Primer Solenoid: Position, Function, and Troubleshooting

Learn about the primer solenoid in outboard motors, its function, symptoms of failure, and troubleshooting steps for optimal performance.

The primer solenoid is a critical component in outboard motors, ensuring smooth engine starts, particularly in cold conditions. This article provides an in-depth exploration of the primer solenoid’s role, its position in the fuel system, symptoms of failure, and comprehensive troubleshooting steps to diagnose and resolve issues. Designed for boat owners, marine mechanics, and enthusiasts, this guide also includes practical insights from real-world scenarios, specifications for common outboard motors, and visual aids to enhance understanding.

What is a Primer Solenoid?

The primer solenoid is an electromechanical valve in the fuel system of two-stroke and some four-stroke outboard motors. Its primary function is to deliver a controlled amount of fuel to the engine’s intake manifold during startup, especially when the engine is cold. This additional fuel enriches the air-fuel mixture, facilitating combustion in low-temperature conditions where fuel vaporization is less efficient.

Unlike the fuel pump, which pressurizes the fuel system, or the primer bulb, which manually primes the system, the solenoid acts as an on/off valve. When activated—typically by pushing the ignition key—it opens to allow fuel to flow into the carburetor or intake manifold, driven by pressure from the fuel pump or primer bulb. The solenoid’s operation is critical for cold starts, as it compensates for the engine’s need for a richer mixture until it warms up.

Position in the Fuel System

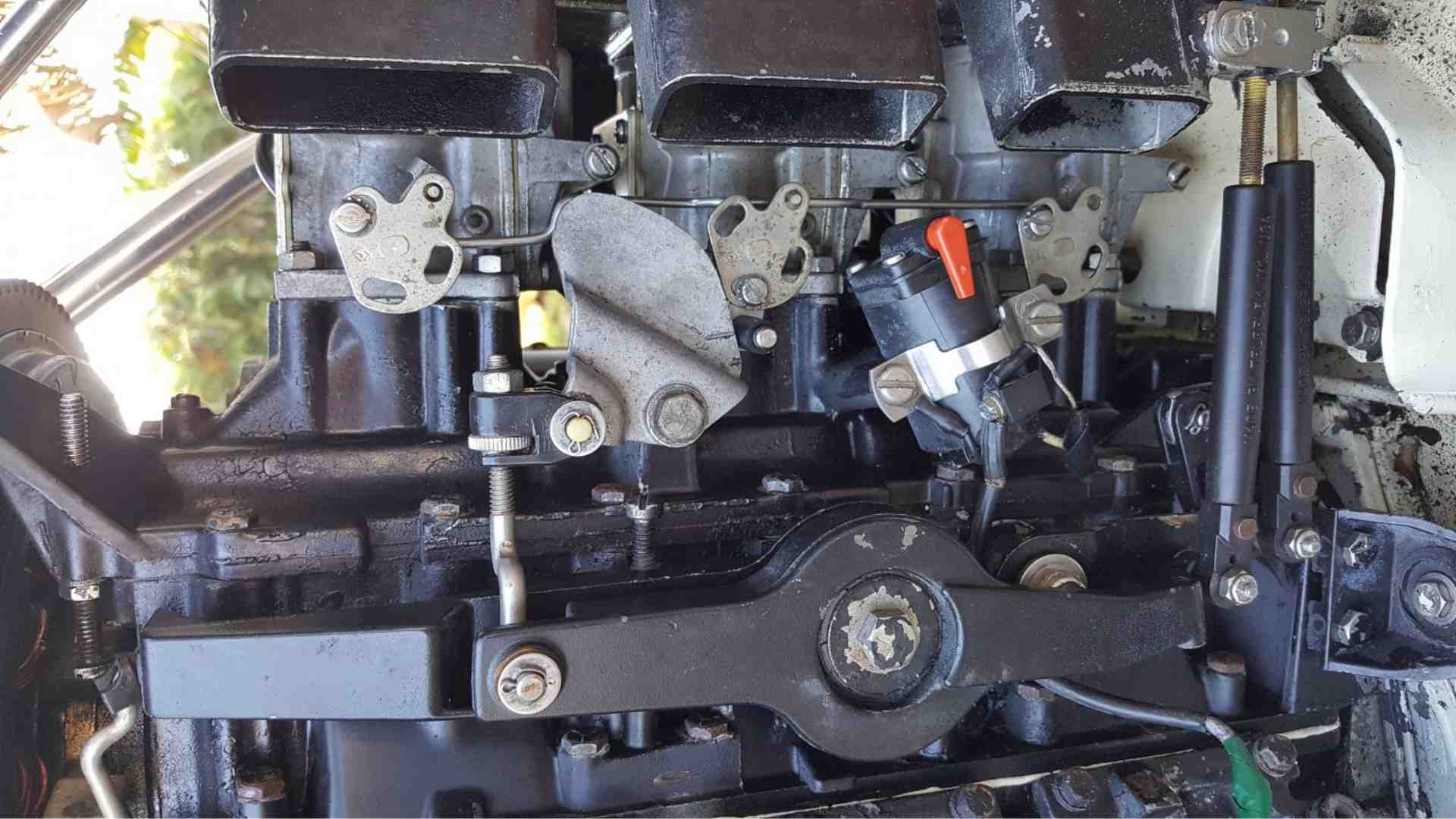

The primer solenoid is typically located between the fuel pump and the carburetor or intake manifold. In most outboard motors, such as Johnson, Evinrude, or Mercury models, it is mounted on or near the engine block, often identifiable by its two electrical wires and a red manual override lever or knob. The solenoid is connected to the fuel line, sometimes via a T-fitting that integrates it with the main fuel line feeding the carburetors.

In a typical setup:

- Fuel Line Connection: The solenoid receives fuel from the fuel pump or primer bulb and directs it to the carburetor or intake manifold.

- Electrical Connection: Two wires connect the solenoid to the ignition switch, allowing it to activate when the key is pushed in.

- Manual Override: The red lever or knob allows manual fuel delivery, bypassing the solenoid’s electrical function for emergency starts.

The exact position varies by engine model. For example, in a 1995 Johnson 50 HP outboard, the solenoid is near the carburetors, with small hoses (e.g., 1/16-inch or 5/16-inch) connecting it to the fuel system. In a 2008 Evinrude E-TEC 200 HP, it’s integrated with the fuel bracket or vapor separator tank (VST).

Function of the Primer Solenoid

The primer solenoid’s primary role is to enrich the fuel mixture during cold starts. When the ignition key is pushed in (with the key in the “RUN” or “ACCESSORY” position), the solenoid receives 12 volts, causing its internal plunger to open a valve. This allows pressurized fuel to flow into the intake manifold or carburetor, providing the extra fuel needed for ignition.

Key functions include:

- Cold Start Enrichment: Delivers additional fuel to ensure reliable ignition in cold conditions.

- Controlled Fuel Delivery: Acts as a precise valve, opening only when activated to prevent over-fueling.

- Manual Override Capability: The red lever allows manual operation if the solenoid fails, ensuring the engine can still start.

The solenoid does not pressurize fuel itself; it relies on the fuel pump or primer bulb for pressure. For instance, in a Johnson 70 HP (2000 model), the solenoid opens to allow fuel to flow into the carburetor throats, driven by the VRO pump or manual bulb pressure.

How It Works

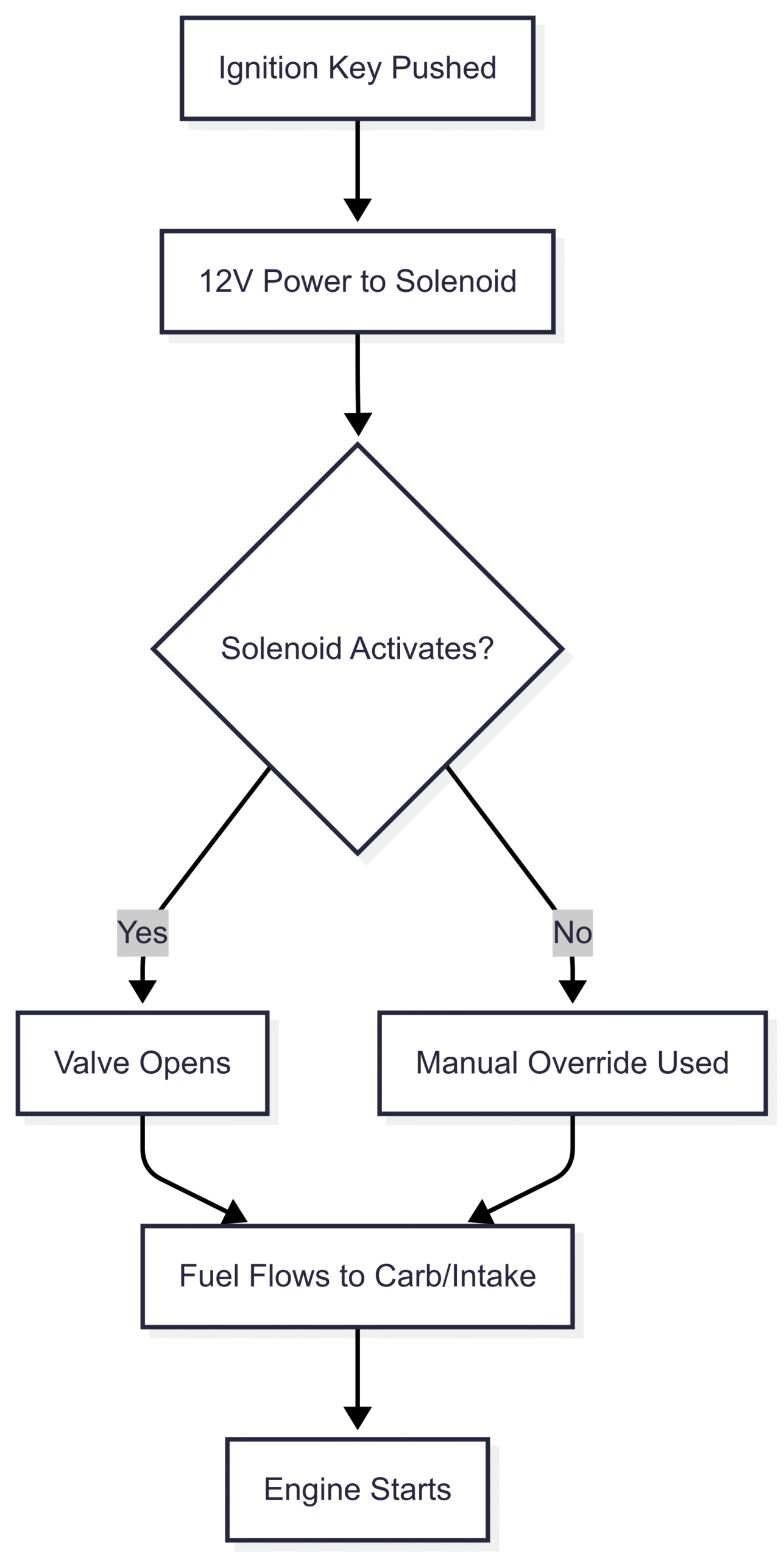

Here’s a simplified flowchart of the primer solenoid’s operation:

This process ensures the engine receives the necessary fuel for a successful cold start. Once the engine warms up, the solenoid typically remains closed, and the carburetor or fuel injection system takes over normal fuel delivery.

Symptoms of a Faulty Primer Solenoid

A malfunctioning primer solenoid can cause a range of starting and performance issues. Below are the most common symptoms, drawn from real-world experiences and technical insights:

- No-Start Condition (Cold Engine):

- The engine fails to start when cold due to insufficient fuel delivery. For example, users of a 1998 Johnson Venom 200 reported that the motor was hard to start when cold but ran normally once warm.

- Cause: The solenoid may not open, preventing fuel from reaching the intake manifold.

- Difficulty Starting:

- The engine requires excessive cranking or multiple priming attempts. A 1995 JohnsonOr 50 HP owner noted that the engine took 10 minutes to start, with sputtering and hesitation.

- Cause: A partially functioning solenoid or clogged internal濾filter may restrict fuel flow.

- Flooded Engine:

- A stuck-open solenoid can deliver too much fuel, flooding the engine. Symptoms include a strong fuel smell, black smoke from the exhaust, or fuel pooling in the carburetor.

- Cause: Damaged internal seals or a stuck plunger allows continuous fuel flow.

- Fuel Leaks:

- Fuel may leak from the solenoid or its hoses, as reported with a 1990 Johnson 60 HP VRO, where fuel trickled around the red knob.

- Cause: Worn seals, a cracked red knob, or a damaged solenoid body.

- No or Reduced Fuel Flow:

- When the key is pushed, no fuel flows through the solenoid, or the flow is weak (e.g., oozing instead of squirting). A user with a Johnson 50 HP noted slow fuel flow even after priming the bulb.

- Cause: Electrical failure (no solenoid activation) or a clogged internal filter.

- Intermittent Operation:

- The solenoid may work sporadically, as seen in a 2008 Evinrude E-TEC 200 HP case where it failed for weeks but suddenly worked again.

- Cause: Loose wiring, poor grounding, or internal solenoid issues.

Table: Common Symptoms and Causes

| Symptom | Possible Cause | Example Engine |

|---|---|---|

| No-start (cold) | Solenoid not opening, no fuel delivery | 1998 Johnson Venom 200 |

| Difficulty starting | Clogged filter, partial solenoid failure | 1995 Johnson 50 HP |

| Flooded engine | Stuck-open solenoid, damaged seals | 1990 Johnson 60 HP VRO |

| Fuel leaks | Cracked knob, worn seals | 1990 Johnson 60 HP VRO |

| No/reduced fuel flow | Electrical failure, clogged filter | 1995 Johnson 50 HP |

| Intermittent operation | Loose wiring, poor grounding | 2008 Evinrude E-TEC 200 HP |

Troubleshooting the Primer Solenoid

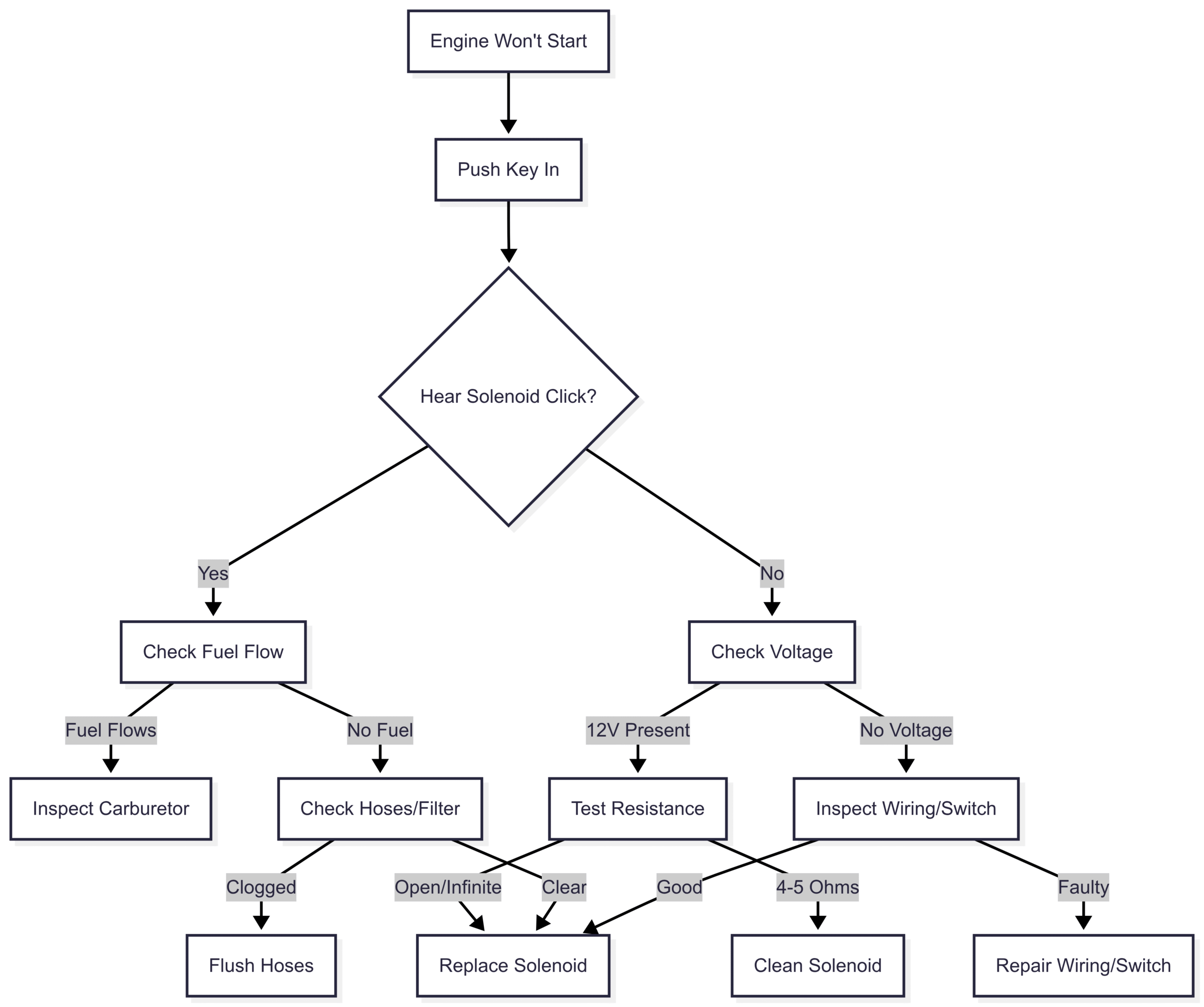

Diagnosing a faulty primer solenoid involves systematic checks of its electrical and mechanical components. Below is a step-by-step guide based on expert advice and user experiences:

Step 1: Verify Voltage Supply

- Tools Needed: Multimeter (volt/ohm meter, available for as low as $8.95).

- Procedure:

- Turn the ignition key to the “RUN” or “ACCESSORY” position and push it in.

- Measure voltage across the solenoid’s two wires. You should see approximately 12 volts DC.

- Example: A 2008 Evinrude E-TEC 200 HP user confirmed 12.5 VDC at the solenoid but no click, indicating a potential internal failure.

- If Voltage is Absent:

- Check the ignition switch for faults.

- Inspect wiring for loose connections, corrosion, or breaks, especially the ground wire.

Step 2: Inspect Wiring and Connections

- Procedure:

- Visually inspect the wires leading to the solenoid for damage, corrosion, or loose connections.

- Clean connectors with electrical contact cleaner or fine sandpaper.

- Example: A 1990 Johnson 60 HP user resolved intermittent clicking by cleaning the ground wire contact.

- Tip: Ethanol fuel can swell gaskets (e.g., black gaskets in older models), causing electrical issues. Newer brown gaskets are more resistant.

Step 3: Test Solenoid Resistance

- Tools Needed: Multimeter set to a low resistance scale.

- Procedure:

- Disconnect the solenoid’s two wires.

- Measure resistance across the solenoid terminals. A reading of 4–5 ohms is typical for a functioning solenoid; 0–1 ohm may also indicate it’s operational, per some tutorials.

- An “open” reading (infinite resistance) indicates a failed solenoid, as seen in a 2008 Evinrude case.

- If Resistance is Incorrect:

- The solenoid is likely faulty and should be replaced.

Step 4: Check Fuel Flow

- Tools Needed: None (optional: container to catch fuel).

- Procedure:

- Pump the primer bulb until firm to pressurize the fuel system.

- Disconnect a primer line from the carburetor or intake manifold.

- Turn the key to “RUN” and push it in. Fuel should flow (ideally squirt, not ooze) from the disconnected hose.

- Example: A Johnson 50 HP user noted slow oozing, indicating a clogged filter or weak solenoid action.

- If No Fuel Flows:

- Check for a clogged internal filter in the solenoid.

- Verify the fuel pump is delivering adequate pressure.

- Use the manual override lever to test fuel flow manually.

Step 5: Inspect the Manual Override

- Procedure:

- Turn the red lever or knob (typically 1/3 of a turn) to manually open the solenoid valve.

- Check if fuel flows and the engine starts. This bypasses the electrical system, as used successfully in a 1998 Johnson Venom 200.

- Note: The red lever is for emergency use only. Continuous use indicates a solenoid or electrical issue that needs repair.

Step 6: Check for Clogs

- Procedure:

- Flush small hoses (e.g., 1/16-inch lines) with carburetor cleaner and a straw attachment.

- Inspect the solenoid’s internal filter, which can clog over time, reducing fuel flow.

- Example: A 1995 Johnson 50 HP user improved flow by flushing hoses after noticing weak fuel delivery.

Step 7: Adjust Idle and Carburetor Settings

- Procedure:

- If the solenoid appears functional but starting issues persist, adjust the carburetor’s low-speed needle valve.

- Initial Setting: Gently seat the needle, then open 1-1/2 turns. Fine-tune in 1/8-turn increments until the engine idles smoothly at 1,000–1,500 RPM (in gear, in water).

- Example: A 1994 Evinrude 25 HP user resolved surging by adjusting the carburetor after confirming the solenoid was not the issue.

- Note: Check the carburetor float setting (slightly higher at the free end when upside down) to prevent fuel delivery issues.

Step 8: Replace the Solenoid

- Procedure:

- If all tests indicate a faulty solenoid (no click, incorrect resistance, no fuel flow), replace it.

- Cost: Replacement solenoids for Johnson/Evinrude models typically cost $50–$150, depending on the model and whether purchased new or used (e.g., eBay).

- Example: A 2008 Evinrude user sourced a used solenoid for a lower cost, which restored normal operation.

Troubleshooting Flowchart

Specifications and Pricing

The primer solenoid’s specifications vary by engine model, but common characteristics include:

- Voltage: 12V DC

- Resistance: 4–5 ohms (typical)

- Hose Sizes: 1/16-inch, 5/16-inch, or 3/8-inch, depending on the model

- Material: Corrosion-resistant metal and plastic, with rubber seals

Table: Sample Primer Solenoid Specifications

| Engine Model | Part Number | Hose Size | Price (USD) |

|---|---|---|---|

| 1995 Johnson 50 HP | 0437237 | 5/16-inch | $80–$120 |

| 1998 Johnson Venom 200 | 0437237 | 3/8-inch | $90–$150 |

| 2008 Evinrude E-TEC 200 HP | 0586785 | 3/8-inch | $100–$150 |

| 1994 Evinrude 25 HP | 0437237 | 1/16-inch | $50–$100 |

Note: Prices are approximate and based on online retailers (e.g., eBay, marine supply stores). Always verify the part number for your specific engine model.

Common Issues and Solutions

Intermittent Solenoid Operation

- Issue: The solenoid works sporadically, as seen in a 2008 Evinrude case where it failed but later worked again.

- Solution: Check and clean all electrical connections. Replace the solenoid if it continues to fail.

Clogged Hoses or Filter

- Issue: Small hoses or the solenoid’s internal filter clog, reducing fuel flow.

- Solution: Flush with carburetor cleaner. Replace hoses if they feel soft or degraded.

Fuel Leaks

- Issue: Fuel leaks from the solenoid or red knob, often due to cracked components or worn seals.

- Solution: Replace the red knob, seals, or the entire solenoid. Ensure ethanol-resistant gaskets are used.

Engine Surging or Stalling

- Issue: The engine surges or stalls, as reported with a 1994 Evinrude 25 HP, even with a functional solenoid.

- Solution: Adjust the carburetor low-speed needle and check the float setting. Verify the fuel pump’s diaphragm for tears.

Tips for Maintenance

- Regular Inspection: Check hoses and connections for wear, especially in saltwater environments where corrosion is common.

- Use Ethanol-Resistant Components: Modern fuels with ethanol can degrade older gaskets. Upgrade to brown gaskets for better durability.

- Test Periodically: Before each boating season, test the solenoid’s click and fuel flow to catch issues early.

- Avoid Over-Priming: Hold the key in for 5–10 seconds during cold starts to avoid flooding, as advised for Mercury outboards.

- Keep a Spare: Solenoids are relatively inexpensive, and having a spare (as one user did with a 2008 Evinrude) can save a trip.

Real-World Insights

User experiences highlight the primer solenoid’s critical role and the frustration of diagnosing intermittent issues. For instance:

- A 1998 Johnson Venom 200 owner struggled with cold starts but found that manual priming worked, pointing to a solenoid issue.

- A 2008 Evinrude E-TEC user experienced a solenoid that failed, then mysteriously worked again, underscoring the importance of thorough electrical checks.

- A 1995 Johnson 50 HP owner resolved weak fuel flow by flushing hoses, avoiding a costly solenoid replacement.

These cases emphasize the need for systematic troubleshooting and the value of community forums for sharing practical solutions.

Conclusion

The primer solenoid is a small but vital component in outboard motors, ensuring reliable cold starts by delivering the right amount of fuel. Understanding its position, function, and potential failure symptoms empowers boat owners to diagnose and fix issues efficiently. By following the troubleshooting steps outlined—checking voltage, inspecting wiring, testing fuel flow, and adjusting carburetors—most solenoid-related problems can be resolved without professional help. Regular maintenance and the use of ethanol-resistant components can prevent issues, while keeping a spare solenoid on hand ensures you’re never stranded on the water.

For specific engine models like the Johnson 50 HP, Evinrude 25 HP, or E-TEC 200 HP, always consult the manufacturer’s manual for part numbers and specifications. With the right tools and knowledge, you can keep your outboard motor running smoothly, season after season.

Happy boating!

Share Primer Solenoid: Position, Function, and Troubleshooting with your friends and leave a comment below with your thoughts.

Read 5 Most Common Problems with Craigcat Boat until we meet in the next article.