PSC focus on nox technical files and machinery components

Learn how PSC inspections enforce NOx Technical File and machinery compliance to meet MARPOL Annex VI, avoiding costly detentions.

As global regulations on air pollution tighten under the International Maritime Organization’s (IMO) MARPOL Annex VI, Port State Control (PSC) inspections are intensifying their scrutiny of nitrogen oxide (NOx) emissions from ships. This heightened focus targets NOx Technical Files, Engine International Air Pollution Prevention (EIAPP) Certificates, Record Books of Engine Parameters, and machinery components to ensure compliance with stringent environmental standards. Non-compliance can lead to vessel detentions, operational delays, and significant financial penalties, making it critical for shipowners and operators to prioritize adherence. This article provides an in-depth exploration of PSC inspection priorities, common deficiencies, their implications, and actionable steps to ensure compliance, aiming to equip maritime stakeholders with the knowledge to navigate these challenges effectively.

Understanding the Role of PSC in NOx Compliance

Port State Control (PSC) serves as the maritime industry’s enforcement mechanism to ensure vessels comply with international regulations, including those outlined in MARPOL Annex VI, which governs air pollution from ships. NOx, a major contributor to air pollution and smog, is a primary focus due to its environmental and health impacts. PSC inspections verify that ships meet NOx emission limits by examining documentation and physical components onboard. The goal is to confirm that vessels operate within the parameters set by their NOx Technical Files and adhere to global sustainability standards.

PSC inspections are conducted by Port State Control Officers (PSCOs) in various regions, with each jurisdiction emphasizing compliance with IMO regulations. Recent trends show a particular focus on NOx-related documentation and machinery, driven by the need to meet Tier I, II, and III emission standards, especially in designated Emission Control Areas (ECAs). Non-compliance can result in detainable deficiencies, triggering detailed inspections and operational disruptions.

Key Areas of PSC Inspection Focus

PSC inspections target several critical areas to verify NOx compliance. Below is a detailed breakdown of these focus areas, their significance, and what PSCOs look for during inspections.

1. NOx Technical Files and EIAPP Certificates

The NOx Technical File is a comprehensive document that outlines the specifications, components, and operational parameters of a marine diesel engine to ensure compliance with NOx emission limits. Accompanied by the EIAPP Certificate, it serves as proof that the engine meets MARPOL Annex VI requirements. PSCOs verify:

- Availability: Original NOx Technical Files and EIAPP Certificates must be onboard, either in physical or digital form (PDFs are considered originals for digitally issued documents).

- Accuracy: The file must align with the onboard engine’s configuration, including main engines and auxiliary generators.

- Updates: Any modifications to engine components or settings must be reflected in the file.

Common Issues:

- Missing files due to poor handover during ownership changes.

- Outdated files that do not reflect recent engine modifications.

- Digital files not recognized as originals due to improper formatting.

2. Record Book of Engine Parameters

The Record Book of Engine Parameters is a critical log that documents all changes to engine components, settings, or parameters that could affect NOx emissions. It is used in the engine parameter check method to verify compliance with the NOx Technical File. PSCOs check:

- Completeness: All changes, including component replacements (e.g., injection pumps) and settings adjustments, must be logged.

- Accuracy: Entries must include dates, old and new component IDs, and verified settings.

- Consistency: Records must align with the specifications in the NOx Technical File.

Common Issues:

- Missing entries for replaced components, such as fuel injectors or charge air coolers.

- Incomplete records lacking critical details like IMO identification numbers.

- Poor crew understanding of record-keeping requirements.

3. Machinery Components and Spare Parts

PSC inspections include physical verification of engine components and spare parts to ensure they match the specifications in the NOx Technical File. This involves checking:

- IMO Identification Numbers: All components and spare parts must carry valid IMO IDs as specified in the Technical File.

- Compliance: Components must be approved for use in the engine’s configuration.

- Condition: Parts must be in good working order and properly installed.

Common Issues:

- Components lacking IMO IDs, such as charge air coolers or fuel pumps.

- Spare parts not matching Technical File specifications.

- Unauthorized or unapproved component replacements.

4. Tier III Compliance in Emission Control Areas (ECAs)

In NOx Tier III ECAs, such as parts of the Baltic Sea, North Sea, and North American coasts, ships must meet stricter emission limits. PSCOs verify:

- Engine Certification: Engines must be Tier III-certified when operating in ECAs.

- Operational Records: Logs must confirm the engine’s tier status and compliance measures in ECAs.

- Documentation: Records must demonstrate adherence to Tier III requirements.

Common Issues:

- Missing documentation proving Tier III compliance.

- Non-certified engines operating in ECAs.

- Inadequate records of ECA operations.

Common Deficiencies and Their Implications

PSC inspections frequently uncover deficiencies that lead to detainable findings, disrupting operations and incurring costs. Below is a table summarizing the most common deficiencies, their associated codes, and their implications, based on recent inspection trends.

| Deficiency Code | Defective Item | Description | Implications |

|---|---|---|---|

| 14601 | NOx Technical Files | Missing or incomplete files for main or auxiliary engines. | Immediate detention; inability to verify compliance. |

| 14602 | Record Book of Engine Parameters | Incomplete or missing entries for component replacements or settings. | Detention; triggers detailed inspections. |

| 14606 | Diesel Engine Air Pollution Control | Components (e.g., charge air coolers) lack IMO IDs. | Detention; may require disassembly for verification. |

| 14607 | Spare Parts Compliance | Spare parts do not match Technical File specifications. | Detailed inspections; potential detention. |

| 14613 | MARPOL Annex VI Compliance | Failure to meet Tier III standards in ECAs. | Detention; operational restrictions in ECAs. |

Underlying Causes of Deficiencies

DNV, a leading classification society, notes that many deficiencies stem from:

- Inadequate Crew Training: Lack of understanding of MARPOL Annex VI requirements.

- Poor Documentation Practices: Missing or outdated records during ownership changes.

- Inventory Mismanagement: Spare parts not verified against Technical File specifications.

- Misunderstandings: Unclear instructions on maintaining Record Books or component IDs.

Consequences of Non-Compliance

Non-compliance with NOx regulations can have severe repercussions, including:

- Vessel Detentions: Delays disrupt schedules, impacting charter agreements and revenue.

- Detailed Inspections: PSCOs may request disassembly of components, increasing costs and downtime.

- Financial Penalties: Fines vary by jurisdiction but can be substantial.

- Reputational Damage: Frequent detentions harm an operator’s standing with regulators and clients.

- Environmental Impact: Non-compliance undermines global efforts to reduce air pollution.

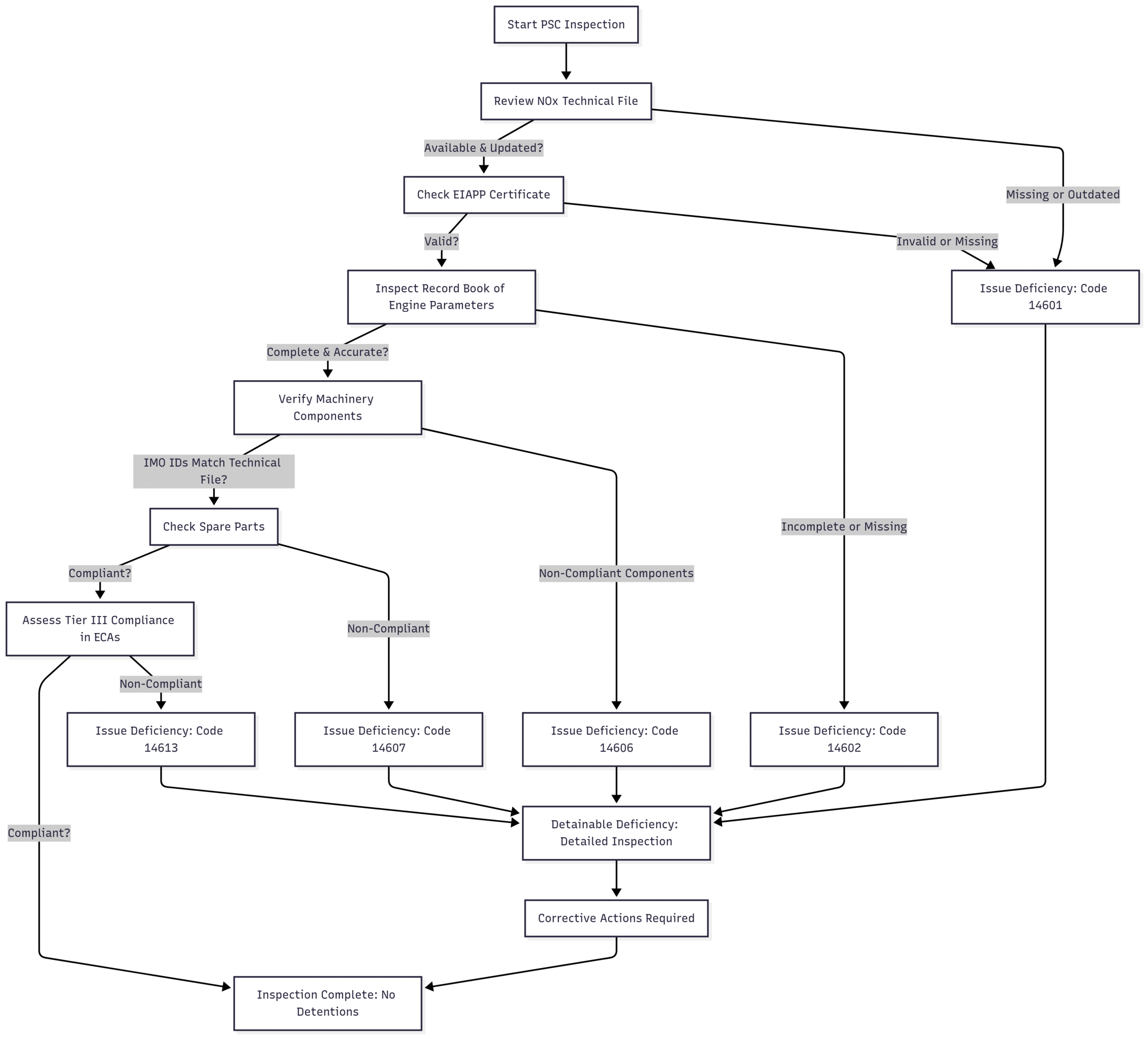

Chart: PSC Inspection Workflow for NOx Compliance

To illustrate the PSC inspection process for NOx compliance, the following flowchart outlines the steps PSCOs typically follow.

This chart highlights the sequential nature of PSC inspections and the points where deficiencies can lead to detentions, emphasizing the importance of thorough preparation.

Steps to Ensure Compliance

To avoid deficiencies and ensure smooth PSC inspections, shipowners and operators should adopt the following best practices, tailored to address the key focus areas outlined above.

1. Maintain Up-to-Date Documentation

- Action: Ensure NOx Technical Files and EIAPP Certificates are onboard in their original form (physical or digital PDFs).

- Process: During ownership changes, verify that all documents are transferred. If missing, contact the engine manufacturer for replacements or DNV for reissued certificates.

- Tools: Use digital document management systems to track and store files securely.

2. Keep the Record Book of Engine Parameters Updated

- Action: Log all parameter changes, component replacements, and settings adjustments.

- Details: Include dates, old and new component IDs, and verified settings. Use templates provided in some Technical Files if available.

- Training: Train crew on proper record-keeping practices to ensure consistency and accuracy.

3. Verify Spare Parts Compliance

- Action: Regularly inspect spare parts to confirm they carry valid IMO IDs and match Technical File specifications.

- Process: Implement an inventory management system to track spare parts against approved documentation.

- Resolution: If discrepancies arise, consult the engine manufacturer to amend the Technical File or replace non-compliant parts.

4. Conduct Routine Engine Inspections

- Action: Inspect engine components and adjustable features to ensure compliance with Technical File specifications.

- Frequency: Schedule inspections before entering ports with strict PSC enforcement.

- Preparation: Be ready for potential disassembly requests by maintaining detailed maintenance logs.

5. Prepare for Tier III Requirements in ECAs

- Action: Verify that engines operating in ECAs are Tier III-certified.

- Records: Maintain logs of ECA operations and tier status to demonstrate compliance.

- Collaboration: Work with engine manufacturers to ensure engines are upgraded or certified as needed.

6. Leverage Expert Support

- Action: Consult engine manufacturers, classification societies, or DNV for guidance on complex issues.

- Resources: Use DNV’s PSC Planner tool, which includes updated checklists for NOx compliance.

- Engagement: Participate in industry forums like forums such as Seafarer’s World or DNV’s technical support channels for real-time advice.

Case Study: Addressing Common Scenarios

To provide practical insights, consider these hypothetical scenarios and how to address them:

- Missing NOx Technical File:

- Situation: A vessel is detained due to a missing Technical File after a recent ownership change.

- Solution: Contact the engine manufacturer to obtain a replacement file. Temporarily provide evidence of the request to PSCOs to mitigate penalties. Train crew to verify documentation during ownership transitions.

- Incomplete Log Book:

- Situation: The Record Book lacks entries for a replaced injection pump, triggering a deficiency.

- Solution: Update the Record Book with all missing details, including dates and IDs. Implement crew training on log-keeping and use a digital logbook template for consistency.

- Non-Compliant Spare Part:

- Situation: A spare charge air cooler lacks an IMO ID, leading to a detailed inspection.

- Solution: Contact the manufacturer to confirm if the part is approved via a Technical File amendment. Replace the part if unapproved and update inventory checks.

Why Compliance Matters

Compliance with NOx regulations is not only a legal requirement but also a strategic imperative for maritime operators. The benefits of proactive compliance include:

- Operational Continuity: Avoiding detentions ensures schedules are met, maintaining revenue and client trust.

- Cost Savings: Preventing fines and inspection delays reduces operational expenses.

- Environmental Responsibility: Meeting NOx standards contributes to global sustainability efforts, aligning with IMO’s 2050 GHG reduction goals.

- Reputation: Consistent compliance enhances an operator’s standing with regulators and stakeholders.

Conversely, non-compliance risks include:

- Delays: Detentions can last days, disrupting schedules and charters.

- Costs: Fines, repairs, and inspections can cost thousands of dollars per incident.

- Reputational Harm: Repeated issues can lead to scrutiny from charters and regulators.

Recommendations for Long-Term Success

To stay ahead of PSC inspections and maintain compliance, consider these strategic recommendations:

- Invest in Training: Regular crew training on MARPOL Annex VI and PSC requirements.

- Implement Digital Solutions: Use tools like DNV’s PSC Planner or electronic record-keeping systems.

- Conduct Internal Audits: Regularly verify documentation, spare parts, and engine compliance.

- Stay Informed: Monitor updates to IMO regulations and PSC guidelines via industry forums.

- Collaborate: Work with classification societies and manufacturers for ongoing support.

Conclusion

The maritime industry faces increasing pressure to comply with NOx emission regulations under MARPOL Annex VI, with PSC inspections playing a critical role in enforcement. By prioritizing NOx Technical Files, Record Books of Engine Parameters, and machinery component compliance, shipowners and operators can avoid costly detentions and contribute to global sustainability efforts. Proactive documentation, crew training, and collaboration with experts are essential to navigating these challenges successfully. Stay prepared, stay compliant, and keep your fleet operational with these actionable insights.

For further guidance, engage with industry resources like DNV’s PSC Planner, Seafarer’s World, or Marine Surveyor Consultant for updates and support. Keep your operations ahead of the curve in the ever-evolving landscape of maritime compliance.

Happy Boating!

Share PSC focus on nox technical files and machinery components with your friends and leave a comment below with your thoughts.

Read MAN B&W Two-Stroke Slow-Speed Diesel Engines until we meet in the next article.