Ship Design and Construction

Ship design and construction stand as one of the most sophisticated, multidisciplinary, and capital-intensive engineering disciplines in the world. Unlike mass-produced automobiles or aircraft, every commercial vessel is a unique, purpose-built machine engineered to operate reliably for 25 to 40 years in some of the planet’s harshest environments—corrosive saltwater, extreme waves, sub-zero Arctic conditions, or tropical humidity.

The process integrates naval architecture, structural engineering, mechanical systems, electrical power distribution, hydrodynamics, materials science, regulatory compliance, project management, and global supply chain logistics. A single large vessel may involve over 100,000 individual components, 50,000 engineering drawings, 10,000 tons of steel, and a workforce of 5,000+ specialists across multiple continents.

This guide examines every phase of ship design and construction in granular detail—conceptualization, preliminary and detailed engineering, production planning, modular fabrication, hull assembly, outfitting, launching, sea trials, regulatory frameworks, vessel classifications, construction economics, global shipyard capabilities, sustainability mandates, and emerging technologies such as autonomous navigation and zero-emission propulsion. Technical specifications, cost breakdowns, performance metrics, classification society requirements, and real-world examples are included throughout.

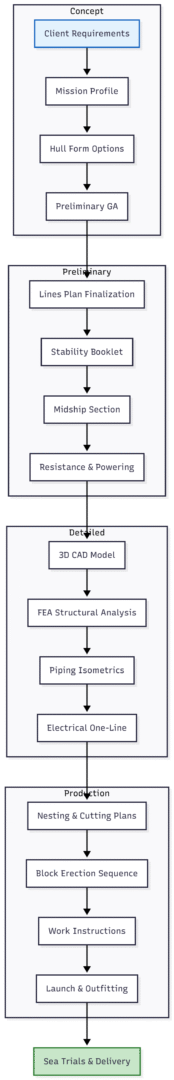

The Ship Design Spiral

Ship design is not linear—it is a design spiral, where each revolution refines the vessel with increasing precision. The spiral begins broad and conceptual, then narrows into detailed production-ready documentation. At every stage, naval architects, marine engineers, classification societies, shipowners, and flag states provide input, forcing iterations until technical feasibility, economic viability, regulatory compliance, and operational efficiency converge.

Stage 1: Concept Design – Defining the Vessel’s DNA

Client-Driven Mission Requirements

The journey begins when a shipowner, operator, or charterer issues a Request for Proposal (RFP) or Shipbuilding Specification. This document is the vessel’s genetic code.

Example: Bulk Carrier RFP

| Parameter | Specification |

|---|---|

| Deadweight | 82,000 DWT |

| Cargo | Coal, grain, iron ore |

| Service Speed | 14.0 knots @ 85% MCR |

| Range | 25,000 nautical miles |

| Ice Class | 1C (Baltic winter) |

| Crew | 22 persons |

| Fuel | VLSFO + scrubber |

| Port Restrictions | Panama Canal (New Panamax) |

Hull Form Generation

Using parametric design software (e.g., NAPA, Maxsurf, Paramarine), naval architects generate lines plans—mathematical curves defining the hull’s shape.

Key non-dimensional coefficients:

- Block Coefficient (Cb) = ∇ / (LPP × B × T) → 0.80–0.85 for full-form bulkers

- Prismatic Coefficient (Cp) = ∇ / (Am × LPP) → 0.82–0.87

- Waterplane Coefficient (Cwp) → 0.88–0.92

A lower Cb reduces resistance at high speeds but sacrifices cargo volume. Optimization uses genetic algorithms to minimize total resistance (Rt) across a speed range.

Preliminary General Arrangement (GA)

The GA is a 2D top/side/profile view showing:

- Cargo holds (5–7 for Handymax)

- Engine room aft

- Accommodation superstructure

- Double bottom height (≥ B/20 or 760 mm per SOLAS)

- Collision bulkhead at 0.05L–0.08L from FP

Techno-Economic Analysis

A Required Freight Rate (RFR) model compares:

- Capital Expenditure (CAPEX): $35M build cost

- Operating Expenditure (OPEX): $6,500/day (fuel, crew, insurance)

- Revenue: $25,000/day at Baltic Dry Index (BDI) 1,500

If RFR > market rate → redesign (e.g., reduce speed to 13.5 knots, save 12% fuel).

Stage 2: Preliminary (Basic) Design – Locking the Architecture

Hydrostatics and Stability

Using intact and damage stability criteria (IMO Res. A.749, SOLAS Ch. II-1):

| Criterion | Requirement |

|---|---|

| Area under GZ curve (0°–30°) | ≥ 0.055 m·rad |

| Area (0°–40° or flood) | ≥ 0.09 m·rad |

| Area (30°–40°) | ≥ 0.03 m·rad |

| Max GZ | ≥ 0.20 m at ≥ 25° |

| Angle of max GZ | ≥ 25° |

| GM₀ | ≥ 0.15 m |

Inclining experiment post-launch verifies lightship weight and KG.

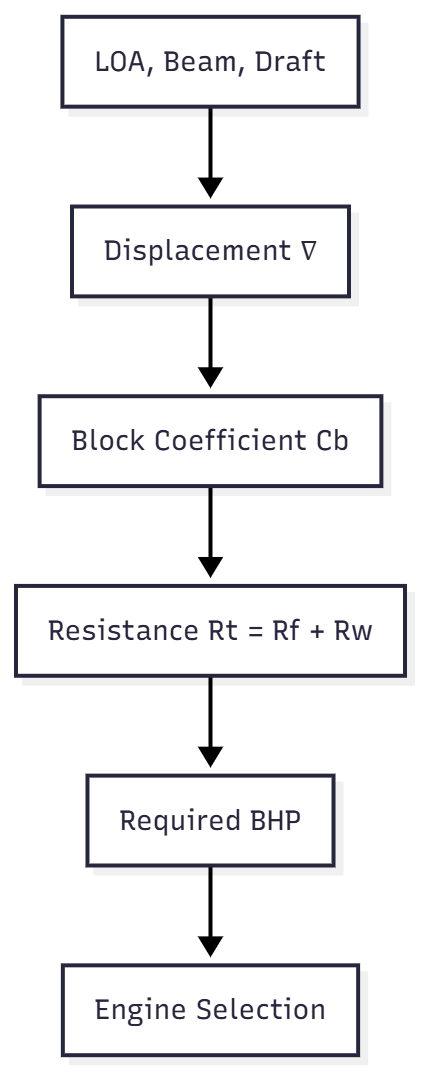

Resistance and Powering

Using Holtrop-Mennen regression or CFD (STAR-CCM+, OpenFOAM):

| Speed (knots) | Total Resistance (kN) | Effective Power (kW) |

|---|---|---|

| 12.0 | 420 | 5,300 |

| 14.0 | 680 | 9,900 |

| 15.0 | 880 | 13,800 |

Sea margin: 15%

Engine margin: 10%

Transmission efficiency: 98%

→ Brake Horsepower (BHP) = 14,500 kW → MAN 6S60ME-C10.2 (16,800 kW MCR)

Structural Design

Midship section defines:

- Double bottom height

- Frame spacing (800–900 mm)

- Plate thickness (12–22 mm)

- Longitudinals (bulb flats HP 260×10)

Global strength via IACS Common Structural Rules (CSR):

- Bending moment: M = ±0.1 × L² × B × (Cb + 0.7) × 10⁻³ kNm

- Shear force: F = ±0.025 × L × B × (Cb + 0.7) × 10⁻¹ kN

Stage 3: Detailed Design – Production-Ready Engineering

3D Product Model (Digital Twin)

Using AVEVA Marine, Siemens NX, or Cadmatic:

- Full hull, structure, outfitting in one model

- Clash detection (piping vs. structure)

- Weight and CG tracking (±1% accuracy)

Finite Element Analysis (FEA)

Global model: Entire hull, 1.2 million elements

Local models: Hatch corners, bilge keel roots

| Load Case | Stress (MPa) | Allowable (355 MPa steel) |

|---|---|---|

| Sagging | 220 | 280 |

| Hogging | 210 | 280 |

| Torsion | 180 | 250 |

Systems Engineering

Piping

- 12,000+ pipes

- Materials: Carbon steel (Sch 40), stainless (316L), CuNi

- Pressure ratings: 10–150 bar

- Isometric drawings with BOM

Electrical

- Main switchboard: 6.6 kV, 3,000 A

- Emergency generator: 750 kW

- Cable trays: 45 km total

- Load analysis: 8.5 MW peak

HVAC

- 600 tons refrigeration

- AHUs for accommodation, engine room

- CO₂ fire suppression in holds

Classification Society Approval

| Drawing Type | Submitted To | Approval Time |

|---|---|---|

| Lines Plan | DNV | 2 weeks |

| Midship Section | ABS | 3 weeks |

| Stability Booklet | LR | 4 weeks |

| FEA Report | BV | 6 weeks |

Stage 4: Production Design – From Drawing to Steel

Steel Material Specification

| Grade | Yield Strength | Application |

|---|---|---|

| AH36 | 355 MPa | Shell, strength deck |

| DH36 | 355 MPa | Ice-strengthened areas |

| EH36 | 355 MPa | High-stress zones |

| Mild Steel | 235 MPa | Internal bulkheads |

CNC Nesting and Cutting

AutoNEST optimizes plate usage:

- 92% material utilization

- 8% scrap (recycled)

- Cutting speed: 800 mm/min (plasma)

Block Construction Workflow

Block Example: Engine Room Double Bottom

- Weight: 420 tons

- Dimensions: 24m × 32m × 8m

- Pre-installed: Main engine beds, pump foundations, 1,200 m piping

Ship Construction Phases

1. Keel Laying

- First block placed on keel blocks

- Official construction start (contract milestone)

- Coin ceremony (tradition)

2. Block Erection

- 50–80 grand blocks

- 1,600-ton gantry cranes

- Weld shrinkage allowance: 1 mm/m

- Alignment tolerance: ±5 mm

3. Pre-Launch Outfitting

| System | % Installed Pre-Launch |

|---|---|

| Piping | 70% |

| Electrical | 65% |

| Machinery | 90% |

| HVAC | 60% |

4. Launching Methods

| Method | Applicability | Example |

|---|---|---|

| Slipway | Small–medium ships | Traditional |

| Shiplift | Up to 25,000 tons | Syncrolift |

| Float-Out | Mega-ships | Icon-class in dry dock |

| Sideways Launch | Space-constrained | European yards |

Launch Calculations:

- Declivity: 1:20

- Triggering force: 1,200 tons

- Sliding velocity: 0.5 m/s

- Stopping distance: 120 m

Testing and Commissioning

Dock Trials

- Main engine turning gear test

- Generator load bank (100% for 4 hrs)

- Bilge pump capacity: 2 × 150 m³/h

- Steering gear: 28° in 28 sec (SOLAS)

Harbor Trials

- Anchor windlass: 3 shackles in 3 min

- Lifeboat lowering: 60 sec

- Fire pump: 1,200 m³/h at 12 bar

Sea Trials Program

| Test | Duration | Metrics |

|---|---|---|

| Speed Trial | 6 hrs | 14.8 knots @ 85% MCR |

| Crash Stop | 1 hr | 11.2 ship lengths |

| Zigzag | 30 min | 12° overshoot |

| Turning Circle | 20 min | 3.8 ship lengths |

| Endurance | 12 hrs | Vibration < 8 mm/s |

Noise Levels (IMO Code on Noise):

- Cabins: ≤ 55 dB(A)

- Bridge: ≤ 65 dB(A)

- Engine Room: ≤ 110 dB(A)

Regulatory Framework

SOLAS (Safety of Life at Sea)

Key Chapters:

- II-1: Construction, stability, machinery

- II-2: Fire protection, detection, extinction

- III: Life-saving appliances

- V: Navigation safety

- XI-2: Enhanced surveys (ESP for bulkers)

2024 Amendments:

- GMDSS: Iridium recognized alongside Inmarsat

- Mooring: Line design factor ≥ 1.5, LSA mandatory

- Watertight Doors: Power-operated, local + remote control

- Free-fall Lifeboats: No 5-knot launch test required

MARPOL (Pollution Prevention)

| Annex | Focus | Key Limit |

|---|---|---|

| I | Oil | 15 ppm discharge |

| IV | Sewage | 25m from shore |

| V | Garbage | Zero plastic |

| VI | Air | 0.5% sulfur (global), EEDI Phase 3 |

EEXI (Energy Efficiency Existing Ship Index):

- Required Attained EEXI ≤ Required EEXI

- Remedies: Engine power limitation (EPL), shaft generators, bulbous bow retrofit

Load Line Convention

- Freeboard calculation: Tabular + corrections

- Type A (tankers): Full subdivision

- Type B (dry cargo): Reduced freeboard

Vessel Types and Classifications

Bulk Carriers

| Class | DWT | LOA | Beam | Draft | Holds | Hatch Size |

|---|---|---|---|---|---|---|

| Handysize | 15–39k | 130–160m | 23–28m | 9–10m | 5 | 15×12m |

| Handymax | 40–50k | 170–190m | 30m | 11m | 5 | 18×14m |

| Supramax | 50–60k | 190–200m | 32m | 12.5m | 5 | 20×16m |

| Panamax | 60–80k | 225m | 32.26m | 14m | 7 | 22×18m |

| Post-Panamax | 80–110k | 250m | 40m | 14.5m | 7 | 25×20m |

| Capesize | 160–210k | 290–310m | 45–50m | 18m | 9 | 30×25m |

Price Range:

- Handysize: $24–28M

- Capesize: $58–65M

Tankers

| Type | DWT | Cargo System | Tank Coating | Price |

|---|---|---|---|---|

| Product | 10–160k | Segregated ballast | Epoxy | $40–90M |

| Aframax | 80–120k | COW, IGS | Epoxy | $55–70M |

| Suezmax | 120–200k | Double hull | Epoxy | $70–85M |

| VLCC | 280–320k | SBT, IGS | Epoxy | $95–110M |

| ULCC | >320k | Rare | Epoxy | $120M+ |

Chemical Tankers:

- IMO Type 1: Full double hull, deepwell pumps

- Cargo heating: Steam coils to 80°C

- Nitrogen blanketing for IMO Type 2

Container Ships

| Class | TEU | LOA | Beam | Rows | Price |

|---|---|---|---|---|---|

| Feeder | <3,000 | <200m | <30m | 12 | $20–40M |

| Panamax | 5,000 | 294m | 32.2m | 13 | $60M |

| Post-Panamax | 8–14k | 350m | 42m | 18 | $100–140M |

| ULCV | 18–24k | 400m | 61m | 24 | $180–220M |

Example: MSC Irina (24,346 TEU)

- Builder: Yangzijiang Shipbuilding

- Engine: WinGD 11X92DF (dual-fuel LNG)

- Bunker capacity: 22,000 m³ LNG

- Delivery: 2023

Global Shipbuilding Industry

Market Share (Newbuild Tonnage)

| Country | Share | Key Players |

|---|---|---|

| South Korea | 40% | Hyundai, Samsung, Daewoo |

| China | 35% | CSSC, CSIC, Hudong-Zhonghua |

| Japan | 15% | Imabari, Oshima |

| Europe | 5% | Fincantieri, Damen |

| Others | 5% | Vietnam, Philippines |

South Korean “Big Three”

| Yard | Specialty | Annual Capacity |

|---|---|---|

| Hyundai Heavy (Ulsan) | LNG, VLCC | 40 vessels |

| Samsung (Geoje) | ULCV, drillships | 35 vessels |

| Daewoo (Okpo) | LNG, FPSO | 30 vessels |

Automation Level:

- Robotic welding: 80%

- Digital twin integration: 100%

- Build time: 12 months (VLCC)

Cost Breakdown and Economics

| Cost Element | % of Total | 60k DWT Bulker ($36M) | 300k DWT VLCC ($105M) |

|---|---|---|---|

| Steel | 20% | $7.2M | $21M |

| Labor | 30% | $10.8M | $31.5M |

| Machinery | 40% | $14.4M (engine $9M) | $42M (engine $25M) |

| Design | 5% | $1.8M | $5.25M |

| Outfitting | 5% | $1.8M | $5.25M |

Daily Operating Cost:

- Handysize: $5,500

- Capesize: $8,000

- VLCC: $12,000

Charter Rates (2024 avg):

- Capesize: $25,000/day

- VLCC: $40,000/day

Sustainability and Future Technologies

Energy Efficiency Design Index (EEDI)

Phase 3 (2025+):

- Bulk carriers: 30% reduction vs. 2013 baseline

- Tankers: 35% reduction

Alternative Fuels

| Fuel | Energy Density | Infrastructure | Maturity |

|---|---|---|---|

| LNG | 48 MJ/kg | Growing | Commercial |

| Ammonia | 19 MJ/kg | Emerging | Pilot (2028) |

| Hydrogen | 120 MJ/kg | Limited | R&D |

| Methanol | 20 MJ/kg | Available | Dual-fuel engines |

Example: Icon of the Seas (LNG-powered cruise ship)

- 6 × Wärtsilä 14V46DF

- 100 tons LNG/day

- 40% lower CO₂ vs. HFO

Autonomous Ships

Yara Birkeland:

- 120 TEU

- Battery-electric

- Fully autonomous by 2026

- Route: Herøya to Brevik (7 nm)

Project Management and Quality Control

Critical Path Method (CPM)

| Milestone | Duration from Keel |

|---|---|

| Keel Laying | Day 0 |

| Launch | Day 240 |

| Sea Trials | Day 300 |

| Delivery | Day 330 |

Quality Assurance

- ISO 9001 certified

- NDT: 100% UT on butt welds, 20% MT on fillets

- Dimensional Control: Laser scanning, ±3 mm tolerance

- Warranty Claims: <1% of contract value

Frequently Asked Questions

Ship design and construction follow a structured spiral: Concept Design (defining mission requirements and hull form), Preliminary (Basic) Design (general arrangement, stability, and powering), Detailed Design (3D modeling, FEA, systems integration), and Production Design (fabrication drawings and block assembly plans). After design, construction includes steel cutting, block fabrication, hull erection, outfitting, launching, and sea trials before delivery.

Construction time varies by type and yard efficiency:

Handysize bulker (30,000 DWT): 6–9 months

Panamax container ship (5,000 TEU): 12–15 months

VLCC tanker (300,000 DWT): 12–18 months

Ultra Large Container Vessel (24,000 TEU): 18–24 months Modern Korean and Chinese yards using block construction and automation achieve the fastest timelines.

Block construction is a modular method where the ship is built in large prefabricated sections (blocks) weighing 300–600 tons. Each block is fully outfitted with piping, cables, and equipment before being transported to the dry dock for final assembly. This reduces on-site work, improves quality control, cuts construction time by up to 40%, and allows year-round indoor fabrication.

The International Convention for the Safety of Life at Sea (SOLAS) is the primary treaty, covering construction, stability, fire protection, and life-saving appliances. Other key regulations include MARPOL (pollution prevention), Load Line Convention, and IACS Common Structural Rules (CSR). Classification societies (DNV, ABS, Lloyd’s) approve designs and issue certificates. Port State Control enforces compliance globally.

Costs depend on size, type, and technology:

Handysize bulker (35,000 DWT): $24–28 million

Supramax bulker (58,000 DWT): $32–36 million

VLCC tanker (310,000 DWT): $95–110 million

ULCV container ship (24,000 TEU): $180–220 million Steel (~20%), labor (~30%), and machinery (~40%) are the largest cost components. Dual-fuel (LNG) or scrubber-fitted ships add 10–20% to the price.

Conclusion

Ship design and construction represent the pinnacle of human engineering ingenuity—blending centuries-old naval architecture principles with cutting-edge digital tools, robotics, and sustainable technologies. From the first lines plan sketched in NAPA to the final sea trial where a 300,000-ton behemoth achieves 15 knots under its own power, every step is a testament to precision, collaboration, and foresight.

The vessels built today will trade for decades, navigating evolving regulations, fuel transitions, and digital transformation. Whether a modest Handysize bulker carrying grain from Ukraine or a 24,000 TEU megaship linking Shanghai to Rotterdam, each ship is a floating city of steel, systems, and human expertise.

The global fleet—over 100,000 vessels—forms the backbone of world trade, carrying 11 billion tons of cargo annually. Behind every voyage lies a design and construction story of relentless optimization, regulatory rigor, and industrial might.

This article serves as the definitive reference for students, engineers, shipowners, and maritime professionals seeking to understand the full lifecycle of modern ship design and construction.

Happy Boating!

Share Ship Design and Construction with your friends and leave a comment below with your thoughts.

Read Ship Surveys and Inspections until we meet in the next article.