Ship Machinery and Systems: Guide for Maritime Learners

Comprehensive guide to ship machinery and systems for maritime learners, covering propulsion, auxiliary, and electrical systems with detailed insights.

Ship machinery and systems form the backbone of maritime operations, enabling vessels to navigate, transport cargo, and ensure crew safety. From propulsion systems that drive ships through vast oceans to auxiliary machinery that supports onboard functions, these systems are critical to a vessel’s functionality. This guide provides an in-depth exploration of ship machinery, tailored for maritime learners, cadets, engineers, and enthusiasts. It covers main propulsion, auxiliary, electrical, and electronic systems, their components, challenges, future trends, and educational importance, ensuring a thorough understanding of marine engineering.

Understanding Ship Machinery

Ship machinery encompasses the mechanical, electrical, and electronic equipment that powers and operates a vessel. These systems ensure propulsion, safety, habitability, and operational efficiency at sea. The engine room, often described as the heart of a ship, houses most of these components, requiring meticulous organization for maintenance and operation. Key objectives of ship machinery include:

- Propulsion: Moving the vessel through water.

- Power Generation: Supplying electricity for onboard systems.

- Auxiliary Support: Enabling essential services like cooling, heating, and waste management.

- Safety and Compliance: Ensuring adherence to maritime regulations and environmental standards.

For maritime learners, mastering these systems is essential for operating machinery efficiently, troubleshooting issues, and promoting sustainable practices.

Core Ship Systems

Ships rely on interconnected systems to perform their functions. Below is a detailed breakdown of the primary systems found on modern vessels.

1. Main Propulsion Systems

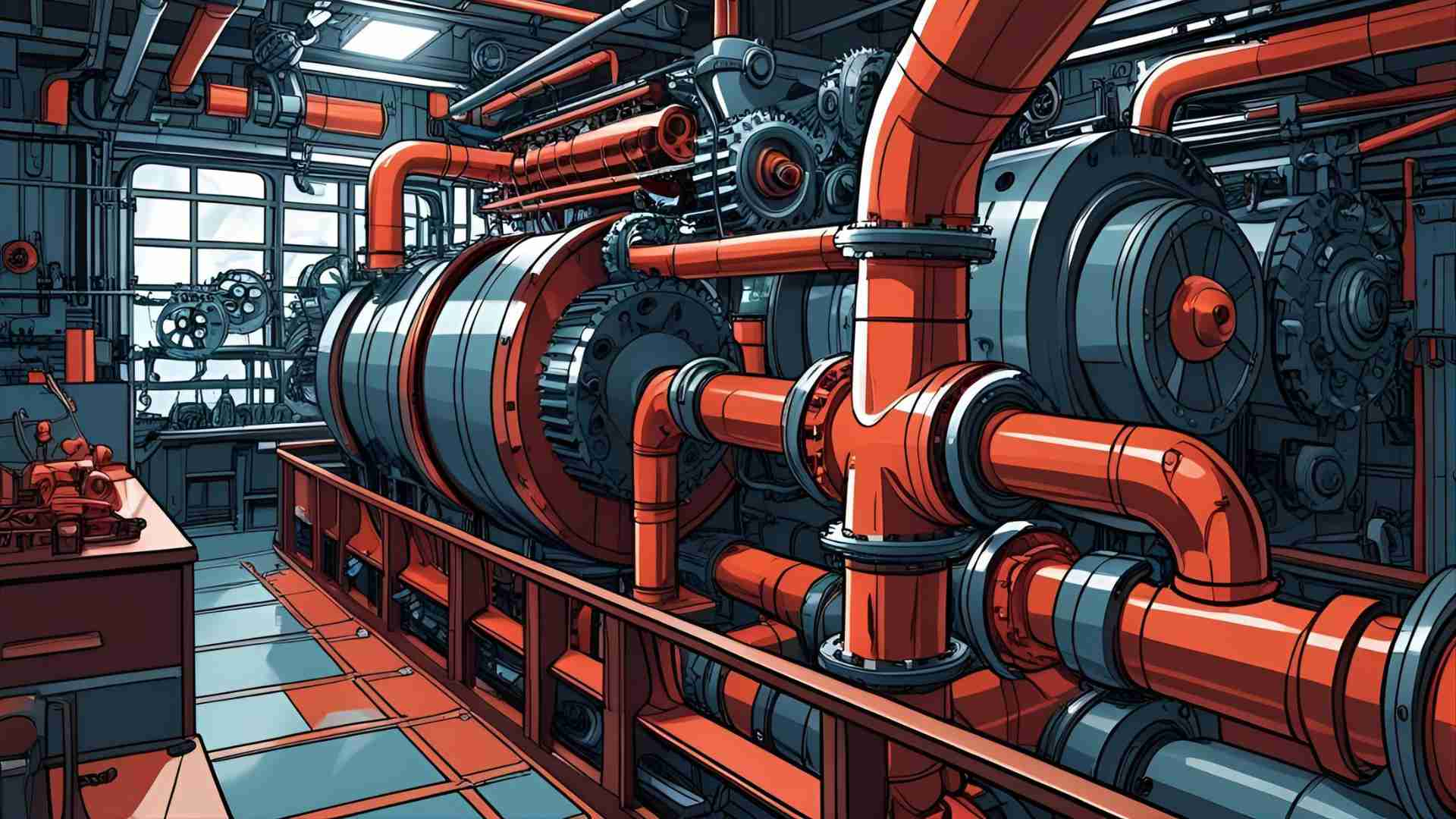

The propulsion system is responsible for generating thrust to move the ship. Common propulsion technologies include:

- Diesel Engines: Widely used due to their reliability and efficiency, diesel engines convert fuel into mechanical power to drive propellers. Leading manufacturers like MAN B&W and Wärtsilä produce engines ranging from 10,000 to over 100,000 horsepower for large vessels like container ships and tankers.

- Steam Turbines: These convert high-pressure steam into rotational energy, often used in LNG carriers and older cruise ships. They are less common today due to higher fuel consumption compared to diesel engines.

- Propulsion Electric Motors (PEMs): Found in diesel-electric or gas turbine-electric systems, PEMs offer flexibility in power distribution and precise control, ideal for dynamic positioning in offshore vessels.

- Water Jets: Used in high-speed crafts like ferries and yachts, water jets propel vessels by ejecting water at high velocity, offering superior maneuverability.

Table 1: Comparison of Propulsion Systems

| System | Fuel Efficiency | Applications | Maintenance Complexity | Cost (Approximate) |

|---|---|---|---|---|

| Diesel Engines | High | Cargo Ships, Tankers | Moderate | $10M–$50M |

| Steam Turbines | Moderate | LNG Carriers, Cruise Ships | High | $15M–$60M |

| PEMs | High | Offshore Vessels, Ferries | Moderate | $5M–$30M |

| Water Jets | Low | Yachts, Ferries | Low | $1M–$10M |

2. Auxiliary Machinery

Auxiliary machinery supports propulsion and provides essential services for ship operations. Key components include:

- Generators: Powered by diesel or gas turbines, generators produce electricity for lighting, navigation, and other systems. Typical power outputs range from 500 kW to 10 MW.

- Boilers: Generate steam for propulsion, power generation, or heating. Modern boilers often use waste heat from exhaust gases for efficiency.

- Air Compressors: Supply compressed air for starting engines, operating pneumatic tools, and controlling valves. They are categorized into service air, control air, and starting air systems.

- Purifiers: Remove water and contaminants from fuel and lubricating oil, ensuring machinery longevity.

- Refrigeration and HVAC Systems: Maintain crew comfort and preserve perishable goods. HVAC systems also protect sensitive equipment in engine control rooms.

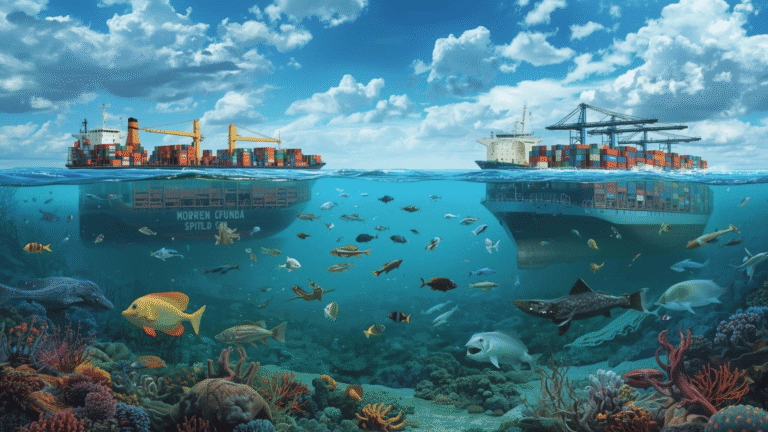

- Ballast Water Treatment Systems: Treat ballast water to prevent invasive species spread, complying with IMO regulations.

- Sewage Treatment Plants: Process wastewater to meet environmental standards.

- Bilge Water Separators: Remove oil from bilge water before discharge, preventing marine pollution.

3. Electrical and Electronic Systems

These systems manage power distribution, control, and communication:

- Power Generation and Distribution: Ensures electricity reaches all onboard systems, from propulsion to lighting.

- Control Systems: Automate engine control, navigation, and safety functions, often integrated with Planned Maintenance Systems (PMS).

- Communication Systems: Include radar, GPS, AIS, and radios for vessel-to-vessel and vessel-to-shore communication.

- Navigation Systems: Equip ships with tools like ECDIS and gyrocompasses for safe navigation.

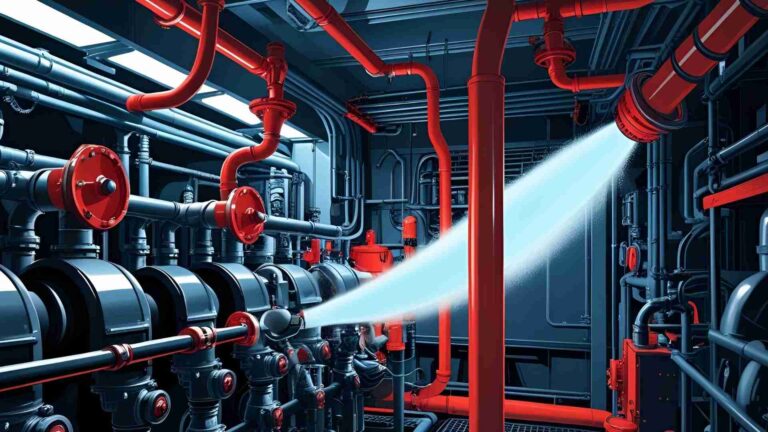

4. Other Critical Systems

- Steering Gear: Controls the rudder for directional changes, using hydraulic or electric systems.

- Pumps: Transfer liquids like fuel, ballast, and cooling water. Common types include centrifugal and positive displacement pumps.

- Valves: Regulate fluid flow in piping systems, ensuring precise control.

- Tanks: Store fuel, water, and ballast, with capacities varying by vessel size.

- Piping: Transports fluids throughout the ship, designed to withstand corrosion and pressure.

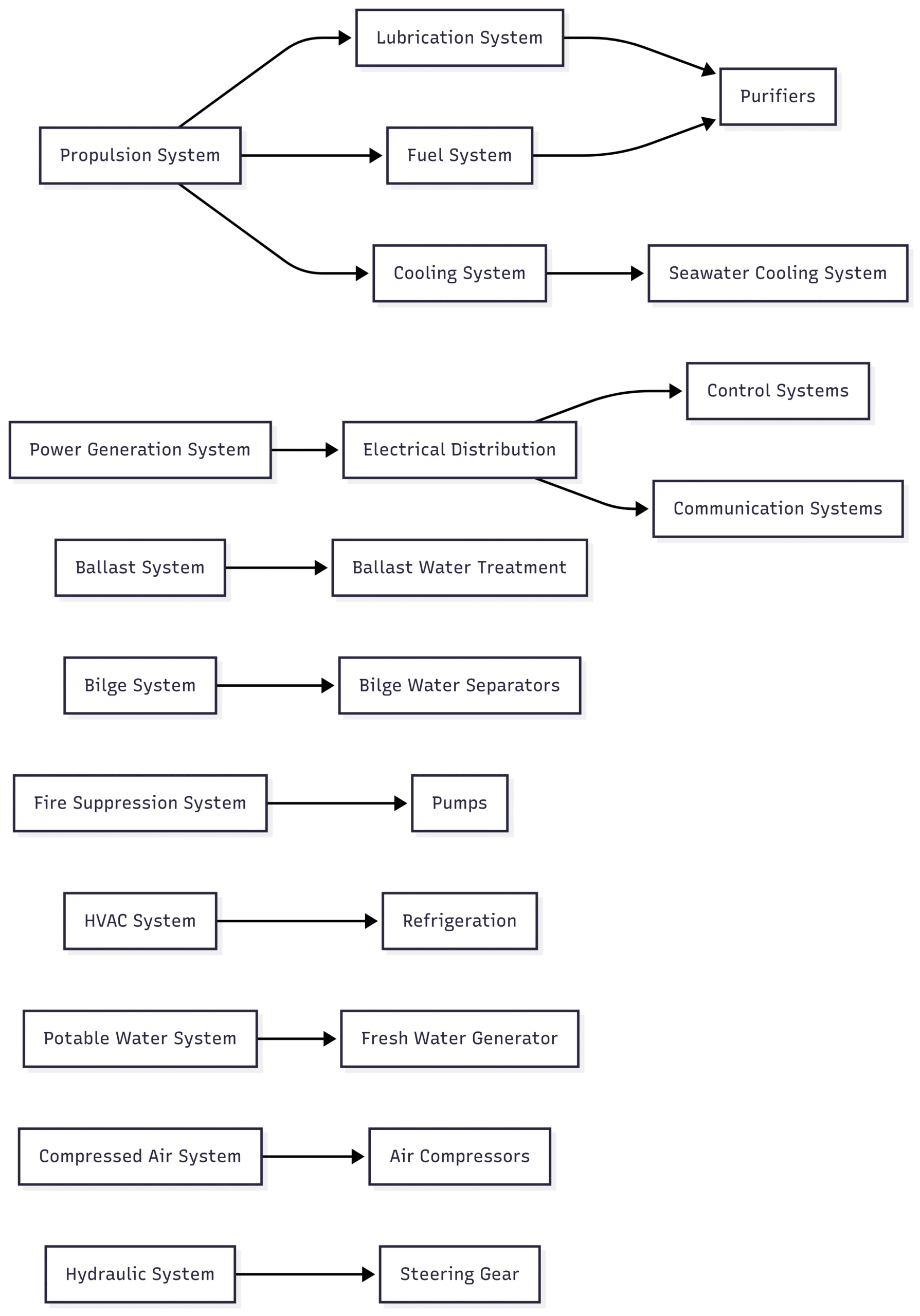

Chart: Ship System Interconnections

This chart illustrates how systems like propulsion, cooling, and electrical distribution are interconnected, highlighting the complexity of ship operations.

Five Core Systems in Marine Engineering

Marine engineering emphasizes five critical systems that ensure vessel functionality:

- Propulsion System: Converts fuel into thrust, typically via diesel engines or turbines.

- Electrical System: Powers onboard equipment, from navigation to lighting.

- Fuel System: Stores, transfers, and delivers fuel to engines, including bunkering and purification processes.

- Lubrication System: Reduces friction in engines and stern tubes, using oils with properties like detergency and alkalinity.

- Cooling System: Maintains optimal engine temperatures, often using fresh water circuits linked to seawater cooling.

These systems are interdependent, with failures in one potentially affecting others. For example, a malfunctioning lubrication system can overheat engines, impacting propulsion.

Ship Management Systems

Ship management systems are frameworks for overseeing operations, maintenance, and compliance. Modern systems include:

- Planned Maintenance Systems (PMS): Schedule maintenance to prevent breakdowns.

- Safety Management Systems (SMS): Ensure compliance with IMO and flag state regulations.

- Enterprise Resource Planning (ERP): Manage crewing, inventory, and finances.

These systems enhance efficiency, reduce downtime, and promote safety, often using IoT sensors for real-time monitoring.

Examples of Common Machinery

- Main Engines: MAN B&W and Wärtsilä engines dominate, with models like the 12RT-flex96C delivering up to 80,000 kW.

- Auxiliary Engines: Typically Caterpillar or Cummins, generating 1–5 MW.

- Air Compressors: Atlas Copco or Ingersoll Rand models, with pressures up to 30 bar.

- Pumps: Grundfos or KSB centrifugal pumps, handling flows from 10 to 1,000 m³/h.

- Boilers: Alfa Laval or Mitsubishi, producing 1–50 tons of steam per hour.

- Purifiers: Westfalia or Alfa Laval, processing 1,000–10,000 liters/hour.

Table 2: Machinery Specifications and Costs

| Machinery | Brand/Example | Specification | Approx. Cost |

|---|---|---|---|

| Main Engine | MAN B&W 12RT-flex96C | 80,000 kW, 2-stroke | $30M–$50M |

| Auxiliary Engine | Caterpillar C32 | 1–2 MW, 4-stroke | $500K–$1M |

| Air Compressor | Atlas Copco GA30 | 30 bar, 5 m³/min | $50K–$100K |

| Pump | Grundfos CR45 | 50 m³/h, 10 bar | $10K–$50K |

| Boiler | Alfa Laval Aalborg | 10 tons/h steam | $200K–$500K |

| Purifier | Alfa Laval MAPX-207 | 5,000 L/h | $50K–$150K |

Educational Importance for Maritime Learners

Understanding ship machinery is vital for maritime professionals. Key benefits include:

- Operational Efficiency: Proper operation maximizes fuel efficiency and performance.

- Troubleshooting Skills: Diagnosing issues minimizes downtime and repair costs.

- Regulatory Compliance: Knowledge ensures adherence to IMO and MARPOL standards.

- Safety and Sustainability: Skilled engineers enhance vessel safety and reduce environmental impact.

Maritime academies emphasize hands-on training with simulators and engine room mock-ups to prepare cadets for real-world challenges.

Challenges in Ship Machinery Operation

Operating ship machinery is complex due to:

- Harsh Environments: Saltwater corrosion and extreme weather accelerate wear.

- System Complexity: Interconnected systems require advanced diagnostics.

- Maintenance Demands: Regular upkeep is critical but time-intensive.

- Technological Evolution: Rapid advancements necessitate continuous learning.

Preventive maintenance and crew training are essential to mitigate these challenges.

Future Trends in Ship Machinery

The maritime industry is evolving, with trends shaping ship machinery:

- Hybrid Propulsion: Combining diesel, battery, and LNG systems for efficiency.

- Smart Maintenance: IoT sensors enable predictive maintenance, reducing downtime.

- Eco-Friendly Systems: Low-sulfur fuels and scrubbers comply with IMO 2020 regulations.

- Automation: Remote diagnostics and autonomous systems enhance efficiency.

Table 3: Future Trends and Benefits

| Trend | Benefit | Implementation Cost |

|---|---|---|

| Hybrid Propulsion | 20–30% fuel savings | $5M–$20M |

| IoT Sensors | 15% reduction in maintenance costs | $100K–$500K |

| Eco-Friendly Systems | Compliance with IMO regulations | $1M–$10M |

| Automation | 10–20% operational efficiency gain | $500K–$5M |

Conclusion

Ship machinery and systems are the lifeblood of maritime operations, enabling vessels to navigate, generate power, and ensure safety. For maritime learners, understanding these systems is crucial for a successful career in marine engineering. From propulsion and auxiliary machinery to electrical and management systems, each component plays a vital role. Despite challenges like harsh environments and technological complexity, advancements in hybrid propulsion, automation, and eco-friendly technologies promise a sustainable future. By mastering these systems, cadets and professionals can contribute to safer, more efficient, and environmentally responsible maritime operations.

Happy Boating!

Share Ship Machinery and Systems: Guide for Maritime Learners with your friends and leave a comment below with your thoughts.

Read What are concepts every electrical engineer SHOULD know? until we meet in the next article.