SEEMP – Ship Energy Efficiency Management Plan

Discover SEEMP: A vital IMO-mandated plan to boost ship energy efficiency, reduce fuel costs, and cut GHG emissions effectively.

The maritime industry, a cornerstone of global trade, is under increasing pressure to reduce its environmental footprint. With ships contributing significantly to greenhouse gas (GHG) emissions, the International Maritime Organization (IMO) has introduced measures to enhance energy efficiency and curb emissions. Among these, the Ship Energy Efficiency Management Plan (SEEMP) stands out as a mandatory, ship-specific framework designed to optimize vessel performance, reduce fuel consumption, and lower emissions. This article delves into the intricacies of SEEMP, exploring its structure, implementation, benefits, and role in shaping a sustainable maritime future.

What is SEEMP?

The SEEMP is a structured, practical tool mandated by the IMO to help shipowners and operators improve the energy efficiency of their vessels while reducing GHG emissions. Introduced in 2013 and enhanced in 2023, SEEMP provides a systematic approach to managing a ship’s operational performance using the Plan-Do-Check-Act (PDCA) cycle. It is tailored to each vessel’s unique characteristics, ensuring that efficiency measures align with its operational profile, cargo type, and routes.

The SEEMP is not a one-size-fits-all solution. Unlike fleet-wide policies, it is ship-specific, recognizing that even sister ships operating under different conditions require distinct plans. By focusing on operational and technological improvements, SEEMP aims to achieve cost-effective reductions in fuel consumption and emissions, aligning with the IMO’s ambitious target of cutting maritime emissions by at least 50% by 2050 compared to 2008 levels.

Structure of SEEMP: Three Key Parts

The SEEMP is divided into three parts, each addressing specific aspects of energy efficiency and emissions reduction:

- SEEMP Part I: Ship Management Plan for Energy Efficiency

This part focuses on operational measures to enhance a vessel’s energy efficiency. It is mandatory for all ships above 400 gross tonnage (GT) and must be kept on board. Part I outlines strategies such as speed optimization, weather routing, and hull maintenance to reduce fuel consumption. - SEEMP Part II: Fuel Oil Consumption Data Collection Plan

Mandatory for ships above 5,000 GT, Part II establishes a system for collecting and reporting fuel oil consumption data. This data feeds into the IMO’s Data Collection System (DCS), enabling operators to monitor fuel usage and assess performance against efficiency benchmarks. - SEEMP Part III: Ship Operational Carbon Intensity Plan

Introduced to support the IMO’s Carbon Intensity Indicator (CII) requirements, Part III is mandatory for cargo, Ro-Pax, and cruise passenger vessels above 5,000 GT. It focuses on reducing a ship’s carbon intensity, aligning with the IMO’s goal of improving carbon efficiency by 40% by 2030 compared to 2008.

The following table summarizes the scope and applicability of each SEEMP part:

| SEEMP Part | Focus | Applicability | Mandatory Requirements |

|---|---|---|---|

| Part I | Energy Efficiency Management | Ships > 400 GT | Kept on board, outlines operational measures |

| Part II | Fuel Oil Consumption Data | Ships > 5,000 GT | Verified data collection for IMO DCS |

| Part III | Carbon Intensity Reduction | Cargo, Ro-Pax, Cruise > 5,000 GT | Verified plan for CII compliance |

The Importance of SEEMP in Maritime Sustainability

The maritime sector accounts for approximately 2.5% of global GHG emissions, with fuel consumption being the largest operational cost for shipowners. SEEMP addresses both environmental and economic concerns by promoting fuel-efficient practices that reduce emissions and operational expenses. For instance, fuel costs can account for up to 60% of a vessel’s operating budget, making efficiency measures critical for profitability.

SEEMP’s alignment with the IMO’s 2050 emissions reduction target underscores its role in driving the industry toward sustainability. By integrating operational and technological innovations, SEEMP helps shipowners comply with regulations like the Energy Efficiency Design Index (EEDI) for new ships and the Carbon Intensity Indicator (CII) for existing vessels. These regulations aim to improve hull design, machinery efficiency, and operational practices to minimize CO₂ emissions.

Key Features of SEEMP

SEEMP’s effectiveness lies in its comprehensive approach to energy management. Below are its core features:

1. Ship-Specific Customization

Each SEEMP is tailored to a vessel’s operational profile, considering factors like ship type, cargo, routes, and machinery. This customization ensures that efficiency measures are practical and relevant, maximizing their impact.

2. Broader Corporate Energy Management Policy

While SEEMP is ship-specific, it aligns with a company’s overarching energy management policy. This policy provides a framework for developing individual SEEMPs, ensuring consistency across a fleet while addressing unique vessel needs.

3. Fuel Consumption Reduction

By implementing measures like speed optimization and hull maintenance, SEEMP directly reduces fuel consumption. This not only lowers costs but also decreases emissions, contributing to environmental goals.

4. GHG Emissions Reduction

SEEMP promotes the use of alternative fuels (e.g., LNG, methanol, hydrogen) and energy-saving technologies to reduce GHG emissions. For example, adopting alternative fuels can significantly lower a vessel’s carbon footprint, with 20% of ships on order now designed to use non-conventional fuels.

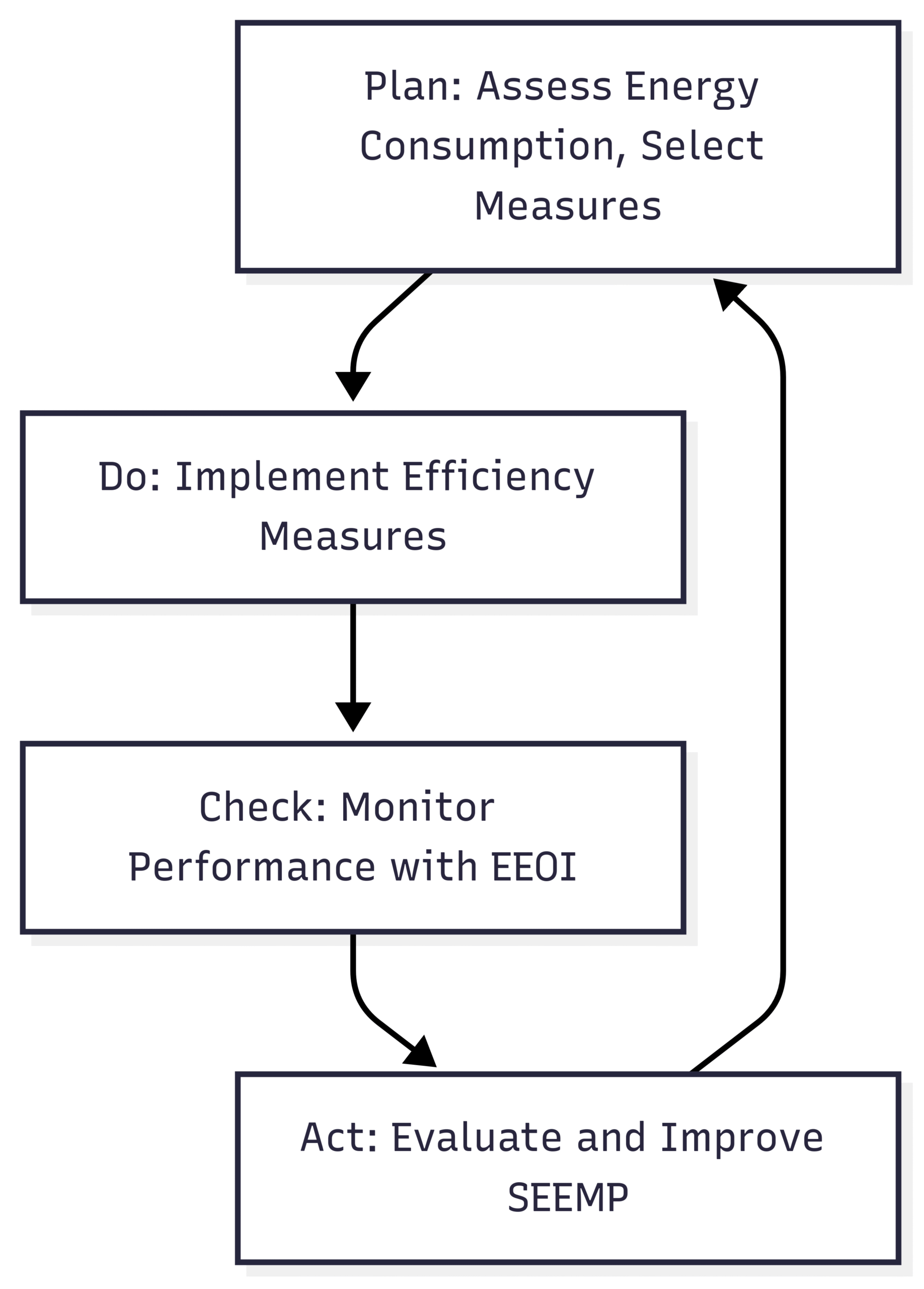

5. Continuous Improvement via PDCA Cycle

The PDCA cycle (Plan-Do-Check-Act) ensures that SEEMP evolves over time. By planning efficiency measures, implementing them, monitoring performance, and evaluating results, operators can refine their strategies for ongoing improvements.

How SEEMP Works: The PDCA Cycle

The PDCA cycle is the backbone of SEEMP, providing a structured approach to energy management. Here’s how each stage contributes to the plan’s success:

1. Planning

Planning is the foundation of SEEMP. Operators assess the vessel’s current energy consumption by analyzing fuel usage, machinery efficiency, hull condition, and operational patterns. This data informs the selection of efficiency measures, such as:

- Speed Optimization: Determining the optimal speed to balance fuel consumption and voyage schedules.

- Weather Routing: Using advanced forecasting to avoid rough weather, reducing fuel-intensive operations.

- Hull Maintenance: Scheduling regular cleaning to minimize biofouling, which can increase fuel consumption by up to 17.7%.

- Technology Upgrades: Installing energy-saving devices like heat recovery systems or propeller enhancements.

The planning stage also incorporates the company’s corporate energy management policy to ensure alignment with broader goals.

2. Implementation

Once measures are identified, operators develop a detailed implementation plan, assigning roles and responsibilities to stakeholders (e.g., ship operators, seafarers, and shore staff). Clear documentation and record-keeping are critical to track progress and ensure accountability. For example, implementing slow steaming requires coordination between the ship’s crew and charterers to maintain schedules.

3. Monitoring

Monitoring evaluates the effectiveness of implemented measures using tools like the Energy Efficiency Operational Indicator (EEOI). The EEOI measures a ship’s carbon intensity based on fuel consumption, cargo carried, and distance traveled. The formula is:

[ EEOI = \frac{\sum_j (FC_j \times C_{carbon,j})}{m_{cargo} \times D} ]

Where:

- ( FC_j ): Mass of fuel type ( j ) consumed (tonnes)

- ( C_{carbon,j} ): CO₂ conversion factor for fuel type ( j )

- ( m_{cargo} ): Mass of cargo carried (tonnes)

- ( D ): Distance traveled (nautical miles)

Operators collect data during voyages and report it to the IMO’s DCS (for Part II) or use it to assess CII compliance (for Part III). Alternative monitoring methods may be used if deemed effective by the company.

4. Self-Evaluation and Improvement

The final stage involves analyzing monitoring data to evaluate the SEEMP’s performance. Feedback from seafarers, operators, and shore staff is used to identify areas for improvement. This stage ensures that SEEMP remains dynamic, adapting to new technologies, operational changes, and regulatory updates.

The following chart illustrates the PDCA cycle in SEEMP implementation:

Practical Measures for SEEMP Implementation

SEEMP outlines several operational and technological measures to enhance efficiency. Below are the most effective strategies:

1. Speed Optimization

Speed significantly impacts fuel consumption. Slow steaming, where a ship operates at a reduced speed, can save hundreds of dollars per voyage. However, operators must balance speed with charter agreements and port schedules to avoid delays. Optimal speed is determined by analyzing fuel consumption data and voyage requirements.

2. Weather Routing

Advanced weather forecasting tools allow ships to avoid storms and rough seas, reducing fuel-intensive operations. By altering routes based on real-time weather data, operators can enhance safety and efficiency while minimizing emissions.

3. Hull Monitoring and Maintenance

Biofouling, the accumulation of marine organisms on a ship’s hull, increases drag and fuel consumption. Regular hull cleaning and the use of anti-fouling coatings can reduce fuel costs by up to 17.7% and CO₂ emissions by 19%, according to industry reports. Advanced systems like the Marine Growth Prevention System (MGPS) further improve hull performance.

4. Efficient Cargo Operations

Streamlined cargo operations reduce port turnaround times, allowing ships to maintain schedules without increasing speed. Effective communication between the ship, port authorities, and agents is critical to minimizing delays and fuel consumption.

5. Electric Power Management

Optimizing the use of onboard generators and auxiliary equipment reduces fuel consumption. For example, running generators at optimal loads and training seafarers to manage power efficiently can enhance overall energy performance.

6. Alternative Fuels and Technologies

The adoption of alternative fuels like LNG, methanol, and hydrogen is a growing trend. Approximately 20% of ships on order are designed to use these fuels, which produce fewer emissions than conventional marine fuels. Technologies like heat recovery systems and energy-saving devices (e.g., propeller ducts) further enhance efficiency.

Role of Seafarers in SEEMP

Seafarers are pivotal to SEEMP’s success, as specifically responsible for implementation and monitoring. Their roles include:

- Implementing SEEMP Procedures: Following planned efficiency measures, such as speed optimization and power management.

- Monitoring Performance: Collecting data for EEOI calculations and reporting to shore staff.

- Providing Feedback: Sharing insights on operational performance to refine SEEMP strategies.

- Promoting Sustainability: Fostering a culture of energy efficiency and safety on board.

- Navigation and Maintenance: Using modern navigation techniques and maintaining machinery to prevent inefficiencies.

Benefits of SEEMP

SEEMP offers significant benefits for shipowners, operators, and the environment:

- Cost Savings: Reduced fuel consumption lowers operating costs, which can account for up to 60% of a vessel’s budget. For example, proactive hull cleaning can save up to $6.5 million in fuel costs over five years per ship.

- Environmental Impact: Lower fuel use reduces GHG emissions, supporting global sustainability goals.

- Regulatory Compliance: SEEMP ensures compliance with IMO regulations like EEDI and CII, avoiding penalties.

- Operational Efficiency: Optimized operations improve voyage planning, machinery performance, and port turnarounds.

Challenges and Future Outlook

While SEEMP is a powerful tool, challenges remain. Implementing new technologies, such as alternative fuels, requires significant investment, and the high cost of these fuels can offset savings. Additionally, coordinating stakeholders—shipowners, operators, seafarers, and port authorities—can be complex, especially for global fleets.

Looking ahead, SEEMP will evolve with advancements in technology and stricter regulations. The rise of alternative fuels, digital monitoring tools, and AI-driven voyage optimization will enhance SEEMP’s effectiveness. The IMO’s ongoing efforts to refine EEDI and CII standards will further integrate SEEMP into the industry’s sustainability framework.

Conclusion

The Ship Energy Efficiency Management Plan (SEEMP) is a cornerstone of the maritime industry’s efforts to enhance energy efficiency and reduce GHG emissions. By leveraging the PDCA cycle, ship-specific measures, and advanced technologies, SEEMP enables shipowners to achieve cost-effective fuel savings while meeting environmental goals. From speed optimization to alternative fuels, SEEMP provides a roadmap for sustainable shipping, benefiting both operators and the planet. As the industry moves toward the IMO’s 2050 emissions target, SEEMP will remain a critical tool in navigating the path to a greener future.

Happy Boating!

Share SEEMP – Ship Energy Efficiency Management Plan with your friends and leave a comment below with your thoughts.

Read Ship Ratings: Roles, Responsibilities, and Career Insights until we meet in the next article.