NMEA 2000 Engine Sensors and NMEA Network Technology

Discover NMEA 2000 engine sensors and network technology for boats. Monitor engine performance, enhance safety, and integrate devices seamlessly.

NMEA 2000, developed by the National Marine Electronics Association, is a standardized communication protocol that revolutionizes how marine electronics share data on boats. Unlike traditional analog systems, NMEA 2000 creates a networked environment where devices like sensors, gauges, and displays communicate seamlessly over a single backbone cable. This plug-and-play system simplifies installation and enhances the reliability of data exchange, making it a game-changer for boat owners seeking to monitor vessel performance and improve navigation. In this guide, we’ll explore NMEA 2000 engine sensors, their integration with outboard engines, conversion from analog systems, essential components, and user experiences to help you optimize your boating setup.

What is NMEA 2000?

NMEA 2000 is a marine-specific Controller Area Network (CAN) protocol that enables marine electronics to connect and share data efficiently. It operates on a common backbone—a single cable that connects all devices—allowing instruments to display or act on data from multiple sources. For example, a chartplotter can show engine data, GPS coordinates, and navigation sensor readings simultaneously. Its plug-and-play design minimizes wiring complexity, making it accessible for DIY installations. Unlike older NMEA 0183 systems, NMEA 2000 supports higher data transfer rates and multi-manufacturer compatibility, ensuring devices from brands like Garmin, Raymarine, and Simrad work together seamlessly.

Key Benefits of NMEA 2000

- Interoperability: Devices from different manufacturers can share data.

- Ease of Installation: Plug-and-play connections reduce setup time.

- Scalability: Add new devices without major rewiring.

- Reliability: Robust protocol ensures accurate data transmission.

- Comprehensive Monitoring: Tracks engine, navigation, and environmental data.

NMEA 2000 Engine Sensors: Monitoring Vessel Performance

Engine sensors are the heart of NMEA 2000’s monitoring capabilities, providing real-time data on critical engine parameters. These sensors help boaters maintain engine health, optimize performance, and diagnose issues early. Below is a detailed overview of common NMEA 2000 engine sensors and their functions:

| Sensor Type | Description | Key Benefits |

|---|---|---|

| Engine RPM | Measures engine revolutions per minute. | Optimizes fuel efficiency and detects performance issues. |

| Fuel Flow | Tracks fuel consumption rate (gallons per hour or liters per hour). | Enables precise fuel management and trip planning. |

| Oil Pressure | Monitors lubricating oil pressure. | Prevents engine damage by detecting low pressure early. |

| Engine Temperature | Tracks engine block temperature. | Alerts to overheating risks, protecting engine longevity. |

| Coolant Temperature | Measures engine coolant temperature. | Ensures cooling system efficiency and prevents overheating. |

| Exhaust Gas Temperature | Monitors exhaust temperature. | Detects combustion issues or exhaust system inefficiencies. |

| Battery Voltage | Tracks battery voltage levels. | Ensures electrical system reliability and prevents battery failure. |

| Engine Hours | Records total engine operating hours. | Aids in maintenance scheduling and resale value assessment. |

Example Use Case

A boater with a Garmin 1042xsv chartplotter can integrate NMEA 2000 engine sensors to display RPM, fuel flow, and oil pressure on a single screen, eliminating the need for separate analog gauges. This centralized monitoring enhances situational awareness and simplifies troubleshooting.

Compatible Outboard Engines

Most modern outboard engines are NMEA 2000-compatible, allowing seamless integration with the network. Brands like Yamaha, Honda, Suzuki, and Evinrude support NMEA 2000, providing access to detailed performance metrics. However, Mercury Marine outboards are an exception, as they use proprietary systems incompatible with standard NMEA 2000 networks.

Benefits of NMEA 2000-Compatible Engines

- Enhanced Data Access: Monitor RPM, fuel flow, and temperature directly on a multifunction display (MFD).

- Improved Diagnostics: Identify issues like low oil pressure or overheating before they cause damage.

- Performance Optimization: Adjust throttle settings based on real-time fuel consumption data.

- Maintenance Tracking: Engine hours data helps schedule timely maintenance.

For example, a Yamaha F300 outboard, like the one on a Boston Whaler 255 Conquest, can connect to an NMEA 2000 network using a Yamaha interface cable, enabling data display on a Garmin MFD.

Converting Analog Sensors to NMEA 2000

Many older boats rely on analog gauges, which lack the connectivity and precision of digital systems. Converting these to NMEA 2000 allows boaters to integrate legacy sensors into a modern network. This process requires an analog-to-NMEA 2000 converter, which translates analog signals into digital NMEA 2000 data.

Conversion Process

- Identify Analog Sensors: Determine which sensors (e.g., fuel level, oil pressure) need conversion.

- Select a Converter: Popular options include:

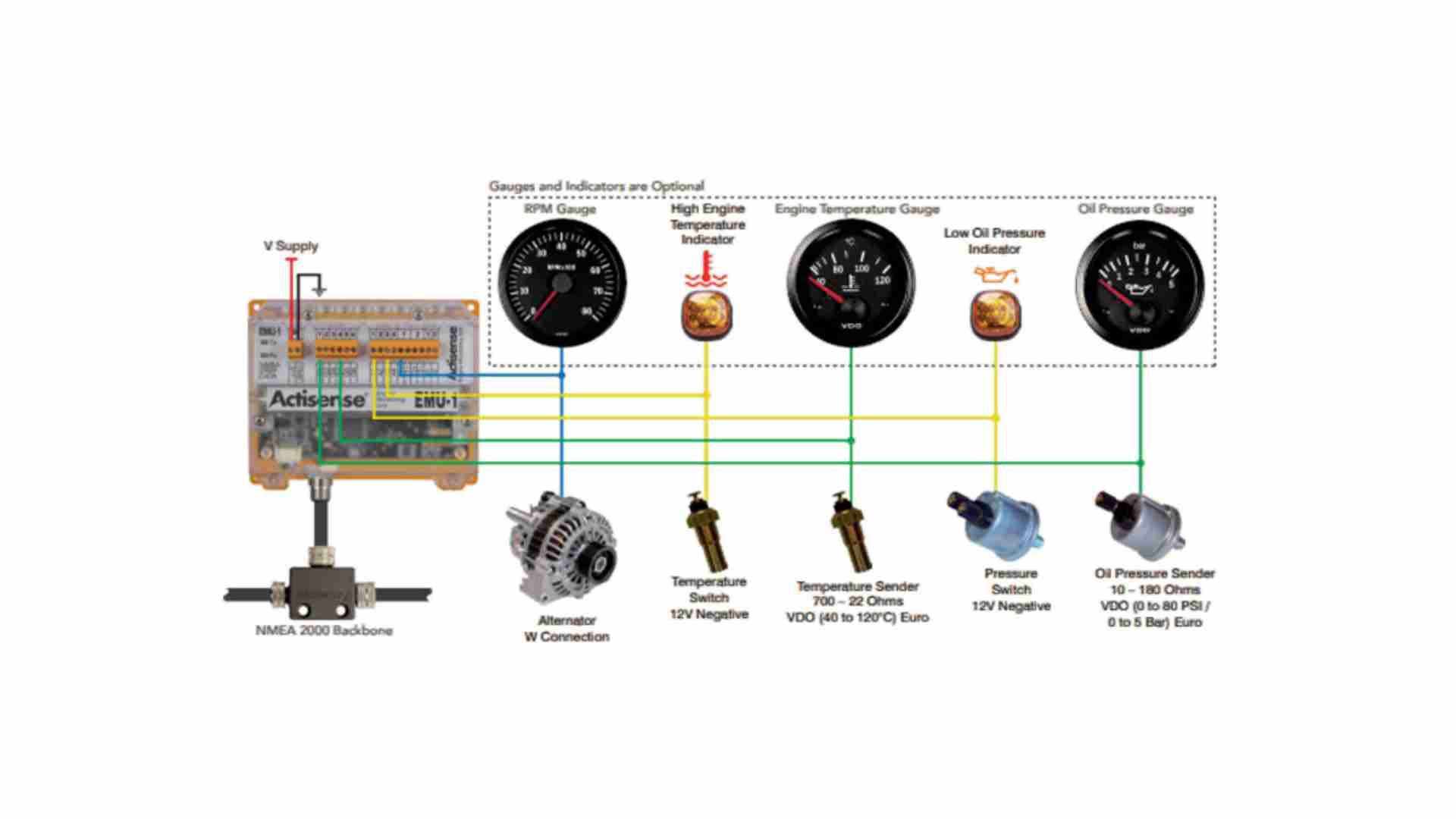

- Actisense EMU-1: Converts analog signals for up to six channels. Price: ~$300.

- Noland RS11: Supports single or twin engines. Price: ~$250.

- Alba-Combi: Customizable for multiple inputs, including exhaust temperature. Price: ~$350.

- Yacht Devices YDEG-04: Engine gateway for specific engines. Price: ~$200.

- Connect to NMEA 2000 Backbone: Use T-connectors and drop cables to integrate the converter.

- Configure the System: Use an MFD or software to assign data types (e.g., oil pressure, fuel level) and calibrate sensors.

- Test and Calibrate: Ensure accurate readings by comparing with known values or manual gauges.

Challenges and Considerations

- Wiring Complexity: Some converters, like the Actisense EMU-1, may require tapping into existing wiring without cutting the harness.

- Compatibility: Ensure the converter supports your engine’s analog sensors.

- Calibration: Analog sensors may need tuning for accurate digital output, especially for non-linear inputs like fuel tank levels.

Example

A boater with a Yanmar 3YM30 engine used an Actisense EMU-1 to convert analog oil pressure and temperature signals to NMEA 2000, displaying them on a Simrad NSS plotter. The installation cost ~$350, including cables, and took 4 hours for a DIY setup.

Essential Components for an NMEA 2000 Network

Building an NMEA 2000 network requires specific components to ensure reliable data transmission. Below is a breakdown of the essential parts and their roles:

| Component | Description | Approximate Cost |

|---|---|---|

| Backbone Cable | Main cable connecting all devices (max length: 100m). | $20–$50 |

| T-Connectors | Connect devices to the backbone. | $15–$25 each |

| Terminators | Placed at each end of the backbone to prevent signal reflection. | $10–$15 each |

| Drop Cables | Connect individual devices to T-connectors (max length: 6m). | $15–$30 each |

| Power Cable | Supplies 12V power to the backbone, ideally connected near the center. | $15–$25 |

| Starter Kit | Includes backbone cable, terminators, T-connectors, and power cable. | $70–$150 |

Installation Tips

- Central Power Connection: Place the power cable near the backbone’s midpoint to balance electrical load.

- Cable Length Limits: Ensure the backbone does not exceed 100m and drop cables stay under 6m.

- Device Power: Some devices draw power from the backbone, while others (e.g., MFDs) require separate power sources.

- DIY Feasibility: A basic NMEA 2000 network can be installed in 2–4 hours with minimal tools.

Diagram: NMEA 2000 Network Layout

This diagram illustrates a typical NMEA 2000 network with a backbone, T-connectors, terminators, and devices like a chartplotter, engine sensor, and VHF radio.

Additional NMEA 2000 Devices to Consider

For a Boston Whaler 255 Conquest with a Yamaha F300, Garmin 1042xsv, radar, B60 transducer, and Fusion RA70N stereo, integrating an NMEA 2000 backbone offers several upgrade possibilities. Here are recommended additions based on user needs and forum insights:

VHF Radio with DSC and AIS:

- Why: Integrates GPS data for emergency broadcasts and AIS for collision avoidance.

- Example: Garmin VHF 215 AIS (~$600).

- User Benefit: Enhances safety by broadcasting precise location during emergencies.

Heading Sensor:

- Why: Improves radar overlay accuracy and autopilot performance.

- Example: Garmin MSC10 (~$400).

- User Benefit: Provides precise heading data, especially useful for radar functions.

Fuel Level Sensors:

- Why: Monitors tank levels for accurate fuel management.

- Example: Maretron TLM100 (~$200 per tank).

- User Benefit: Tracks fuel remaining, reducing reliance on analog senders.

Autopilot:

- Why: Integrates with NMEA 2000 for seamless navigation control.

- Example: Garmin Reactor 40 (~$2,000).

- User Benefit: Simplifies long-distance cruising and maintains course stability.

Temperature Sensors:

- Why: Monitors engine block, exhaust, or ambient temperatures.

- Example: Yacht Devices YDTS-04 (~$99).

- User Benefit: Early warning for overheating issues.

Example Upgrade Plan

For the Boston Whaler 255 Conquest, a practical upgrade includes:

- NMEA 2000 Starter Kit: Ancor kit (~$70).

- VHF with AIS: Garmin VHF 215 AIS (~$600).

- Heading Sensor: Garmin MSC10 (~$400).

- Fuel Level Sensor: Maretron TLM100 (~$200).

- Total Cost: ~$1,270.

- Installation Time: ~6–8 hours DIY.

This setup allows engine data display on the Garmin 1042xsv, radio control from the helm, and enhanced safety features.

User Reviews and Experiences

Pros

- Ease of Installation: Users like MarineChemistNYNJ praise the simplicity of DIY setups, with an Ancor starter kit costing ~$70 and taking 2–3 hours to install.

- Interoperability: GregMachy notes seamless integration of devices from Garmin, Simrad, and Raymarine, calling it “awe-inspiring.”

- Safety Enhancements: kgs365 highlights the value of VHF integration for emergency GPS broadcasting.

- Data Accuracy: Worldwithin resolved fuel management issues with a single FDM, achieving accurate per-engine fuel usage after troubleshooting.

- Cost-Effectiveness: Aerice511 installed a backbone on a 22-foot boat for ~$100, deeming it “worth every penny.”

Cons

- Configuration Challenges: Bikerwookie reported issues with the Matsutec CX5003 converter, where starboard engine data didn’t display correctly on Simrad plotters.

- Cost of Converters: Actisense and Noland converters (~$250–$350) are pricier than eBay options (~$100), though vas warns cheaper units may lack precision.

- Fuel Data Limitations: Worldwithin struggled with Lowrance FDMs displaying combined fuel usage instead of per-tank data, requiring manual calculations.

- Engine Compatibility: Dockhead noted challenges with older Yanmar engines lacking digital controls, requiring complex analog conversions.

- Calibration Needs: Moonlighter475 emphasized the importance of calibrating fuel sensors to ensure accuracy, which can be time-consuming.

User Quote

“I’ve never connected three devices from three different brands and watched them all function. I’m still in awe.” – MarineChemistNYNJ

Troubleshooting Common Issues

- No Data Displayed:

- Solution: Check T-connector and drop cable connections. Reset network data sources via MFD (Menu > Settings > Network > Auto Select).

- Inaccurate Fuel Data:

- Solution: Calibrate FDM after refueling, ensuring each engine is correctly assigned in the device list.

- Starboard Engine Data Missing:

- Solution: Inspect engine interface cables (e.g., Worldwithin’s faulty Honda cable) and replace if necessary.

- Converter Compatibility:

- Solution: Use reputable brands like Actisense or Noland for reliable performance, especially with non-linear sensors.

Pricing and Specifications

| Device | Specifications | Price (USD) |

|---|---|---|

| Ancor NMEA 2000 Starter Kit | Backbone cable, 2 terminators, 2 T-connectors, power cable | $70–$150 |

| Actisense EMU-1 | 6-channel analog-to-NMEA converter, supports RPM, pressure, temperature | $300 |

| Noland RS11 | Single/twin engine converter, USB configuration | $250 |

| Alba-Combi | 10-channel converter, customizable for EGT, alarms | $350 |

| Yacht Devices YDEG-04 | Engine gateway for CAN-bus engines | $200 |

| Garmin VHF 215 AIS | NMEA 2000-compatible VHF with AIS receiver | $600 |

| Garmin MSC10 | Heading and GPS sensor, 10Hz output | $400 |

| Maretron TLM100 | Fuel level sensor, configurable for tank geometry | $200 |

| Yacht Devices YDTS-04 | Temperature sensor, configurable via chartplotter | $99 |

Conclusion

NMEA 2000 engine sensors and network technology transform boating by providing real-time, centralized data on engine performance, navigation, and safety systems. For a Boston Whaler 255 Conquest owner, integrating a Yamaha F300, Garmin 1042xsv, and Fusion RA70N into an NMEA 2000 network offers significant benefits, from displaying engine gauges on the MFD to controlling the stereo from the helm. Adding a VHF with AIS, heading sensor, and fuel level sensors further enhances functionality. While challenges like converter compatibility and calibration exist, the system’s ease of installation, interoperability, and cost-effectiveness make it a worthy upgrade. With starter kits as low as $70 and a DIY-friendly setup, NMEA 2000 is accessible to most boaters, delivering data-driven insights for safer, more efficient voyages.

Happy Boating!

Share NMEA 2000 Engine Sensors and NMEA Network Technology with your friends and leave a comment below with your thoughts.

Read A Beginner’s Guide to Mooring Buoys until we meet in the next article.