50 Questions and Answers Asked in Oral Exam for Marine Third Engineer Officers

The role of a Third Engineer Officer on a commercial ship is critical, requiring a deep understanding of marine engineering systems, safety protocols, and regulatory compliance. The oral examination for this position tests a candidate’s technical knowledge, problem-solving skills, and ability to manage complex machinery under pressure. This comprehensive guide addresses the top 50 questions commonly asked during the oral exam, providing detailed answers to help aspiring Third Engineers prepare effectively. From engine operations to safety systems and international regulations, this article covers essential topics to ensure success.

Duties and Responsibilities of a Third Engineer Officer

The Third Engineer Officer is responsible for the operation, maintenance, and oversight of the ship’s machinery, particularly in the engine room. Key duties include:

- Watchkeeping: Monitoring engine room operations, ensuring all machinery, including main engines, auxiliary engines, boilers, and pumps, operates within safe parameters.

- Maintenance: Conducting routine and preventive maintenance on engines, pumps, and auxiliary systems to ensure optimal performance.

- Fuel and Lubrication Management: Overseeing fuel oil, lube oil, and cooling water systems, ensuring proper levels and quality.

- Safety Compliance: Ensuring adherence to safety and environmental regulations, including MARPOL and SOLAS.

- Emergency Response: Acting swiftly in emergencies like fires, equipment failures, or environmental incidents.

- Record-Keeping: Maintaining accurate logs in the Engine Room Logbook, recording operational parameters and maintenance activities.

Engine and Propulsion Systems

1. Explain the Operation and Maintenance of Marine Diesel Engines

Marine diesel engines, either two-stroke or four-stroke, are the heart of a ship’s propulsion system. Their operation involves:

- Combustion Process: Fuel is injected into the cylinder, ignited by compressed air, driving the piston to produce mechanical energy.

- Components: Key parts include pistons, cylinders, fuel injectors, turbochargers, and cooling systems.

- Maintenance:

- Routine Checks: Monitor temperature, pressure, and lubrication levels.

- Overhauls: Inspect and replace piston rings, cylinder liners, and bearings as per manufacturer schedules.

- Fuel System Maintenance: Clean fuel injectors and purifiers to prevent clogging.

- Lubrication: Ensure proper lubrication to minimize wear and tear.

2. Why Is a Firing Order Given to an Engine?

The firing order ensures balanced power delivery and minimizes engine vibrations. For example, in a four-cylinder engine, a typical firing order (1-3-4-2) distributes combustion events evenly across the crankshaft rotation, enhancing engine stability and efficiency.

3. What Is the Purpose of Balance Weights in a Medium-Speed Main Engine?

Balance weights counterbalance the reciprocating and rotating masses, reducing vibrations. They are strategically placed on the crankshaft to offset forces from pistons and connecting rods, ensuring smooth operation.

4. What Is a Node in Relation to Engine Balance?

A node is a point in the engine where vibrational forces cancel out, resulting in minimal movement. Proper engine balancing ensures nodes are strategically located to reduce stress on components.

5. Explain the Operation and Maintenance of the Ship’s Oily Water Separator (OWS) and MARPOL Annex I Compliance

Operation: The Oily Water Separator (OWS) removes oil from bilge water to meet MARPOL Annex I’s 15 ppm oil content limit. It uses:

- Gravity Separation: Oil rises; coalescers form larger droplets for collection.

- Filtration: Fine filters remove residual oil.

- Monitoring: A capacitance probe and oil content meter divert water exceeding 15 ppm back to the bilge tank.

Maintenance:

- Clean coalescer filters and oil collection tanks weekly.

- Calibrate the 15 ppm monitor monthly.

- Inspect pumps and valves for leaks.

- Record operations in the Oil Record Book (ORB).

Compliance:

- Ensure discharge is below 15 ppm using approved OWS.

- Log all operations in ORB Part I.

- Follow SOPEP for accidental spills.

- Verify equipment certification per MARPOL Annex I.

6. What Are the Checks When Overhauling a Pump?

- Inspect impeller and casing for wear or corrosion.

- Check shaft alignment and bearings.

- Verify seal integrity to prevent leaks.

- Measure clearances and replace worn components.

- Test motor and ensure proper priming post-overhaul.

7. What Happens If Air Is Taken in from a Pump’s Suction?

Air ingress reduces pump efficiency, causing cavitation, noise, and potential damage to the impeller. Priming the pump and checking suction line integrity resolve this issue.

8. How Do You Prime a Pump?

- Open the vent valve to release trapped air.

- Fill the pump casing with liquid via the priming port.

- Ensure the suction line is free of leaks and properly submerged.

9. What Is the Requirement for an Emergency Fire Pump’s Priming Unit?

The emergency fire pump must self-prime within 30 seconds, ensuring immediate operation during emergencies, as per SOLAS requirements.

10. What Do You Do If a Pump Won’t Turn After Overhauling?

- Check for mechanical binding or misalignment.

- Verify lubrication of bearings.

- Inspect motor connections and power supply.

- Ensure impeller is not seized or obstructed.

11. What Is the Ideal Position of the Thrust Block?

The thrust block, which absorbs propeller thrust, is ideally located near the engine bedplate to distribute forces evenly to the ship’s structure.

Boiler and Steam Systems

12. What Are the Hardness Salts Found in Boiler Water?

Hardness salts include calcium carbonate (CaCO₃), magnesium chloride (MgCl₂), and calcium sulfate (CaSO₄), which cause scale formation.

13. Why Is Alkalinity Important in Boiler Water, and What Are the Limits?

Alkalinity prevents corrosion by neutralizing acids. Typical limits are:

- P-Alkalinity: 100–150 ppm

- Total Alkalinity: 300–500 ppm

Excessive alkalinity can cause foaming, while low levels lead to corrosion.

14. How Is Water Hardness Reduced?

- Chemical Treatment: Use lime (Ca(OH)₂) and soda ash (Na₂CO₃) to precipitate hardness salts.

- Ion Exchange: Pass water through resin beds to remove calcium and magnesium ions.

- Reverse Osmosis: Filter water to remove dissolved salts.

15. What Is the Basic Difference Between Open and Closed Feed Systems?

- Open Feed System: Water is exposed to the atmosphere, requiring deaeration to remove oxygen.

- Closed Feed System: Water is contained, minimizing oxygen ingress and corrosion.

16. What Can Cause Total Dissolved Solids (TDS) to Decrease in a Boiler?

- Blowdown to remove sludge.

- Dilution with fresh, low-TDS feed water.

17. What Can Cause Only the Alkalinity to Decrease in a Boiler?

- Acidic contamination from leaking condensers.

- Overuse of neutralizing chemicals.

18. Why Measure Both P-Alkalinity and Total Alkalinity?

P-alkalinity measures hydroxide and carbonate ions, while total alkalinity includes bicarbonates. Both are critical to assess corrosion risk and chemical balance.

19. Why Use the Same Sample for Chloride and Alkalinity Tests?

Using the same sample ensures consistency in test conditions, reducing errors in assessing water chemistry.

20. How Is a Boiler Prepared for a Hydraulic Test?

- Fill the boiler with water to the test pressure.

- Isolate all valves and fittings.

- Pressurize to 1.5 times the working pressure and hold for inspection.

- Check for leaks or structural weaknesses.

Safety and Emergency Procedures

21. What Do You Do in Case of a Fire on Board?

Follow the FIRE protocol:

- Find: Locate the fire source.

- Inform: Alert the bridge and raise the alarm.

- Restrict: Isolate the fire by closing ventilation and fuel supplies.

- Extinguish: Use appropriate firefighting equipment (e.g., CO₂, foam, or water).

22. What Do You Inform the Bridge in Case of a Fire?

- Location and extent of the fire.

- Actions taken (e.g., isolation, firefighting).

- Any casualties or equipment damage.

23. What Are Common Places for a Fire to Start?

- Engine room (fuel leaks, electrical faults).

- Galley (cooking equipment).

- Cargo holds (hazardous materials).

24. What Are Motor Protections?

- Overload Protection: Trips the motor if current exceeds safe limits.

- Short-Circuit Protection: Fuses or circuit breakers prevent damage.

- Thermal Protection: Sensors detect overheating.

25. What Is the Purpose of Fuses?

Fuses protect circuits by breaking the connection when current exceeds the rated value, preventing overheating or fire.

26. What Would You Do If There Was a Casualty?

- Raise the emergency alarm.

- Inform the bridge and Chief Engineer.

- Provide first aid and ensure medical evacuation if needed.

- Secure the area and investigate the cause.

27. Where Are EEBDs Located?

Emergency Escape Breathing Devices (EEBDs) are located in engine rooms, control rooms, and accommodation areas, as per SOLAS requirements.

28. What Are the Regulations Regarding EEBDs?

- At least two EEBDs in the engine room and control room.

- Provide 10–15 minutes of breathable air.

- Must be regularly inspected and maintained.

29. How Many EEBDs Should Be in a Control Room?

Two EEBDs are required, as per SOLAS Chapter II-2.

30. What Are the Fixed Firefighting Systems?

- CO₂ Total Flooding: For engine rooms and cargo holds.

- Water Mist: For accommodation and machinery spaces.

- Foam Systems: For fuel-related fires.

- Dry Powder Systems: For specific hazards.

31. How Does a Water Mist System Detect a Fire?

It uses heat or smoke detectors to trigger water release, atomizing water into a fine mist to suppress the fire.

32. What Are the Different Types of Fire Detectors?

- Smoke Detectors: Photoelectric or ionization-based.

- Heat Detectors: Fixed temperature or rate-of-rise.

- Flame Detectors: Infrared or ultraviolet sensors.

Daily Duties and Watchkeeping

33. How Do You Take Over a Watch?

- Arrive early and inspect the engine room for abnormalities (noise, leaks, smells).

- Review the logbook for recent entries and parameter changes.

- Check main and auxiliary machinery, alarms, and standby equipment.

- Verify communication with the bridge and ensure the relieving officer is fit.

34. What Is Your Role in a Watch If Another Engineer Is Doing Maintenance?

- Monitor machinery parameters.

- Ensure safety protocols are followed during maintenance.

- Assist if required and maintain communication with the bridge.

35. What Are the Duties of a Third Engineer Regarding Fuel, Lube Oil, and Cooling Water Tanks?

- Monitor levels and quality.

- Conduct fuel transfers and purifications.

- Test lube oil for contamination and viscosity.

- Ensure cooling water is treated to prevent corrosion.

36. What Parameters Must Be Monitored for Running Machinery?

- Temperature: Exhaust, cooling water, and lube oil.

- Pressure: Fuel, lube oil, and air systems.

- Levels: Fuel, oil, and water tanks.

- Vibrations: To detect misalignment or wear.

Environmental and Regulatory Compliance

37. How Do You Ensure Compliance with Environmental Regulations?

- Adhere to MARPOL Annexes (e.g., Annex I for oil, Annex V for garbage).

- Use approved equipment like oily water separators (15 ppm limit).

- Maintain accurate Oil Record Book (ORB) entries.

- Follow Shipboard Oil Pollution Emergency Plan (SOPEP).

38. What Is Port State Control?

Port State Control involves inspections by coastal state authorities to ensure ships comply with international regulations like SOLAS and MARPOL.

39. What Is Flag State Control?

Flag State Control is the responsibility of the ship’s registering country to enforce compliance with international and national regulations.

40. What Is the Content of the SOLAS Training Manual and How Is It Used?

The SOLAS Training Manual provides guidance on safety procedures, emergency response, and equipment operation. It is used for crew training and drills.

41. What Is the Cargo Securing Manual?

It outlines procedures for safely securing cargo to prevent shifting, as required by SOLAS Chapter VI.

42. What Is the Purpose of the Hydrostatic Release Unit?

It automatically releases life rafts or EPIRBs in case of sinking, ensuring they float free.

43. What Is a Precision Aneroid Barometer and What Information Does It Provide?

It measures atmospheric pressure accurately, aiding in weather forecasting and navigation.

44. What Are Common Amendments to RORO Ship Regulations Regarding Fire Safety?

Enhanced fire detection, sprinkler systems, and structural fire protection are required, as per SOLAS Chapter II-2.

45. What Is the ISM Code?

The International Safety Management (ISM) Code ensures safe ship operations and pollution prevention through a safety management system.

46. What Is an IMO Convention?

IMO Conventions are binding legal instruments regulating maritime safety, pollution, and liability. Examples include SOLAS (1974) and MARPOL (1973/78).

47. How Many IMO Conventions Are There?

Approximately 50 conventions, covering safety, pollution, and liability.

48. What Is a Protocol?

A protocol modifies an existing convention to accelerate its enforcement, e.g., MARPOL 73/78.

49. Name Major IMO Conventions

- Safety: SOLAS (1974), STCW (1978), COLREGS (1972).

- Pollution: MARPOL (1973/78), OPRC (1990).

- Liability: CLC (1969), HNS (1996).

50. How Many Conventions Has Bangladesh Ratified?

Bangladesh has ratified 13 IMO conventions, including SOLAS, MARPOL, and STCW.

Auxiliary Systems and Maintenance

Operation of the Ship’s Sewage Treatment Plant

The sewage treatment plant processes waste to meet MARPOL Annex IV standards. It uses biological digestion and chemical treatment to break down solids, followed by disinfection. Maintenance includes:

- Cleaning filters and tanks.

- Checking pump and aerator functionality.

- Monitoring discharge quality (BOD < 25 mg/L).

Function of the Ship’s Ballast Water Treatment System

It removes invasive species from ballast water, as per the Ballast Water Management Convention. Systems use filtration, UV treatment, or chemical dosing. Maintenance involves cleaning filters and calibrating sensors.

Operation of the Ship’s Hydraulic Systems

Hydraulic systems power cranes, steering gears, and winches. They use pressurized fluid to transmit force. Maintenance includes checking fluid levels, filters, and seals for leaks.

Function of the Ship’s Emergency Generator

It provides power during main generator failure, supplying critical systems like emergency lighting and navigation. Operation involves regular testing and fuel checks.

Maintenance of Safety Equipment

- Lifeboats: Inspect davits, release mechanisms, and provisions.

- Fire Extinguishers: Check pressure, seals, and expiry dates.

Operation of the Fuel Oil Purifier

The purifier removes water and impurities from fuel oil using centrifugal force. Operation involves setting correct gravity discs and monitoring discharge quality.

Engine Room Workflow

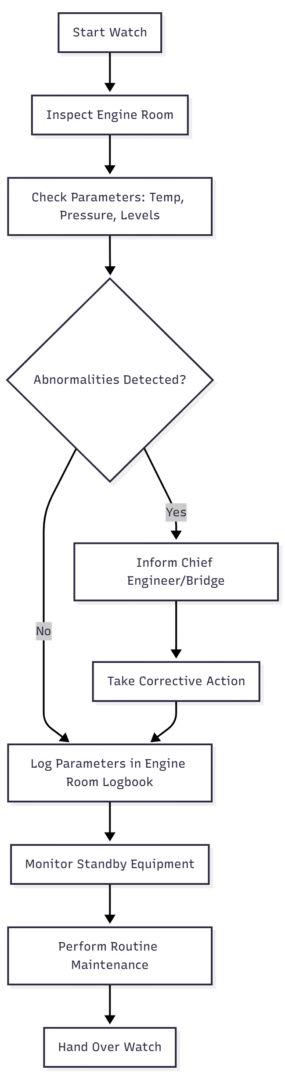

Below is a simplified workflow for Third Engineer duties during a watch, depicted using a flowchart:

This chart outlines the systematic approach to watchkeeping, ensuring all critical tasks are addressed.

Specifications and Costs (Where Applicable)

While specific costs for marine equipment vary by manufacturer and region, approximate ranges for key systems include:

- Oily Water Separator: $20,000–$50,000 (15 ppm compliance).

- Sewage Treatment Plant: $30,000–$100,000, depending on ship size.

- Emergency Generator: $50,000–$150,000, based on power capacity (100–500 kW).

- Firefighting Systems (CO₂/Water Mist): $100,000–$500,000 for installation.

Conclusion

The oral exam for Marine Third Engineer Officers is a rigorous test of technical expertise, safety awareness, and regulatory knowledge. By mastering the 50 questions outlined above, candidates can demonstrate their readiness to manage complex shipboard systems. From diesel engine maintenance to compliance with IMO conventions, preparation is key. Use this guide, complete with charts and practical insights, to excel in your exam and thrive in your role as a Third Engineer.

Happy Boating!

Share 50 Questions and Answers Asked in the Oral Exam for Marine Third Engineer Officers with your friends and leave a comment below with your thoughts.

Read Scavenge Fire of Two Stroke Marine Diesel Engine on Ships until we meet in the next article.