Omega Pressure Transducers are Accurate, Durable: Benefits

Discover the benefits of Omega pressure transducers: high accuracy, durability, and versatility for industrial, medical, and more applications.

Pressure transducers are critical tools in modern industries, enabling precise measurement and control of pressure in diverse applications. Among the leading brands, Omega Engineering stands out for its high-quality pressure transducers, renowned for their accuracy, durability, and adaptability. This article explores the comprehensive benefits of Omega pressure transducers, delving into their technical specifications, applications, and advantages over competitors. Whether you’re in manufacturing, aerospace, or medical fields, understanding why Omega transducers are a top choice can enhance your operations.

What is a Pressure Transducer?

A pressure transducer converts physical pressure from a fluid or gas into an electrical signal, which is then used to monitor and control systems. These devices are essential in industries where precise pressure measurements ensure safety, efficiency, and performance. Omega pressure transducers, in particular, excel in delivering reliable data across various environments, from harsh industrial settings to sensitive medical applications.

How Pressure Transducers Work

At the core of a pressure transducer is a sensing element, typically a diaphragm made of materials like stainless steel or silicon. When pressure is applied, the diaphragm flexes, altering the electrical properties (resistance, capacitance, or charge) of the sensing element. This change is processed by internal circuitry to produce an electrical output—commonly in millivolts, volts, or milliamps—that corresponds to the applied pressure. Omega transducers are designed to ensure this process is highly accurate and repeatable.

Types of Pressure Transducers

Omega offers a range of pressure transducers tailored to specific needs:

- Piezoresistive Transducers: These use a strain gauge on a diaphragm to measure resistance changes caused by pressure. They are ideal for high-precision applications due to their low hysteresis and excellent repeatability.

- Capacitive Transducers: These measure changes in capacitance as the diaphragm moves, offering high sensitivity for low-pressure applications.

- Piezoelectric Transducers: These generate an electrical charge from pressure-induced deformation, suitable for dynamic pressure measurements.

- Strain Gauge Transducers: Similar to piezoresistive models, these measure diaphragm deformation to produce accurate pressure readings.

Each type is optimized for specific applications, and Omega’s diverse portfolio ensures a solution for every requirement.

The Omega Brand: A Legacy of Excellence

Founded in 1962 by Betty Ruth Hollander and Dr. Robert N. Krakauer, Omega Engineering has grown into a global leader in measurement and control technologies. The company’s commitment to innovation and quality has made its pressure transducers a preferred choice across industries. Omega’s ISO 9001-certified facilities ensure rigorous quality control, delivering products that meet the highest standards.

Omega’s product range extends beyond pressure transducers to include temperature sensors, flowmeters, and data loggers, all designed with precision and reliability in mind. The company’s focus on continuous improvement keeps it at the forefront of technological advancements, making its transducers a trusted solution worldwide.

Key Benefits of Omega Pressure Transducers

Omega pressure transducers are engineered to deliver superior performance. Below are the primary benefits that set them apart:

1. High Accuracy and Stability

Omega transducers are renowned for their precision, with some models achieving errors as low as 0.05% of full scale (FS). This high accuracy is critical in applications where even minor deviations can lead to significant consequences, such as in aerospace or medical devices. Additionally, Omega transducers offer long-term stability, ensuring consistent performance over extended periods without frequent recalibration.

For example, the PX140 series uses computer-controlled laser trimming to fine-tune parameters like null and full-scale output, ensuring exceptional accuracy without user adjustments. This precision is vital for applications requiring exact measurements, such as hydraulic system monitoring or material testing.

2. Durability and Ruggedness

Designed for harsh environments, Omega transducers feature robust enclosures, often constructed from stainless steel. This durability makes them suitable for industrial settings with extreme temperatures, vibrations, or corrosive substances. The PX119 series, for instance, is machined from a single piece of stainless steel, protecting internal electronics and ensuring longevity.

Omega transducers also incorporate features to mitigate risks like fluid hammer and surges, which can damage sensors. Recommendations include installing pressure snubbers and surge chambers to protect the transducer, ensuring reliable performance even in challenging conditions.

3. Versatility and Customization

Omega offers a broad range of transducers, including flush diaphragm, high-accuracy, and special-purpose models. This variety allows them to cater to diverse applications, from material handling to medical diagnostics. Customizable options, such as modular systems, enable users to tailor transducers to specific needs, enhancing flexibility.

The PX140 series, for example, supports multiple pressure types—absolute, gauge, and differential—across various ranges (e.g., 0-1 to 0-30 psi for gauge, ±1 to ±15 psi for differential). This versatility ensures Omega transducers can meet the demands of industries like automotive, aerospace, and oil and gas.

4. Compact Design

For applications with space constraints, Omega offers compact models like the PX165 series, which are PCB-mountable and ideal for integration into tight spaces. These transducers maintain high performance despite their small footprint, making them suitable for consumer electronics, medical devices, and other compact systems.

5. Specialized Features

Omega transducers include advanced features like zero and span adjustments, allowing for easy calibration in the field. This is particularly useful in dynamic environments where conditions may change, ensuring consistent accuracy. The use of application-specific integrated circuits (ASICs) in models like the PX119 enhances performance by optimizing signal processing.

6. Long-Distance Transmission

Many Omega transducers, particularly those with 4-20mA output, are designed for long-distance signal transmission. The 4-20mA current loop is immune to electrical noise and signal degradation, making it ideal for applications where the transducer is far from the control system. This feature is critical in large industrial facilities, such as oil refineries or manufacturing plants, where lead wires may extend over 1,000 feet.

7. Cost-Effectiveness

While high-accuracy models may carry a premium, Omega’s general-purpose transducers, like the PX119 series starting at $99, offer cost-effective solutions without compromising quality. The combination of durability, low maintenance, and reliable performance translates into long-term savings, making Omega transducers a smart investment.

Applications of Omega Pressure Transducers

Omega pressure transducers are used across a wide range of industries due to their versatility and reliability. Key applications include:

- Industrial Automation: Monitoring pressure in hydraulic and pneumatic systems to ensure operational efficiency.

- Aerospace: Measuring pressure in fuel systems and hydraulic actuators for safety and performance.

- Automotive: Testing tire pressure, engine performance, and fuel systems.

- Medical Devices: Ensuring precise pressure control in equipment like ventilators and infusion pumps.

- Material Handling: Monitoring blow molding pressure, as with the PX119 series, to maintain product quality.

- Oil and Gas: Measuring pressure in pipelines and drilling equipment under harsh conditions.

This broad applicability underscores Omega’s ability to address diverse industry needs.

Technical Specifications

The following table summarizes key specifications for select Omega pressure transducer series:

| Series | Pressure Range | Accuracy | Output | Key Features | Price (Starting) |

|---|---|---|---|---|---|

| PX140 | 0-1 to 0-30 psi (gauge), ±1 to ±15 psi (differential), 0-15 to 0-30 psi (absolute) | 0.05% FS | Millivolt | Compact, laser-trimmed, no user calibration needed | $150 |

| PX119 | 15 to 5,000 psi | 0.5% BFSL | 4-20mA | Stainless steel, ASIC, compact design | $99 |

| PX165 | 0-1 to 0-100 psi | 0.1% FS | Voltage | PCB-mountable, compact | $120 |

Note: Prices are approximate and may vary based on configuration and vendor.

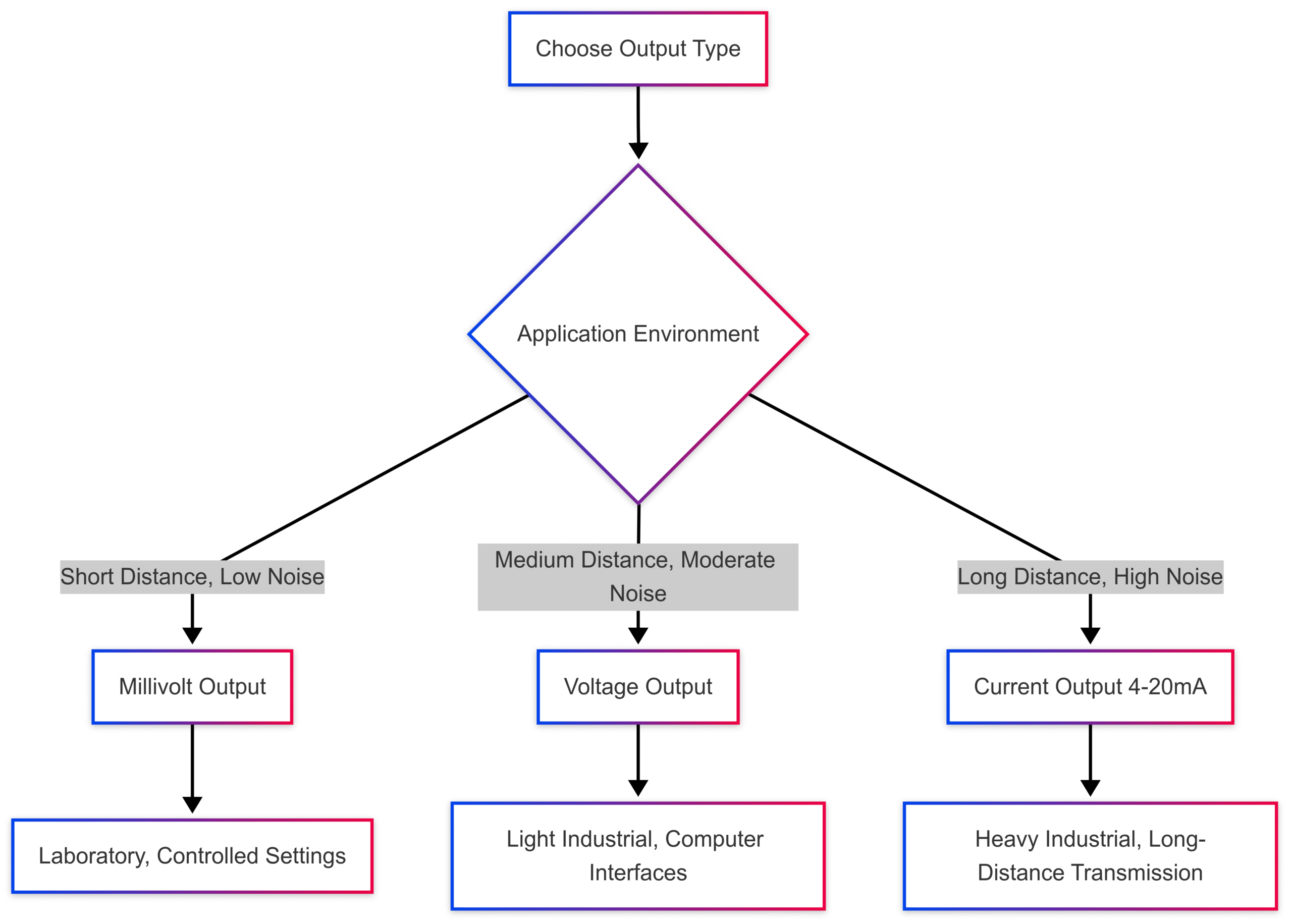

Electrical Output Options

Omega transducers offer three primary electrical outputs, each suited to specific applications:

Millivolt Output:

- Pros: Economical, compact, ideal for laboratory use.

- Cons: Sensitive to electrical noise, limited to short distances (up to 200 feet).

- Best for: Controlled environments with minimal interference.

Voltage Output (0-5Vdc or 0-10Vdc):

- Pros: Higher output, less sensitive to noise, suitable for light industrial settings.

- Cons: Requires signal conditioning, slightly larger than millivolt models.

- Best for: Applications needing medium-distance transmission.

Current Output (4-20mA):

- Pros: Immune to electrical noise, ideal for long-distance transmission.

- Cons: Higher cost due to built-in signal conditioning.

- Best for: Industrial environments with long lead wires.

The following chart illustrates the decision-making process for selecting an output type:

Installation and Maintenance Best Practices

To maximize the performance and lifespan of Omega pressure transducers, follow these guidelines:

- Avoid Diaphragm Damage: Do not touch or press the diaphragm, especially on low-pressure models, to prevent calibration issues.

- Use Proper Fittings: Ensure fittings match the transducer’s pressure rating and thread type.

- Protect Against Fluid Hammer and Surges: Install pressure snubbers and surge chambers to mitigate sudden pressure changes, which can cause zero offset or sensor failure.

- Operate Within Specifications: Maintain ambient temperatures within the transducer’s specified range (typically near 25°C) and avoid excessive vibration.

- Proper Wiring: Follow Omega’s wiring configurations (e.g., Figures 1-3 in the PX140 instruction sheet) to ensure accurate signal transmission.

- Cleaning: Use alcohols or fluorinated solvents for cleaning, avoiding contaminants that could damage the sensor.

Handling Fluid Hammer and Surges

Fluid hammer and surges can severely damage transducers. Symptoms include:

- Large Zero Offset: If the offset is less than 10% FS, re-zero the transducer and install a snubber.

- Constant Output: Indicates potential sensor damage, requiring replacement.

- No Output: Suggests severe damage, necessitating immediate replacement.

By implementing protective measures, such as slow valve operation and full fluid lines, users can prevent these issues.

Comparing Omega with Competitors

Omega pressure transducers compete with brands like Dwyer Instruments, Honeywell, and Ashcroft. Here’s how they stack up:

Performance Comparison

- Accuracy: Omega’s 0.05% FS accuracy (e.g., PX140 series) rivals or exceeds competitors like Honeywell (0.1% FS for some models) and Ashcroft (0.25% FS).

- Durability: Omega’s stainless steel construction and noise-immune 4-20mA output outperform many budget brands in harsh environments.

- Customization: Omega’s modular systems and custom options provide greater flexibility than Dwyer’s standard models.

Price Comparison

While Omega transducers may have a higher upfront cost than some budget options, their durability and low maintenance needs offer better long-term value. For example:

- Omega PX119: Starts at $99, competitive with Dwyer’s general-purpose transducers ($80-$120).

- Honeywell High-Accuracy Models: Often exceed $200, making Omega a cost-effective alternative for similar performance.

- Ashcroft: Mid-range models start at $150, but lack Omega’s customization options.

Omega’s balance of performance and price makes it a preferred choice for businesses seeking reliable, long-term solutions.

Wiring Configurations for Optimal Performance

Proper wiring is critical for accurate measurements. Omega provides detailed guidance for its transducers:

- Millivolt Output: Requires a regulated power supply and short lead wires to minimize noise. Suitable for lab settings (see Figure 1 in PX140 documentation).

- Voltage Output: Uses integral signal conditioning, allowing use with unregulated power supplies. Ideal for light industrial environments (see Figure 2).

- Current Output (4-20mA): Best for long-distance transmission, supporting multi-instrument setups with minimal calibration issues (see Figure 4).

For multi-instrument setups, the 4-20mA current loop is preferred due to its simplicity and noise immunity. The minimum voltage required for a current loop can be calculated using Ohm’s Law:

V = I × (R_LINE + R_LOAD) + V_S_TRANSDUCERFor example, a system with a 5-ohm lead wire, 235-ohm combined instrument resistance, and a 12V transducer requires:

V = 0.020 × (5 + 235) + 12 = 16.8VA 24V power supply is typically sufficient for most 4-20mA setups.

Conclusion

Omega pressure transducers are a cornerstone of precision measurement, offering unmatched accuracy, durability, and versatility. Their ability to perform in diverse applications—from industrial automation to medical devices—makes them a valuable asset for businesses worldwide. With advanced features like zero/span adjustments, compact designs, and noise-immune outputs, Omega transducers deliver reliable performance in even the most demanding environments. When compared to competitors, Omega stands out for its balance of quality, customization, and cost-effectiveness.

Whether you’re monitoring pressure in a manufacturing plant or ensuring safety in aerospace systems, Omega pressure transducers provide the precision and reliability needed to excel. By choosing Omega, you invest in a solution that enhances operational efficiency and delivers long-term value.

Happy Boating!

Share Omega Pressure Transducers are Accurate, Durable: Benefits with your friends and leave a comment below with your thoughts.

Read What Is One Part of a Regular Vessel and Engine Maintenance Program? until we meet in the next article.