Ship Construction and Basic Ship Stability (Operational)

Explore ship stability and construction: key concepts, materials, regulations, and safety for seaworthy vessels.

Ship stability and construction form the backbone of naval architecture, ensuring vessels remain safe, functional, and resilient in the unpredictable marine environment. Stability refers to a ship’s ability to return to an upright position after being tilted by external forces like waves or wind, while construction encompasses the design, materials, and building techniques that enable a ship to withstand the stresses of the sea. For maritime officers, understanding these principles is critical to operating vessels safely, protecting crew and cargo, and complying with international regulations. This article provides an in-depth exploration of ship stability and construction, covering key concepts, calculations, materials, regulations, and their critical role in maritime safety.

Understanding Ship Stability

Ship stability is the ability of a vessel to resist capsizing and return to an upright position after being disturbed by external forces. It is a fundamental aspect of maritime safety, as poor stability can lead to catastrophic incidents, including capsizing or sinking. Stability is divided into two primary categories: transverse stability (resistance to rolling side to side) and longitudinal stability (resistance to pitching bow to stern). Both are essential for maintaining a vessel’s equilibrium in challenging conditions, such as rough seas or heavy winds.

Key Stability Concepts

Several core principles govern ship stability:

- Center of Gravity (CG): The point where the ship’s weight is concentrated. A lower CG enhances stability by reducing the tendency to tilt excessively.

- Center of Buoyancy (CB): The center of the volume of water displaced by the ship’s hull. As the ship tilts, the CB shifts to counteract the tilt, aiding stability.

- Metacentric Height (GM): The distance between the CG and the metacenter (M), a theoretical point related to the CB and waterline. A positive GM indicates stable equilibrium, while a larger GM suggests greater stability. A negative GM can lead to instability and potential capsizing.

- Buoyancy: The upward force exerted by water that supports the ship’s weight. For a ship to float, buoyancy must equal the total weight of the vessel and its contents.

- Equilibrium States:

- Stable Equilibrium: The ship returns to its upright position after tilting.

- Unstable Equilibrium: The ship continues to tilt further, risking capsizing.

- Neutral Equilibrium: The ship remains tilted without returning or capsizing further.

Factors Affecting Stability

Several factors can compromise a ship’s stability, requiring careful management by maritime officers:

- Weight Distribution: Improperly distributed cargo or equipment, especially if placed high, raises the CG, reducing stability.

- Free Surface Effect: Liquids in partially filled tanks (e.g., fuel or ballast) can slosh, shifting the CG and destabilizing the vessel. Officers minimize this by keeping tanks full or empty.

- Water on Deck: Accumulated water from waves or rain adds weight, raises the CG, and reduces stability. Proper drainage systems are critical.

- Bilging: Flooding in compartments reduces buoyancy and can shift the CB, compromising stability.

- Angle of Loll: Occurs when a ship leans to one side due to insufficient stability, often caused by a negative GM. Corrective measures, such as redistributing weight, are essential.

Maintaining Stability

To ensure a vessel remains stable, officers follow best practices:

- Proper Weight Distribution: Cargo and equipment are stowed to keep the CG low and evenly distributed.

- Avoid Overloading: Adhering to load line marks prevents exceeding the ship’s weight capacity, which could reduce buoyancy.

- Manage Free Surfaces: Tanks are monitored to minimize liquid movement.

- Clear Decks: Drainage systems and proper maintenance prevent water accumulation.

- Secure Loads: Cargo is fastened to prevent shifting during voyages.

- Monitor Stability Parameters: Officers regularly check GM, draft, and trim using stability books and calculations.

Ship Construction: Design and Materials

Ship construction involves designing and building vessels that can withstand the harsh marine environment while maintaining stability, safety, and efficiency. The construction process integrates advanced materials, structural engineering, and regulatory compliance to ensure seaworthiness.

Hull Design

The hull is the ship’s primary structural component, designed to optimize hydrodynamics, stability, and load-carrying capacity. Key aspects include:

- Shape: Hull shapes (e.g., bulbous bows, V-shaped, or flat-bottomed) affect fuel efficiency, speed, and stability. Bulbous bows reduce wave resistance, while V-shaped hulls improve stability in rough seas.

- Structural Integrity: The hull must resist bending, shearing, and torsional forces caused by waves and cargo loads. Officers monitor stress points to prevent structural failure.

Materials

Modern ships are primarily constructed from steel due to its strength, durability, and cost-effectiveness. However, other materials are used for specialized applications:

- Steel: Used for hulls and structural frameworks, offering high tensile strength to withstand sea forces.

- Aluminum: Employed in lightweight vessels like high-speed ferries, reducing weight but increasing costs.

- Composite Materials: Used in specialized craft (e.g., racing yachts) for their strength-to-weight ratio and corrosion resistance.

- Wood: Rarely used in modern commercial vessels but still found in traditional or small-scale boats.

Officers must understand the properties of these materials, as they impact maintenance, corrosion resistance, and operational limits.

Watertight Compartments

Watertight compartments are critical for maintaining buoyancy in case of a hull breach. By dividing the ship into sealed sections, flooding is contained, preventing progressive flooding that could sink the vessel. Officers conduct regular drills to manage these compartments during emergencies, ensuring rapid response to damage.

Deck and Superstructure

The deck houses critical areas like cargo holds, machinery spaces, and crew accommodations, while the superstructure includes the bridge and elevated structures. High cargo stacks on deck can raise the CG, reducing stability, so officers ensure proper stowage and monitor weather conditions.

Stress and Strain

Ships face various forces at sea, including:

- Bending Forces: Waves cause the hull to bend, with the midship section experiencing different stresses than the bow or stern.

- Shearing Forces: Uneven wave pressures can shear the hull, stressing structural joints.

- Torsional Forces: Twisting occurs during sharp turns or uneven wave impacts, straining the hull.

Officers monitor these forces through regular inspections, identifying issues like cracks or corrosion to maintain structural integrity.

Stability Calculations and Tools

Before a voyage, officers perform stability calculations to ensure the ship is seaworthy under various conditions. These calculations use data from the ship’s stability book, which includes:

- Load Lines: Marks on the hull indicating maximum safe loading depths for different conditions (e.g., tropical, freshwater, winter).

- Displacement and Draft: Displacement is the weight of water displaced by the ship, while draft is the depth of the hull below the waterline. Officers adjust cargo and ballast to maintain proper draft and trim.

- Free Surface Effect Data: Guidelines to minimize liquid movement in tanks.

Example: Stability Calculation Table

| Parameter | Description | Typical Value (Example) |

|---|---|---|

| Displacement | Total weight of ship and contents | 50,000 tons |

| Draft | Depth of hull below waterline | 10 meters |

| Metacentric Height (GM) | Distance between CG and metacenter | 1.5 meters |

| Center of Gravity (CG) | Vertical position of weight concentration | 8 meters above keel |

| Center of Buoyancy (CB) | Center of displaced water volume | 5 meters above keel |

This table illustrates how officers track key parameters to ensure stability.

International Regulations Governing Ship Construction and Stability

Ship construction and stability are governed by international regulations to ensure safety and environmental protection. Key organizations and standards include:

International Maritime Organization (IMO)

The IMO sets global standards through conventions like:

- SOLAS (Safety of Life at Sea) Chapter II-1: Covers construction, subdivision, stability, and machinery. It mandates watertight compartments, damage stability requirements, and stability calculations.

- 1966 Load Line Convention: Establishes freeboard limits to ensure reserve buoyancy and stability. It includes provisions for different zones and seasons, with additional measures for timber-carrying ships.

- 2008 International Code on Intact Stability (IS Code): Provides mandatory and recommended criteria for intact stability, including GM, righting lever (GZ), and weather considerations. The IS Code was updated in 2010 to address modern ship designs.

Classification Societies

Organizations like Lloyd’s Register and DNV certify ships for structural integrity and compliance with IMO standards. Officers work with these societies to maintain certification, which is essential for insurance and operations.

Goal-Based Standards (GBS)

GBS apply to oil tankers and bulk carriers over 150 meters, ensuring they are designed for a specified lifespan, remaining safe and environmentally friendly under intact and damaged conditions.

Second Generation Intact Stability Criteria

The IMO is developing performance-based criteria to address dynamic stability failures like parametric rolling and surf-riding. These Interim Guidelines use first-principle approaches and advanced technology to assess stability in waves, enhancing safety for non-conventional ship designs.

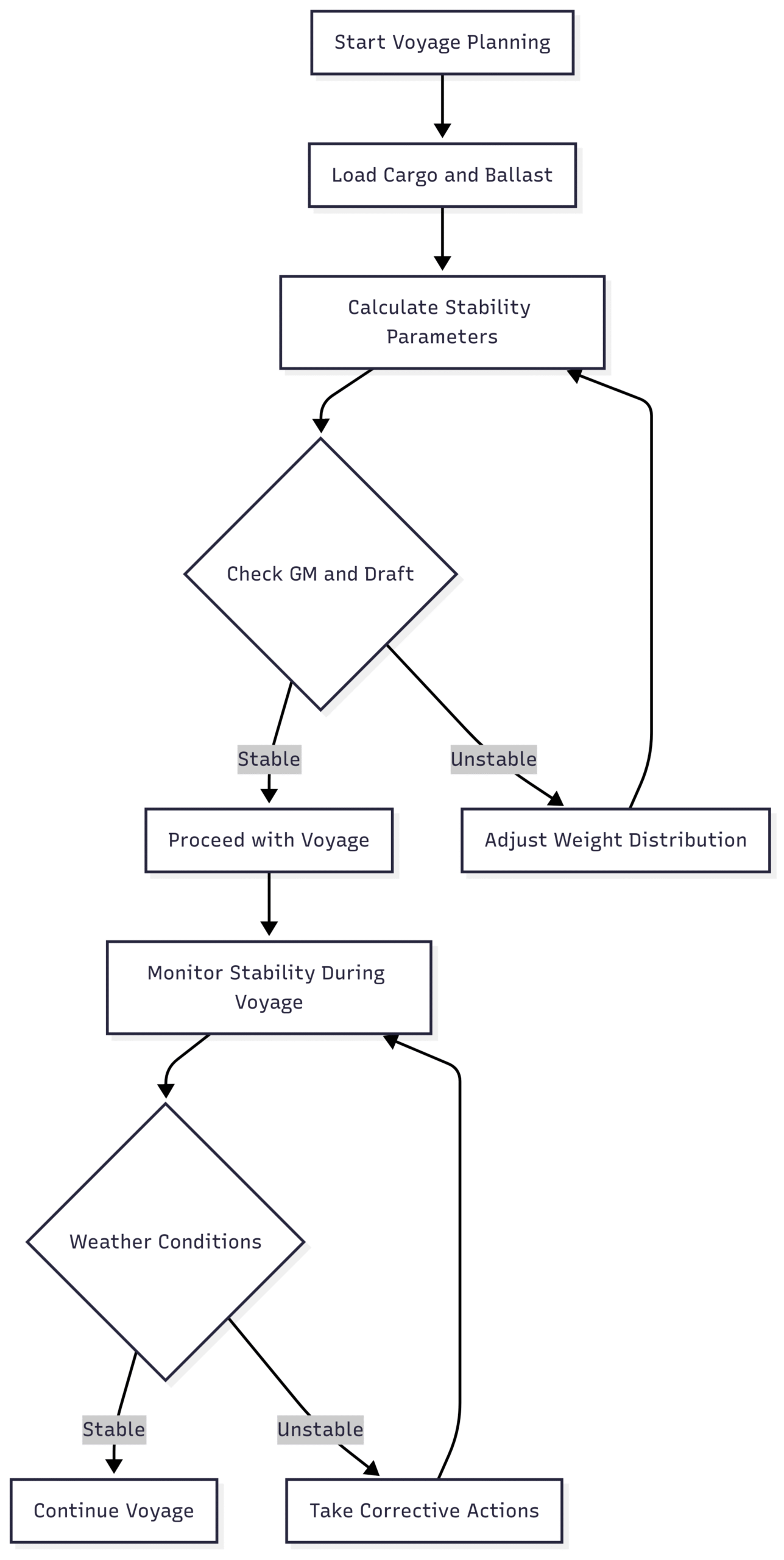

Chart: Ship Stability Workflow

This chart illustrates the iterative process officers follow to maintain stability.

Importance of Stability and Construction

The integration of robust stability management and sound construction practices ensures:

- Crew and Passenger Safety: Stable ships reduce the risk of capsizing, protecting lives.

- Cargo Protection: Proper stability prevents cargo shifts, minimizing damage and financial loss.

- Seaworthiness: Well-constructed ships withstand harsh conditions, ensuring successful voyages.

- Environmental Protection: Stable, structurally sound ships reduce the risk of accidents like oil spills, protecting marine ecosystems.

Practical Applications for Ship Officers

Maritime officers apply stability and construction knowledge daily:

- Pre-Voyage Planning: Using stability books to calculate load limits and ensure compliance with load lines.

- Onboard Monitoring: Regularly checking GM, draft, and trim during voyages.

- Emergency Response: Managing watertight compartments and damage control to mitigate flooding or structural damage.

- Maintenance: Inspecting hulls and superstructures for corrosion or cracks to maintain integrity.

Case Study: Stability in Action

Consider a 50,000-ton cargo ship preparing for a transatlantic voyage. Officers calculate the GM to be 1.2 meters, within safe limits. However, a storm forecast prompts a review of cargo stowage. By lowering heavy containers and filling ballast tanks, the CG is reduced, increasing the GM to 1.5 meters, enhancing stability for rough seas. This proactive approach ensures the ship remains safe and seaworthy.

Conclusion

Ship stability and construction are critical to maritime safety and efficiency. Officers must master stability principles like GM, buoyancy, and trim, while understanding hull design, materials, and regulatory standards. By applying this knowledge, they ensure vessels remain stable, structurally sound, and compliant with international regulations, safeguarding lives, cargo, and the environment. As the IMO continues to refine standards like the Second Generation Intact Stability Criteria, the maritime industry evolves to meet the challenges of modern ship design, ensuring safer seas for all.

Happy Boating!

Share Ship Construction and Basic Ship Stability (Operational) with your friends and leave a comment below with your thoughts.

Read Water-Mist And Sprinkler Systems On Passenger Ships until we meet in the next article.