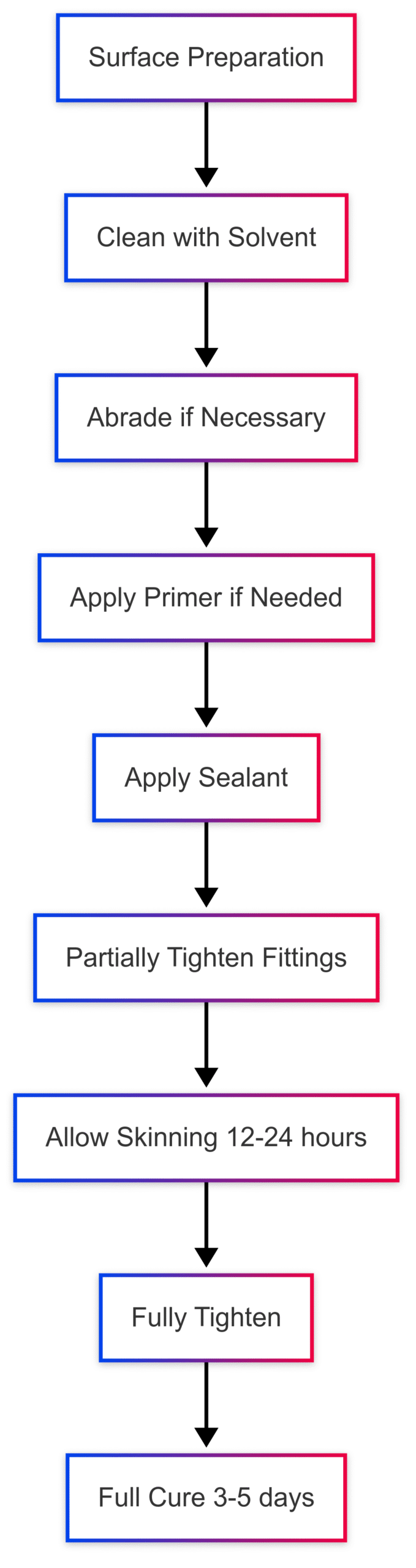

Proper application is critical for both sealants to achieve optimal performance:

- Surface Preparation: Clean surfaces with a solvent like Sika Cleaner-205 or 3M Scotch-Weld Cleaner to remove grease, dust, or mold-release agents. For metals, abrading with 400-grit sandpaper can enhance adhesion.

- Priming: Sikaflex 295 UV may require a primer (e.g., Sika Primer-206 G+P) for metals, while Sikaflex 291 benefits from priming on challenging substrates like aluminum.

- Application: Use a standard caulking gun, applying a uniform bead. For bolts or fittings, apply sealant to the hole and bolt shaft, partially tighten to 1/8”–1/4” gap, allow to skin over (12–24 hours), then tighten fully to avoid squeezing out the sealant.

- Curing: Both products skin over within hours but require 3–5 days for a full cure, depending on humidity. Polyurethanes cure faster in moist environments, so misting or increasing humidity can accelerate curing.

Choosing the Right Sealant: Factors to Consider

Selecting between Sikaflex 291 and 295 UV depends on several factors:

- Application Type: Use Sikaflex 291 for above-the-waterline tasks like deck fittings; choose Sikaflex 295 UV for below-the-waterline or glazing applications.

- Substrate Compatibility: Sikaflex 295 UV is essential for acrylic or polycarbonate bonding to avoid chemical reactions.

- Environmental Exposure: Sikaflex 295 UV’s superior UV resistance makes it better for exposed areas like windows.

- Flexibility Needs: Sikaflex 291 offers greater elasticity for dynamic joints, while 295 UV prioritizes adhesion strength.

- Budget: Sikaflex 291 is more cost-effective for general use, while 295 UV’s higher cost is justified for specialized tasks.

Practical Tips from Users

Marine forums highlight user experiences that can guide your decision:

- Sikaflex 291: Praised for its versatility and ease of use in DIY projects. Users recommend storing partially used tubes in a freezer to extend shelf life, as polyurethane sealants cure with moisture.

- Sikaflex 295 UV: Preferred for bonding plastic windows and below-the-waterline fittings. Users emphasize proper surface preparation and the use of spacers to maintain adhesive thickness.

Alternatives to Sikaflex

While Sikaflex 291 and 295 UV are top performers, other sealants may suit specific needs:

- 3M 4200 Fast Cure: A polyurethane sealant for above- and below-the-waterline use, offering moderate adhesion and faster curing than Sikaflex 291. RRP: ~$9.69/300ml.

- 3M 5200: A high-strength adhesive for permanent below-the-waterline bonding, but difficult to remove. RRP: ~$19.09/300ml.

- Loctite PL S40: A budget-friendly polyurethane sealant with good performance above and below the waterline. RRP: ~$7/300ml.

- Dow 795 Silicone: Best for glazing due to easy removal and excellent UV resistance. RRP: ~$10/300ml.

- Butyl Tape: Ideal for bedding hardware like hatches, easy to remove, but not suitable for below-the-waterline use. RRP: ~$5–10/roll.

Table 3: Alternative Sealants Comparison

| Sealant | Primary Use | Adhesion Strength | UV Resistance | Price (USD/300ml) |

|---|---|---|---|---|

| 3M 4200 Fast Cure | Above/below waterline | Moderate | Good | $9.69 |

| 3M 5200 | Below waterline, permanent bond | High | Moderate | $19.09 |

| Loctite PL S40 | Above/below waterline | Moderate | Good | $7.00 |

| Dow 795 Silicone | Glazing, plastic lenses | Moderate | Excellent | $10.00 |

| Butyl Tape | Bedding hardware | Low | Moderate | $5–10/roll |

Final Verdict

Both Sikaflex 291 and 295 UV are exceptional marine sealants, but their applications differ:

- Choose Sikaflex 291 for general-purpose, above-the-waterline sealing where flexibility and cost-effectiveness are priorities. It’s ideal for deck fittings, hull joints, and non-plastic substrates.

- Choose Sikaflex 295 UV for below-the-waterline applications or bonding acrylic/polycarbonate windows, where superior UV resistance and strong adhesion are critical.

Proper surface preparation, priming (if needed), and application techniques are essential for both products to achieve optimal performance. For budget-conscious users, Sikaflex 291 offers excellent value, while Sikaflex 295 UV’s specialized features justify its higher cost for demanding tasks. By aligning your choice with your project’s specific requirements, you can ensure a durable, watertight, and professional result.

Happy Boating!

Share Sikaflex 291 vs 295: A Comprehensive Comparison with your friends and leave a comment below with your thoughts.

Read IntelliSteer Type S Wireless Steering System – INTTYPES until we meet in the next article.

Clear and helpful comparison! Made it easy to understand the differences between Sikaflex 291 and 295. Great for anyone choosing the right sealant for their project.