Port State Control Inspections Explained: What to Expect

Understand Port State Control inspections: what they are, who’s targeted, and how to prepare. Ensure compliance and avoid detentions with our expert guide.

Port State Control (PSC) inspections are a cornerstone of maritime safety, ensuring that ships sailing international waters comply with global standards for safety, environmental protection, and crew welfare. These inspections, conducted by port authorities on foreign-flagged vessels, act as a critical safety net, catching substandard ships that could pose risks to lives, property, or the environment. This article dives deep into what PSC inspections entail, who they impact, how they’re conducted, and how to prepare effectively to avoid costly detentions.

What Is Port State Control?

Port State Control refers to the process by which countries inspect foreign ships in their ports to verify compliance with international maritime regulations. These regulations stem from conventions established by the International Maritime Organization (IMO), including:

- SOLAS (Safety of Life at Sea): Governs ship safety and emergency preparedness.

- MARPOL (International Convention for the Prevention of Pollution from Ships): Focuses on environmental protection.

- STCW (Standards of Training, Certification, and Watchkeeping): Ensures crew competency.

- ISPS (International Ship and Port Facility Security Code): Addresses maritime security.

- BWM (Ballast Water Management): Regulates ballast water to prevent ecological harm.

PSC inspections serve as a backup to flag state oversight, ensuring that vessels meet these standards regardless of their country of registry. Governed by regional agreements called Memoranda of Understanding (MoUs), PSC regimes like the Paris MoU (Europe and North Atlantic), Tokyo MoU (Asia-Pacific), and others harmonize inspection efforts to target substandard vessels efficiently.

The legal foundation for PSC lies in international frameworks like the United Nations Convention on the Law of the Sea (UNCLOS). Articles 218 and 219 of UNCLOS empower port states to investigate and detain vessels that violate international rules, particularly those threatening marine environments. IMO conventions, such as SOLAS regulation I/19 and MARPOL article 6, further outline control procedures, ensuring inspections are consistent and fair.

Why PSC Inspections Matter

Substandard ships—those with deficient equipment, untrained crews, or non-compliant operations—pose significant risks. A single failure, like a faulty fire suppression system or an oil leak, can lead to catastrophic accidents, environmental disasters, or loss of life. PSC inspections mitigate these risks by:

- Enhancing Safety: Ensuring vessels are seaworthy and equipped for emergencies.

- Protecting the Environment: Preventing pollution from oil spills, untreated ballast water, or improper waste disposal.

- Safeguarding Crew Welfare: Verifying that crew members are trained, certified, and working in safe conditions.

The Global Integrated Shipping Information System (GISIS) plays a pivotal role in this process. Its PSC module allows authorities to share inspection data, track deficiencies, and monitor corrective actions across regions. This global collaboration ensures that a ship flagged in one port can’t simply sail to another to evade scrutiny.

Who’s Involved and Who’s at Risk?

PSC inspections impact a wide range of stakeholders in the maritime industry. Understanding who’s affected and why certain vessels are targeted is key to preparing effectively.

Key Stakeholders

- Ship’s Masters: As the primary point of contact during inspections, masters must present all documentation, demonstrate operational knowledge, and set a professional tone. A flustered or unprepared master can escalate a routine inspection into a detailed one.

- Technical Managers: Responsible for vessel maintenance, technical managers ensure equipment like bilge alarms, fire systems, and navigation gear is operational. Poor maintenance records or neglected repairs often lead to deficiencies.

- Crewing Departments: Crew certifications, medicals, and training records must be current. Expired or mismatched credentials are among the top reasons for detentions.

- Port Agents and Operations Teams: Detentions disrupt schedules, requiring agents to manage delays, reschedule cargo operations, and liaise with stakeholders. Proactive communication with the master can mitigate fallout.

- Flag State Authorities: A flag state’s reputation hinges on its fleet’s performance. High detention rates can land a flag state on regional MoU blacklists, increasing scrutiny for all its vessels.

High-Risk Vessels

Not all ships face the same level of scrutiny. PSC authorities use risk-based targeting, leveraging GISIS data to prioritize inspections. Vessels are more likely to be inspected if they:

- Operate under a flag state with a poor detention record (e.g., those on Paris or Tokyo MoU blacklists).

- Have a history of deficiencies or detentions.

- Are older or belong to high-risk ship types (e.g., bulk carriers, oil tankers).

- Enter regions with strict enforcement, such as Europe (Paris MoU) or Asia-Pacific (Tokyo MoU).

- Are part of a concentrated inspection campaign (CIC), which focuses on specific issues like fire safety or crew welfare for a set period.

Once a vessel is flagged as high-risk, it’s subject to more frequent and thorough inspections, making preparation critical.

How PSC Inspections Work

PSC inspections are methodical but unpredictable. They can range from quick document checks to exhaustive physical inspections, depending on the vessel’s risk profile and initial findings. Here’s a step-by-step breakdown of what to expect:

1. Boarding the Vessel

PSC officers, often from the Coast Guard or maritime authorities, board the vessel—sometimes unannounced. They expect immediate access and cooperation. The ship’s master greets them, setting the tone for the inspection. A disorganized or evasive response raises red flags, prompting a deeper investigation.

2. Document and Certificate Review

The inspection begins with a review of statutory and classification documents, including:

- SOLAS, MARPOL, ISPS, and STCW certificates.

- Crew licenses, medical certificates, and training records.

- Safety Management System (SMS) and Ship Security Plan (SSP) documentation.

- Port entry documents, such as the electronic Notice of Arrival/Departure (eNOAD).

- Previous PSC reports and corrective action records.

Missing, expired, or inconsistent documents can trigger a more detailed inspection. For example, a single outdated medical certificate can lead to crew competency questions, extending the inspection.

3. Physical Walkthrough and Equipment Check

If documents pass muster, inspectors conduct a physical walkthrough, focusing on:

- Bridge: Navigation equipment (radar, AIS, GPS) must be functional, with up-to-date logbooks. Inspectors may request equipment demonstrations.

- Engine Room: Cleanliness, absence of oil leaks, and functioning alarms are critical. Worn belts or fire hazards are common deficiencies.

- Firefighting and Life-Saving Gear: Extinguishers, lifeboats, liferafts, and emergency exits must be operational, serviced, and free of corrosion.

- Deck and Hull: Mooring equipment, ladders, and hatch covers are checked for safety and maintenance.

Attempting to conceal issues often backfires, as inspectors are trained to spot discrepancies.

4. Crew Interviews and Spot Checks

Inspectors may question crew members about emergency procedures, security protocols, or equipment operation. Inconsistent or incorrect answers suggest inadequate training or falsified drill records, which can lead to detentions. For example, a crew member unable to explain their role in a fire drill can escalate the inspection.

5. Types of Inspections

PSC inspections vary in scope based on risk and findings:

- Initial Inspection: A basic check of certificates and general compliance. Typically brief unless issues arise.

- More Detailed Inspection: Triggered by inconsistencies, such as missing documents or equipment failures.

- Expanded Inspection: Reserved for high-risk vessels or those with poor inspection histories. Covers all systems in depth.

- Follow-Up Inspection: Verifies corrections from previous deficiencies.

The type of inspection isn’t always clear upfront, and a routine check can escalate if problems are detected.

6. Outcomes

Post-inspection, officers issue a report with one of three outcomes:

- Clean Report: No deficiencies; the vessel is cleared to proceed.

- Deficiencies with Correction Timeline: Minor issues must be fixed by a specified date or port call.

- Detention: Serious violations (e.g., expired certificates, unseaworthy conditions) result in the vessel being held until corrections are made.

Detentions are costly, disrupting schedules, incurring port fees, and frustrating stakeholders. Incomplete customs bonds or port entry documents can compound delays.

Regional PSC Regimes and GISIS

PSC inspections are coordinated through ten regional regimes, each with its own MoU or agreement:

| Regime | Region | Key Focus |

|---|---|---|

| Paris MoU | Europe, North Atlantic | Strict enforcement, frequent CICs |

| Tokyo MoU | Asia-Pacific | High volume of inspections |

| Acuerdo de Viña del Mar | Latin America | Growing regional coordination |

| Caribbean MoU | Caribbean | Focus on cruise and cargo ships |

| Abuja MoU | West and Central Africa | Developing PSC capabilities |

| Black Sea MoU | Black Sea | Emphasis on regional collaboration |

| Mediterranean MoU | Mediterranean Sea | Security and environmental compliance |

| Indian Ocean MoU | Indian Ocean | Targeting substandard vessels |

| Riyadh MoU | Persian Gulf | Oil tanker and regional trade focus |

| U.S. Coast Guard | United States | Rigorous inspections, high standards |

These regimes share data via GISIS, enabling a global approach to tracking substandard ships. The system’s PSC module records inspection outcomes, deficiencies, and detentions, allowing authorities to:

- Assess Risk: Identify high-risk vessels based on age, flag state, or inspection history.

- Monitor Compliance: Track corrective actions and ensure vessels meet standards before departure.

- Coordinate Globally: Prevent non-compliant ships from moving undetected between regions.

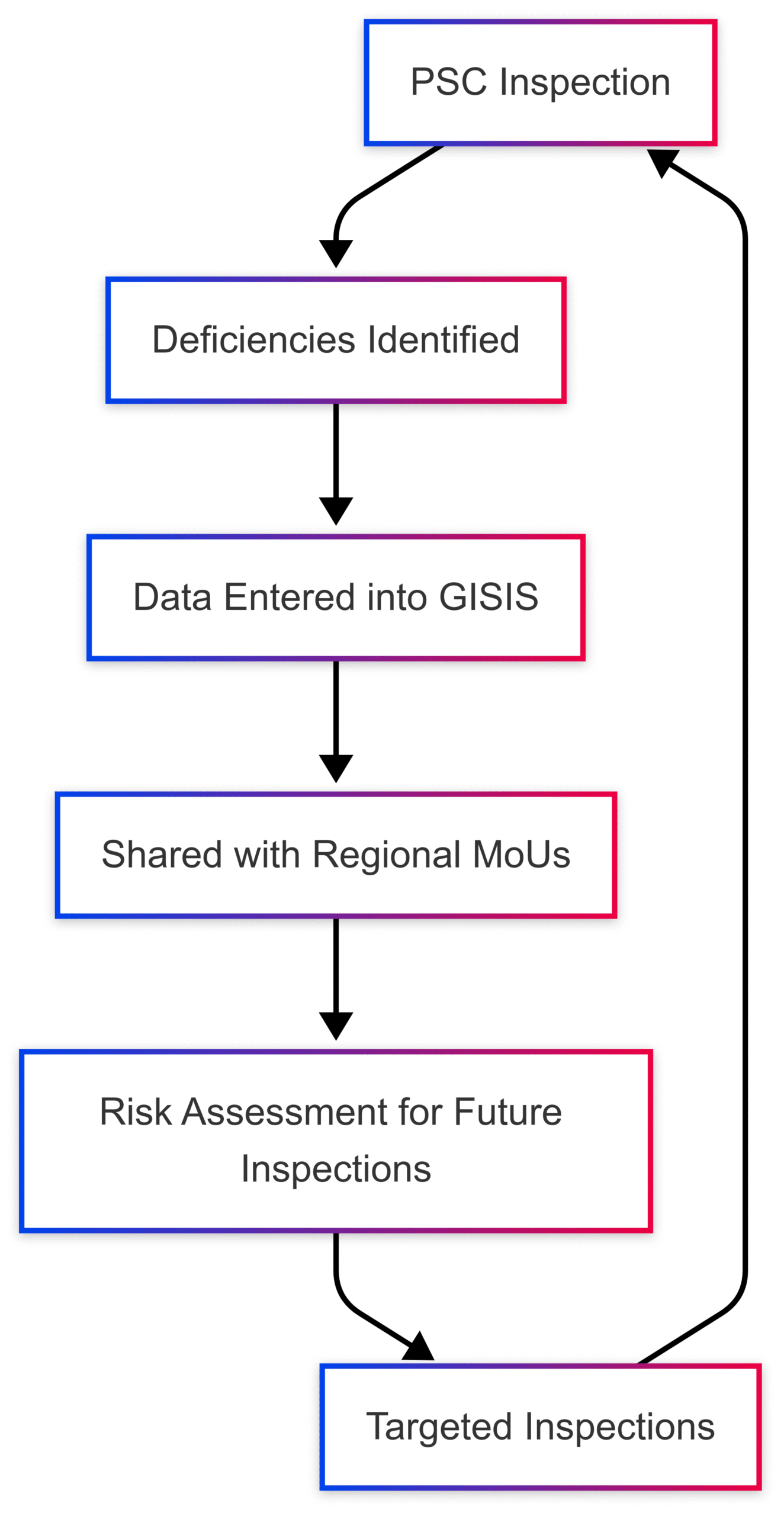

The following chart illustrates the data flow in GISIS:

This interconnected system ensures that a vessel detained in one port is flagged globally, reducing the chances of substandard ships slipping through the cracks.

How to Prepare for a PSC Inspection

Preparation is the difference between a smooth inspection and a costly detention. Here’s a comprehensive guide to getting ready:

1. Maintain Impeccable Documentation

- Statutory Certificates: Ensure SOLAS, MARPOL, ISPS, and other certificates are valid and accessible.

- Crew Records: Verify licenses, medicals, and training certificates are current. Use a digital tracking system to avoid oversights.

- SMS and SSP: Align the Safety Management System and Ship Security Plan with actual operations, not just theoretical policies.

- Previous Reports: Keep records of past PSC inspections and corrective actions organized and ready for review.

2. Ensure Equipment and Machinery Readiness

- Life-Saving Equipment: Test lifeboats, liferafts, and emergency lighting regularly.

- Firefighting Gear: Service extinguishers, hoses, and alarms, ensuring no expired or rusty equipment.

- Navigation Systems: Confirm AIS, radar, and GPS are operational, with logs up to date.

- Engine Room: Maintain cleanliness, address leaks, and log all maintenance activities.

3. Train and Prepare the Crew

- Drills: Conduct and log regular emergency and security drills. Ensure every crew member knows their role.

- Interviews: Prepare crew for spot checks by practicing responses to common questions (e.g., “What’s your role in a fire emergency?”).

- Welfare: Provide adequate living conditions, including clean galleys and functional sanitation.

4. Strengthen Security Protocols

- ISPS Compliance: Control and log access points. Ensure the Ship Security Officer is well-versed in protocols.

- Drill Records: Document security drills and ensure crew awareness of procedures.

5. Build Proactive Habits

- Checklists: Use classification society or flag state checklists to audit your vessel regularly.

- Early Reporting: Log and report issues proactively to your company and flag state.

- Digital Tools: Leverage platforms like Base to organize documentation, track maintenance, and streamline port operations.

Tips for Navigating the Inspection

When PSC officers board, your preparation is put to the test. Here’s how to handle the inspection itself:

- Stay Professional: Greet officers courteously and avoid defensiveness. Offer refreshments if appropriate to set a cooperative tone.

- Own Known Issues: Disclose minor problems with documentation (e.g., a logged repair order) to build trust.

- Escort Inspectors: Assign a senior officer to accompany inspectors, answering questions and providing context.

- Be Concise: Answer questions clearly and avoid volunteering unrelated information.

- Fix Minor Issues Immediately: Address small deficiencies (e.g., a loose wire) during the inspection and document the fix.

Consequences of Failing an Inspection

Failing a PSC inspection can have serious repercussions:

- Operational Delays: Detentions halt operations, delaying cargo delivery and increasing port costs.

- Financial Impact: Fines, repair costs, and lost contracts can add up quickly.

- Reputational Damage: A detained vessel reflects poorly on the flag state and operator, increasing future scrutiny.

- Increased Inspections: A poor inspection history raises a vessel’s risk profile, leading to more frequent checks.

The table below summarizes common deficiencies and their potential impact:

| Deficiency Type | Example | Impact |

|---|---|---|

| Documentation | Expired SOLAS certificate | Detention, fines |

| Equipment | Faulty fire extinguisher | Deficiency, correction required |

| Crew Competency | Untrained crew in emergency drills | Detention, mandatory retraining |

| Environmental Compliance | Oil leak in engine room | Detention, environmental fines |

| Security | Unlogged access points | Deficiency, ISPS violation |

The Role of Technology in PSC Compliance

Modern maritime operations rely on technology to streamline compliance. Tools like Base help operators manage:

- Documentation: Centralize certificates and logs for easy access.

- Maintenance Tracking: Monitor equipment service intervals to prevent deficiencies.

- Crew Management: Track certifications and training schedules.

- Port Operations: Coordinate with agents to handle delays or detentions efficiently.

By integrating these tools, operators can stay ahead of PSC requirements, reducing the risk of surprises during inspections.

Conclusion

Port State Control inspections are a critical mechanism for ensuring maritime safety, environmental protection, and crew welfare. While they can be unpredictable, thorough preparation—through meticulous documentation, equipment maintenance, crew training, and proactive habits—can make the difference between a clean report and a costly detention. By understanding the process, leveraging tools like GISIS for global coordination, and adopting digital solutions, maritime professionals can navigate PSC inspections with confidence.

For operators, masters, and crews, the message is clear: stay prepared, stay professional, and stay compliant. With the right approach, PSC inspections become a manageable part of operations, not a threat to your schedule or bottom line.

Happy Boating!

Share Port State Control Inspections Explained: What to Expect with your friends and leave a comment below with your thoughts.

Read Top Fish And Seafood Exporting Countries until we meet in the next article.