Ship Propulsion Loss: Guideline on Reducing Risks

Learn about ship propulsion loss, its causes, consequences, and effective prevention strategies to ensure maritime safety and reliability.

Ship propulsion systems are the lifeblood of maritime operations, driving vessels across vast oceans and through challenging waterways. However, propulsion loss—defined as the unexpected failure or reduction in a ship’s ability to maneuver due to propulsion system issues—poses significant risks to safety, economic stability, and environmental integrity. This article provides an in-depth exploration of propulsion loss, its causes, consequences, and actionable strategies to mitigate risks, ensuring safer and more reliable maritime operations.

Introduction to Ship Propulsion

Ship propulsion involves a complex interplay of mechanical, electrical, and fuel systems that work together to move a vessel. From traditional diesel engines to modern hybrid and electric systems, propulsion technologies have evolved to meet the demands of efficiency and environmental regulations. However, the complexity of these systems introduces vulnerabilities that can lead to propulsion loss, resulting in navigational hazards, operational delays, and environmental damage. Understanding these systems and their potential failure points is critical for maritime professionals aiming to maintain operational reliability.

Types of Propulsion Systems

- Diesel Engines: The most common propulsion system, relying on internal combustion to drive propellers. These systems are robust but susceptible to mechanical wear and fuel issues.

- Gas Turbines: Used in high-speed vessels, offering efficiency but requiring precise maintenance.

- Electric Propulsion: Increasingly popular in modern vessels, these systems rely on electrical power but are vulnerable to electrical faults.

- Hybrid Systems: Combining diesel and electric propulsion, these systems offer flexibility but add complexity to maintenance.

Each system has unique components, such as crankshafts, pistons, fuel injectors, and control systems, that must be meticulously maintained to prevent failures.

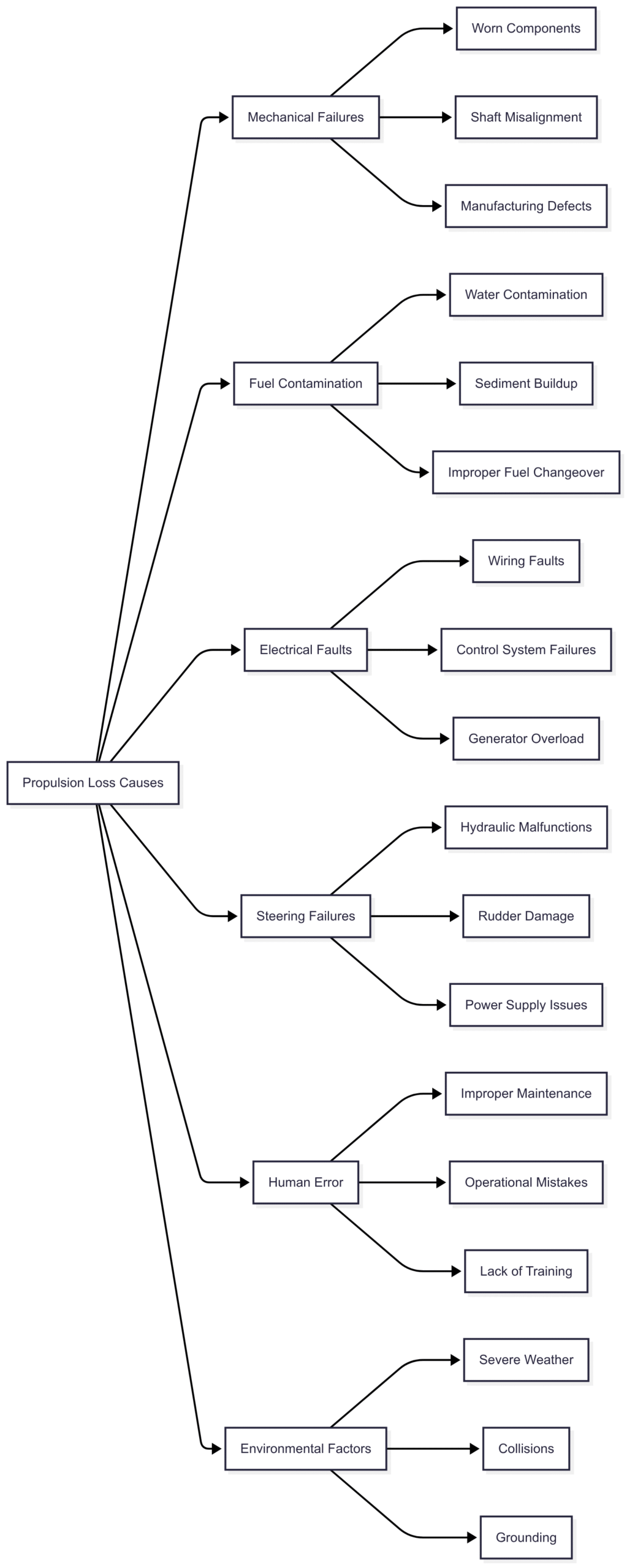

Causes of Propulsion Loss

Propulsion loss can result from a variety of factors, ranging from mechanical breakdowns to human error. Below, we explore the primary causes in detail.

Mechanical and Equipment Failures

Mechanical failures are among the leading causes of propulsion loss. Components such as bearings, pistons, and shafts wear out over time due to constant stress and friction. Inadequate maintenance or manufacturing defects can exacerbate these issues, leading to reduced engine performance or complete failure. For instance, a worn crankshaft can cause catastrophic engine failure, halting propulsion entirely.

Key Mechanical Issues:

- Worn Components: Bearings and pistons degrade over time, reducing efficiency.

- Shaft Misalignment: Improper alignment can cause excessive vibration and damage.

- Manufacturing Defects: Faulty parts can fail under operational stress.

Fuel and Lubrication Issues

Fuel quality is critical to engine performance. Contaminated fuel—containing water, sediments, or microbial growth—can clog fuel lines, injectors, and filters, leading to engine stalling or failure. Improper lubrication, such as using low-quality oil or failing to maintain proper oil levels, can increase friction and cause overheating or component failure.

Fuel-Related Challenges:

- Water Contamination: Leads to corrosion and microbial growth.

- Sediment Buildup: Clogs fuel systems, reducing efficiency.

- Improper Fuel Changeover: Switching between fuel types without proper procedures can disrupt engine operation.

Electrical and Control System Failures

Modern ships rely heavily on electrical systems to control propulsion. Faulty wiring, circuit board failures, or issues with electronic control units (ECUs) can cause sudden power loss. Blackouts, often triggered by overloaded generators or faulty Automatic Voltage Regulators (AVRs), can disable propulsion systems entirely.

Common Electrical Issues:

- Wiring Faults: Short circuits or corrosion can disrupt power supply.

- Control System Failures: Malfunctions in ECUs can misinterpret commands, halting propulsion.

- Generator Overload: Insufficient load-shedding protocols can lead to blackouts.

Steering and Rudder System Failures

While propulsion systems drive the ship, steering systems ensure directional control. Failures in hydraulic systems, steering motors, or rudders can render a vessel uncontrollable, even if propulsion is intact. For example, a hydraulic leak in the steering gear can prevent the rudder from responding to helm commands.

Steering System Vulnerabilities:

- Hydraulic Malfunctions: Leaks or pressure loss impair rudder movement.

- Rudder Damage: Physical impacts can compromise steering integrity.

- Power Supply Issues: Loss of power to steering motors disables control.

Human Error

Human error, often stemming from inadequate training or procedural lapses, is a significant contributor to propulsion loss. Crew members unfamiliar with engine room systems or emergency protocols may mishandle equipment or fail to respond effectively to issues. For example, incorrect fuel changeover procedures can introduce air into fuel lines, causing engine failure.

Common Human Errors:

- Improper Maintenance: Skipping scheduled checks or using incorrect procedures.

- Operational Mistakes: Mishandling controls during critical operations.

- Lack of Training: Inadequate knowledge of emergency response protocols.

Environmental Factors

External conditions, such as severe weather, strong currents, or collisions with debris, can damage propulsion systems or exacerbate existing issues. For instance, heavy seas can strain engines, while grounding can damage propellers or shafts.

Environmental Risks:

- Severe Weather: Increases stress on propulsion systems.

- Collisions: Impacts with objects can damage propellers or rudders.

- Grounding: Can misalign or destroy critical components.

Consequences of Propulsion Loss

The ramifications of propulsion loss extend beyond operational disruptions, posing significant risks to safety, the environment, and economic stability.

Navigational and Safety Risks

Propulsion loss can lead to a complete loss of maneuverability, making vessels vulnerable to drifting, grounding, or collisions. In confined waterways or during port maneuvers, these risks are amplified, especially in adverse weather. For passenger ships, the safety of crew and passengers is paramount, and propulsion loss can create life-threatening situations.

Key Safety Risks:

- Loss of Control: Vessels may drift into hazardous areas.

- Collision Hazards: Uncontrolled ships risk hitting other vessels or structures.

- Grounding: Drifting onto shoals can cause severe structural damage.

Economic Impact

Propulsion loss disrupts maritime operations, leading to significant financial losses. Delays in delivery schedules, repair costs, and potential legal liabilities can strain a shipping company’s finances. Major incidents, such as the grounding of the Ever Given in the Suez Canal, can disrupt global trade, costing billions.

Economic Consequences:

- Operational Delays: Missed schedules increase costs and reduce reliability.

- Repair Costs: Damaged components require expensive repairs or replacements.

- Reputation Damage: High-profile incidents can harm a company’s market position.

Environmental Damage

Propulsion loss increases the risk of environmental disasters, particularly when vessels ground or collide near sensitive marine areas. Oil spills, as seen in the Wakashio incident, can devastate ecosystems, harm wildlife, and disrupt local economies reliant on marine resources.

Environmental Impacts:

- Oil Spills: Fuel leaks contaminate water and shorelines.

- Habitat Destruction: Groundings damage coral reefs and marine habitats.

- Regulatory Fines: Environmental violations lead to hefty penalties.

Case Studies of Propulsion Loss Incidents

| Ship Name | Type | Cause of Accident | Consequences |

|---|---|---|---|

| Costa Concordia | Cruise Ship | Human error, propulsion failure | Capsizing, loss of life, environmental damage |

| Wakashio | Bulk Carrier | Engine failure due to grounding | Oil spill, extensive environmental damage |

| MSC Opera | Cruise Ship | Electrical and propulsion failure | Collision with dock, operational delays |

| Norwegian Epic | Cruise Ship | Power failure affecting propulsion | Loss of maneuverability, passenger disruption |

| Ever Given | Container Ship | Mechanical and steering failure | Blocked Suez Canal, global trade disruption |

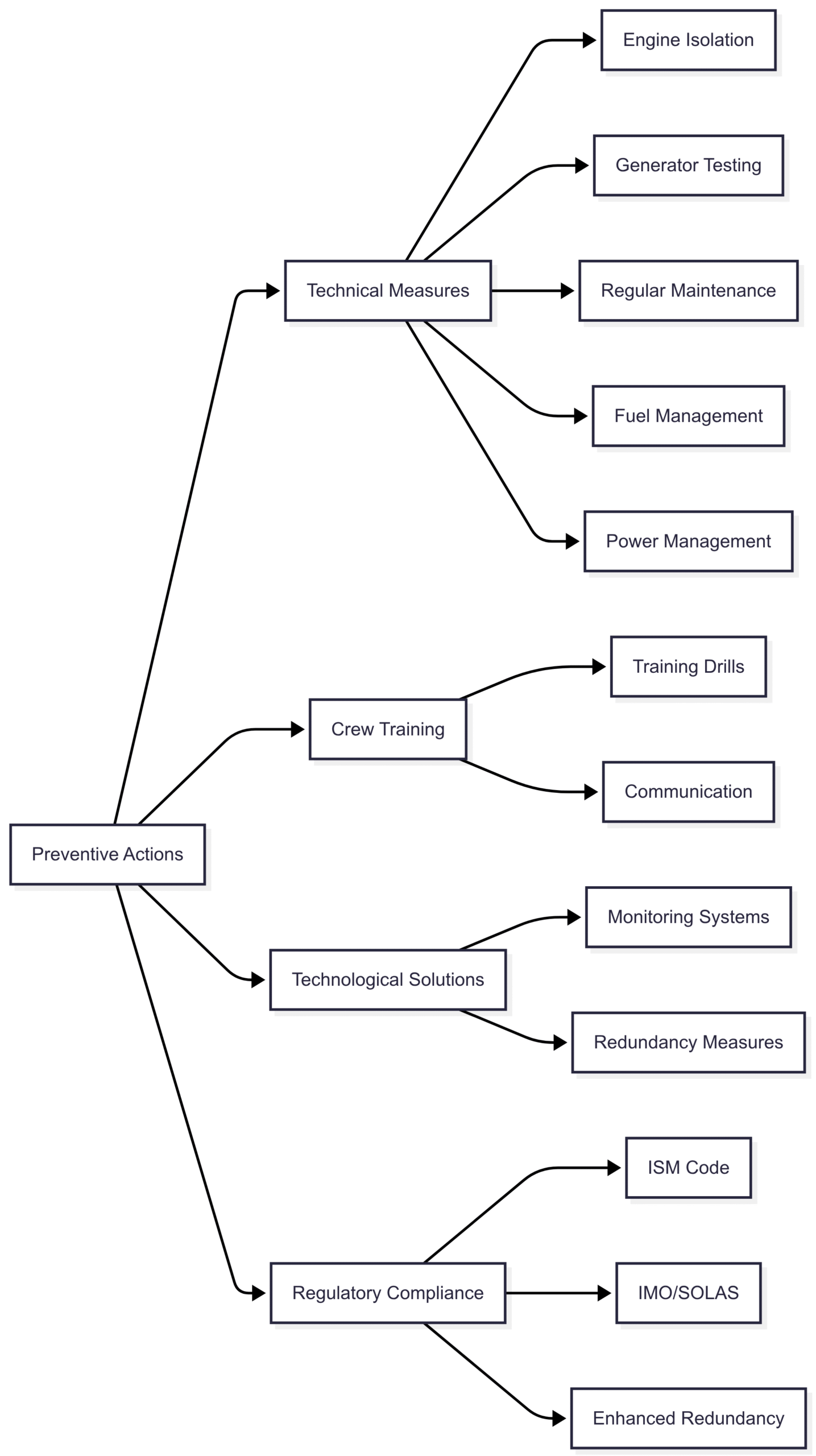

Preventive Actions to Mitigate Propulsion Loss

Preventing propulsion loss requires a multifaceted approach, combining technical measures, crew training, and regulatory compliance. Below are key strategies to enhance vessel reliability.

Technical and Procedural Measures

- Engine Isolation and Failure Procedures:

- Train engineers on isolating faulty cylinders and managing “failure to start” scenarios.

- Develop blackout checklists to streamline response during power loss.

- Emergency Generator Testing:

- Conduct weekly tests to ensure emergency generators are operational.

- Run multiple generators in parallel during high-risk maneuvers, such as port entry.

- Regular Maintenance:

- Implement a rigorous maintenance schedule for engines, fuel systems, and electrical components.

- Replace worn parts before they fail, using predictive maintenance tools.

- Fuel Quality Management:

- Use high-quality fuel from reputable suppliers.

- Regularly drain water from fuel tanks and treat for microbial contamination.

- Electrical Power Management:

- Implement load-shedding protocols to prevent generator overload.

- Ensure adequate power capacity for heavy equipment during critical operations.

- Emergency Generator Readiness:

- Operate emergency generators monthly at near-maximum capacity for at least one hour to verify performance.

Crew Preparedness and Training

- Training and Drills:

- Conduct regular training on propulsion control, blackout recovery, and emergency procedures.

- Simulate engine room scenarios to prepare crew for real-world incidents.

- Communication and Coordination:

- Maintain continuous communication between the bridge and engine room.

- Use standardized protocols to ensure rapid decision-making during emergencies.

Technological and Monitoring Solutions

- Advanced Monitoring Systems:

- Install real-time monitoring systems to detect issues in engines, fuel systems, and electrical components.

- Regularly test system alarms and control system accuracy.

- Redundancy Measures:

- Incorporate redundant propulsion systems (e.g., Redundant Propulsion or Dynamic Positioning systems) to maintain control during failures.

Safety and Regulatory Compliance

- ISM Code Compliance:

- Implement a Safety Management System (SMS) per the International Safety Management (ISM) Code.

- Conduct regular reviews and drills to ensure crew familiarity with safety protocols.

- IMO and SOLAS Regulations:

- Adhere to International Maritime Organization (IMO) and Safety of Life at Sea (SOLAS) standards for emergency preparedness and blackout prevention.

- Enhanced Redundancy:

- Adopt additional safety measures, such as Redundant Propulsion (RP) or Dynamic Positioning (DYNPOS) systems, to exceed minimum regulatory requirements.

Corrective Actions Post-Incident

When propulsion loss occurs, swift and effective corrective actions are essential to minimize damage and restore control.

- Incident Documentation:

- Record the time, position, and circumstances of the incident in logbooks.

- Conduct a root cause analysis to identify failure points.

- Emergency Procedures:

- Deploy anchors to stabilize the vessel if drifting is a risk.

- Request assistance from nearby vessels or authorities if needed.

- Power Restoration:

- Follow established protocols to restore power, such as switching to emergency generators or resetting control systems.

- Verify system integrity before resuming operations.

- Post-Incident Review:

- Analyze incident data to identify trends and implement corrective measures.

- Update training and procedures based on lessons learned.

Areas of Specific Attention

Certain systems and protocols require heightened focus to prevent propulsion loss:

- Emergency Generator Management: Ensure generators are tested and maintained to provide reliable backup power.

- Load Shedding: Implement protocols to prevent generator overload during high-demand operations.

- Power Feedback: Establish procedures to feed power from emergency switchboards to main switchboards during blackouts.

- Blackout Recovery: Train crew on rapid recovery techniques to restore propulsion and steering.

- ISM Code Compliance: Maintain a robust SMS to ensure continuous safety improvements.

Conclusion

Propulsion loss is a critical challenge in maritime operations, with far-reaching consequences for safety, economics, and the environment. By understanding the causes—mechanical failures, fuel contamination, electrical faults, human error, and environmental factors—maritime professionals can implement effective preventive measures. Regular maintenance, fuel quality management, crew training, and adherence to safety regulations are essential to reducing risks. Post-incident corrective actions, such as root cause analysis and emergency response, further enhance vessel reliability. Through a comprehensive approach, the maritime industry can ensure safer, more efficient operations, protecting lives, assets, and the environment.

For those affected by propulsion-related incidents, legal support from firms like Spagnoletti Law Firm can provide guidance and compensation. Contact them at 713-804-9306 or online for expert advice on maritime accidents.

Happy Boating!

Share Ship Propulsion Loss: Guideline on Reducing Risks with your friends and leave a comment below with your thoughts.

Read Compliance of Marine Boilers With MARPOL Air Pollution Regulations until we meet in the next article.