Ship Repair and Dry Docking: Vessel Safety

Ship repair and dry docking are critical processes in the maritime industry, ensuring vessels remain safe, efficient, and compliant with international regulations. These procedures involve intricate planning, specialized facilities, and skilled professionals to maintain and repair ships, extending their operational life and ensuring the safety of crews and cargo. This comprehensive guide delves into the intricacies of ship repair and dry docking, exploring the processes, types of dry docks, regulatory requirements, cost considerations, and technological advancements that optimize these operations. Whether you’re a ship owner, operator, or maritime enthusiast, this article provides a detailed understanding of these essential maritime practices.

What is Ship Repair and Dry Docking?

Ship repair encompasses the maintenance and restoration of a vessel’s hull, machinery, and systems to ensure operational readiness and safety. This can include fixing structural damage, overhauling engines, or upgrading navigation systems. Dry docking, a subset of ship repair, involves removing a ship from the water and placing it in a controlled, dry environment—typically a dry dock—for maintenance tasks that cannot be performed afloat, such as hull cleaning, painting, and inspecting underwater components.

Dry docking is analogous to taking a car to a garage for servicing, but on a much larger and more complex scale. The process exposes the ship’s underwater areas, allowing for thorough inspections, repairs, and upgrades. It is a mandatory requirement for commercial vessels to comply with regulations set by bodies like the International Maritime Organization (IMO) and classification societies, ensuring seaworthiness and safety.

Importance of Ship Repair and Dry Docking

- Safety: Regular maintenance prevents structural or mechanical failures that could endanger crew, cargo, or the environment.

- Regulatory Compliance: Dry docking ensures vessels meet stringent standards set by the IMO and classification societies, such as SOLAS (Safety of Life at Sea) requirements.

- Operational Efficiency: Well-maintained ships perform optimally, reducing fuel consumption and operational costs.

- Longevity: Routine repairs and inspections extend a vessel’s operational life, protecting the owner’s investment.

- Emergency Response: Dry docks facilitate urgent repairs for vessels damaged by collisions, groundings, or other incidents.

Types of Dry Docks

Dry docks are specialized structures designed to lift ships out of the water. The two primary types used for seagoing vessels are graving docks and floating docks, each with unique features, advantages, and limitations.

Graving Docks

Graving docks are permanent, land-based basins constructed from concrete or steel, typically located near coastal waters. They feature watertight gates that allow the basin to be flooded, enabling a ship to float in. Once the ship is positioned over keel blocks, the water is pumped out, leaving the vessel resting on these supports.

Advantages of Graving Docks

- Capacity for Large Vessels: Graving docks can accommodate large ships, such as oil tankers and container ships.

- Cost-Effective for Large Repairs: They are often more economical for extensive repairs or retrofitting due to their proximity to shipyards and access to resources.

- Accessibility: Located near industrial areas, graving docks benefit from readily available skilled labor, spare parts, and equipment.

- Advanced Facilities: Modern graving docks include workshops, cranes, and retractable ramps, streamlining repair processes.

- Multi-Vessel Capability: Larger docks can service multiple ships simultaneously, with some featuring dual gates for independent operations.

Disadvantages of Graving Docks

- Time-Consuming Refloating: Reflooding the dock requires removing all equipment, which can delay operations.

- High Maintenance Costs: Aging docks require significant upkeep, particularly for gates and pumping systems.

- Operational Dependency on Gates: A malfunctioning gate can render the entire dock inoperable.

- Limited Flexibility: If multiple ships are docked, refloating one requires stopping all operations to flood the basin.

Floating Dry Docks

Floating dry docks are buoyant, U-shaped structures made of steel, equipped with ballast tanks to submerge and raise the dock. The ship is floated into the dock, which is then raised by pumping water out of the tanks, lifting the vessel clear of the water.

Advantages of Floating Docks

- Portability: They can be moved to a vessel’s location, ideal for salvage operations or remote repairs.

- Space-Saving: Positioned in harbors, they don’t occupy valuable shore space.

- Flexibility: Floating docks can be resized, split into independent units, or retrofitted for larger vessels.

- Cost-Effective Maintenance: Maintenance costs are lower than graving docks, and they offer higher resale value.

Disadvantages of Floating Docks

- Limited Access: Supplies and personnel typically enter via a single gangway, slowing operations.

- Weather Sensitivity: Tides or strong winds can disrupt docking processes.

- Ship-Like Maintenance: The dock’s hull, submerged in saltwater, requires regular maintenance similar to a ship.

- Time-Intensive Refloating: Equipment must be removed before reflooding, adding to downtime.

Other Types of Dry Docks

- Marine Rail Docks: Used for smaller vessels (up to 5,000 tons), these involve hauling a ship onto a cradle along an inclined track.

- Shiplifts: Platforms that lift smaller vessels, such as yachts or tugs, out of the water.

- Marine Mobile Lifts: Primarily used for recreational boats or small commercial vessels, offering mobility and flexibility.

Choosing the Right Dry Dock

The choice of dry dock depends on several factors:

- Vessel Size: Graving docks are preferred for large vessels, while marine rail docks or shiplifts suit smaller ones.

- Vessel Condition: Floating docks are ideal for immobilized or damaged ships.

- Repair Type: Major retrofitting favors graving docks due to their proximity to resources, while routine maintenance can use floating docks.

- Schedule and Budget: Graving docks may be more cost-effective for large-scale repairs, but floating docks offer flexibility for urgent or remote operations.

The Dry Docking Process

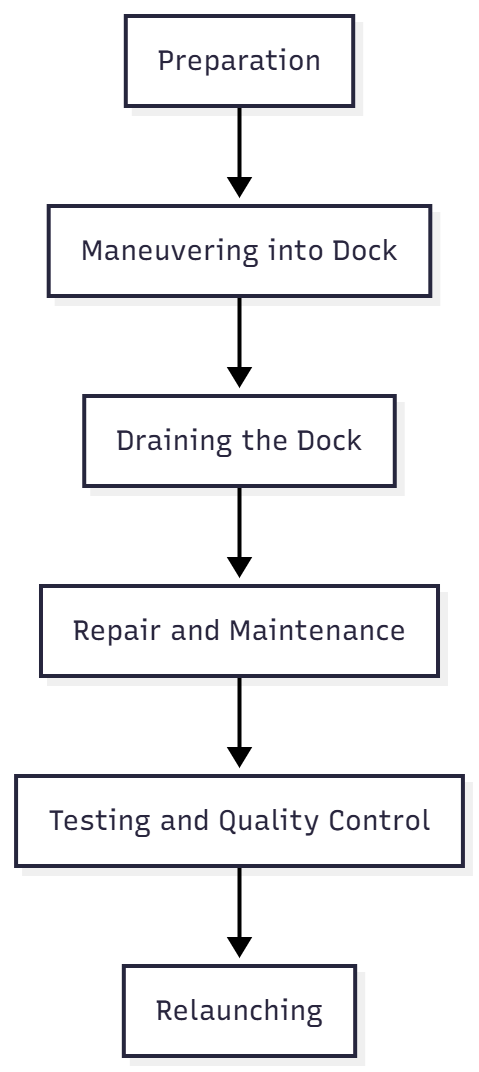

Dry docking is a meticulously planned operation involving multiple stages, from preparation to relaunch. Below is a detailed breakdown of the process:

1. Preparation

Before entering the dry dock, the ship’s crew and shore personnel, such as Technical Superintendents, conduct a thorough inspection to draft a repair specification plan. This plan identifies necessary repairs, prioritizes tasks, and allocates resources. Key preparatory steps include:

- Hull Inspection: Assessing the hull for corrosion, dents, or structural damage.

- Propulsion System Evaluation: Checking propellers, shafts, and bearings for wear or damage.

- Electrical and Navigation Checks: Ensuring systems like radar, communication devices, and electrical wiring meet standards.

- Safety System Assessment: Verifying fire suppression systems, lifeboats, and other safety equipment.

- Ballast Tank Inspection: Conducting ultrasonic thickness measurements to identify steel renewal needs.

- Vessel Preparation: Reducing ballast, removing cargo, and ensuring the ship is upright with a slight aft trim for stability.

2. Maneuvering into the Dock

The ship is carefully positioned over keel blocks arranged according to its docking plan. For graving docks, the basin is flooded, the ship floats in, and the gate is closed. For floating docks, the dock is partially submerged, allowing the ship to enter before the dock is raised.

3. Draining the Dock

Once the ship is secured, water is pumped out, transferring the vessel’s weight from water buoyancy to the keel blocks. This is a critical phase, as improper block placement can cause the ship to tip or sustain damage.

4. Repair and Maintenance

With the hull exposed, workers perform tasks such as:

- Hull Cleaning: Using high-pressure water jetting or grit blasting to remove marine growth and corrosion.

- Painting: Applying anti-corrosive and anti-fouling coatings to protect the hull.

- Structural Repairs: Welding or replacing damaged hull sections, ballast tanks, or double bottoms.

- Propulsion System Overhaul: Repairing or replacing propellers, rudders, and tail shafts.

- Underwater Fittings: Inspecting and replacing stern seals, anodes, or sea suction valves.

- Tank Cleaning and Surveys: Ensuring ballast and cargo tanks meet regulatory standards.

5. Testing and Quality Control

After repairs, the ship undergoes rigorous testing to verify compliance with safety and performance standards. This includes pressure tests, electrical system checks, and propulsion trials.

6. Relaunching

The dock is reflooded, allowing the ship to float. The gate is opened, and the vessel is towed out for sea trials to confirm all repairs are effective.

The flowchart above illustrates the sequential stages of the dry docking process, highlighting the structured approach required for efficient execution.

Regulatory Requirements

Dry docking is governed by strict regulations to ensure vessel safety and environmental protection. The IMO’s SOLAS requirements mandate:

- Merchant Vessels: A complete hull survey twice within five years, with an intermediate survey within 36 months.

- Passenger Vessels: Annual bottom inspections, with two dry dock surveys within five years, spaced no more than three years apart.

Classification societies, such as Lloyd’s Register or DNV, enforce these standards, issuing safety construction certificates upon compliance. Non-compliance can result in penalties, operational restrictions, or loss of certification.

Cost Considerations

Dry docking is a significant expense, with costs varying based on vessel size, repair scope, and location. Below is a breakdown of typical cost categories:

| Cost Category | Description | Estimated Range (USD) |

|---|---|---|

| Shipyard Fees | Charges for dock usage, docking, and undocking processes | $50,000 – $500,000 |

| Labor Costs | Wages for shipyard workers, contractors, and crew | $100,000 – $1,000,000 |

| Materials and Spare Parts | Costs for steel, paint, anodes, and replacement components | $50,000 – $2,000,000 |

| Upgrades and Modifications | Expenses for retrofitting or regulatory compliance upgrades | $100,000 – $5,000,000 |

| Lost Revenue | Income lost due to vessel downtime (varies by vessel type and charter rates) | $10,000 – $100,000/day |

Budgeting Strategies

- Detailed Repair Specifications: A comprehensive plan reduces unexpected costs by identifying all repair needs upfront.

- Shipyard Selection: Choosing a reputable shipyard with competitive pricing and expertise minimizes delays and cost overruns.

- Proactive Maintenance: Regular inspections reduce the need for extensive repairs, lowering overall costs.

- Digital Tools: Software like ShipManager Drydock helps manage budgets, track progress, and compare supplier quotes.

Safety Protocols

Dry docking involves significant risks, including confined space hazards, heavy machinery, and hot work (e.g., welding). Robust safety protocols are essential to protect workers and the vessel:

- Permit-to-Work Systems: Required for high-risk tasks like welding or confined space entry.

- Personal Protective Equipment (PPE): Mandatory use of helmets, gloves, and safety harnesses.

- Safety Audits: Regular inspections ensure compliance with safety standards.

- Emergency Response Plans: Drills and protocols prepare teams for accidents or equipment failures.

Leveraging Technology for Efficiency

Modern technology enhances dry dock planning and execution, reducing downtime and costs. Key tools include:

- Ship Management Software: Platforms like ShipManager Drydock integrate modules for planned maintenance, procurement, and project management, enabling real-time collaboration and data-driven decisions.

- Predictive Maintenance: Sensors and analytics predict component failures, allowing proactive repairs.

- Digital Checklists: Mobile apps streamline inspections and ensure accurate data collection.

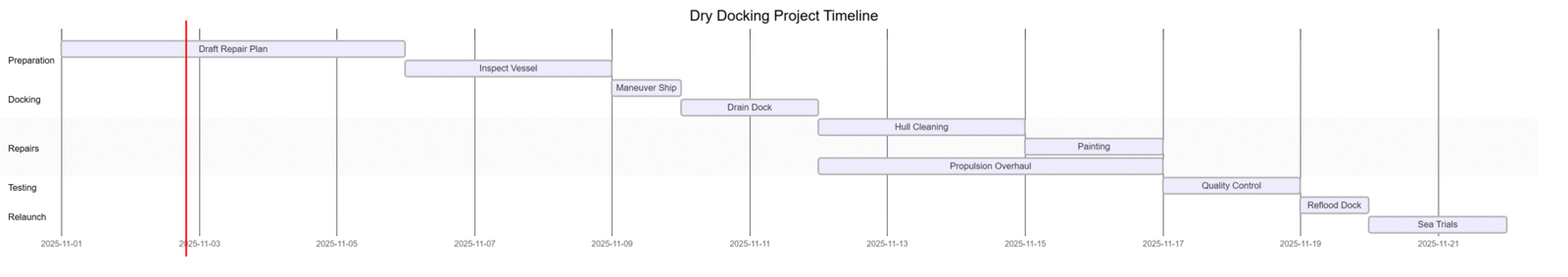

- Gantt Charts: Visual tools track project milestones and timelines, improving resource allocation.

This chart outlines a typical dry docking timeline, illustrating task dependencies and durations to optimize project management.

Managing Challenges and Delays

Unforeseen challenges, such as equipment failures or supply chain disruptions, can derail dry docking projects. Strategies to mitigate these include:

- Contingency Planning: Maintain backup equipment and secondary suppliers to address shortages.

- Proactive Communication: Regular updates with stakeholders prevent misunderstandings and delays.

- Milestone Tracking: Use project management tools to monitor progress and address issues promptly.

Continuous Improvement

Post-dry dock reviews are critical for refining future operations. Key practices include:

- Documenting Lessons Learned: Centralized databases store insights from past projects.

- Feedback Integration: Incorporate stakeholder suggestions into future plans.

- Training Programs: Equip teams with skills based on identified improvement areas.

Frequently Asked Questions

Dry docking is essential for inspecting, cleaning, and repairing a ship’s hull and underwater components that are inaccessible while the vessel is afloat. It ensures safety, regulatory compliance, and operational efficiency by addressing issues like corrosion, marine growth, and mechanical wear, while also allowing for upgrades to improve performance.

Merchant ships: twice every 5 years, with an intermediate survey within 36 months. Passenger ships: annual bottom checks, two dry dock surveys in 5 years.

Graving docks (land-based basins) and floating docks (buoyant structures). Smaller vessels use marine rail docks, shiplifts, or mobile lifts.

Vessel size, repair scope, shipyard fees ($50,000–$500,000), labor ($100,000–$1M), materials ($50,000–$2M), and downtime ($10,000–$100,000/day).

Software, predictive analytics, digital twins, drones, and mobile apps streamline planning, inspections, and workflows, cutting downtime and costs.

Conclusion

Ship repair and dry docking are indispensable for maintaining vessel safety, efficiency, and regulatory compliance. By understanding the types of dry docks, adhering to meticulous planning, leveraging technology, and prioritizing safety, ship owners and operators can optimize these complex operations. A well-executed dry docking process minimizes downtime, controls costs, and extends a vessel’s operational life, ensuring it meets the demands of the competitive maritime industry. Through continuous improvement and strategic resource management, the maritime sector can achieve safer, more sustainable, and efficient vessel operations, safeguarding crews, cargo, and the environment.

Happy Boating!

Share Ship Repair and Dry Docking with your friends and leave a comment below with your thoughts.

Read Ship Surveying until we meet in the next article.